Selective etching solution for copper or copper alloy

A copper alloy and selective technology, which is applied in the field of metal surface chemical treatment, can solve the problems of difficult control of concentration stability and damage, and achieve the effect of improving etching selectivity, high etching efficiency and improving activity

Active Publication Date: 2017-05-31

江苏和达电子科技有限公司

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

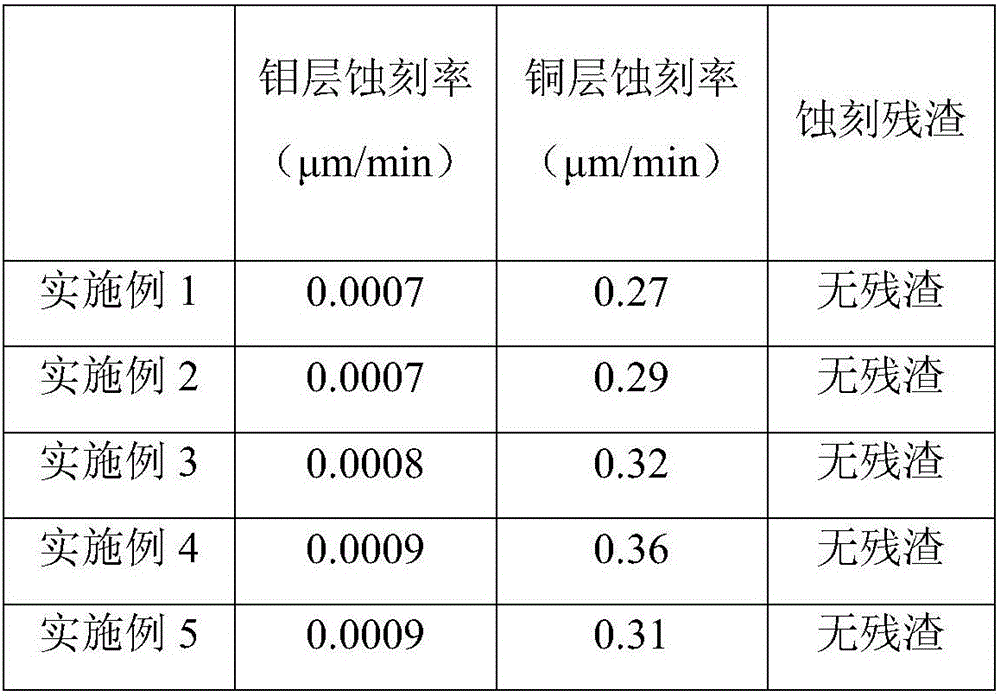

Effect test

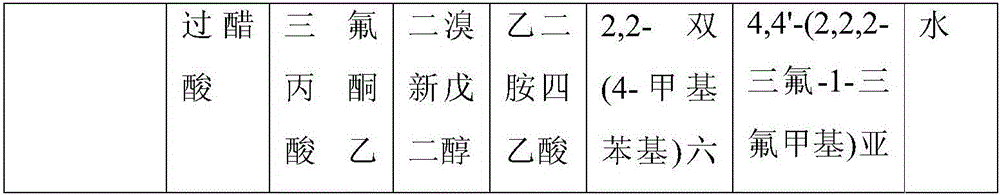

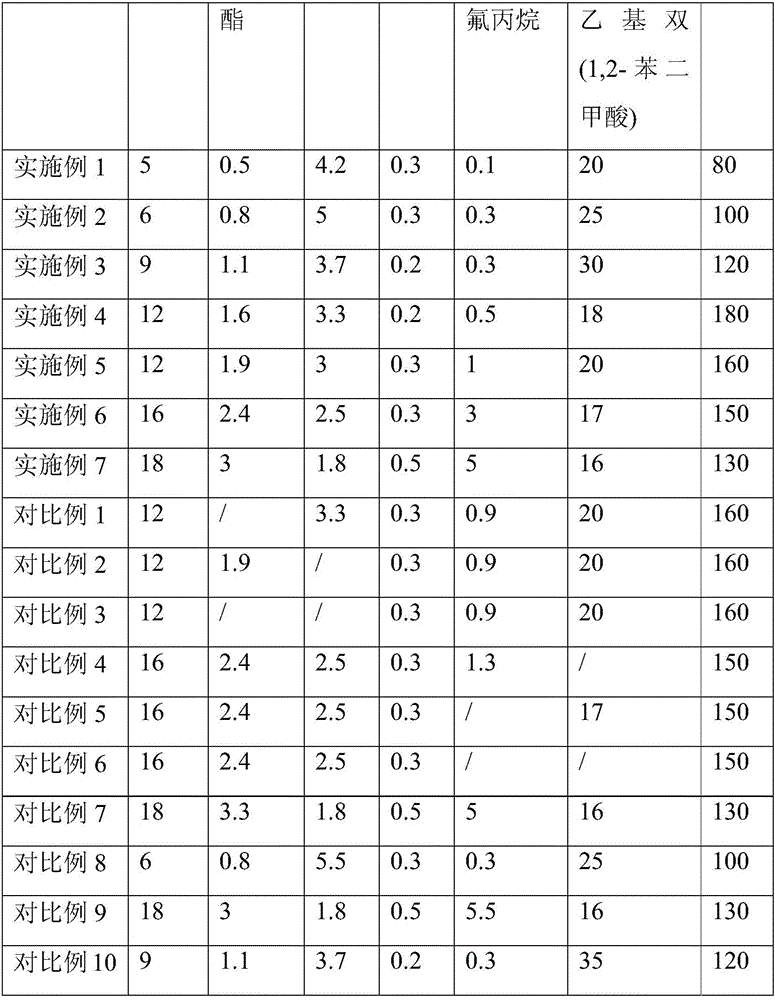

Embodiment 1-7 and comparative example 1-10

[0030] According to the ratio of each component shown in Table 1 below, mix each component evenly.

[0031] Table 1 embodiment 1-7 and each group distribution ratio of comparative example 1-10

[0032]

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a selective etching solution for copper or copper alloy. The etching solution comprises peracetic acid, ethyl trifluoropyruvate, dibromoneopentyl glycol, ethylenediamine tetraacetic acid, 2,2-bis(4-methylphenyl)hexafluoropropane, 4,4'-(2,2,2-trifluoro-1-(trifluoromethyl)ethylidene)bisphthalic acid and water. The etching solution has obviously high etching efficiency and etching selectivity, hardly etches a molybdenum layer, and has a high etching rate for a copper layer. Besides, the etching solution provided by the invention can not produce etching residue in the etching process, thereby having important application value.

Description

technical field [0001] The invention belongs to the field of metal surface chemical treatment, in particular to a selective etching solution for copper or copper alloy. Background technique [0002] In recent years, as the size of thin film transistor liquid crystal display (TFT-LCD) panels has become larger and larger, the resistance and capacitance (RC) delay effect caused by the resistance of the metal wire is not low enough, which will cause distortion and distortion of the signal during transmission. And affect the presentation of panel quality. With the improvement of the refinement of the processing pattern, in terms of physical properties such as no wiring delay and not easy to break, the materials used for metal thin film elements, electrode wiring, and other elements used in semiconductors and liquid crystal display devices, etc. The requirements are also getting higher and higher. Under such circumstances, as a material for such elements, etc., a material with e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/44

CPCC23F1/44

Inventor 王毅明朱霞

Owner 江苏和达电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com