Ammonium sulfite method-based caramel colour production process

A technology of ammonium sulfite method and production process, applied in chemical instruments and methods, organic dyes, natural dyes, etc., can solve the problems of corrosiveness, animal growth tumors, carcinogenic risks, etc., and achieve good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

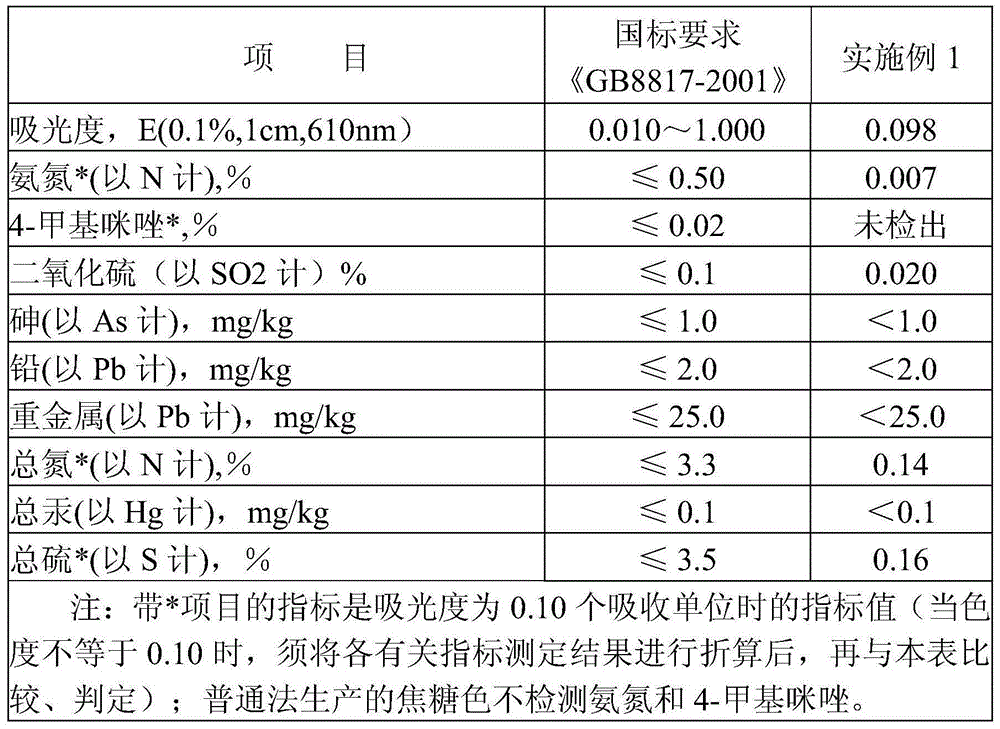

Embodiment 1

[0033] Production of 36Be, 25000EBC ammonium sulfite method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are the measurement indicators of caramel color)

[0034] (1) Metering feed: 6000kg of maltose syrup with a DE value of 42% and a dry basis of 60% is metered into the reaction tank;

[0035] (2) Alkali addition: add an appropriate amount of sodium hydroxide to the maltose syrup that has been prepared to adjust the pH to 10.0;

[0036] (3) The first reaction: put the above-mentioned maltose syrup with adjusted PH value in the reaction tank under normal pressure and raise the temperature to react until the temperature rises to the point where the material boils. Take a sample every 30 minutes to detect its color rate and DE value, and react for 2 hours At 25 minutes, the DE value is equal to 0 to terminate a reaction, and the color rate is 0.035 at this time;

[0037] (4) Cooling: When the...

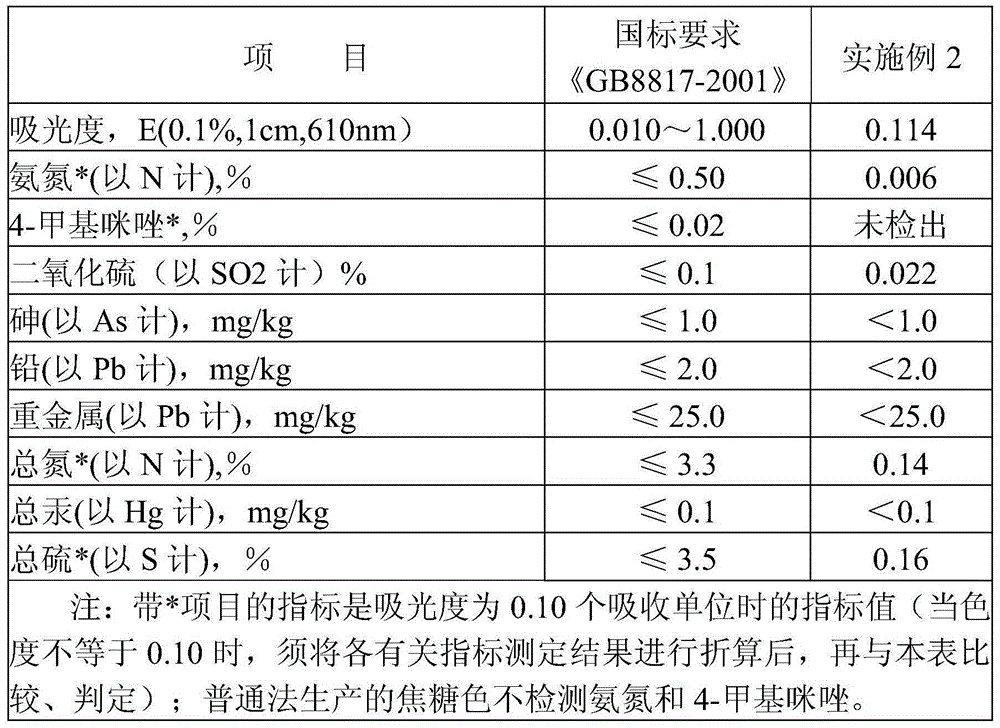

Embodiment 2

[0047] Production of 36Be, 30000EBC ammonium sulfite caramel color

[0048] (1) Metering feed: 6000kg DE value 98%, the glucose syrup that dry basis is 80% is metered into reaction tank;

[0049] (2) Alkali addition: add an appropriate amount of sodium hydroxide to the prepared glucose syrup to adjust the pH to 9.02;

[0050] (3) The first reaction: put the above-mentioned glucose syrup with adjusted PH value in the reaction tank under normal pressure to raise the temperature and react until the temperature rises to the point where the material boils, and take samples every 30 minutes to detect its color rate and DE value, and react for 3 hours At 45 minutes, the DE value is equal to 0 to terminate a reaction, and the color rate is 0.043 at this time;

[0051] (4) Cooling: When the DE value is equal to 0, the first reaction is terminated, the coolant is turned on for 15 minutes, and the material temperature is 87°C;

[0052] (5) Add catalyst: add 24kg (5‰ of maltose syrup dr...

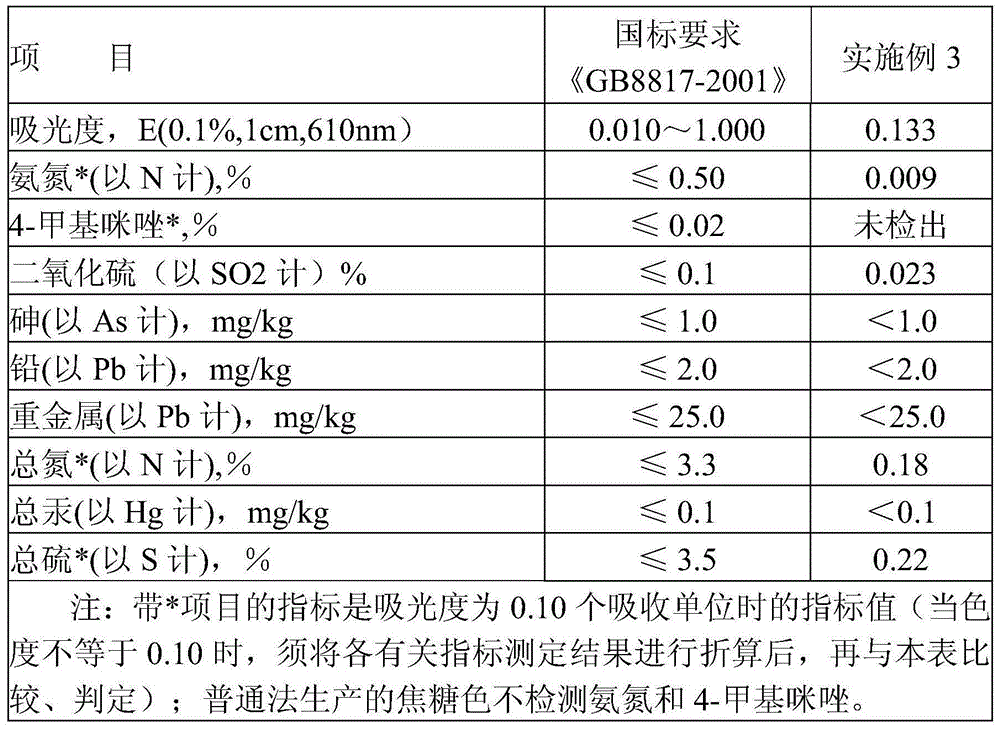

Embodiment 3

[0061] Production of 36Be, 35000EBC ammonium sulfite caramel color

[0062] (1) Metering feed: 6000kg DE value 98%, dry basis is 90% glucose syrup metering into reaction tank;

[0063] (2) Acid addition: add an appropriate amount of sulfuric acid to the prepared glucose syrup to adjust the pH to 1.0;

[0064] (3) The first reaction: put the above-mentioned glucose syrup with adjusted PH value in the reaction tank under normal pressure to raise the temperature and react until the temperature rises to the point where the material boils. Take a sample every 30 minutes to detect its color rate and DE value, and react for 4 hours At 05 minutes, the DE value is equal to 0 to terminate the first reaction, and the color rate is 0.055 at this time;

[0065] (4) Cooling: When the DE value is equal to 0, the first reaction is terminated, the cooling liquid is turned on for 15 minutes, and the material temperature is 88°C;

[0066] (5) Add catalyst: add 32.4kg (6‰ of maltose syrup dry b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com