High-strength strong-acid/alkali-resistant epoxy resin sealant

A technology of alkali epoxy resin and strong acid resistance, applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additive, etc., can solve the problems of unsatisfactory use and performance, poor curing comprehensive performance, poor manufacturability, etc., to achieve Excellent curing performance, stable potting quality, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

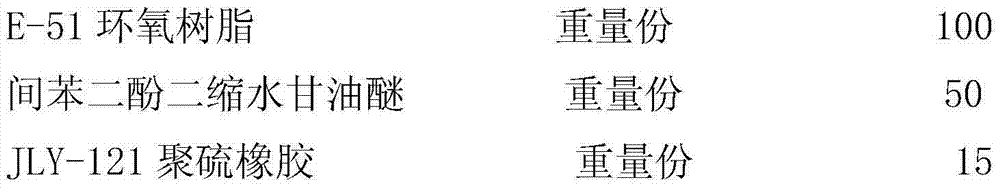

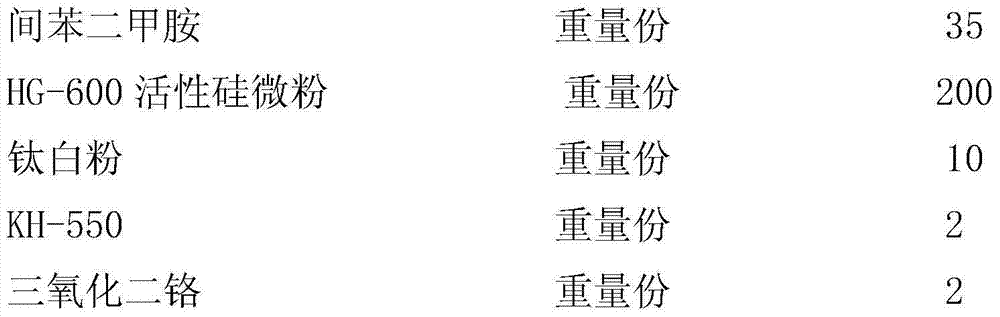

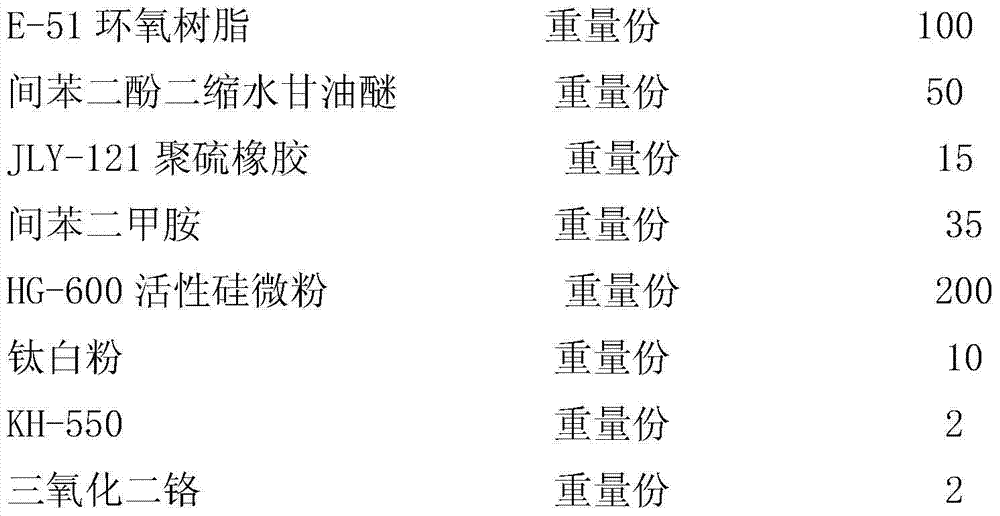

[0020] A high-strength strong acid and strong alkali resistant epoxy resin sealant, comprising the following components:

[0021]

[0022] The above ingredients are cured by heating.

[0023] The temperature during curing was 80° C., and the curing time was 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com