Preparation method of field-induced nonlinear conducting composite material, composite material prepared and application thereof

A conductive composite material, nonlinear technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of difficult protection of instantaneous electromagnetic pulses, slow response time and conduction delay, etc., to achieve easy mass preparation, easy operation, The effect of high conductivity nonlinear coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

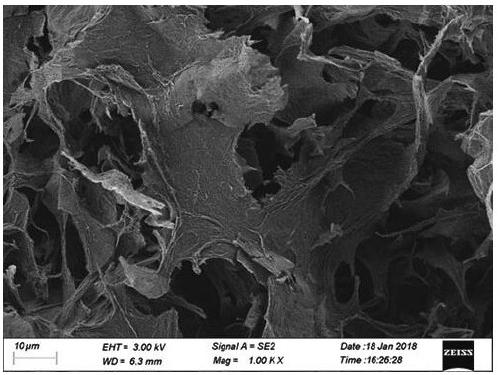

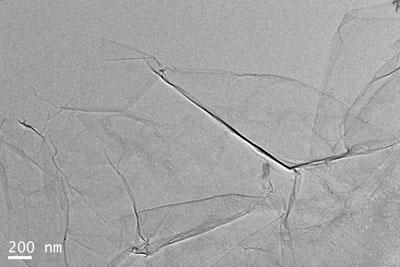

[0043] The method for preparing the modified graphene / epoxy resin field-induced nonlinear conductive composite material after reduction comprises the following steps:

[0044] (1) First, pour 50ml of deionized water, 150ml of ethanol and 10mg of KH560 into a beaker, and ultrasonically disperse for 1 hour until KH560 is completely hydrolyzed to obtain mixed solution A.

[0045] (2) Then add 100 mg GO into solution A, after ultrasonic dispersion, heat to 80 °C and stir for 4 h to obtain KGO suspension B.

[0046] (3) A small amount of KOH solution was added to the suspension B to make the system pH=10, and 147.06 mg of hydrazine hydrate was added to the suspension B, dispersed at room temperature, heated to 90°C with magnetic stirring for 6 hours to obtain RKGO suspension C.

[0047] (4) After the suspension C was washed with ethanol and deionized water and filtered three times, it was placed in a vacuum freeze dryer at -50°C for 24 hours to obtain a black RKGO powder.

[0048]...

Embodiment 2

[0051] The method for preparing the modified graphene / epoxy resin field-induced nonlinear conductive composite material after reduction comprises the following steps:

[0052] Front (1)-(4) are the same as embodiment 1.

[0053] (5) Take 100mg of RKGO, 100ml of acetone and 9.52g of epoxy resin E-51 into a beaker and seal the mouth of the beaker with plastic wrap, ultrasonically disperse for about 30min to obtain a suspension D, then heat to 80°C and stir for 4h, then remove the plastic wrap film, continue to heat and stir until the acetone evaporates completely, and a liquid composite material system is obtained.

[0054] (6) Cool the liquid composite material system prepared in step (5) to 45°C, pour 0.38g of 2E4MZ liquid into it, stir and react at 45°C for 1min, pour it into the mold that has been coated with release agent beforehand, and add it to the vulcanizer first. After standing at room temperature for 24 h under pressure, and then at 100 °C for 4 h, the mold was remo...

Embodiment 3

[0056] The reduced modified graphene / epoxy resin field-induced nonlinear conductive composite material preparation method comprises the following steps:

[0057] Front (1)-(4) are the same as embodiment 1.

[0058] (5) Pour 150mg of RKGO, 100ml of acetone and 9.47g of epoxy resin E-51 into a beaker and seal the mouth of the beaker with plastic wrap, disperse ultrasonically for about 30 minutes to obtain a suspension D, then heat to 80°C and stir for 4 hours, then remove the plastic wrap film, continue to heat and stir until the acetone evaporates completely, and a liquid composite material system is obtained.

[0059] (6) Cool the liquid composite material system prepared in step (5) to 45°C, pour 0.38g of 2E4MZ liquid into it, stir and react at 45°C for 1min, pour it into the mold that has been coated with release agent beforehand, and add it to the vulcanizer first. After standing at room temperature for 24 h under pressure, and then at 100 °C for 4 h, the mold was removed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com