5-aldehyde resorcinol diglycidyl ether and preparation method thereof

A technology of aldehyde resorcinol and diglycidyl ether, which is applied in the field of glyceryl ether and its preparation, can solve problems such as poor bonding strength, achieve good heat resistance, good fluidity and processing performance, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

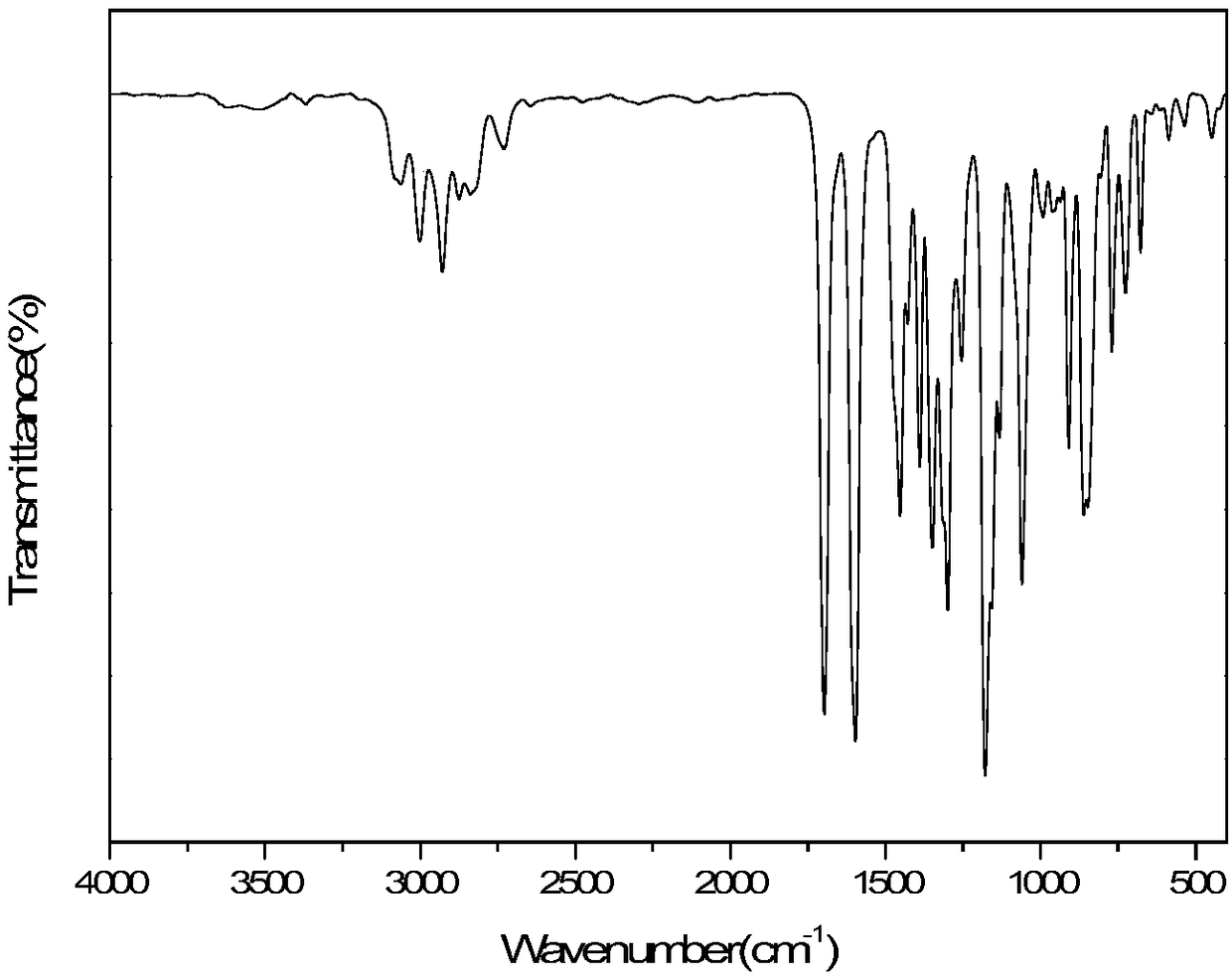

Image

Examples

specific Embodiment approach 1

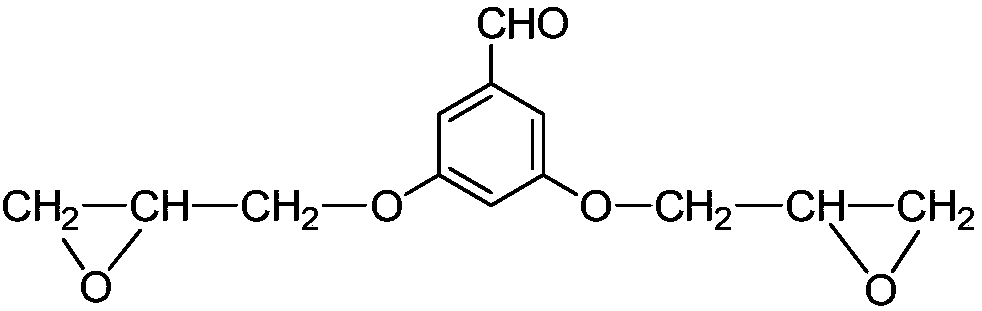

[0028] Specific embodiment one: the molecular structural formula of the present embodiment 5-formyl resorcinol diglycidyl ether is:

[0029]

specific Embodiment approach 2

[0030] Specific embodiment two: the preparation method of 5-formyl resorcinol diglycidyl ether of the present embodiment comprises the following steps:

[0031] 1. Put 3,5-dihydroxybenzaldehyde, epibromohydrin and catalyst into the reaction kettle, raise the temperature to 80℃~100℃, stir for 2h~8h, then raise the temperature to the reflux temperature to remove the excess epoxybromopropane Evaporate under reduced pressure, recover and recycle to obtain a concentrated solution; wherein the molar ratio of 3,5-dihydroxybenzaldehyde and epibromohydrin is 1: (6-20), the ratio of 3,5-dihydroxybenzaldehyde and catalyst The mass ratio is 100: (0.1~5);

[0032] 2. After the temperature of the concentrated solution is cooled to 40°C to 60°C, add organic solvent and metal alkali solid particles, and continue to stir for 2h to 6h; wherein the mass ratio of 3,5-dihydroxybenzaldehyde to organic solvent is 1:(10 ~25), the molar ratio of 3,5-dihydroxybenzaldehyde to metal alkali solid particl...

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the catalyst is benzyltriethylammonium chloride, tetrabutylammonium bromide, tetrabutylammonium chloride, tetrabutylammonium bisulfate , one of trioctylmethyl ammonium chloride, dodecyltrimethylammonium chloride, tetradecyltrimethylammonium chloride, 18-crown-6, 15-crown-5 or A mixture of several. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com