Flame-retarding shell material for fire alarm device and preparation method of shell material

A fire alarm and shell material technology is applied in the field of flame retardant fire alarm shell materials and their preparation, and can solve the problems of fire alarm shells that are prone to burning, the alarm can not continue to work, and the alarm reminder is lost. Suitable for promotion, good use effect, and the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

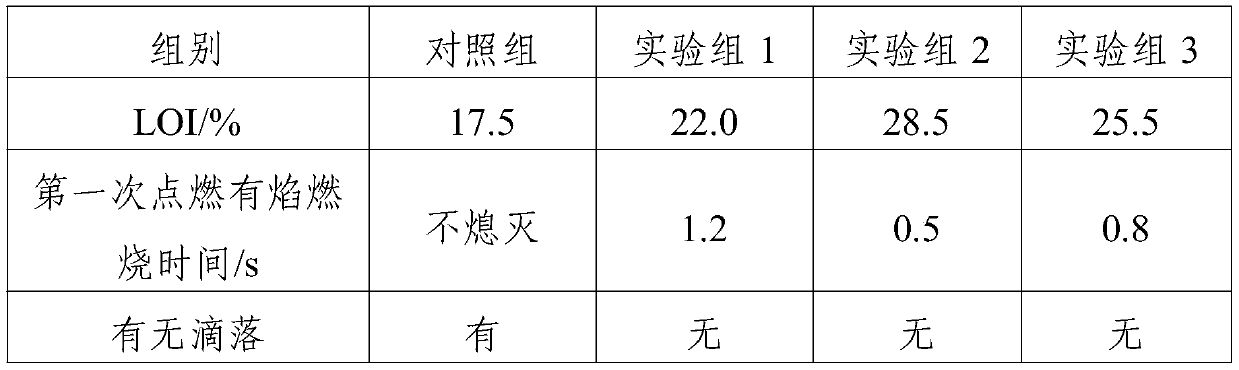

Examples

Embodiment 1

[0025] A flame-retardant fire alarm shell material, the fire alarm is made of the following raw materials in parts by weight: 50 parts of ABS resin, 15 parts of polycarbonate, 1 part of nano diatomite, dibromoneopentyl glycol phosphate 10 parts, 5 parts of decabromodiphenylethane, 5 parts of aluminum isobutyl hypophosphite, 6 parts of brominated epoxy resin, 2 parts of antimony trioxide, 5 parts of silicon carbide, 3 parts of molybdenum disulfide, 2 parts of zirconia part, 0.8 part of modifier, 1 part of coupling agent, and 2 parts of dispersant.

[0026] Wherein, the modifying agent is formed by mixing cetyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 1:2; the coupling agent is composed of vinyltrimethoxysilane and 3- Aminopropyltriethoxysilane is mixed at a mass ratio of 2:3; the dispersant is one or more of sodium lauryl sulfate, triethylhexyl phosphoric acid and potassium succinate.

[0027] The preparation method of the shell material comprise...

Embodiment 2

[0035] A flame-retardant fire alarm shell material, the fire alarm is made of the following raw materials in parts by weight: 55 parts of ABS resin, 20 parts of polycarbonate, 1.5 parts of nano diatomite, dibromoneopentyl glycol phosphate 12.5 parts, 7.5 parts of decabromodiphenylethane, 7.5 parts of aluminum isobutyl hypophosphite, 7 parts of brominated epoxy resin, 3 parts of antimony trioxide, 6 parts of silicon carbide, 4 parts of molybdenum disulfide, 3 parts of zirconia parts, 1.0 parts of modifier, 1.5 parts of coupling agent, and 2.5 parts of dispersant.

[0036] Wherein, the modifying agent is formed by mixing cetyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 1:2; the coupling agent is composed of vinyltrimethoxysilane and 3- Aminopropyltriethoxysilane is mixed at a mass ratio of 2:3; the dispersant is one or more of sodium lauryl sulfate, triethylhexyl phosphoric acid and potassium succinate.

[0037] The preparation method of the shell m...

Embodiment 3

[0045] A flame-retardant fire alarm shell material, the fire alarm is made of the following raw materials in parts by weight: 60 parts of ABS resin, 25 parts of polycarbonate, 2 parts of nano diatomite, dibromoneopentyl glycol phosphate 15 parts, 10 parts of decabromodiphenylethane, 10 parts of aluminum isobutyl hypophosphite, 8 parts of brominated epoxy resin, 4 parts of antimony trioxide, 7 parts of silicon carbide, 5 parts of molybdenum disulfide, 4 parts of zirconia parts, 1.2 parts of modifier, 2 parts of coupling agent, and 3 parts of dispersant.

[0046] Wherein, the modifying agent is formed by mixing cetyltrimethylammonium bromide and polymethylpyrrolidine with a mass ratio of 1:2; the coupling agent is composed of vinyltrimethoxysilane and 3- Aminopropyltriethoxysilane is mixed at a mass ratio of 2:3; the dispersant is one or more of sodium lauryl sulfate, triethylhexyl phosphoric acid and potassium succinate.

[0047] The preparation method of the shell material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com