Mulberry silk flame retardant agent

A flame retardant additive, silk technology, which is applied in the field of silkworm silk flame retardant additives, can solve the problems of yellowing of silk fabrics, unsuitable flame retardant finishing of silk fabrics, poor washability, etc., and achieve high-efficiency flame retardancy , Flame retardant finishing cost is economical and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

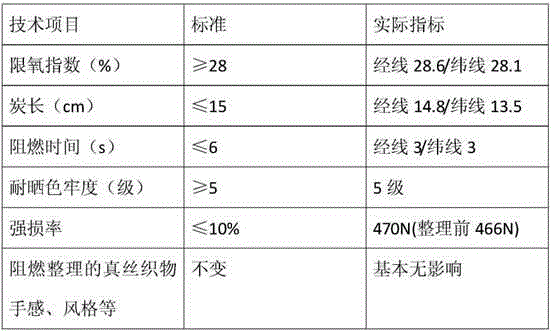

[0021] First, take dibromoneopentyl glycol (DBNPG), dibromoneopentyl glycol phosphate cyanamide salt, polyhydroxy organophosphorus oligomer HFPO, 1,2,3,4-butane tetracarboxylic acid BTCA respectively 500, 750, 750, 250 grams, mix evenly, add 3.375 kg of pure water, stir and dissolve to become a flame retardant solution; soak 20 square meters of silk at 180g / square meter in the prepared flame retardant solution for 30 minutes, and dry it with a dehydrator. Then dry it with a flat stenter machine. After testing, the relevant data are shown in Table 1. The indicators of oxygen-limiting index (%) and char length (cm ) are not ideal. Table 1 :

[0022]

Embodiment 2

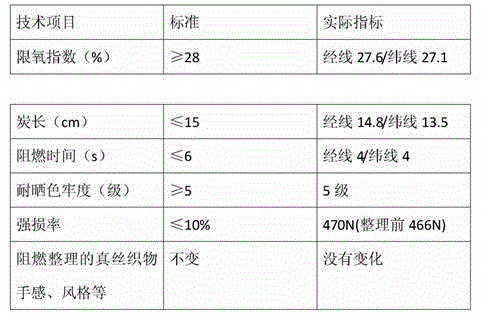

[0024] First, take dibromoneopentyl glycol (DBNPG), dibromoneopentyl glycol phosphate cyanamide salt, polyhydroxy organophosphorus oligomer HFPO, 1,2,3,4-butane tetracarboxylic acid BTCA respectively 500, 750, 750, 250 grams, mix evenly, add 2.5 kg of pure water, stir and dissolve to become a flame retardant solution; soak 20 square meters of 180g / square meter silk in the prepared flame retardant solution for 30 minutes, and dry it with a dehydrator. Then dry it with a flat tenter. After testing, the relevant data are shown in Table 2, and all indicators are ideal. Table 2 :

[0025]

[0026] After repeated experiments and comprehensive comparisons, the process parameters and routes selected in Embodiment 1 are the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com