Salt-tolerant Gemini cation VES (Viscoelastic Surfactant) as well as preparation method thereof and salt-tolerant clean fracturing fluid

A surfactant and cation technology, applied in the field of salt-tolerant gemini cationic viscoelastic surfactant and its preparation, salt-resistant clean fracturing fluid, can solve problems such as non-salinity resistance, and achieve good salt resistance , good viscoelasticity, strong surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the salt-tolerant type gemini cationic viscoelastic surfactant of the present embodiment is as follows:

[0048] Oleamide propyl dimethylamine and dibromoneopentyl glycol are dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 2.1:1, and potassium iodide is added as a catalyst (potassium iodide and oleamide propyl The molar ratio of dimethylamine is 1:10), at 145°C, magnetically stirred at 300r / min, and reflux heating with a condenser tube for 24 hours; vacuumize with an oil pump, under 5 negative pressures, distill under reduced pressure at 80°C to remove DMF Solvent to obtain a viscous paste crude product; dissolve the crude product in ethyl acetate at 40°C, remove unreacted dibromoneopentyl glycol and potassium iodide catalyst by suction filtration; recrystallize the ethyl acetate solution at 3°C to remove unreacted oleic acid amide Propyldimethylamine, after three recrystallizations, ethyl acetate was removed by rotary evaporatio...

Embodiment 2

[0050] The preparation method of the salt-tolerant type gemini cationic viscoelastic surfactant of the present embodiment is as follows:

[0051] Erucamide propyl dimethylamine and dibromoneopentyl glycol were dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 2.1:1, and potassium carbonate was added as a catalyst (potassium carbonate and erucamide The molar ratio of propyldimethylamine is 1:13), at 135°C, the magnetic sub-stirrer is 300r / min, and the condenser tube is added to reflux and heated for 22 hours; the oil pump is used to evacuate, under 4 negative pressures, 70°C vacuum distillation, Remove the DMF solvent to obtain a viscous paste crude product; dissolve the crude product in ethyl acetate at 30°C, remove unreacted dibromoneopentyl glycol and potassium iodide catalyst by suction filtration; recrystallize the ethyl acetate solution at 0°C, remove unreacted mustard Acid amidopropyl dimethylamine, after three times of recrystallization, rotary evaporation to...

Embodiment 3

[0053] The preparation method of the salt-tolerant type gemini cationic viscoelastic surfactant of the present embodiment is as follows:

[0054] Stearic amidopropyl dimethylamine and dibromoneopentyl glycol were dissolved in N,N-dimethylformamide (DMF) at a molar ratio of 2.5:1, and sodium carbonate was added as a catalyst (potassium carbonate and stearic acid The molar ratio of acid amidopropyl dimethylamine is 1:11), at 150°C, the magnet is stirred at 300r / min, and the condenser is added to reflux and heated for 26 hours; vacuumize with an oil pump, under 6 negative pressures, reduce the pressure at 85°C Distill and remove the DMF solvent to obtain a viscous paste crude product; dissolve the crude product in ethyl acetate at 50°C, remove unreacted dibromoneopentyl glycol and potassium iodide catalyst by suction filtration; recrystallize the ethyl acetate solution at 0-5°C, Unreacted stearic acid amidopropyl dimethylamine was removed, and after three times of recrystallizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

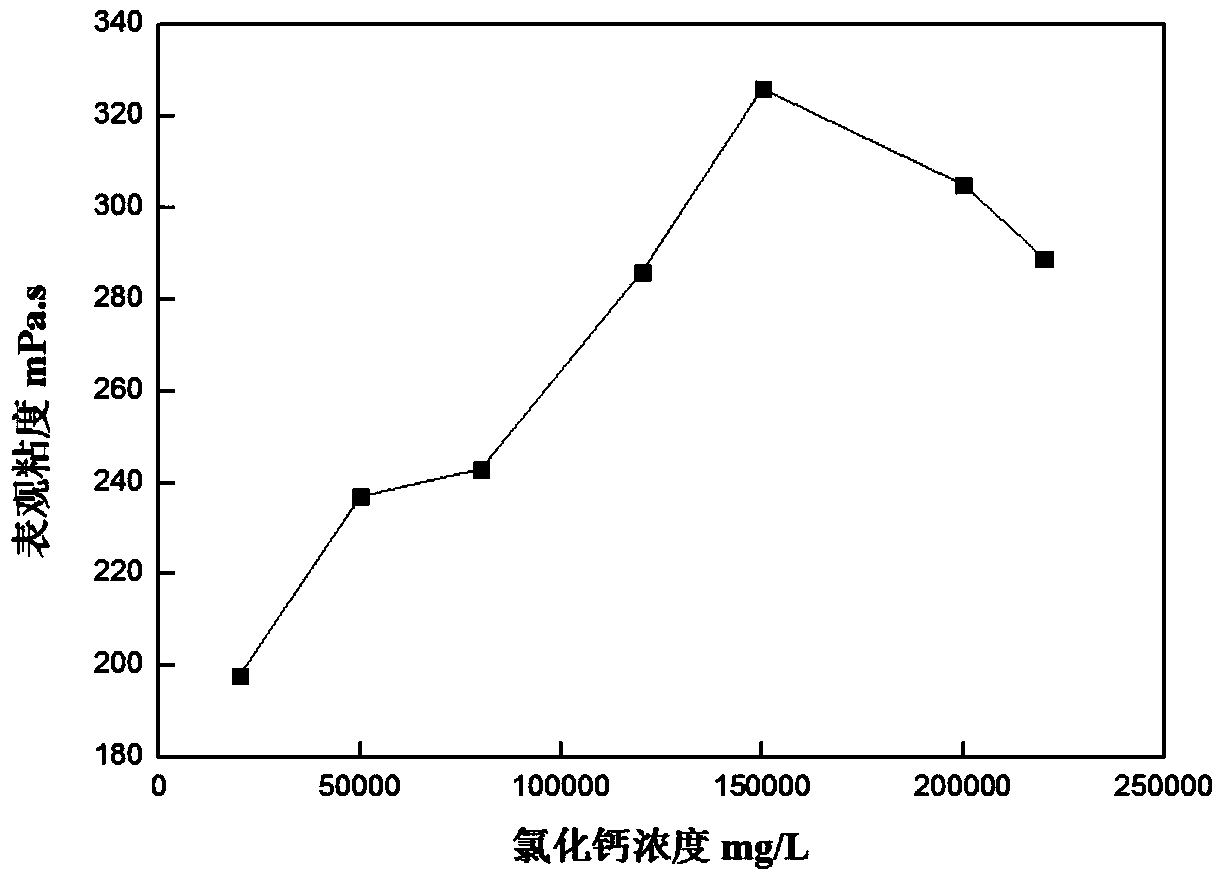

| Apparent viscosity | aaaaa | aaaaa |

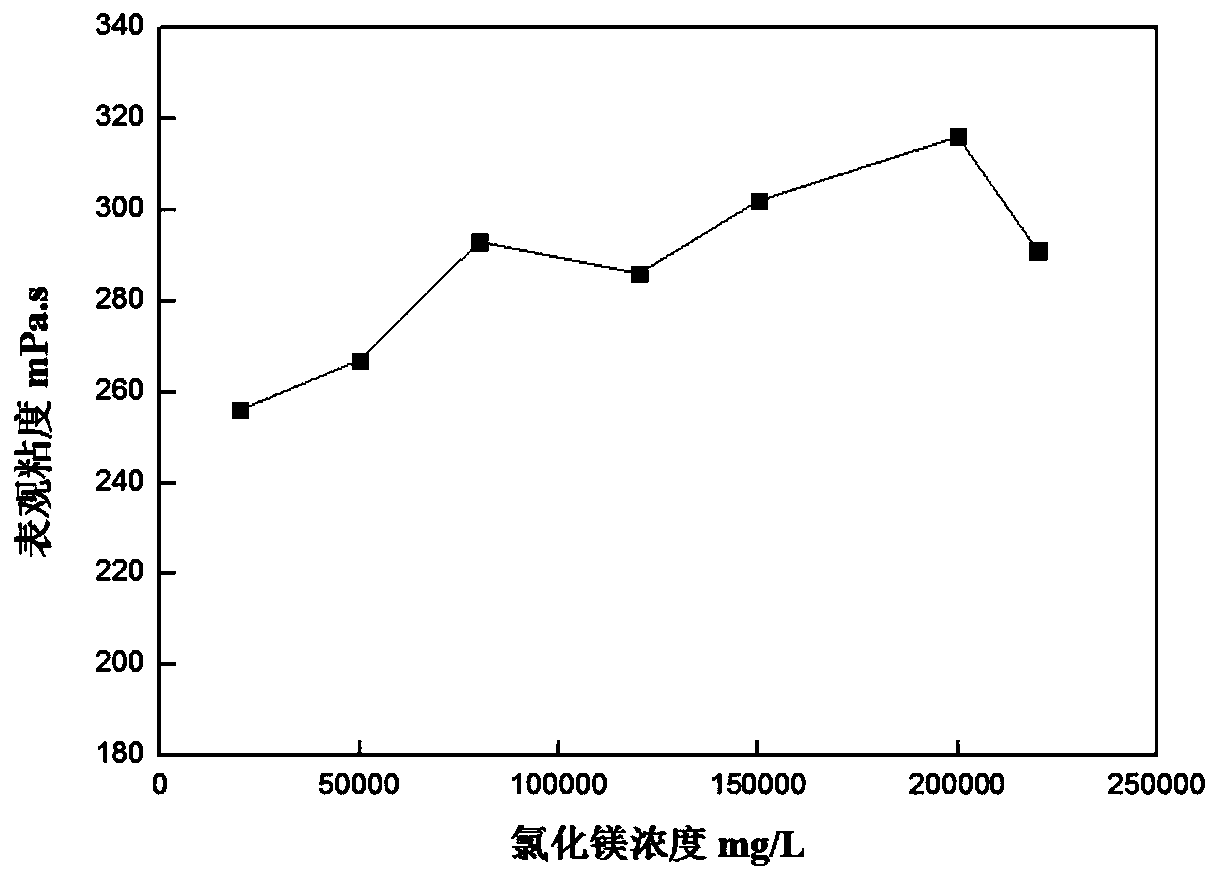

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com