Novel flame-retardant polyurethane adhesive and preparation method thereof

A technology of polyurethane adhesives and reactive flame retardants, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc. Sex and glass transition temperature and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

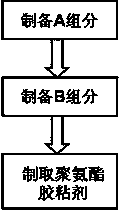

[0016] figure 1 It is a process step diagram of a method for preparing a novel flame-retardant polyurethane adhesive in an embodiment of the present invention; the polyurethane adhesive is prepared from polytetrahydrofuran diol 1000, toluene diisocyanate, a reactive flame retardant, a chain extender and a crosslinking agent. The reactive flame retardant is dibromoneopentyl glycol, the chain extender is 1,4-butanediol, and the crosslinking agent is trimethylolpropane, and the preparation method comprises the following steps : a) preparing component A, b) preparing component B, and c) preparing polyurethane adhesive.

[0017] The new flame-retardant polyurethane adhesive mentioned in the present invention uses polytetrahydrofuran diol 1000 and toluene diisocyanate as main raw materials, and introduces reactive flame retardant dibromoneopentyl glycol, chain extender 1,4-butanediol, cross-linked Agent trimethylolpropane is prepared by semi-prepolymer method. In the preparation p...

Embodiment

[0019] The specific preparation method is as follows:

[0020] a) Preparation of component A, the specific preparation process is as follows: according to the mass percentage, first put 39.8% polytetrahydrofuran diol 1000, 47.8% toluene diisocyanate, and 12.4% reactive flame retardant into the reaction kettle, heat to 80 °C, Stir quickly and evenly; then react under nitrogen protection for 15 minutes; and finally vacuum degas for 30 minutes to obtain the A-component polyisocyanate prepolymer, which is sealed and stored for later use.

[0021] b) Preparation of component B, the specific preparation process is: according to the mass percentage, first put 64.8% polytetrahydrofuran diol 1000, 19.6% reactive flame retardant, 7.8% chain extender, 7.8% crosslinking agent into the reactor , heated to 80°C; then stirred at 400r / min for 20min, and mixed evenly to obtain a colorless and transparent liquid of component B, which was sealed and stored for later use.

[0022] c) Prepare the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com