Polyurethane thermal insulation material and preparation method thereof

A thermal insulation and polyurethane technology, which is applied in the field of external wall thermal insulation materials, can solve the problems of conflict between fire and flame retardant properties and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of modified expanded perlite is:

[0023] Add the expanded perlite to the acrylic resin emulsion and stir evenly, then add KH550 and triethoxysilane, heat in a water bath to 50°C, stir well, react for 3 hours, then remove and dry.

Embodiment 2

[0025] The preparation method of modified expanded perlite is:

[0026] Add the expanded perlite to the acrylic resin emulsion and stir evenly, then add KH560 and triethoxysilane, heat in a water bath to 70°C, stir well, react for 2 hours, then remove and dry.

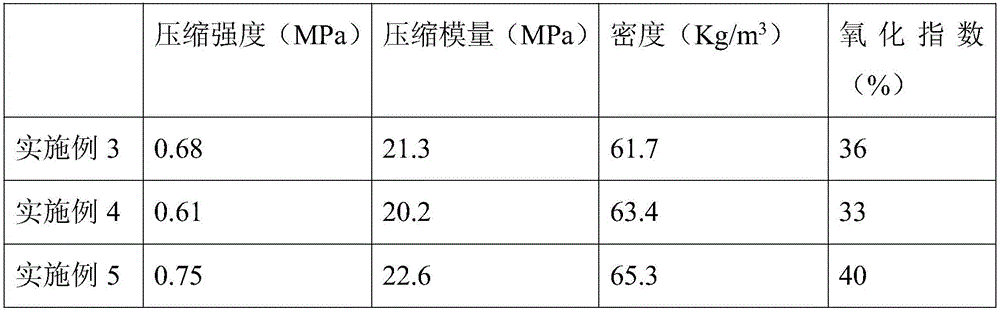

Embodiment 3

[0028] A polyurethane thermal insulation material, which is composed of component A and component B. Calculated in parts by weight, component A consists of 15 parts of dibromopentaerythyl glycol type epoxy resin, 40 parts of polyester polyol, polyether polyol 30 parts of alcohol, 7 parts of modified expanded perlite of Example 1, 1 part of dibutyltin laurate, 15 parts of dimethyl methyl phosphate, 1 part of silicone oil and 15 parts of foaming agent, component B is polyphenyl Polymethylene polyisocyanate, the blowing agent is composed of 1 part of pentafluoropropane, 6 parts of pentafluorobutane and 4 parts of cyclopentane. The mixing weight ratio of A component and B component is 1:1.

[0029] Preparation method: pre-mix dibromopentaerythritol type epoxy resin, polyester polyol, polyether polyol, cyclopentane and pentafluorobutane, and add the modified expanded perlite, silicone oil, Dibutyltin laurate, dimethyl methyl phosphate and pentafluoropropane are used to obtain comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com