Modified imidazole epoxy resin latent curing agent as well as preparation method and application

A latent curing agent, epoxy resin technology, applied in the direction of organic chemistry, etc., can solve the problems of affecting the use efficiency of epoxy resin, increasing the cost of use of materials, affecting the physical properties of materials, etc., which is conducive to full curing and industrialized production. , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Synthesis of modified imidazoles:

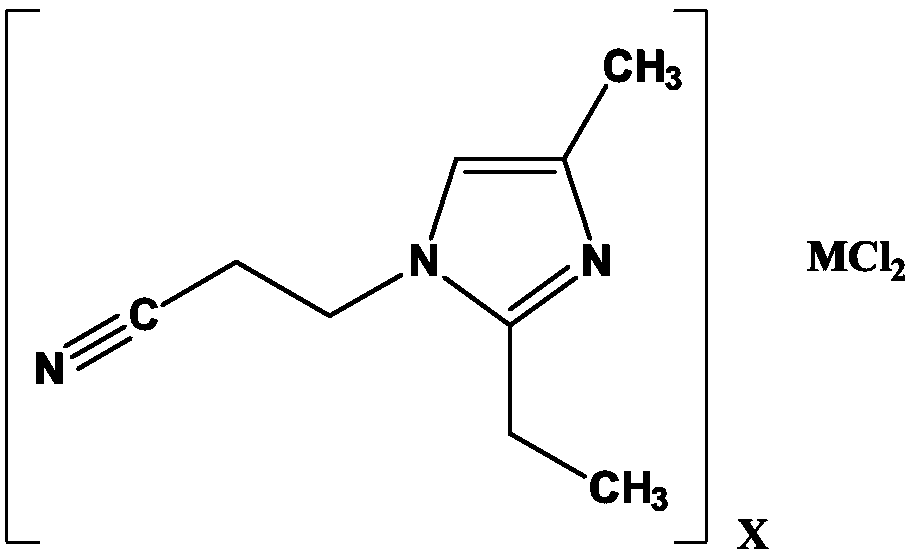

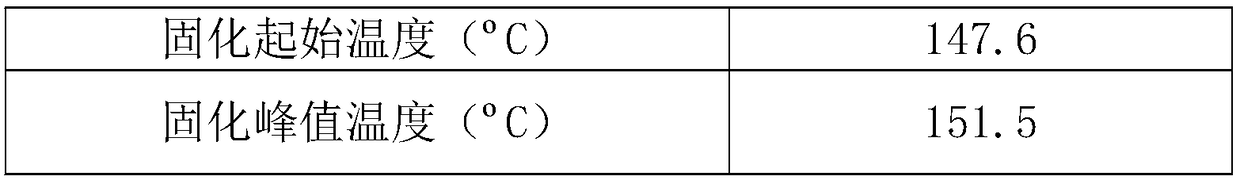

[0023] Add 1-cyanoethyl-2-ethyl-4-methylimidazole (16.3 g, 0.1 mol) and 120 g ethanol into a container, stir for 15 min and set aside. Dissolve copper chloride (3.4g, 0.025mol) in 100g ethanol to form a copper chloride solution, and slowly add it dropwise to the above-mentioned 1-cyanoethyl - In the 2-ethyl-4-methylimidazole solution, the dropping rate is 60 drops / min, and after the dropping, the temperature is raised to 60 degrees Celsius to continue the reaction for 6 hours. After the reaction is completed, the solid by-products produced by the reaction are removed by vacuum filtration, and the obtained filtrate is subjected to vacuum distillation to remove the solvent to obtain a copper chloride-modified imidazole product. The structural composition of the modified imidazole was characterized by elemental analysis and plasma spectroscopic analysis, and the content of each element is shown in Table 1. According to the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com