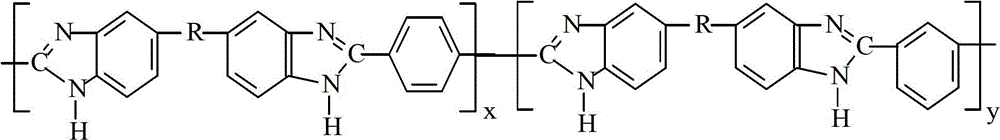

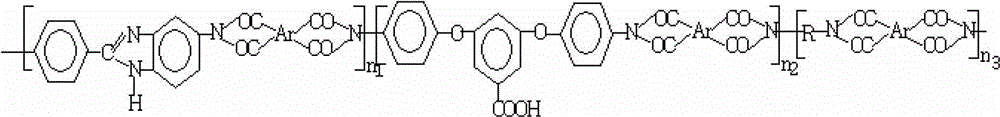

Benzimidazole-type humidity-sensitive high-molecular coating material and preparation method and application thereof

A technology of benzimidazole and polybenzimidazole imide is applied in the fields of humidity-sensitive polymer coatings and their preparation and application, which can solve problems such as poor sensitivity, accuracy and resolution, and achieve convenient source, simple operation, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Put 22.4 grams (0.1 moles) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI) and 1500 grams of N-methyl-2-pyrrolidone into the reaction kettle, stir and dissolve at room temperature, then add 33.6 g (0.1 mol) 3,5-bis(4-aminophenoxy)benzoic acid (35DAPOBA) and 42.8 g (0.1 mol) 1,4-bis(2-trifluoromethyl-4-aminophenoxy) ) benzene (14BAPB-2TF), after stirring and dissolving, add 93.0 g (0.3 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA), stir and react for 3 hours, then add 200 g of toluene , heated to reflux for water separation for 6 hours, then cooled to room temperature to obtain 1891.8 g of polybenzimidazolium imide solution, namely component A, with a solid content of 10.1%, denoted as A1.

Embodiment 2

[0048] Put 2.24 g (0.01 mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI) and 685.2 g of N-methyl-2-pyrrolidone into the reaction kettle, stir and dissolve at room temperature, then add 33.6 g (0.1 mole) 3,5-bis(4-aminophenoxy)benzoic acid (35DAPOBA), and 16.2 g (0.15 mole) p-phenylenediamine (PDA), 20.0 g (0.1 mole) 3,4' -Diaminodiphenyl ether (34DADPE) and 27.33 g (0.05 mol) of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]propane (BAPOPP-2TF), stirred After dissolving, add 67.6 grams (0.31 moles) of pyromellitic anhydride (PMDA) and 29.4 grams (0.1 moles) of 3,3',4,4'-tetracarboxybiphenyl dianhydride (BPDA), and stir for 4 hours , add 100 grams of toluene, heat and reflux for 8 hours, then cool to room temperature to obtain 981.5 grams of polybenzimidazolium imide solution, that is, component A, with a solid content of 20%, which is designated as A2.

Embodiment 3

[0050] Put 22.4 g (0.1 mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI), 500 g of N,N-dimethylacetamide and 500 g of N-methyl-2-pyrrolidone After stirring and dissolving at room temperature, add 168.0 grams (0.5 moles) of 3,5-bis(4-aminophenoxy)benzoic acid (35DAPOBA) and 4.3 grams (0.01 moles) of 1,3-bis(2 -Trifluoromethyl-4-aminophenoxy)benzene (13BAPB-2TF), after stirring to dissolve, add 57.2 g (0.11 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy) Phenyl]propane dianhydride (BPADA), 54.5 g (0.25 mol) pyromellitic anhydride (PMDA), 77.5 g (0.25 mol) 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA ), after stirring and reacting for 6 hours, add 160 grams of toluene, heat and reflux for 10 hours and then cool to room temperature to obtain 1543.9 grams of polybenzimidazolium imide solution, namely component A, with a solid content of 24.8%. Make A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com