Preparation method of epoxy resin microporous materials

A technology of epoxy resin and microporous materials, which is applied in the field of preparation of microporous materials, can solve the problems of low controllability and repeatability of product performance, can not be called microporous foam materials, and reduce material density, etc., and achieves good solubility. ability, reduced cell size, and the effect of good diffusion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

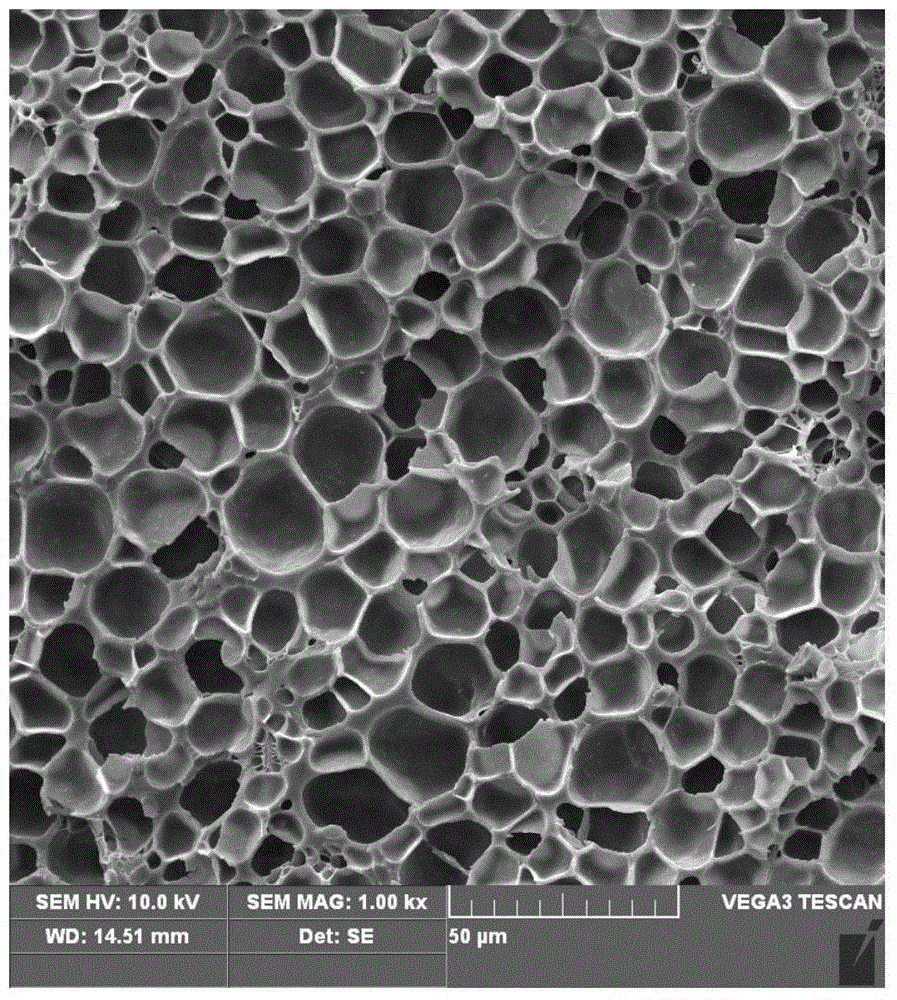

Image

Examples

Embodiment 1

[0018] (1) Add bisphenol A type epoxy resin and 2-ethyl-4-methylimidazole with an epoxy value of 0.11 to 0.14eq / 100g into dichloromethane at a mass ratio of 20:1, and place on a magnetic stirrer After stirring for 1 hour, a mixed solution was obtained, and after the mixed solution was placed in a vacuum oven for vacuum drying, epoxy resin powder was obtained, and the obtained sample was marked as A;

[0019] (2) Place sample A in a hot press at 90°C for 30 minutes under a pressure of 18 MPa, then cool naturally to room temperature, and the obtained sample is marked as B;

[0020] (3) Place sample B in an autoclave and feed supercritical CO 2 Fluid and temperature control, keep sample B in a 36°C, 9MPa autoclave for 72 hours, and quickly release the pressure after the end of the pressure keeping, the obtained sample is marked as C;

[0021] (4) Foam sample C in a constant temperature silicone oil bath at 120°C for 15 seconds. After foaming, place it in an ice-water bath to coo...

Embodiment 2

[0026] (1) Add bisphenol A type epoxy resin and 2-ethyl-4-methylimidazole with an epoxy value of 0.11 to 0.14eq / 100g into dichloromethane at a mass ratio of 20:1, and place on a magnetic stirrer After stirring for 2 hours, a mixed solution was obtained, and after the mixed solution was placed in a vacuum oven for vacuum drying, epoxy resin powder was obtained, and the obtained sample was marked as A;

[0027] (2) Place sample A in a hot press at 100°C and press it under a pressure of 20 MPa for 15 minutes, then naturally cool to room temperature, and the obtained sample is marked as B;

[0028] (3) Place sample B in an autoclave and feed supercritical CO 2 Fluid and temperature control, keep sample B in a 40°C, 10MPa autoclave for 24 hours, and quickly release the pressure after the end of the pressure keeping, the obtained sample is marked as C;

[0029] (4) Place sample C in a constant temperature silicone oil bath at 110°C to foam for 15 seconds. After foaming, place it in...

Embodiment 3

[0033] (1) Add bisphenol A type epoxy resin and 2-ethyl-4-methylimidazole with an epoxy value of 0.11 to 0.14eq / 100g into dichloromethane at a mass ratio of 20:1, and place on a magnetic stirrer After stirring for 2 hours, a mixed solution was obtained, and after the mixed solution was placed in a vacuum oven for vacuum drying, epoxy resin powder was obtained, and the obtained sample was marked as A;

[0034] (2) Place sample A in a hot press at 110°C and press it under a pressure of 20 MPa for 10 minutes, then naturally cool to room temperature, and the obtained sample is marked as B;

[0035] (3) Place sample B in an autoclave and feed supercritical CO 2 Fluid and temperature control, keep sample B in an autoclave at 40°C and 8MPa for 48 hours, and quickly release the pressure after the end of the pressure keeping, and the obtained sample is marked as C;

[0036] (4) Foam sample C in a constant temperature silicone oil bath at 130°C for 5 seconds. After foaming, place it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com