High-thermal conductivity electrical insulation cement and preparation method thereof

An electrical insulating adhesive, high thermal conductivity technology, applied in the field of electrical and electronic materials, can solve problems such as failure to meet practical applications, and achieve the effects of excellent electrical insulation performance, improved solubility, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Disperse 100g of aluminum oxide as an inorganic filler in 500ml of distilled water and stir, and gradually add 10g of polyvinyl alcohol-400 coupling agent under stirring, and continue to stir for 2 minutes, hydrothermally react at 60°C for 12 hours, centrifuge, dry, and process After the inorganic filler.

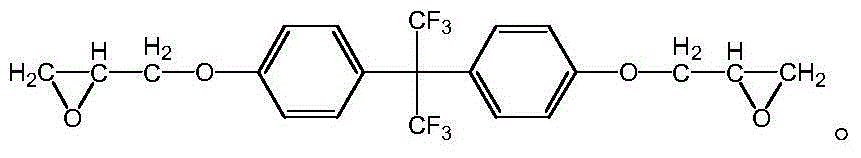

[0018] 100g of fluorine-containing bisphenol A epoxy resin Put 15g of 1,4-bis(2,4-diaminophenoxy)benzene into the reaction kettle, heat to 60-70°C, stir and react until homogeneous, then add 100g of resorcinol diglycidyl ether Epoxy resin, 100g polyimide resin containing carboxylic acid group and 100g inorganic filler, get A component; Mix 100g methyltetrahydrophthalic anhydride and 100g coupling agent-treated aluminum oxide, stir at room temperature until Evenly, get B component; mix and stir A and B two components evenly to get high thermal conductivity electrical insulating adhesive.

Embodiment 2

[0020] Disperse 100g of titanium dioxide as an inorganic filler in 500ml of ethanol and stir, and gradually add 10g of polyvinyl alcohol-400 coupling agent under stirring, and continue to stir for 5 minutes, hydrothermally react at 60°C for 24 hours, centrifuge and dry to obtain the processed Inorganic filler.

[0021] 100g of fluorine-containing bisphenol A epoxy resin Put 20g of 1,4-bis(2,4-diaminophenoxy)benzene into the reaction kettle, heat to 60-70°C, stir and react until homogeneous, then add 120g of resorcinol diglycidyl ether Epoxy resin, 100g polyimide resin containing carboxylic acid groups and 150g treated titanium dioxide inorganic filler, to obtain component A; 120g methyl tetrahydrophthalic anhydride and 150g treated titanium dioxide inorganic filler were stirred at room temperature until uniform , to obtain component B; mix and stir components A and B evenly to obtain a high thermal conductivity electrical insulating adhesive.

Embodiment 3

[0023] Disperse 100g of titanium dioxide as an inorganic filler in 500ml of ethanol and stir, and gradually add 20g of dimethyldiethoxysilane coupling agent under stirring, and continue to stir for 3min, hydrothermally react at 60°C for 12h, centrifuge and dry to obtain Treated inorganic fillers.

[0024] 100g of fluorine-containing bisphenol A epoxy resin Put 30g of 1,4-bis(2,4-diaminophenoxy)benzene into the reaction kettle, heat to 60-70°C, stir and react until homogeneous, then add 150g of resorcinol diglycidyl ether Epoxy resin, 150g polyimide resin containing carboxylic acid groups and 200g treated titanium dioxide inorganic filler, to obtain component A; 150g methyl tetrahydrophthalic anhydride and 200g treated titanium dioxide inorganic filler were stirred at room temperature until uniform , to obtain component B; mix and stir components A and B evenly to obtain a high thermal conductivity electrical insulating adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com