Preparation method of high-strength composite plastic-wood material

A wood-plastic material and high-strength technology, applied in the field of wood-plastic materials, can solve the problems of limited application of wood-plastic materials and the strength of wood-plastic materials cannot meet the requirements, and achieve excellent comprehensive performance, high strength, and good flame retardant properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

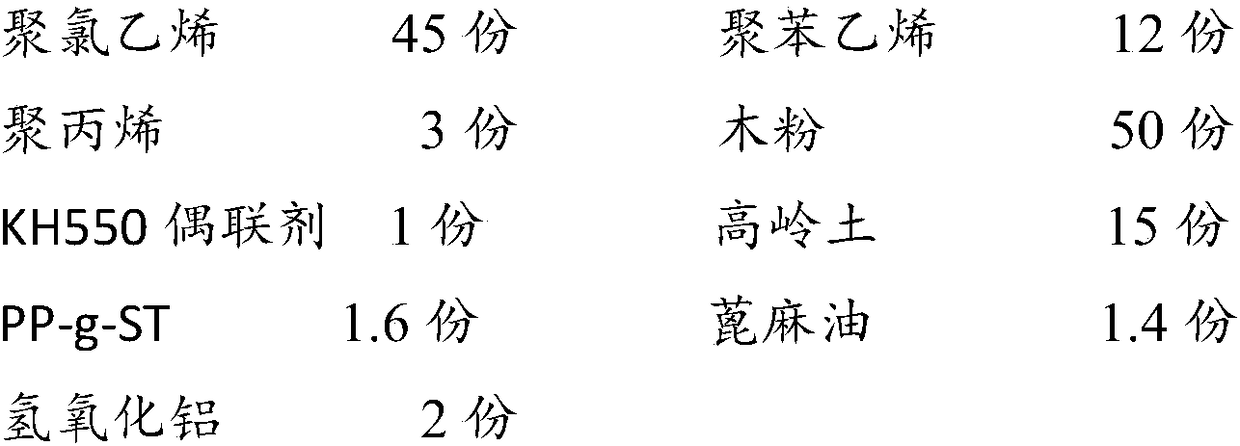

[0029] High-strength composite wood-plastic materials, wood-plastic materials include by mass components:

[0030]

[0031] The preparation method is:

[0032] Weighing components of polyvinyl chloride, polystyrene, polypropylene, wood flour, KH550 coupling agent, kaolin, PP‐g‐ST, castor oil and aluminum hydroxide;

[0033] Add the wood flour to the dryer, and dry it for 25 minutes at a temperature of 150°C, so that the humidity of the wood flour is 1%;

[0034] Add the dried wood flour to the high mixer, control the mixing speed to 600r / min, mix for 3 minutes, add polyvinyl chloride, polystyrene, polypropylene, wood flour and kaolin, mix for 6 minutes, then add KH550 coupling agent, PP-g-ST, castor oil and aluminum hydroxide, mixed for 4min to obtain a mixture;

[0035] Add the mixture into the extruder, control the temperature of the extruder to 240°C, and the screw speed to 400r / min, melt and extrude, cool, and pelletize to obtain wood-plastic material pellets;

[003...

Embodiment 2

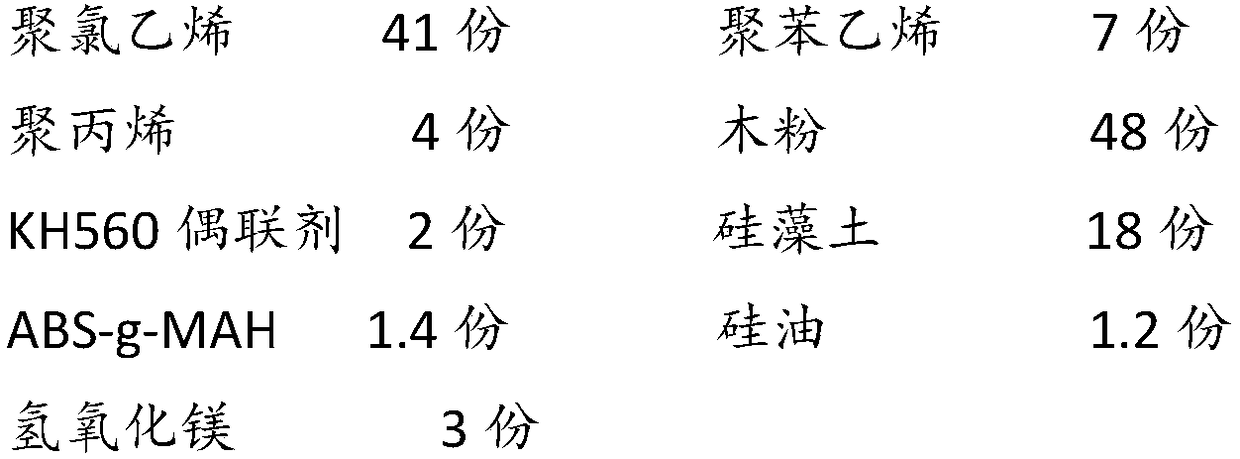

[0038] High-strength composite wood-plastic materials, wood-plastic materials include by mass components:

[0039]

[0040] The preparation method is:

[0041] Weigh the components of polyvinyl chloride, polystyrene, polypropylene, wood flour, KH560 coupling agent, diatomaceous earth, ABS‐g‐MAH, silicone oil and magnesium hydroxide;

[0042] Add the wood flour to the dryer, and dry it for 17 minutes at a temperature of 140°C, so that the humidity of the wood flour is 3%;

[0043] Add the dried wood flour to the high mixer, control the mixing speed to 850r / min, mix for 2 minutes, add polyvinyl chloride, polystyrene, polypropylene, wood flour and diatomaceous earth, mix for 11 minutes, then add KH560 Coupling agent, ABS‐g‐MAH, silicone oil and magnesium hydroxide were mixed for 2 minutes to obtain a mixture;

[0044] Add the mixture into the extruder, control the temperature of the extruder to 210°C, and the screw speed to 470r / min, melt and extrude, cool, and pelletize to ...

Embodiment 3

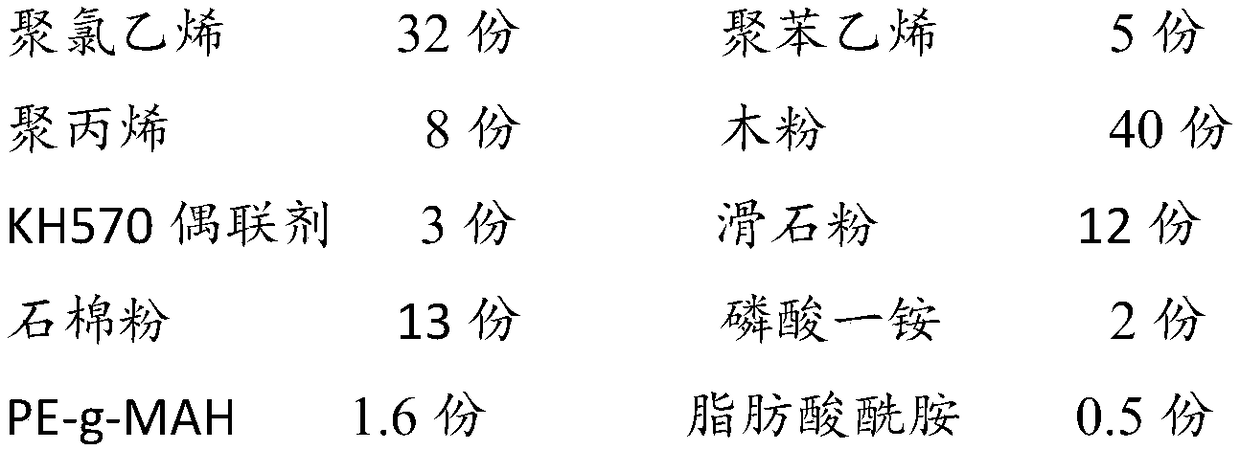

[0047] High-strength composite wood-plastic materials, wood-plastic materials include by mass components:

[0048]

[0049] The preparation method is:

[0050] Weighing components of polyvinyl chloride, polystyrene, polypropylene, wood flour, KH570 coupling agent, talcum powder and asbestos powder, PE‐g‐MAH, fatty acid amides and monoammonium phosphate;

[0051] Add the wood powder into the dryer, and dry it for 15 minutes at a temperature of 100°C, so that the humidity of the wood powder is 4%;

[0052] Add the dried wood flour to the high mixer, control the mixing speed to 900r / min, mix for 1min, add polyvinyl chloride, polystyrene, polypropylene, wood flour, talcum powder and asbestos powder, mix for 12min, then Add KH570 coupling agent, PE-g-MAH, fatty acid amide and monoammonium phosphate, and mix for 2 minutes to obtain a mixture;

[0053] Add the compound into the extruder, control the temperature of the extruder to 200°C, and the screw speed to 600r / min, melt and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Colony count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com