Patents

Literature

46results about How to "No spontaneous combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and equipment for drying lignite particles and pulverized coal granules

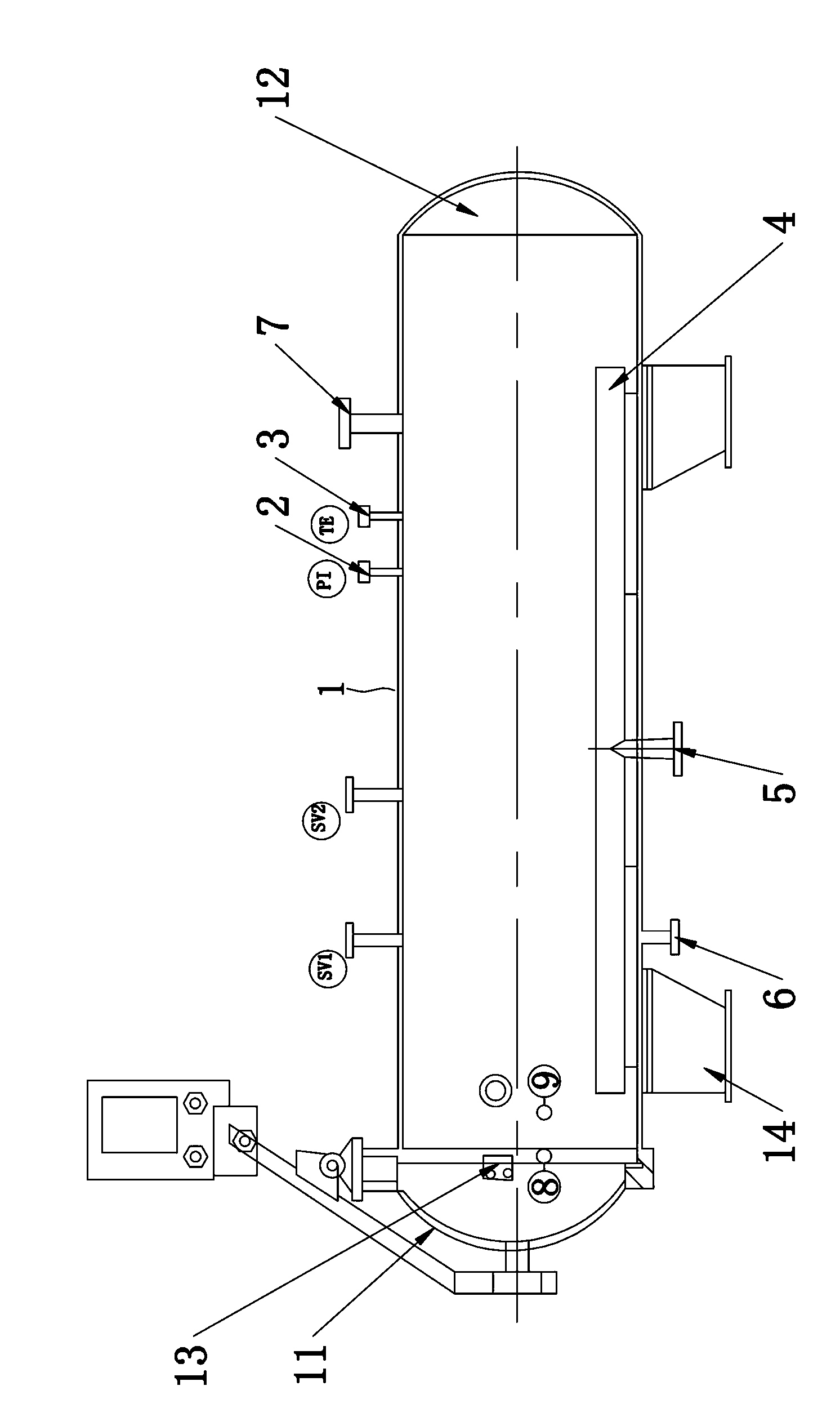

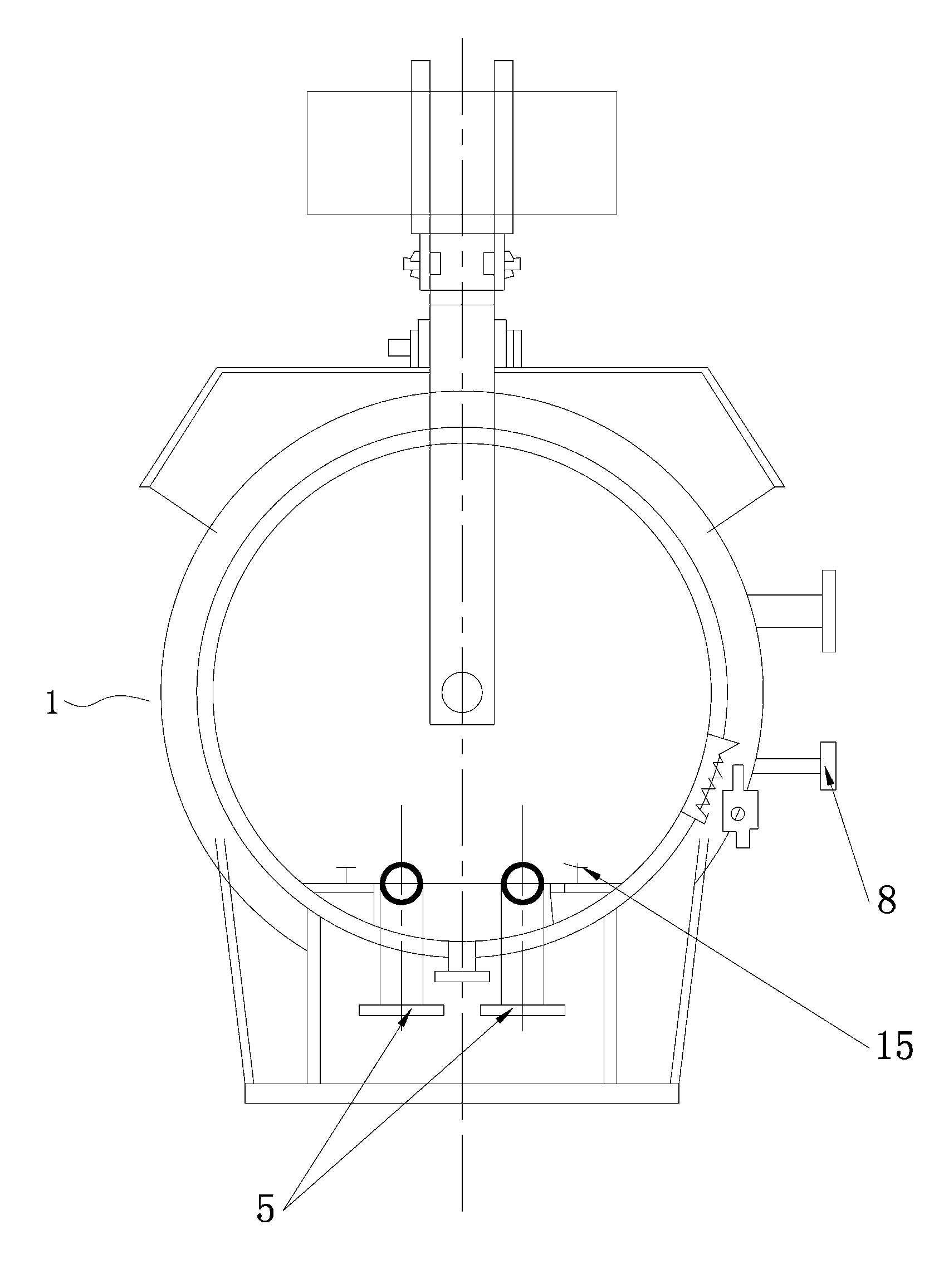

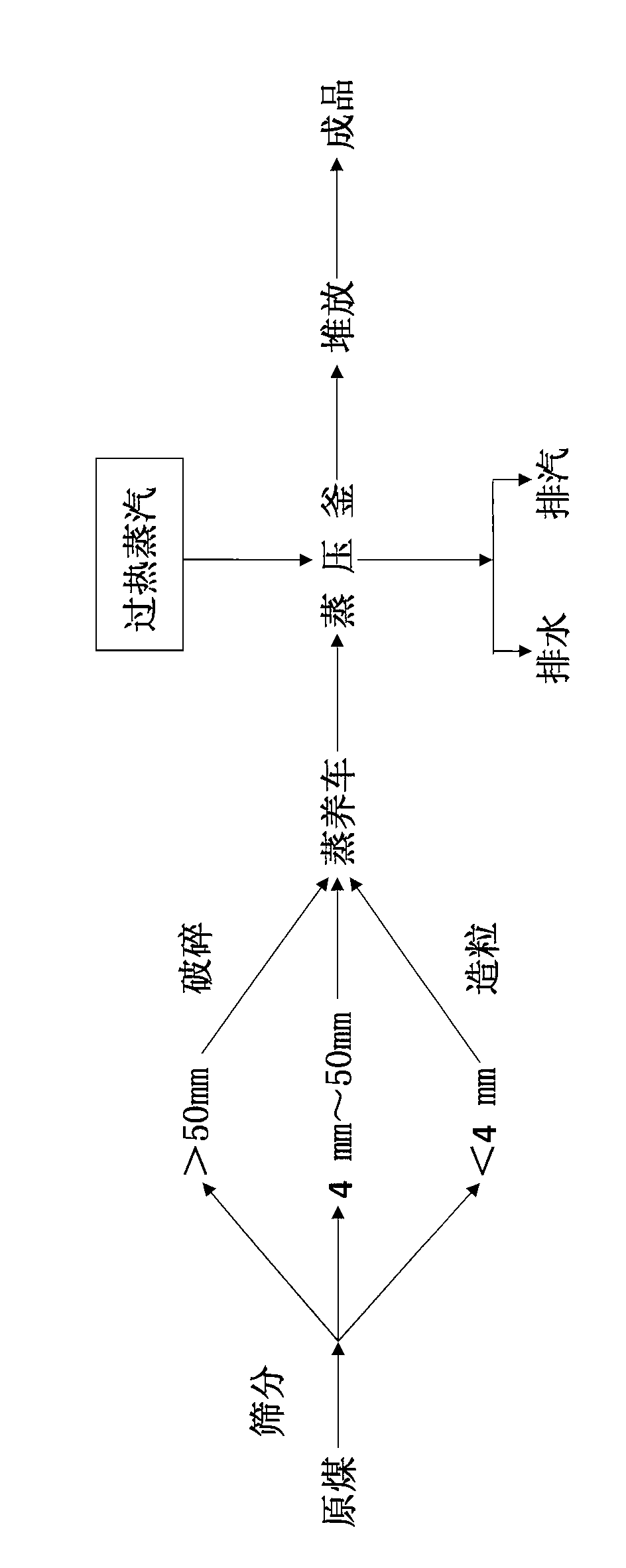

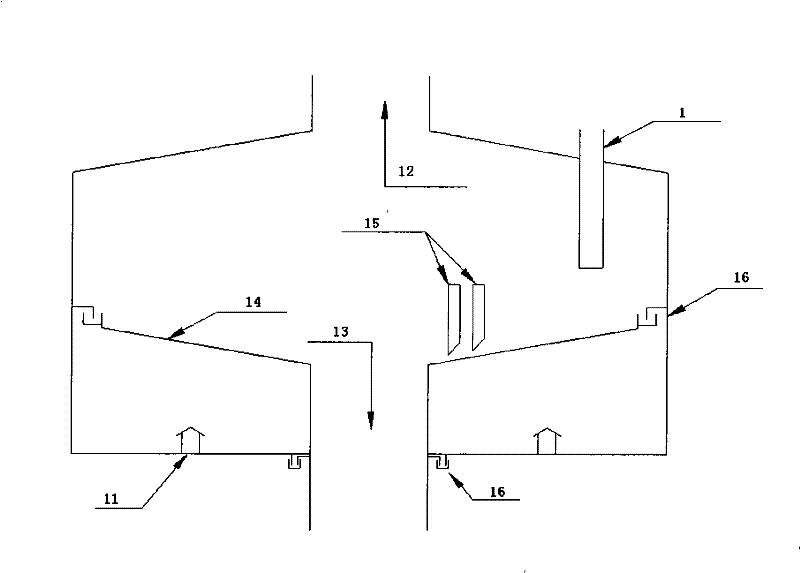

The invention discloses a method and equipment for drying lignite particles and pulverized coal granules. The method comprises the steps of: screening and crushing lignite raw materials with the grain size over 50mm into granules with the grain sizes of 4mm-50mm, and lignite raw materials with the grain size less than 4mm into granules with the grain size of 4mm-12mm, and feeding the particles into a pressure container to be sealed; filling low-pressure high-temperature superheated steam into the pressure container to exchange heat with the lignite particles, stopping supplying the superheated steam when the lignite particle temperature reaches 130 DEG C-290 DEG C or the inside pressure of the pressure container is higher than 1.5 megapascals, and starting stabilizing the pressure; and taking the modified lignite which is heated by superheated steam out after stabilizing the pressure for 10 minutes, and stacking and cooling under natural conditions. The superheated steam is taken as a heating medium, so that the lignite particles are modified to have the characteristics tending to bituminous coal. The pressure container effectively ensure that the lignite particles are dried at the optimum temperature and pressure and timely discharges waste gases and condensed water, so that the water content of the dried lignite particles is obviously reduced, very small back absorption is generated, spontaneous igniting and weathering are not generated, and the unit heating value is greatly increased.

Owner:蔡京鹏

Piston aluminum ingot used for turbo charger car

The invention relates to a piston aluminum ingot used for a turbo charger car. The piston aluminum ingot solves the technical problem that the mechanical property of an aluminum alloy piston in an engine of an existing car is poor, and aluminum scraps generated in the mechanical finishing process of the piston are wasted. Chemical components of the piston aluminum ingot comprise, by weight percent, 11.8-12.8% of Si, 3.0-3.5% of Cu, 0.7-1.0% of Mg, 2.0-2.5% of Ni, 0.1-0.2% of Ti, 0.09-0.2% of Zr, 0.09-0.18% of V, 0.006-0.02% of P, smaller than or equal to 0.5% of Fe, smaller than or equal to 0.2% of Mn, smaller than or equal to 0.12% of Zn, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.01% of Pb, smaller than or equal to 0.02% of Sn, smaller than or equal to 0.002% of Sr,smaller than or equal to 0.001% of Na, smaller than or equal to 0.005% of Ca, smaller than or equal to 0.005% of Sb and the balance Al. The piston aluminum ingot is widely applied to the car with theturbo charger structure and a plug-in hybrid power car.

Owner:文登皇利压铸化工材料有限公司

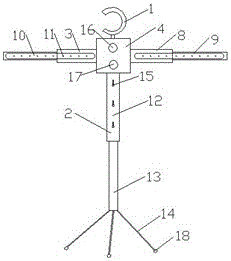

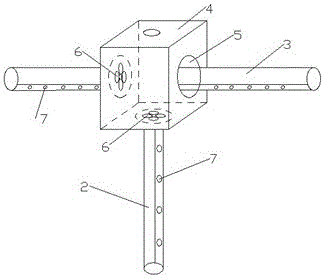

Portable type detachable clothes drying hanger

The invention provides a portable type detachable clothes drying hanger. The portable type detachable clothes drying hanger comprises a hook, an air heater and a clothes hanger body, wherein the clothes hanger body comprises a supporting frame and two clothes supporting rods which are arranged symmetrically from left to right; the lower end face of the hook is movably connected with the air heater; the air heater comprises a shell, and a sterilization device, a heating device and a draught fan which are arranged in an inner cavity of the shell; openings are formed in the left and right sides and the center of the bottom of the shell; fan blades are arranged at the openings; the two clothes supporting rods are symmetrically inserted into the openings formed in the left and right sides of the shell; one end face of the supporting frame is inserted into the opening in the center of the bottom of the shell; the supporting frame and the clothes supporting rods are unsealed hollow pipes; a plurality of air outlet holes are uniformly formed in the outer wall of the supporting frame and the bottom edges of the clothes supporting rods. All the parts of the clothes hanger body are connected by adopting a retractable structure and an inserting and pulling structure, so that the length and height of the clothes drying hanger can be adjusted according to different clothes sizes; corresponding working time is set; and meanwhile, clothes are disinfected.

Owner:陈小磊

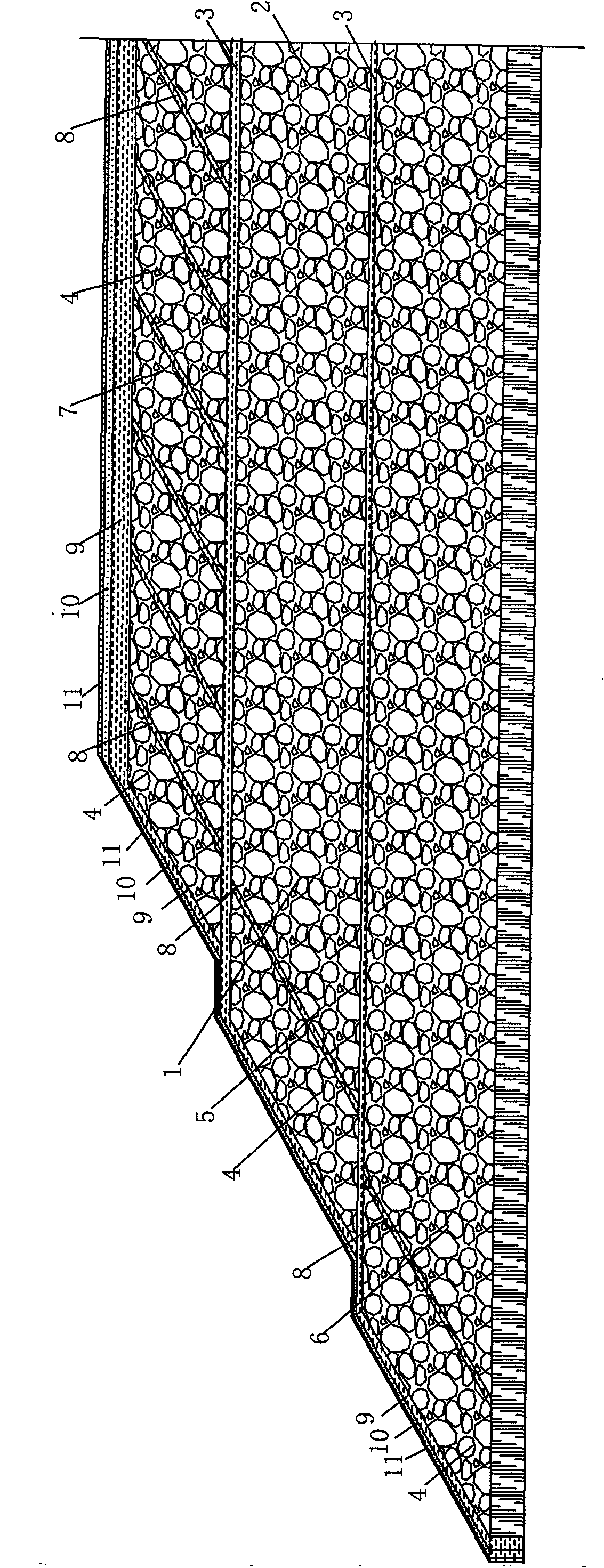

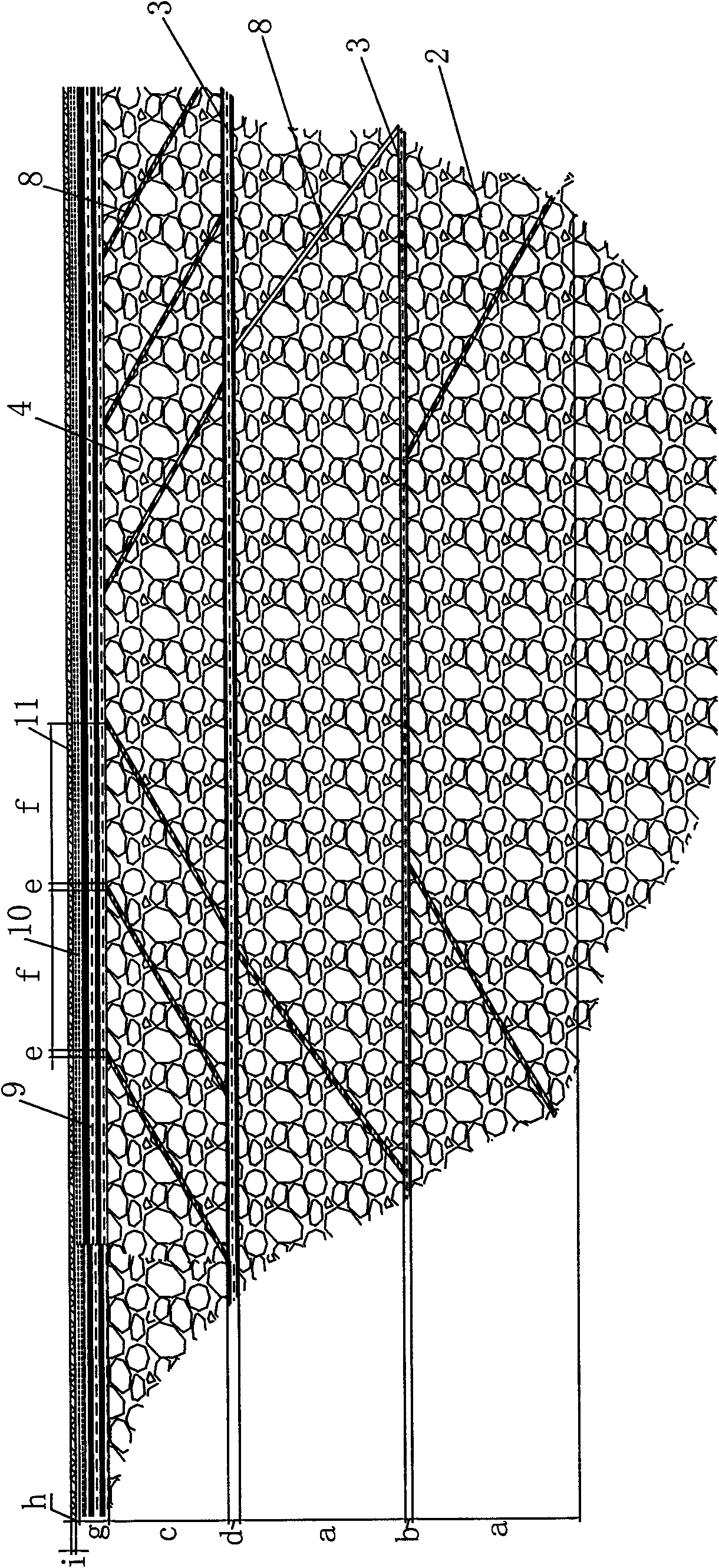

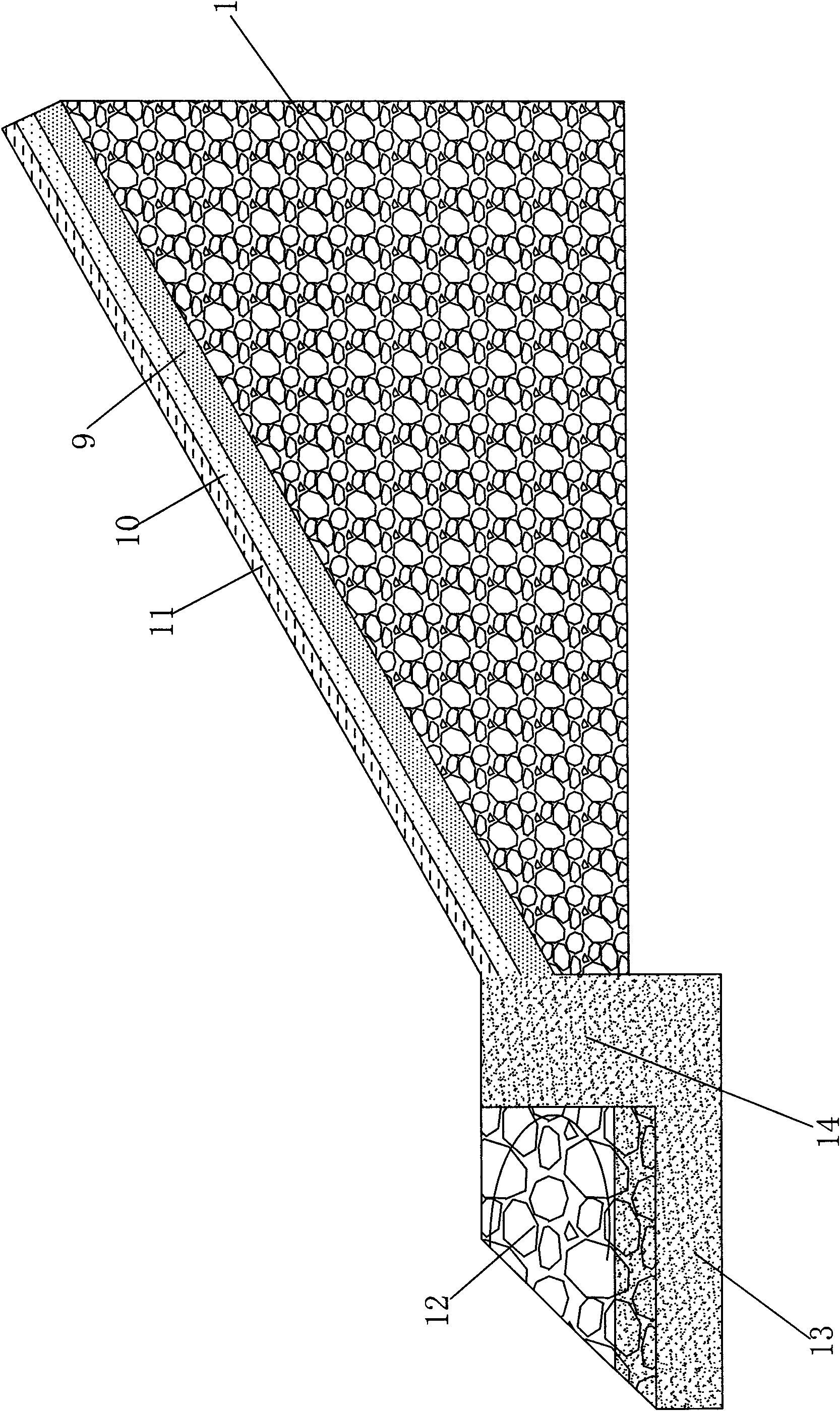

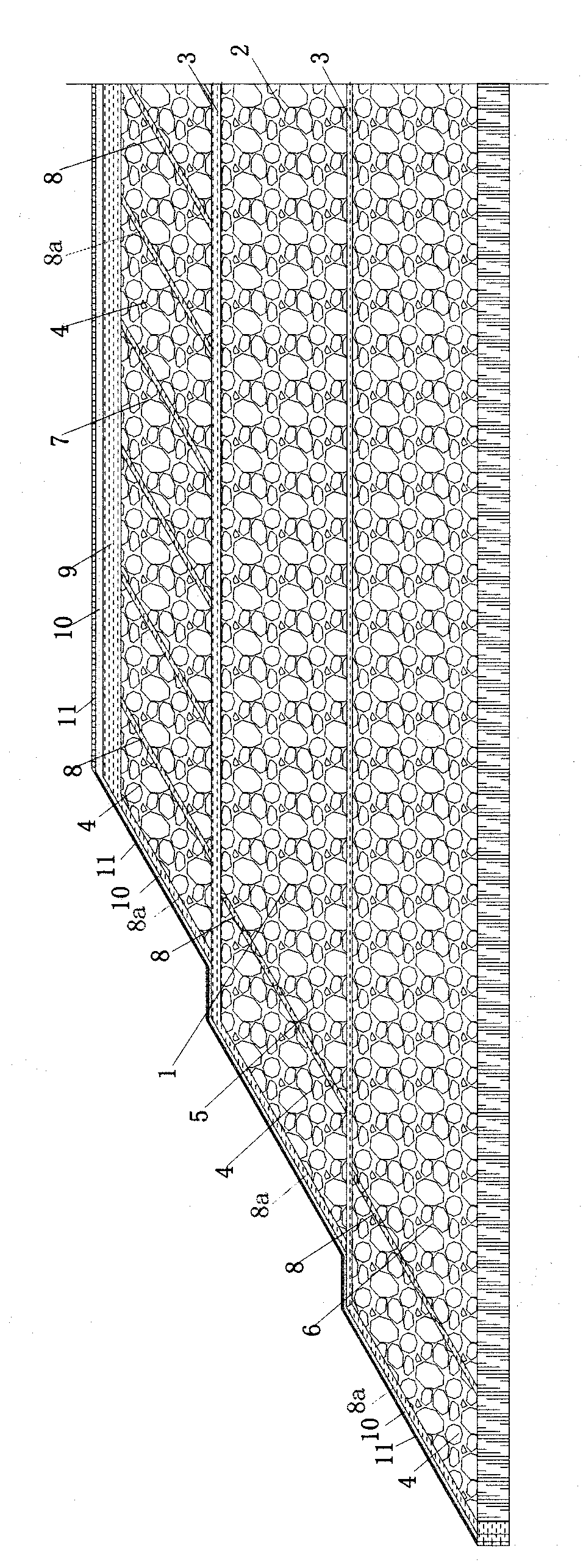

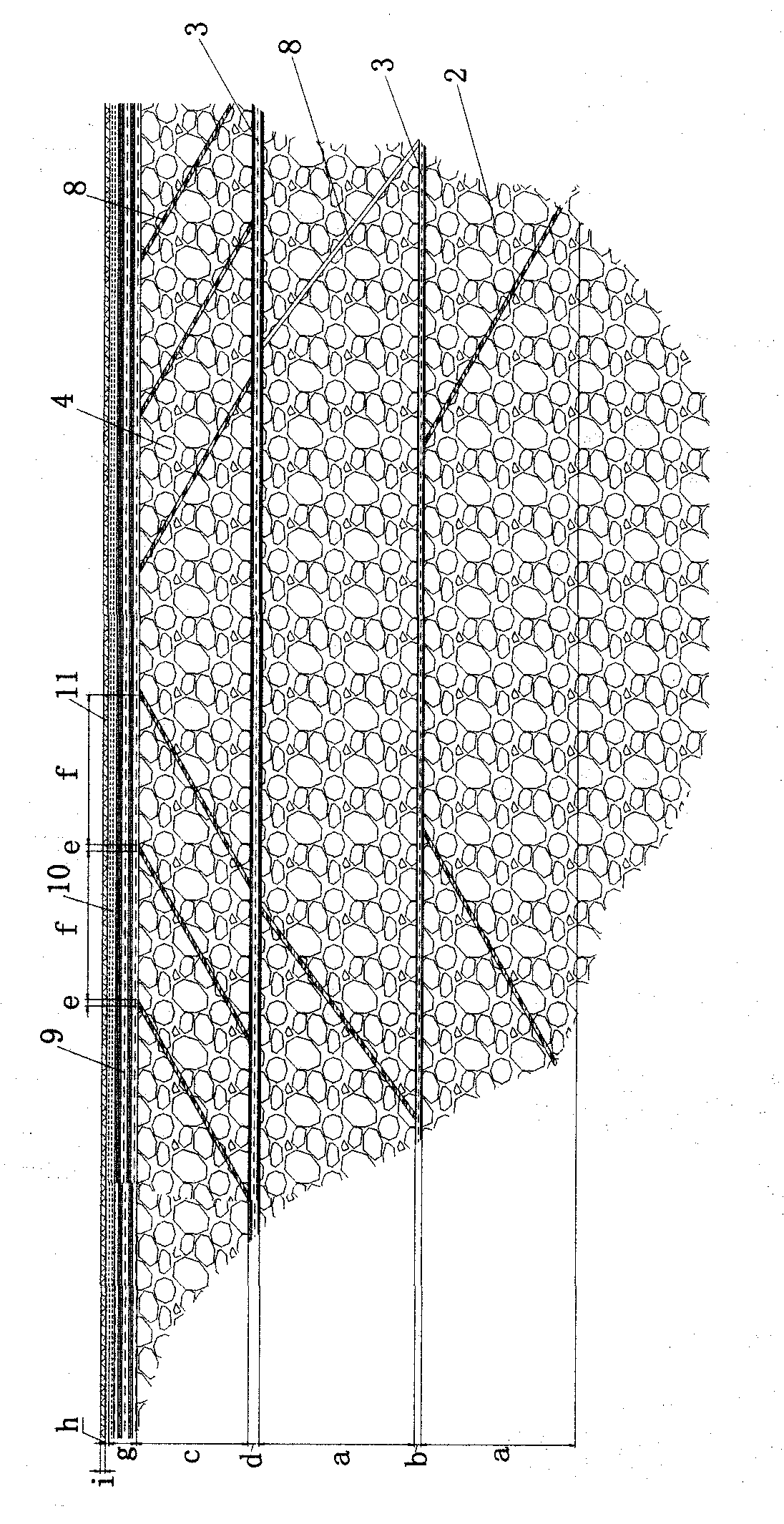

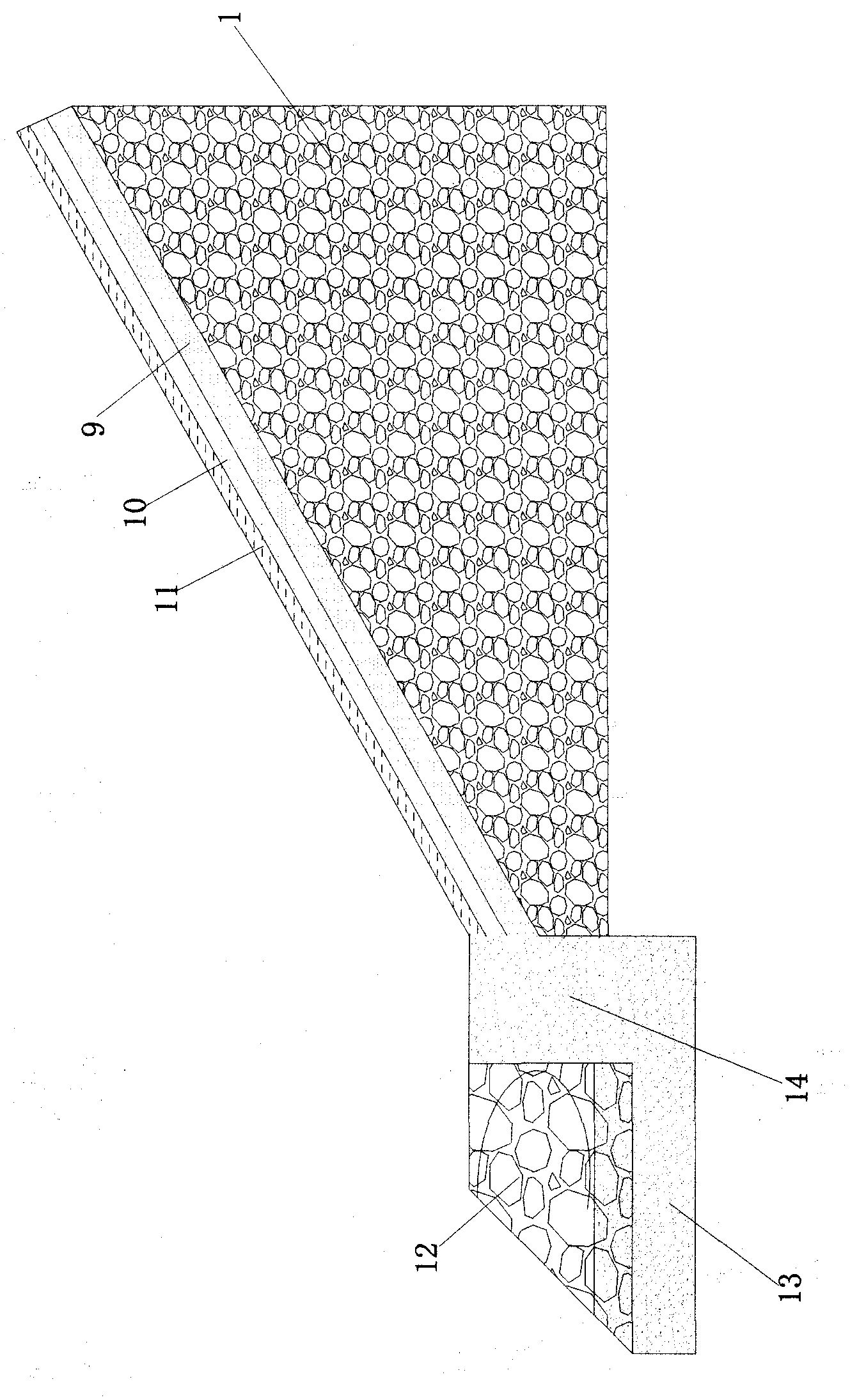

Heap storage method for preventing spontaneous combustion of coal gangue hill

ActiveCN101644158APlay the role of double protectionStop spontaneous combustionUnderground miningSurface miningSpontaneous combustionEngineering

The invention relates to a coal gangue hill control technology, in particular to a heap storage method for preventing spontaneous combustion of a coal gangue hill, thereby solving the problems that the existing heap storage way is easy to cause the spontaneous combustion of the free surface and the edge of a hill body, and once one place occurs the spontaneous combustion, a plurality of places areburnt. The heap storage method comprises the steps of carrying out transverse layered soil coverage grinding treatment in each layer of the coal gangue hill body; setting a soil isolation chamber atthe free place of a slope at the middle and lower part of the coal gangue hill body and the plane place of a top layer along the longitudinal direction; and adopting three layers of soil coverage layers of a grinding loess layer, a loosening loess layer and a fine particle gangue layer at the outmost layer of the coal gangue hill body. The heap storage method can not only effectively prevent the spontaneous combustion of coal gangue, but also prevent water and soil loss caused by rainwater brushing and dust flying with wind and provide a beneficial growth environment for plants; furthermore, the heap storage method adopts the transverse layered soil coverage grinding treatment way and sets the soil isolation chamber at the free place of the slope at the middle and lower part of the hill body and the plane place at the top, thereby being capable of controlling the spontaneous combustion of the coal gangue caused by manual disturbance or other factors in the local region and not causingthe impacts on the whole hill body.

Owner:山西大地民基生态环境股份有限公司

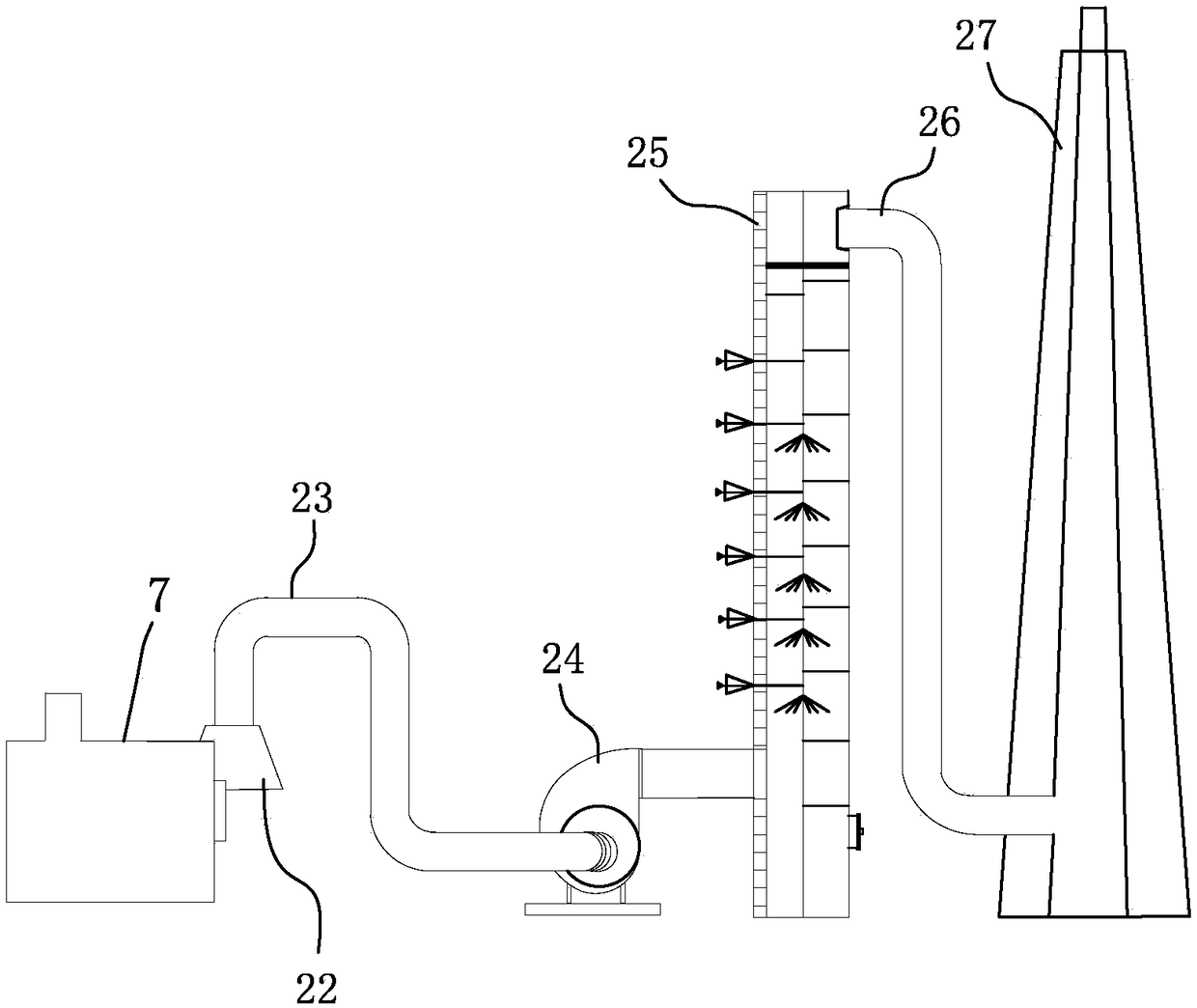

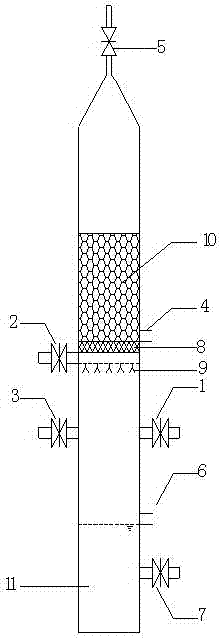

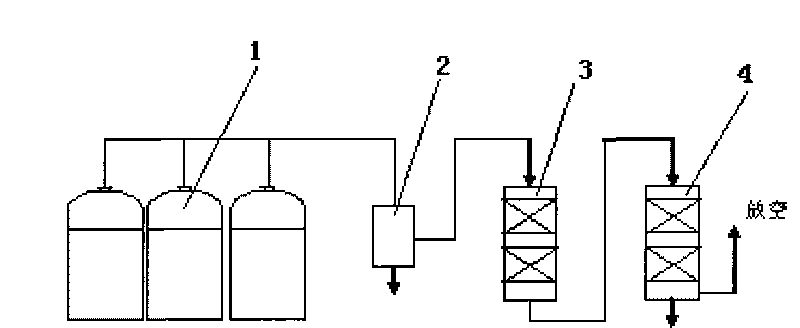

Removal device and removal method for volatile organic compounds in industrial waste gas

InactiveCN107158909ASolve the problem that cannot be regenerated and reusedEasy to operateGas treatmentUsing liquid separation agentMolecular sieveLiquid waste

The application provides a removal device and a removal method for volatile organic compounds in industrial waste gas, wherein the removal method mainly includes five steps: pretreatment of waste gas, adsorption by high-silicon molecular sieve, oxidization by ozone, discharge of waste liquid, and discharge of purified gas. The removal method has reasonable design, simple process and convenient operation and can completely remove the volatile organic compounds.

Owner:HOHAI UNIV

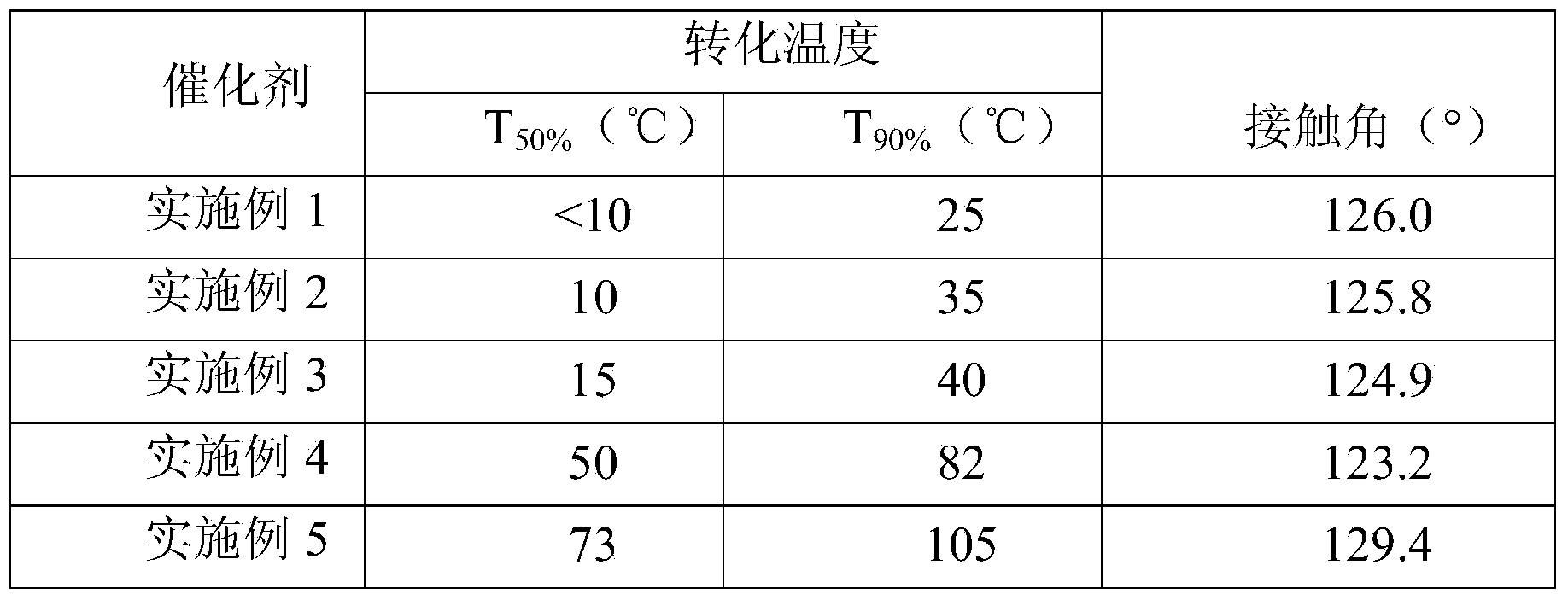

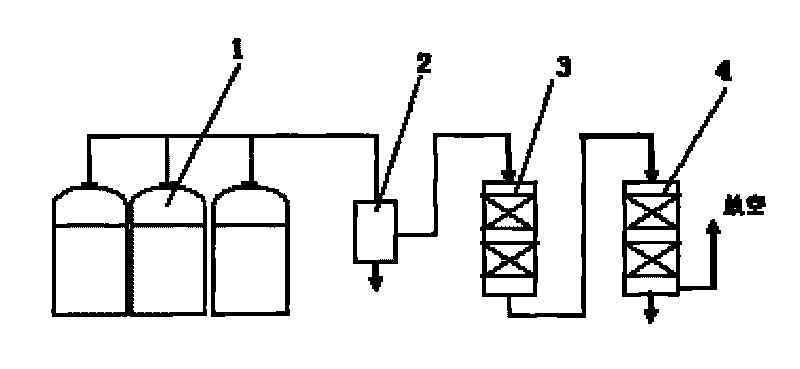

Catalyst for catalytic oxidation of gaseous hydrogen tritide, and preparation method and application of catalyst

InactiveCN103831098ASimple preparation processImprove hydrophobicityHeavy waterMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a catalyst for the catalytic oxidation of gaseous hydrogen tritide. The catalyst is obtained mainly by supporting platinum oxide by adopting the oxide of transition metal as a carrier, wherein the transition metal is Al, Ti, Mn, Co, Fe, Cu and Ni. Air serving as the catalyst is carried into a reactor to convert elementary tritium in the hydrogen tritide into water. The catalyst is subjected to hydrophobic modification, and is high in activity, long in service life and particularly applied to the catalytic oxidation recovery of tritium in the hydrogen tritide.

Owner:EAST CHINA UNIV OF SCI & TECH

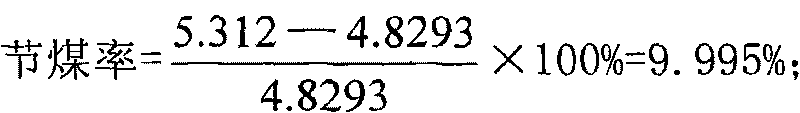

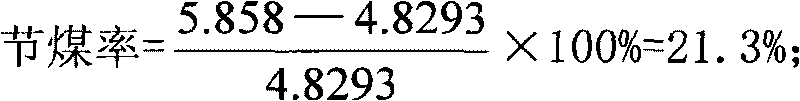

Clean fired coal saving agent

InactiveCN101747978ARealize comprehensive utilizationSolve new waysSolid fuelsFuel additivesLiquid wasteLiquid product

The invention provides a clean fired coal saving agent with the effects of sulfur fixation, dust fall, heat increment and coal saving which is prepared and produced by industrially produced waste liquid and waste residues and chemical and mineral product raw materials. The clean fired coal saving agent is divided into two forms, namely a liquid product and a powder product; the liquid product is obtained by dissolving sodium nitrite, potassium nitrite, potassium nitrate, sodium nitrate, sodium sulfonate and sodium dodecyl benzene sulfonate into mixed liquid of paper making black liquid, alcohol waste liquid and fired coal fume water film dust removal and desulfurization alkali regeneration fluid; and the power product is obtained by absorbing and preparing the liquid product by utilizing hot fired coal slag, then allocating the chemical and mineral product raw materials and finally uniformly mixing, drying and crushing. The invention achieves cyclic resource utilization of industrial wastes, effectively solves the difficult problems of complete control of fired coal pollution and paper making and alcohol waste liquid pollution, has the advantages of innocuity, odorless, no three-waste emission, no increased investment and convenient operation and can use the device required not to be improved, save the coals per ton by 20-50 yuan and be used for all industrial and civil fired coals.

Owner:陈其厚

Ecological restoration method for coal gangue dump

ActiveCN102251775BSolve the problem of infiltrationPromote growthUnderground miningSurface miningActivated sludgeSpontaneous combustion

The invention relates to an ecological restoration method for a coal gangue dump; according to the method, during the arrangement of a coal gangue dump and the arrangement of the dump body, annular plant ditches and longitudinal drainage ditches are disposed from top to bottom; clay is added onto gangue and is tamped; a mixture of dehydrated sludge and gangue is added onto the clay between ditches, and sedum alfredii hance are planted; a mixed substrate of gangue dump surface soil, fermented pig manure, and vermiculite is added into the plant ditches; and prostrate spurge, crape myrtle, and cucurbita pepo are planted orderly and repeatedly in the mixed substrate. The method effectively reduces the spontaneous combustion probability of coal gangue, shortens the restoration period, makes use of dehydrated activated sludge, changes wastes into valuables, and obtain certain economic benefits, environmental benefits, and social benefits.

Owner:ELION ECOLOGICAL RESTORATION +1

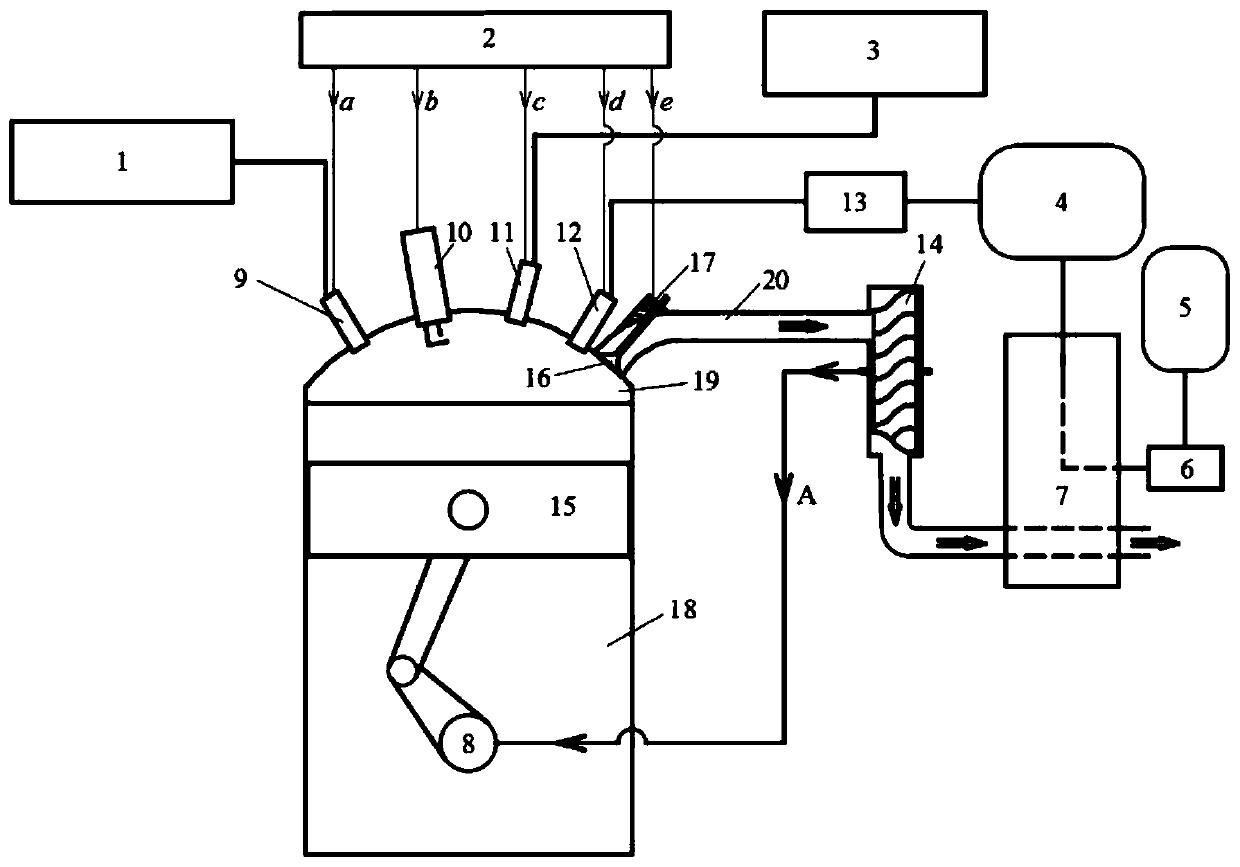

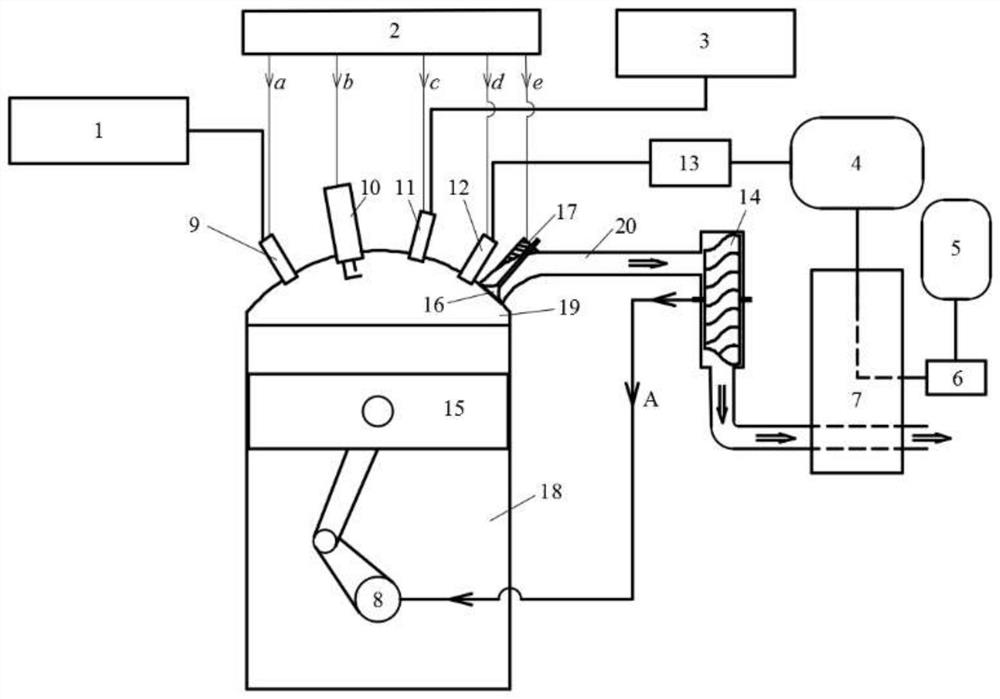

Zero emission two-stroke spark ignition type hydrogen oxygen engine and control method

ActiveCN111365119AImprove power densityEliminate harmful emissionsElectrical controlInternal combustion piston enginesSpray nozzleEnergy recovery

The invention provides a zero emission two-stroke spark ignition type hydrogen oxygen engine and a control method, and particularly relates to a fuel feed system, a water spray system and a tail gas energy recovery system of the zero emission two-stroke spark ignition type hydrogen oxygen engine, and control. Hydrogen and oxygen in the zero emission two-stroke spark ignition type hydrogen oxygen engine correspondingly come into an air cylinder by a hydrogen spray nozzle and an oxygen spray nozzle and are ignited quickly after jump spark of an ignition plug to achieve the efficient constant volume burning process. A water spray nozzle, according to the control of an electronic control unit, sprays water and lowers the temperature to the compressing and burning process in the cylinder to make sure combination gas not occur autoignition and an engine body not destroyed because of burning the hydrogen and the oxygen to lead to increase thermal load. A tail gas energy recovery device and aheat exchanger have a second level utilization for high temperature tail gas waste heat generated from burning and increase the efficiency of conversion of heat into power of the technical scheme in the zero emission two-stroke spark ignition type hydrogen oxygen engine and control method. Engine zero hazard emission operation is achieved indeed by adopting burning the hydrogen and the oxygen.

Owner:BEIJING UNIV OF TECH

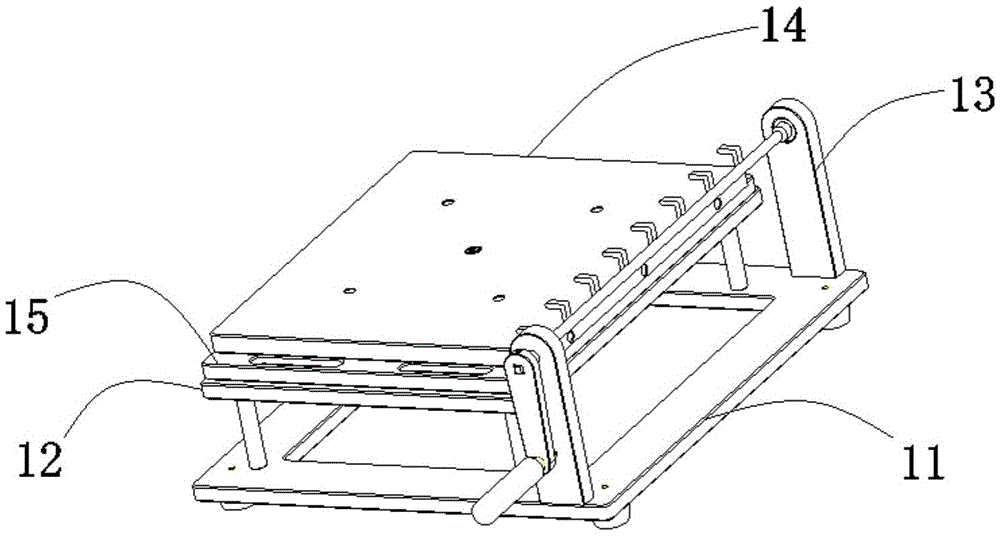

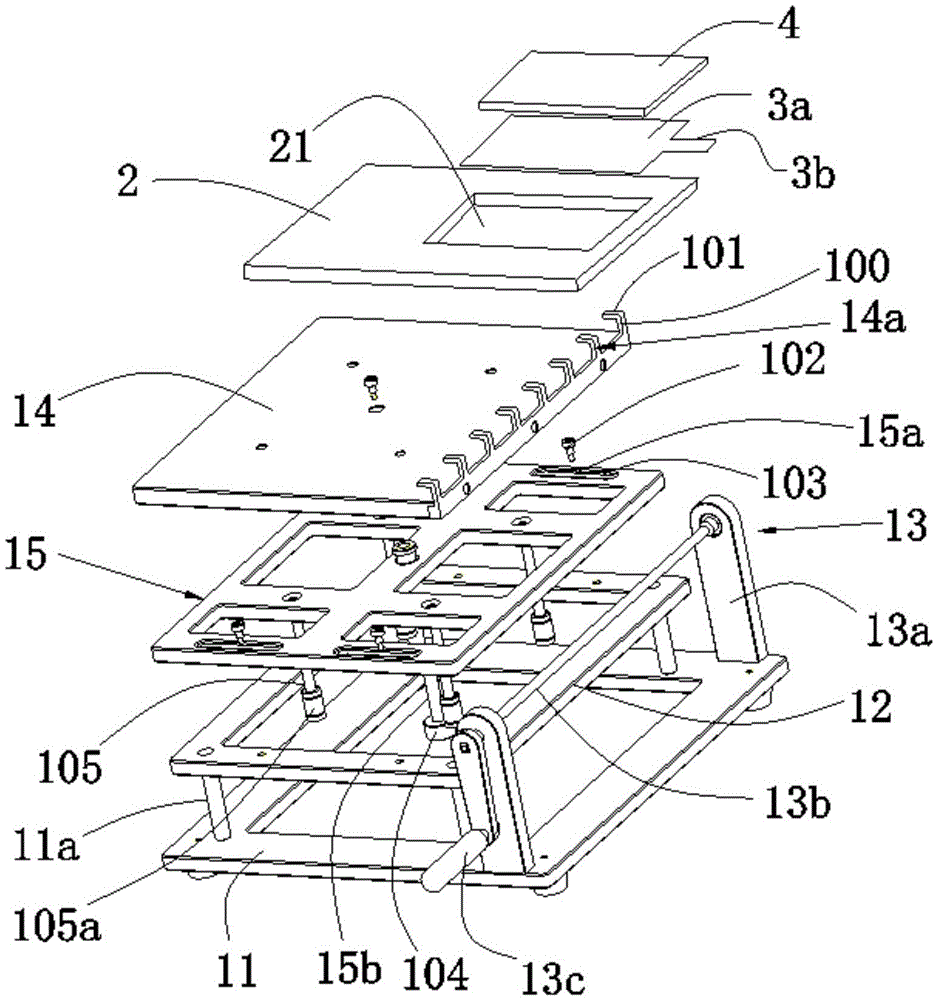

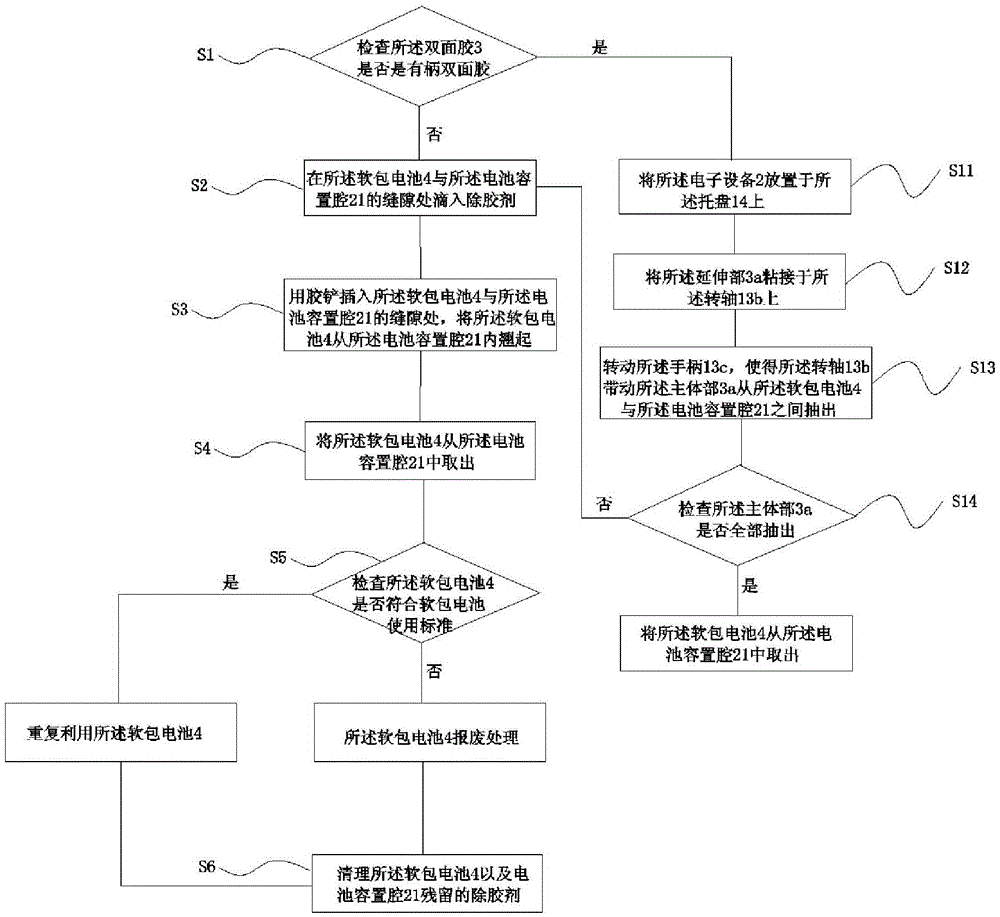

Method and device for removing soft package battery

ActiveCN105552458ASimple structureNo spontaneous combustionSecondary cells servicing/maintenanceAdhesiveEngineering

The invention provides a device for removing a soft package battery. The device comprises a bottom plate, a bearing plate and a degumming mechanism, wherein the degumming mechanism is arranged at one side of the bearing plate and comprises two support seats and a rotating shaft; the two support seats are symmetrically arranged at two sides of the bottom plate; the rotating shaft is movably arranged between the two support seats; and the degumming mechanism is used for pasting an extension part on the rotating shaft and rotating around the axis of the rotating shaft along with the rotating shaft between the two support seats, so that the extension part drives a main body part to be extracted between the soft package battery and a battery accommodating cavity. The invention further provides a method for removing the soft package battery. The device for removing the soft package battery provided by the invention can adjust the vertical distance and the horizontal distance of the soft package battery and is suitable for electronic equipment with different sizes. The method for removing the soft package battery provided by the invention can remove the soft package battery bonded by a shafted double-sided adhesive and can also remove the soft package battery which is not bonded by the shafted double-sided adhesive.

Owner:杭州东南吉通网络有限公司

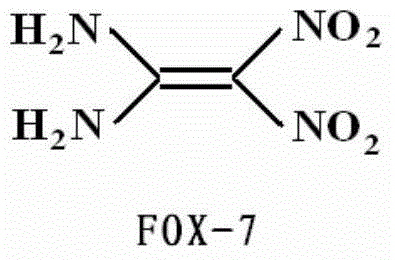

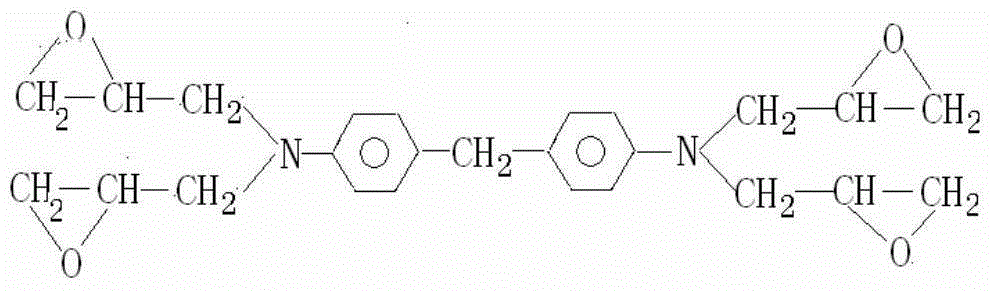

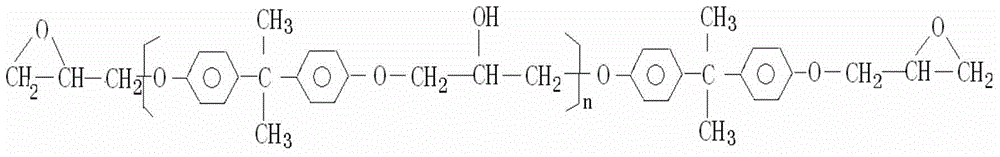

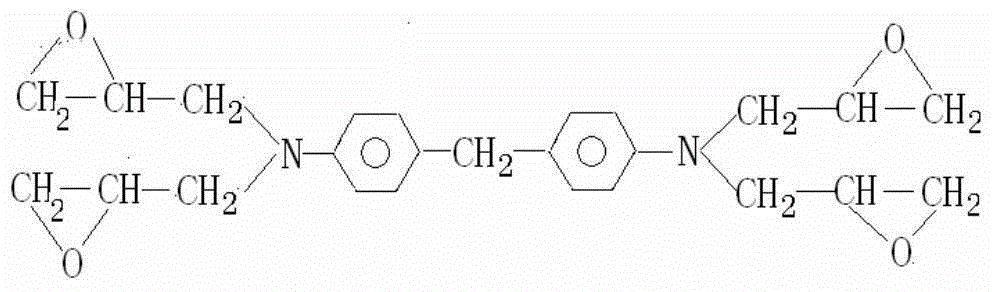

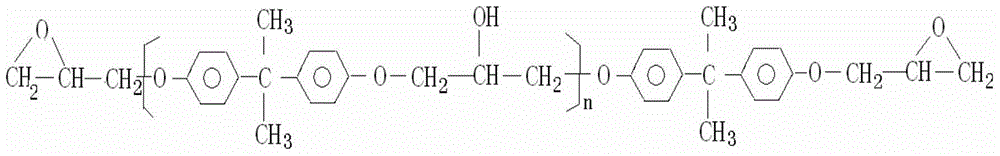

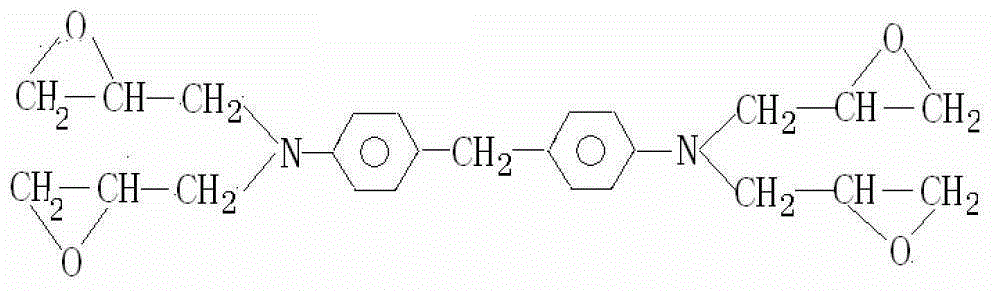

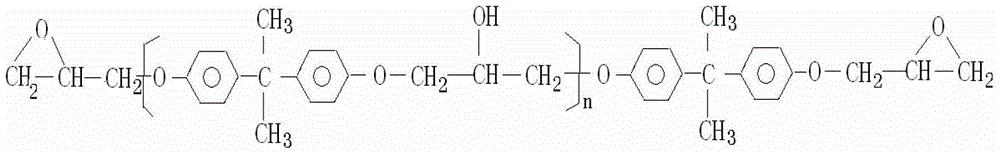

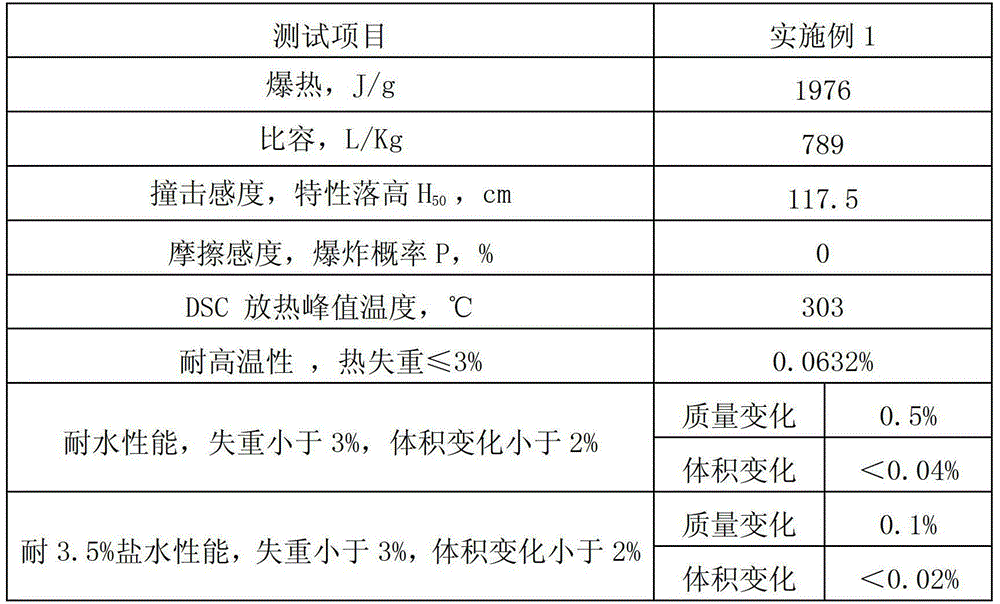

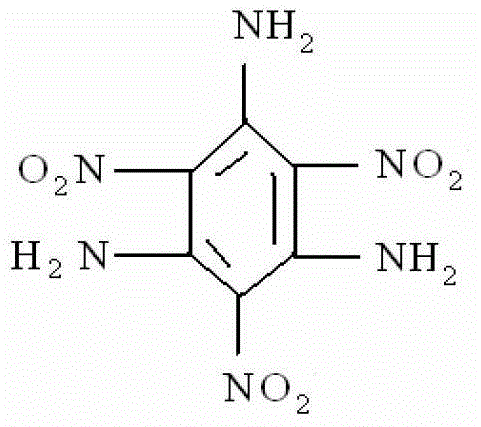

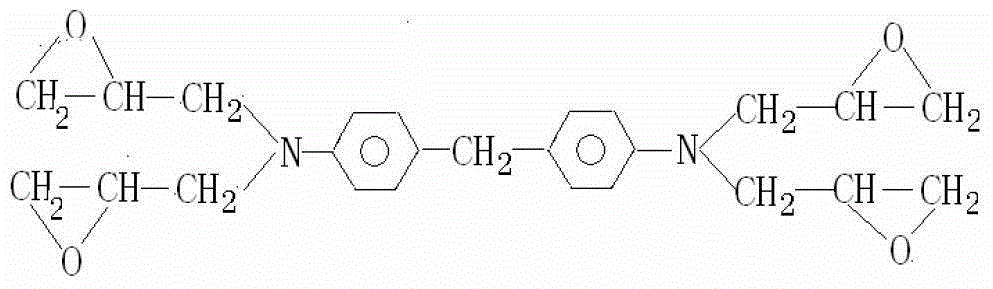

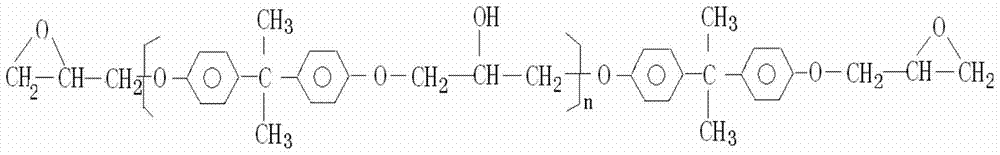

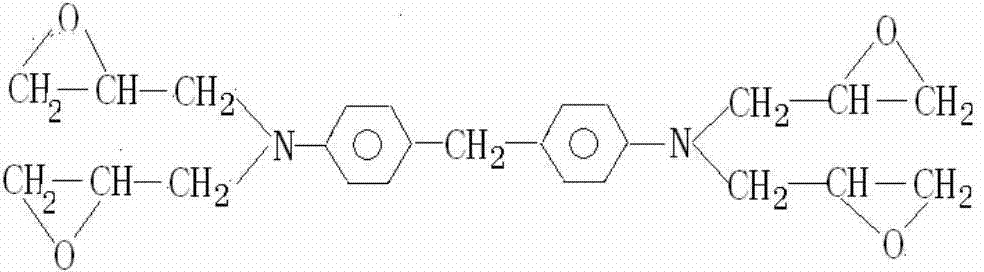

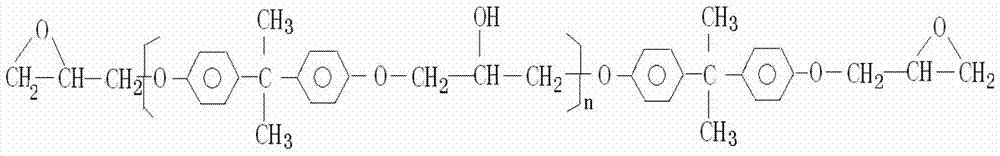

High-temperature-resistant propellant for deep oil-gas well and preparation method thereof

InactiveCN104591934AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustionSaline water

The invention provides a high-temperature-resistant propellant for a deep oil-gas well, and solves the problem that the prior art cannot be used in a high-temperature washy environment. The high-temperature-resistant propellant consists of 35-50 percent of potassium perchlorate, 10-25 percent of 1,1-diamido-2,2-diamino-dinitroethylene, 10-20.90 percent of high-temperature-resistant epoxy resin, 0-16.58 percent of bisphenol A epoxy resin, 4.75-13.03 percent of an epoxy resin active diluting agent, 0.50 percent of a promoting agent, 0.03 percent of a defoaming agent and 6.57-8.14 percent of diaminodiphenyl sulfone. The solid propellant is immersed in clean water and salty water with the concentration of 3.5 percent, so that the weight loss is smaller than 3 percent, and the volume change is smaller than 2 percent; the temperature-resistant grade reaches 200 DEG C for 48 hours, and spontaneous combustion and explosion are avoided; the propellant can be used in the high-temperature washy environment.

Owner:XIAN MODERN CHEM RES INST

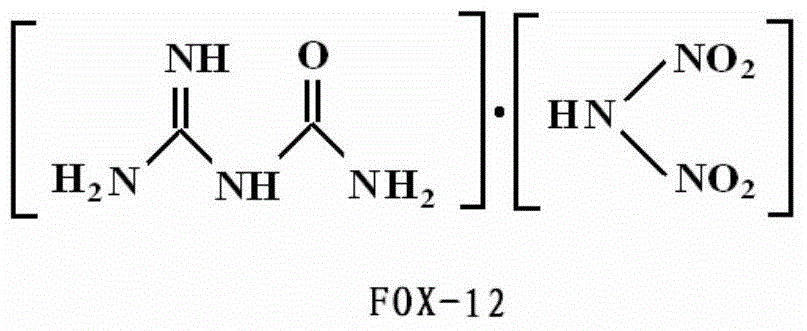

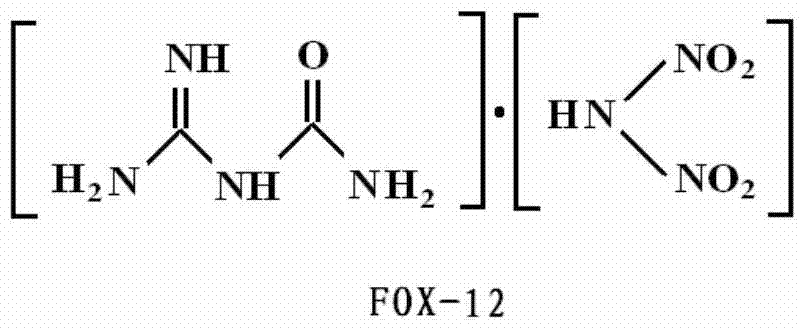

Heat-resistant solid propellant for oil-gas deep well and preparation method of heat-resistant solid propellant

InactiveCN104672037AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsHydrolysisAccelerant

The invention discloses a heat-resistant solid propellant for an oil-gas deep well. The heat-resistant solid propellant is prepared from the following components in percentage by weight: 45%-65% of potassium perchlorate, 0-10% of N-guanylurea dinitramide, 5.59%-26.79% of heat-resistant epoxy resin, 1.77%-10.38% of bisphenol A epoxy resin, 6.04%-13.7% of an epoxy resin reactive diluent, 0.5% of an accelerant, 0.03% of an antifoaming agent and 4.80%-9.87% of diamino diphenyl sulfone, wherein the sum of the raw materials in percentage by weight is 100%. The raw materials for the propellant are premixed, then are mixed, and finally are cast into a mold tobe molded, so as to prepare the finished product. The heat-resistant solid propellant is excellent in hydrolysis resistance. The heat-resistant solid propellant is soaked in clean water and 3.5% saline water for 24-48 hours; the weight loss is smaller than 3%; the volume change is smaller than 2%; the heat resistance is relatively good; the heat-resistant level reaches the condition that the solid propellant does not spontaneously combust or explode when being at 200 DEG C for 48 hours; and the heat-resistant solid propellant can be used in a high-temperature washy environment.

Owner:XIAN MODERN CHEM RES INST

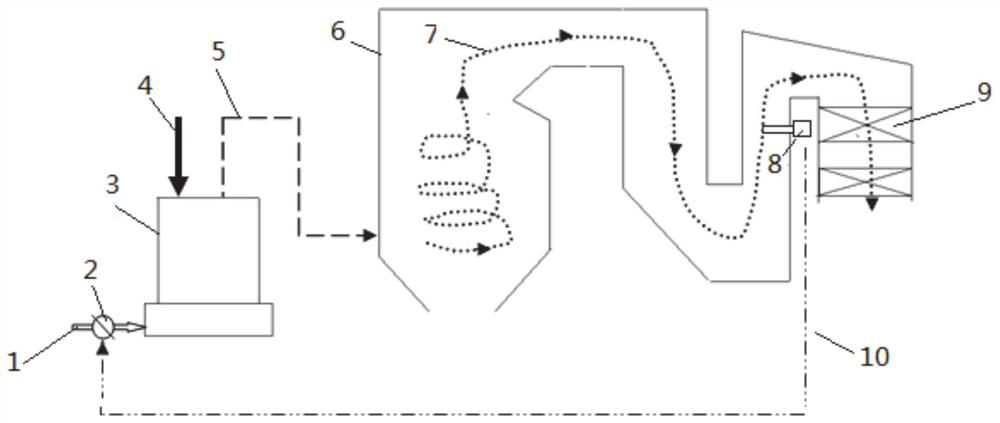

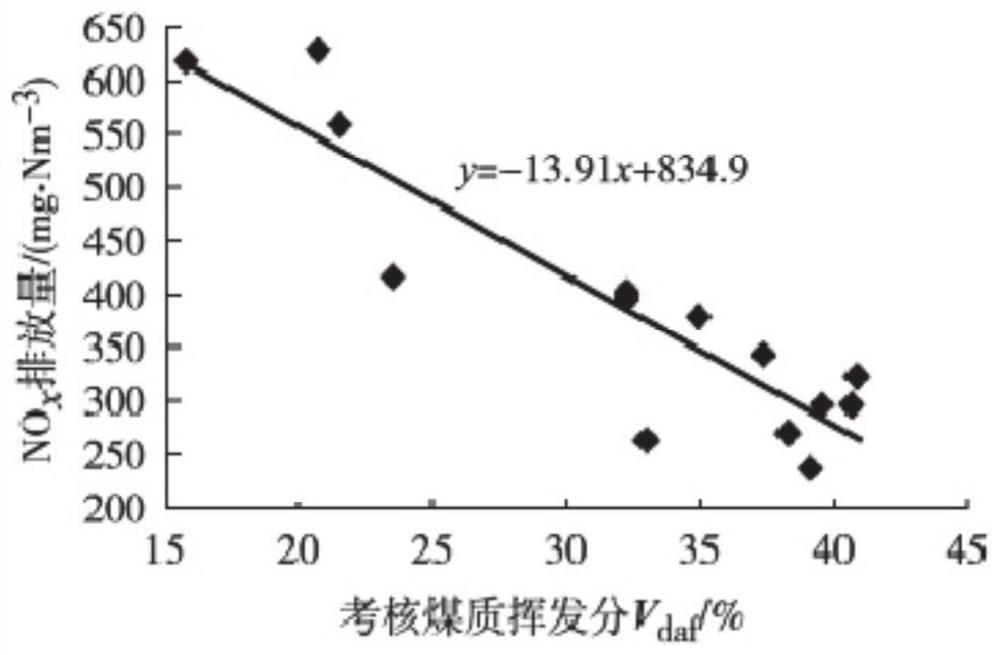

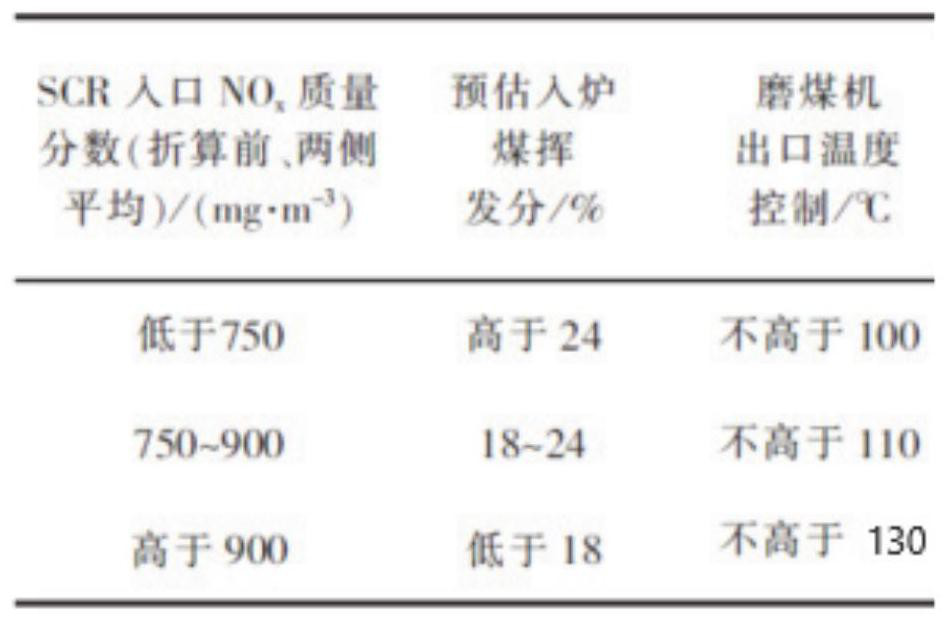

Method and system for controlling outlet temperature of coal mill of direct-fired pulverizing system

PendingCN113578513AAvoid Conservative ModeResolution cycleGrain treatmentsTemperature controlNitrogen oxides

The invention provides a method and a system for controlling an outlet temperature of a coal mill of a direct-fired pulverizing system. The method comprises the steps that a content of nitric oxide at an inlet of an SCR denitration system is acquired; an estimation model is established according to a relation between a dry-ash-free volatile component of furnace coal and the content of the nitric oxide of the inlet of the SCR denitration system, and the content of the nitric oxide is input into the estimation model to determine an estimated value of the dry-ash-free volatile component; and a coal mill outlet temperature control strategy is generated according to the estimated value of the dry-ash-free volatile component, and the outlet temperature of the coal mill is adjusted according to the control strategy. According to the method, the volatile component of coal entering a furnace can be judged in real time, the temperature of the outlet of the coal mill can be adjusted to an optimal value for operation on line according to a level of the volatile component of coal quality during operation, and it is guaranteed that boiler economical efficiency is optimal.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

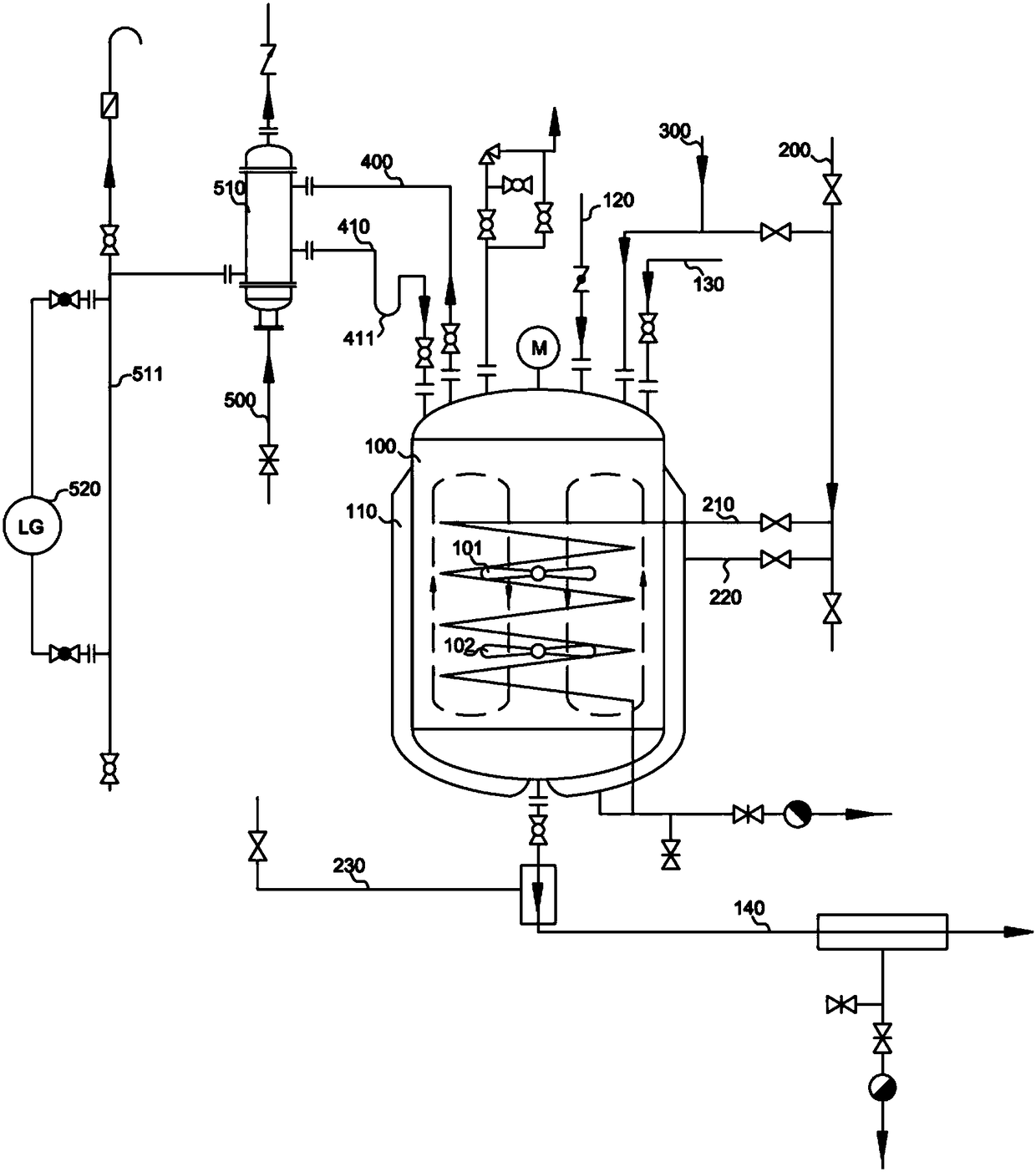

Camphor producing method and isoborneol dissolving equipment thereof

PendingCN108250057AImprove efficiencyImprove solubilityTransportation and packagingRotary stirring mixersThermal insulationBiochemical engineering

The invention discloses a camphor producing method which comprises a dissolving work procedure and a dehydrogenizing work procedure, wherein the dissolving work procedure comprises the step: dissolving isoborneol crystal and a solvent in isoborneol dissolving equipment to obtain a product; and then the product is put into the dehydrogenizing work procedure to produce a camphor product. The camphorproducing method has the advantages that the dissolving work procedure is added before the dehydrogenizing work procedure, so that the isoborneol can be dissolved more fully, and later reaction is beneficiated. A dual dissolving and heating mode can ensure that the isoborneol is fully dissolved; in clamping sleeve dissolving and heating, less steam can be used for thermal insulation under the completely-dissolved situation; in coil heating, the isoborneol can be quickly dissolved. In the dissolving process, a part of water brought by the iroborneol can be removed; by means of additionally arranging a liquidometer on a water draining pipeline, a current water content situation in a kettle body can be known through the removed water, so that dewatering time of the dehydrogenizing work procedure is reduced.

Owner:WUZHOU HUANGPU CHEM PHARM CO LTD

Catalyst for synthesizing carboxylic ester with alcohol and carbon dioxide and its preparing method

ActiveCN1943853AHigh catalytic efficiencyEasy to storeOrganic compound preparationPreparation by carbon monoxide or formate reactionCarboxylic esterCarboxylate

The present invention discloses one kind of mixed metal oxide catalyst for catalyzing the reaction of alcohol and CO2 to synthesize carboxylate with carbon number doubling that of the alcohol. The mixed metal oxide catalyst is granular catalyst comprising oxides of Fe 5-20 wt%, Cr 10-30 wt%, Cu 10-40 wt%, Al 20-45 wt%, Co 2-10 wt%, Zn 15-35 wt% and Zr 5-30 wt%. The mixed metal oxide catalyst is used in catalyzing the reaction of alcohol and CO2 to synthesize carboxylate with carbon number doubling that of the alcohol, and the catalytic reaction has low reaction temperature, high alcohol conversion per pass, high carboxylate selectivity, high space-time yield and other advantages.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

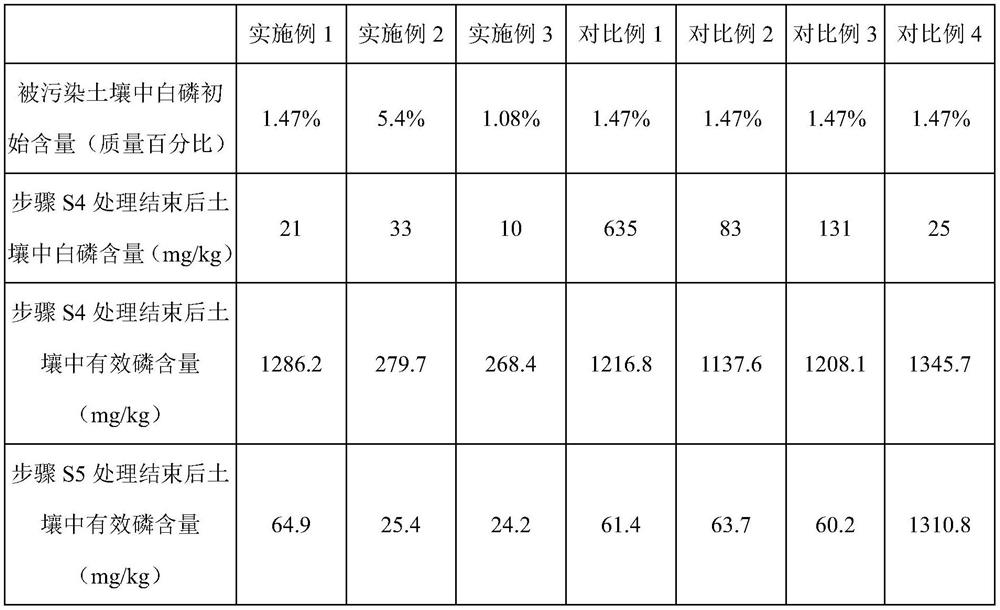

Method for repairing soil polluted by white phosphorus

PendingCN113695376AReduce operational security risksReduce secondary pollutionContaminated soil reclamationEutrophicationEnvironmental chemistry

The invention provides a method for repairing soil polluted by white phosphorus, which belongs to the technical field of restoration of polluted soil. The method comprises the following steps of firstly, adding water into polluted soil to prepare slurry, then removing large-particle stones in the slurry, then adding a dispersing agent to disperse simple substance phosphorus wrapped in silicon dioxide silica gel so as to enable the simple substance phosphorus to be oxidized by two strong oxidants to the greatest extent, and then continuously converting phosphorus oxide into phosphorus salt by using an alkaline substance, and finally, fixing most of the phosphorus salt in the soil through a flocculating agent. The polluted soil is repaired through the method, the content of white phosphorus in the soil can be effectively reduced to be within an acceptable range, and phosphorus is fixed in the soil and prevented from entering a water body to cause eutrophication of the water body.

Owner:葛洲坝集团生态环保有限公司

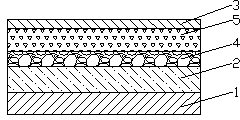

High-temperature-resistant wrapping paper

InactiveCN103395557ANo spontaneous combustionSimple structureFlexible coversWrappersSpontaneous combustionPulp and paper industry

The invention discloses a piece of high-temperature-resistant wrapping paper. The high-temperature-resistant wrapping paper comprises a wrapping paper body, wherein a tensile layer, a waterproof layer and an erosion resistant layer are arranged on the wrapping paper body, the tensile layer and the erosion resistant layer are arranged between the waterproof layer and the wrapping paper body, the tensile layer is arranged between the wrapping paper body and the erosion resistant layer, and an inflaming retarding layer is also arranged on the wrapping paper body and arranged between the waterproof layer and the erosion resistant layer. The high-temperature-resistant wrapping paper is simple in structure and ingenious in design, and therefore the phenomenon of spontaneous combustion caused by high temperature cannot occur when the high-temperature-resistant wrapping paper is used. The high-temperature-resistant wrapping paper is novel and convenient to popularize and use.

Owner:KUNSHAN RONGAO WEIJIE TRADE

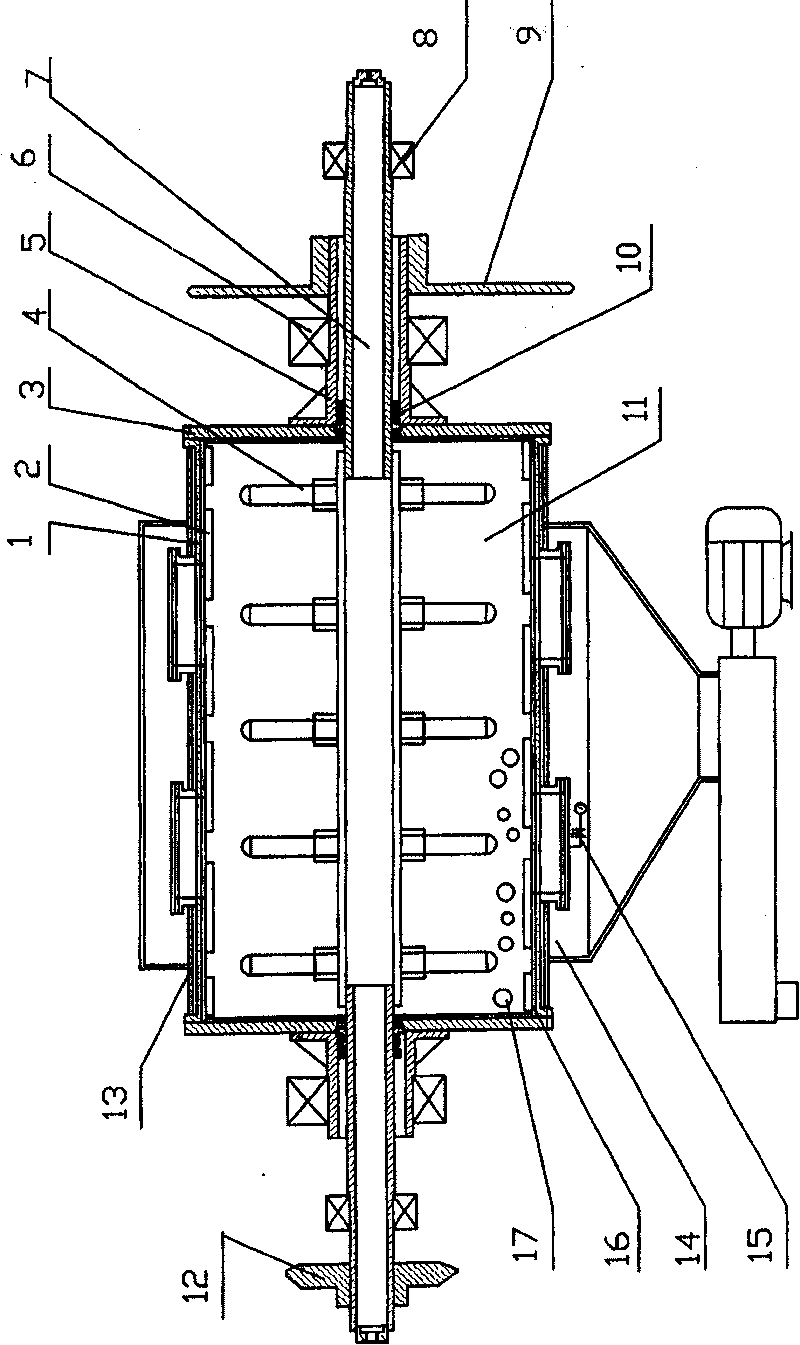

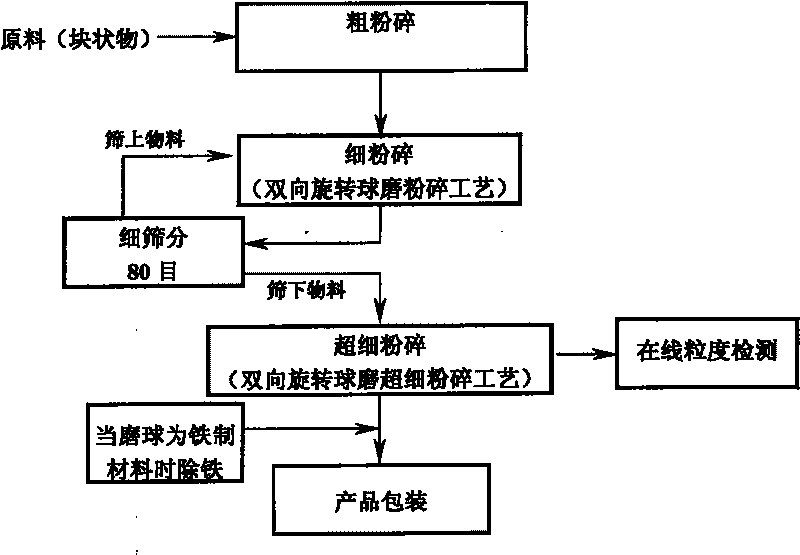

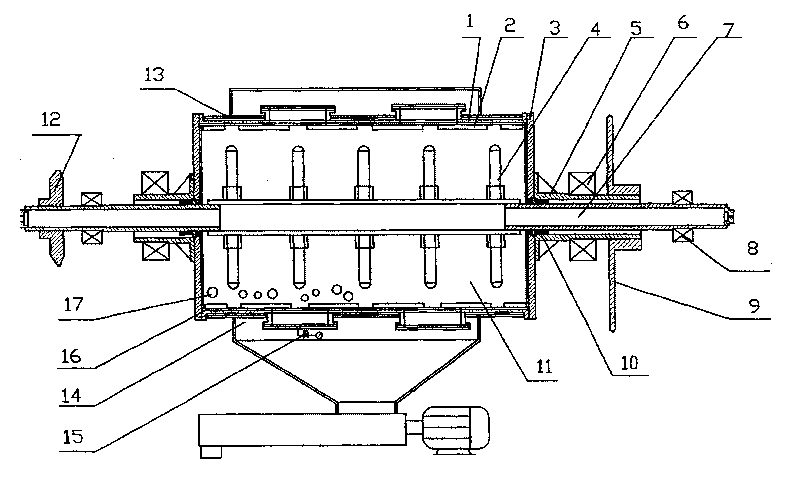

Bidirectional tosh grinding ultra-fine crashing objects and its method

InactiveCN101161347BReduce surface activityReduce the temperatureGrain treatmentsVacuum pumpingMass ratio

The present invention discloses a bidirectional-rotating ball-milling ultra-fine crushing device and the method thereof. The device is arranged with a jacket which is provided with cooling water; a closed material storing warehouse which closes the feeding / discharging material opening is arranged at the lower end of the barrel body; a vacuum pumping valve which is connected with the vacuum pumpingdevice is arranged at random feeding / discharging cover plate on the barrel body; and an inner lining is arranged at the inner surface of the barrel body. The bidirectional-rotating ball-milling ultra-fine crushing method is doing vacuum pumping to the inner side of the barrel body and actuating the transmission device to do ultra-fine crushing when the raw material above 80 mu is added into the barrel body, wherein the rotary speed of the barrel is 40 to 70 rotation / minute and the rotary speed of the inner rotating axle is 20 to 40 rotation / minute; the mass of the grinding ball gradation phibetween 5 to 10mm accounts for 35% to 55% of the total grinding ball mass, phi between 10 to 20mm accounts for 25% to 35% of the total grinding ball mass and the phi between 20 to 30mm accounts for 20% to 35% of the total grinding ball mass; and the mass ratio of the material ball is 1:4 to 1:15. The invention has the advantages of short producing time, low energy consumption and reduced producingcost, and the invention overcomes the fine particle problems of easy aggregation to block and fusing-aggregation, etc.

Owner:NANJING UNIV OF SCI & TECH

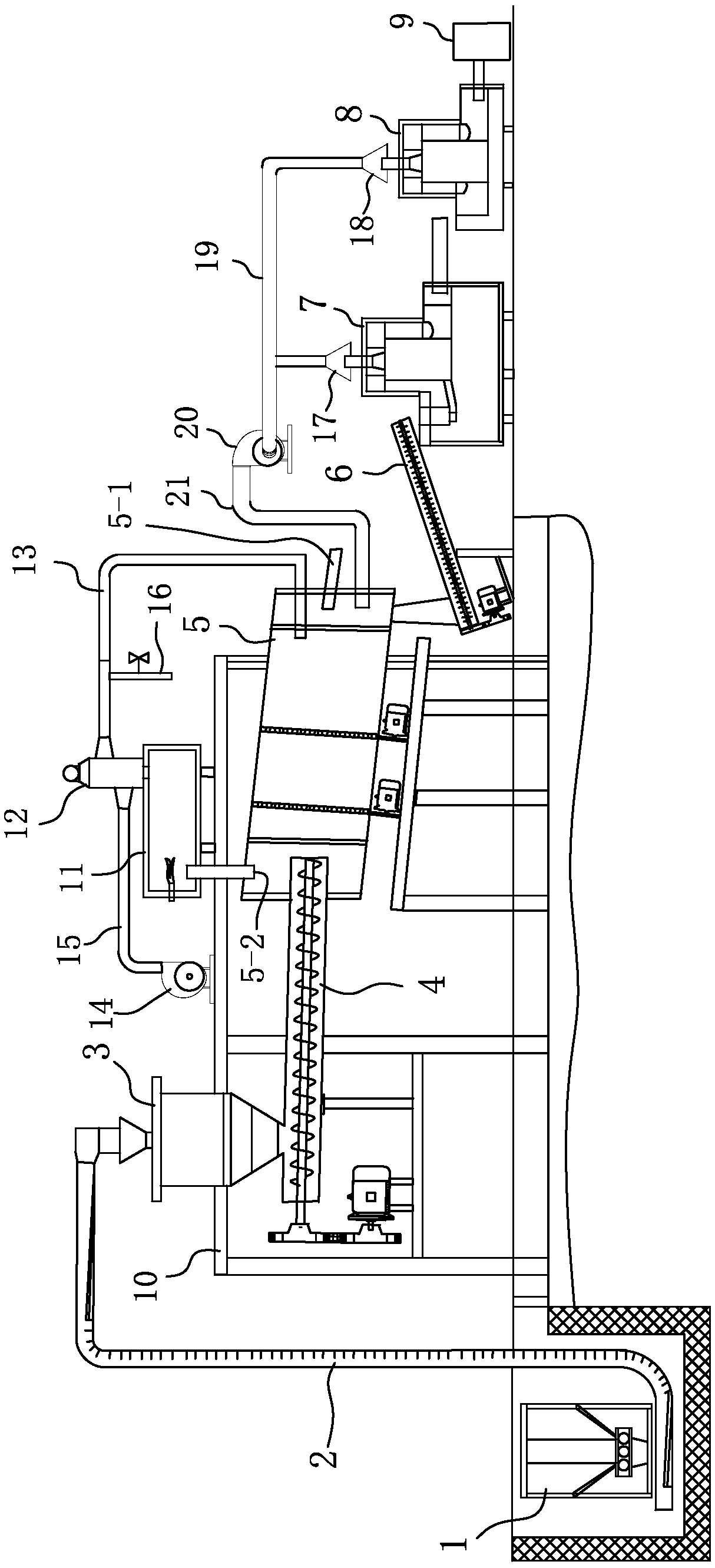

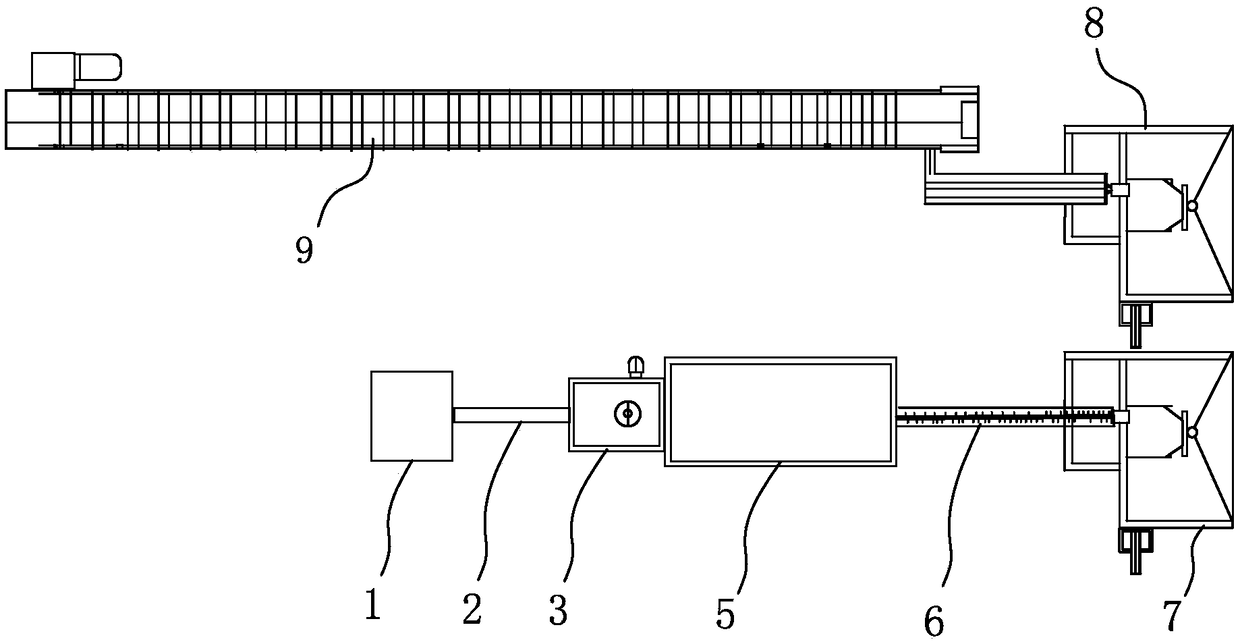

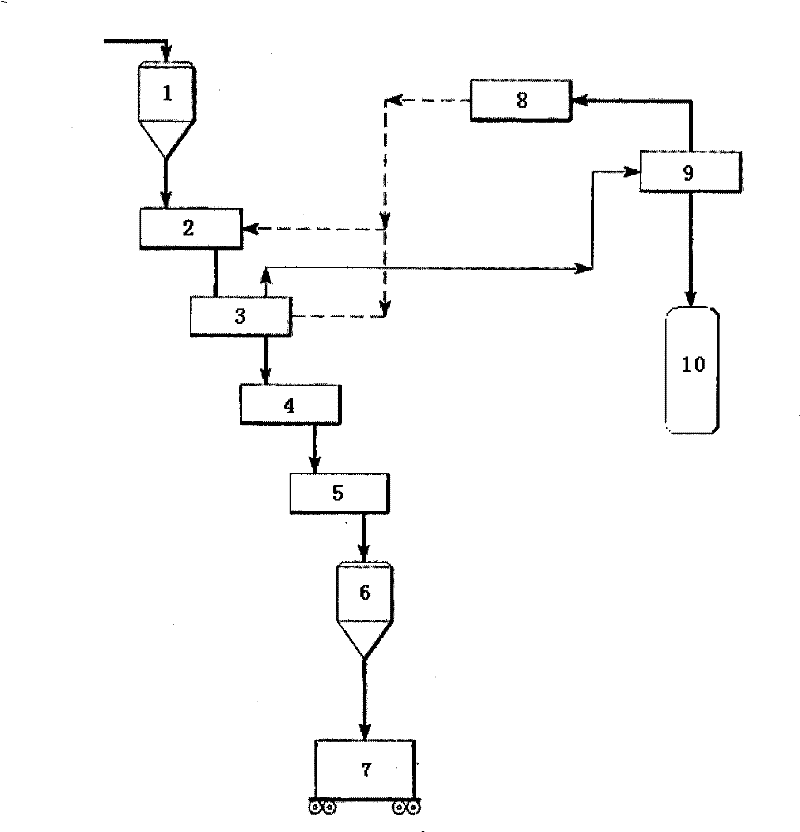

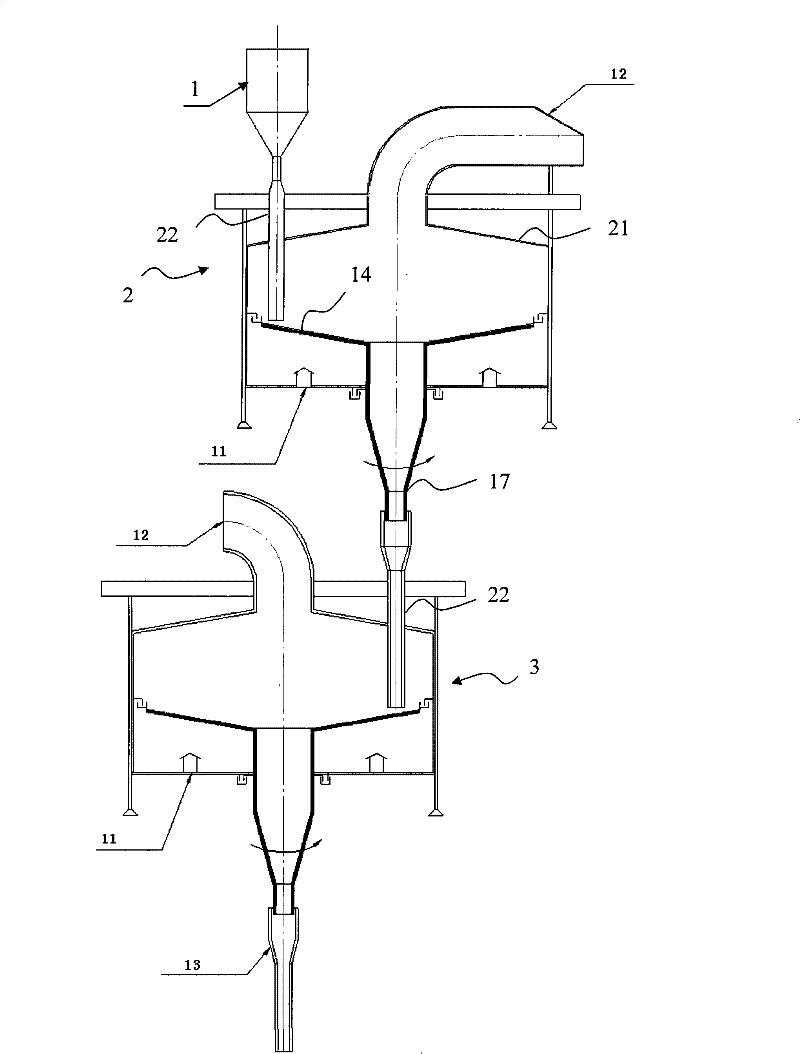

Step-by-step quality-improving processing technique and processing system for low-level coal

InactiveCN101760215BHigh calorific valueImprove stabilitySpecial form destructive distillationProduct gasOxygen

Owner:HUNAN HUAYIN ENERGY TECH

Storage tank breathing waste-gas desulfurization deodorizing technique

ActiveCN101721893AReduce investmentLow costDispersed particle separationEmission standardHuman health

The invention provides a storage tank breathing waste-gas desulfurization deodorizing technique which aims at the offensive odor of sulfur-bearing waste gas (which has a great impact on the environment and human health) produced when the material in sewage tanks, slop oil tanks, oil product tanks and the like in the oil refinery are handled. The technique is realized in a way that: the exhaust gas is desulfurized at -10-100 DEG C under normal pressure by using a DHS-1 H2S fine desulfurizer and an EHC-6 thiol fine desulfurizer, which are produced by Hubei Huabang Chemical Co. Ltd., so that the content of H2S is lower than 0.1 ppm, the content of RSH is lower than 1 ppm, and the waste gas does not have obvious odor and conforms to the emission standard for odor pollutants in China. The technique of the invention has the advantages of high safety and reliability, low equipment investment and operating cost, high handling capacity, and no secondary pollution or pollution transfer.

Owner:HUBEI HUABANG CHEM

Heap storage method for preventing spontaneous combustion of coal gangue hill

ActiveCN101644158BNo spontaneous combustionLarge area spontaneous combustion will not occurUnderground miningSurface miningSpontaneous combustionEngineering

The invention relates to a coal gangue hill control technology, in particular to a heap storage method for preventing spontaneous combustion of a coal gangue hill, thereby solving the problems that the existing heap storage way is easy to cause the spontaneous combustion of the free surface and the edge of a hill body, and once one place occurs the spontaneous combustion, a plurality of places are burnt. The heap storage method comprises the steps of carrying out transverse layered soil coverage grinding treatment in each layer of the coal gangue hill body; setting a soil isolation chamber atthe free place of a slope at the middle and lower part of the coal gangue hill body and the plane place of a top layer along the longitudinal direction; and adopting three layers of soil coverage layers of a grinding loess layer, a loosening loess layer and a fine particle gangue layer at the outmost layer of the coal gangue hill body. The heap storage method can not only effectively prevent the spontaneous combustion of coal gangue, but also prevent water and soil loss caused by rainwater brushing and dust flying with wind and provide a beneficial growth environment for plants; furthermore, the heap storage method adopts the transverse layered soil coverage grinding treatment way and sets the soil isolation chamber at the free place of the slope at the middle and lower part of the hill body and the plane place at the top, thereby being capable of controlling the spontaneous combustion of the coal gangue caused by manual disturbance or other factors in the local region and not causingthe impacts on the whole hill body.

Owner:山西大地民基生态环境股份有限公司

High temperature resistant solid propellant for oil and gas deep wells and preparation method thereof

InactiveCN103304354BImprove hydrolysis resistanceImprove temperature resistancePressure gas generationSpontaneous combustionTemperature resistance

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 55.00-73.00% of potassium perchlorate, 10.00-43.37% of high-temperature-resistant epoxy resin, 0-11.40% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing and remixing and are finally poured into a mold for molding so as to prepare a finished product. The solid propellant has excellent hydrolysis resistance; when the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resistance is better, the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

A zero-emission two-stroke ignition hydrogen-oxygen engine and its control method

ActiveCN111365119BImprove power densityEliminate harmful emissionsElectrical controlInternal combustion piston enginesEnergy recoveryWater spray

The invention provides a zero-emission two-stroke ignition-type hydrogen-oxygen engine and a control method, and specifically relates to a fuel supply system, a water spray system, an exhaust energy recovery system and control of a zero-emission two-stroke ignition-type hydrogen-oxygen engine. The hydrogen and oxygen in the engine enter the cylinder through the hydrogen nozzle and the oxygen nozzle respectively, and are quickly ignited after the spark plug flashes, so as to realize the high-efficiency constant-volume combustion process. The water nozzle sprays water to cool down the compression and combustion process in the cylinder according to the control of the electronic control unit, so as to ensure that the mixture will not spontaneously ignite and the body parts will not be damaged due to the increase in heat load caused by hydrogen-oxygen combustion. The tail gas energy recovery device and the heat exchanger carry out two-stage utilization of the high-temperature tail gas waste heat generated by combustion, which increases the thermal power conversion efficiency of the technical solution provided by the present invention. The invention truly realizes zero harmful emission operation of the engine by adopting hydrogen-oxygen combustion.

Owner:BEIJING UNIV OF TECH

High temperature resistant solid propellant for oil and gas deep wells and preparation method thereof

InactiveCN103304351BImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustion4-Methylimidazole

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 33.00-58.00% of potassium perchlorate, 8.00-33.00% of TATB, 10.00-32.37% of high-temperature-resistant epoxy resin, 0-11.79% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing, remixing and molding so as to prepare a finished product. When the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

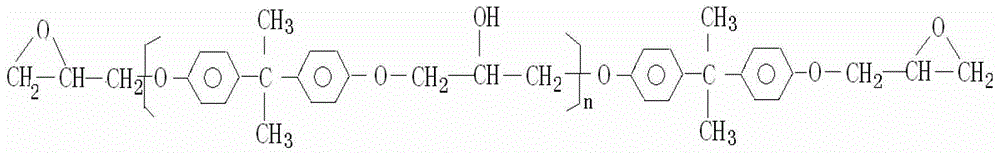

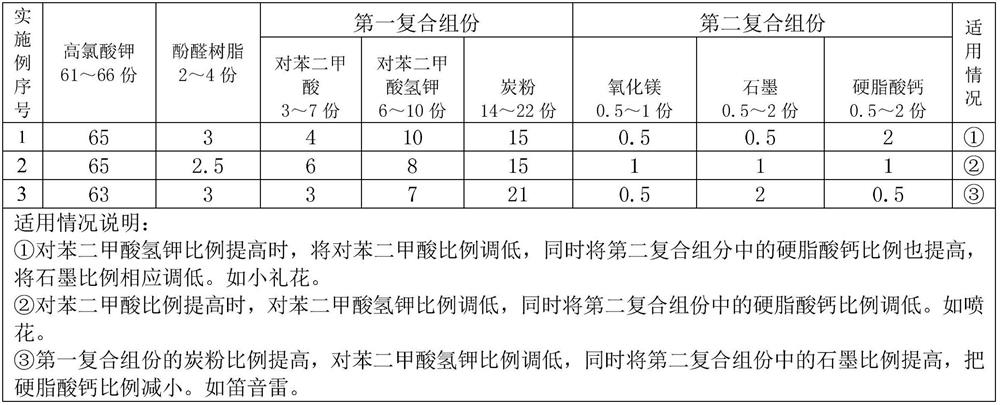

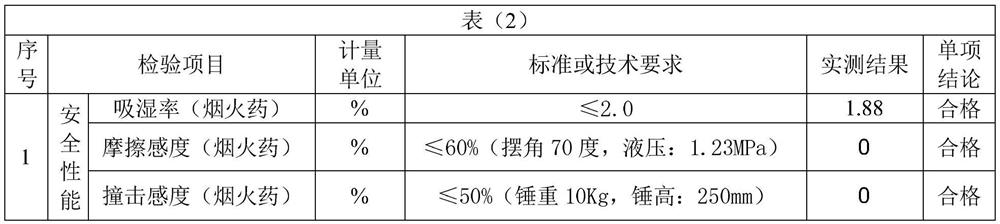

Firework propellant composition

PendingCN114230424ANo spontaneous combustionNo security issues foundExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsStearic acidPotassium chlorate

The invention discloses a firework propellant composition which is prepared from the following components in parts by weight: 61-66 parts of potassium perchlorate, 6-12 parts of a first composite component, 6-12 parts of a second composite component and 6-12 parts of phenolic resin. The weight part ratio of the phenolic resin is 2-4 parts; the first composite component consists of the following components in parts by weight: 3-7 parts of terephthalic acid, 6-10 parts of potassium hydrogen terephthalate and 14-22 parts of powdered carbon; the second composite component is prepared from the following components in parts by weight: 0.5 to 1 part of magnesium oxide, 0.5 to 2 parts of graphite and 0.5 to 2 parts of calcium stearate. The propellant powder has the characteristics of safety, stability, environmental protection, moisture prevention, high efficiency, saving and easiness in popularization and use.

Owner:湖南省惠艺鑫科技有限公司

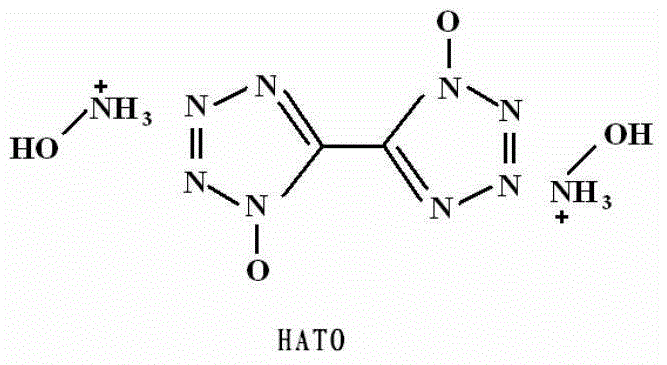

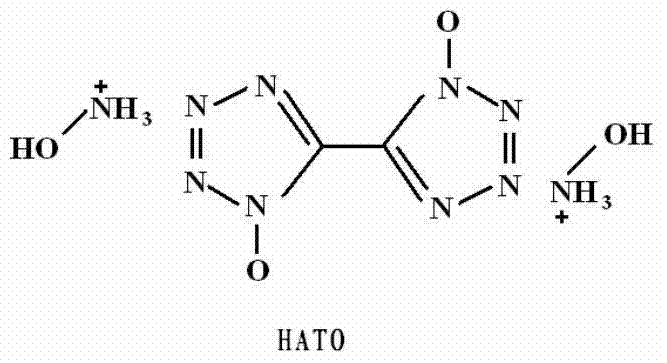

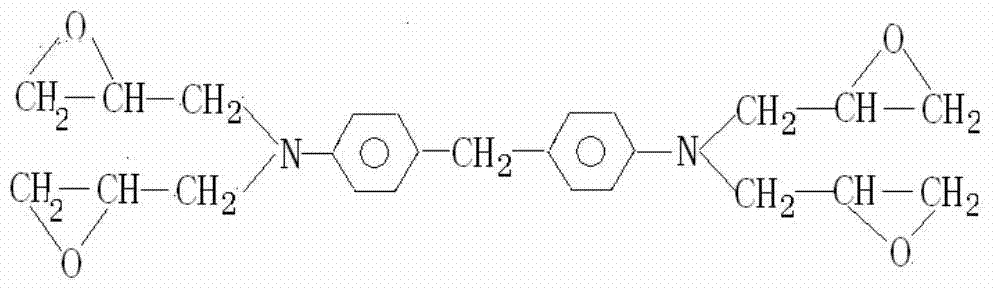

High-temperature-resistant propellant for oil/gas deep well and preparation method of high-temperature-resistant propellant

InactiveCN104628496AImprove hydrolysis resistanceImprove temperature resistanceAlkali metal salt explosive compositionsSpontaneous combustionSaline water

The invention provides a high-temperature-resistant propellant for an oil / gas deep well. The high-temperature-resistant propellant is prepared from the following raw materials by weight percent: 30 to 58 percent of potassium perchlorate, 2 to 30 percent of 1,1'-dihydroxyl-5,5'-bistetrazole dihydroxylamine salt, 10 to 20.90 percent of high-temperature-resistant epoxy resin, 0 to 16.58 percent of bisphenol A epoxy resin, 4.75 to 13.03 percent of epoxy resin active diluting agent, 0.5 percent of accelerant boron trifluoride-amine complex, 0.03 percent of a defoaming agent, 6.57 to 8.14 percent of diaminodiphenyl sulfone, and the sum of the weight percentage of the raw materials is 100 percent. The raw materials of the propellant are mixed after being pre-mixed, and then the mixed materials are formed by virtue of a mold to produce a finished product. After the solid propellant is immersed in clean water and 3.5% saline water for 24 to 48 hours, the weight loss of the solid propellant is less than 3 percent, and the volume variation is less than 2 percent; the temperature-resistant grade can reach 200 DEG C for 48 hours, the spontaneous combustion of the propellant can be avoided, and the high-temperature-resistant propellant can be used in a high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

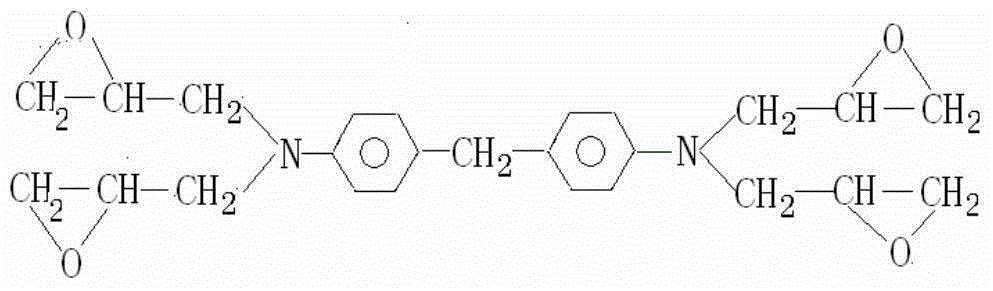

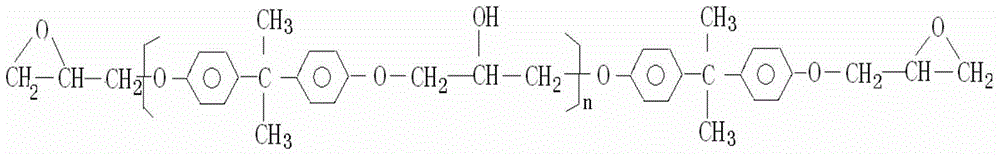

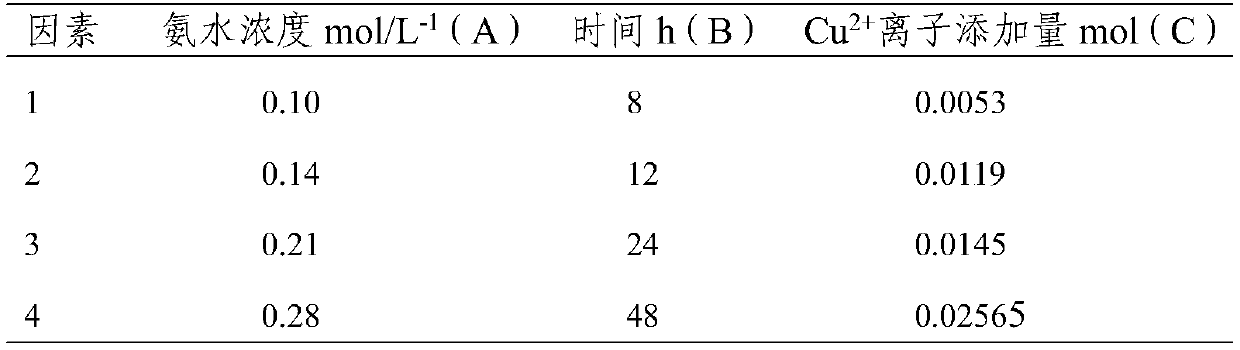

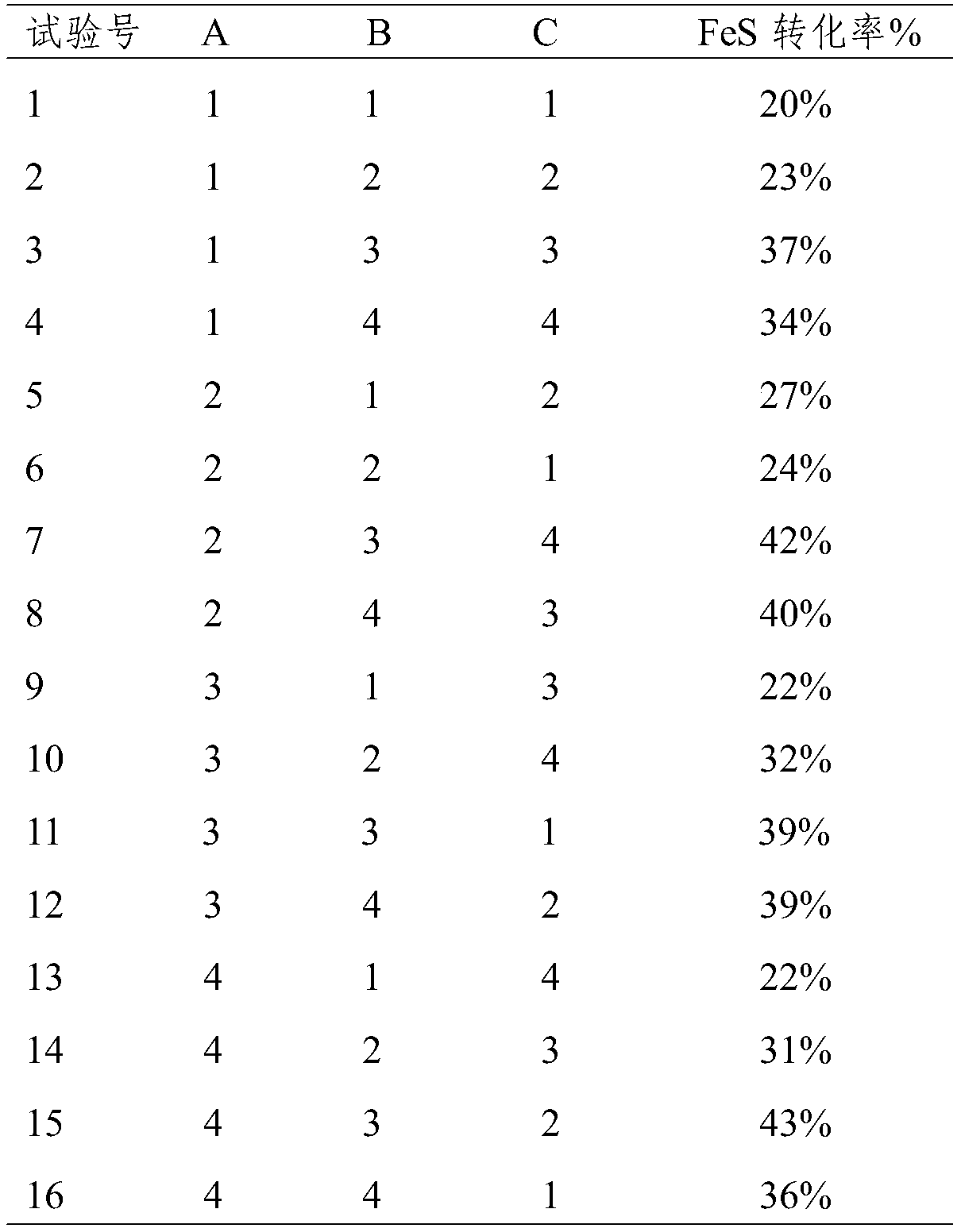

Preparation method for copper-ion ferrous sulfide cleaning agent, and cleaning method

InactiveCN111394736ANo pollution in the processNo spontaneous combustionFerric hydroxidePyrophoricity

The invention discloses a preparation method for a copper-ion ferrous sulfide cleaning agent, and a cleaning method. The preparation method comprises the following steps: weighing CuSO4.5H2O; and dissolving CuSO4.5H2O by deionized water and then adding NH3.H2O to obtain the ferrous sulfide cleaning agent. A cleaning time is 24h, and a cleaning temperature is 15-30 DEG C. The cleaning agent is capable of enabling a conversion rate for ferrous sulfide to reach about 80%; and moreover, the formula of the cleaning agent is environment-friendly, hydrogen sulfide is not generated in a cleaning process, the products generated after cleaning are copper sulfide and ferric hydroxide, and free from pyrophorisity, and a solution generated after cleaning is pollution-free to environment.

Owner:NORTH HUAJIN CHEM IND CO LTD

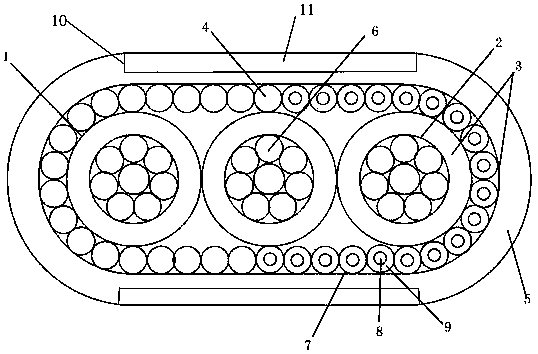

Five-core composite fireproof flat cable

InactiveCN108133773AEasy to identifyEasy to use and maintainFlat/ribbon cablesFlexible cablesElectrical conductorEngineering

The invention discloses a five-core composite fireproof flat cable. The cable has a flat structure. Three insulation wire cores arranged in parallel and in a straight manner are arranged in the centerof the cable. Half circle of a plurality of ground wire core conductors and half circle of a plurality of neural wire cores are arranged outside the insulation wire cores in parallel. A ceramic silicon rubber anti-flaming band wraps the ground wire core conductors and the neural wire cores in a coiling manner. A mineral metal outer sheath wraps the ceramic silicon rubber anti-flaming band in an extruded manner. The mineral metal outer sheath is provided with groove holes filled with heat absorbing cotton. The cable provided by the invention has characteristics of being capable of moving, bending, putting into vertical use repeatedly, being compact in structure, small in outer diameter, easy to process, convenient for construction and the like.

Owner:WUXI JIANGNAN CABLE

High temperature resistant propellant for oil and gas deep wells and preparation method thereof

InactiveCN104628496BImprove hydrolysis resistanceImprove temperature resistanceAlkali metal salt explosive compositionsSpontaneous combustionVolume variation

The invention provides a high-temperature-resistant propellant for an oil / gas deep well. The high-temperature-resistant propellant is prepared from the following raw materials by weight percent: 30 to 58 percent of potassium perchlorate, 2 to 30 percent of 1,1'-dihydroxyl-5,5'-bistetrazole dihydroxylamine salt, 10 to 20.90 percent of high-temperature-resistant epoxy resin, 0 to 16.58 percent of bisphenol A epoxy resin, 4.75 to 13.03 percent of epoxy resin active diluting agent, 0.5 percent of accelerant boron trifluoride-amine complex, 0.03 percent of a defoaming agent, 6.57 to 8.14 percent of diaminodiphenyl sulfone, and the sum of the weight percentage of the raw materials is 100 percent. The raw materials of the propellant are mixed after being pre-mixed, and then the mixed materials are formed by virtue of a mold to produce a finished product. After the solid propellant is immersed in clean water and 3.5% saline water for 24 to 48 hours, the weight loss of the solid propellant is less than 3 percent, and the volume variation is less than 2 percent; the temperature-resistant grade can reach 200 DEG C for 48 hours, the spontaneous combustion of the propellant can be avoided, and the high-temperature-resistant propellant can be used in a high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

High temperature resistant solid propellant for oil and gas deep wells and preparation method thereof

InactiveCN104672037BImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsHydrolysisAccelerant

The invention discloses a heat-resistant solid propellant for an oil-gas deep well. The heat-resistant solid propellant is prepared from the following components in percentage by weight: 45%-65% of potassium perchlorate, 0-10% of N-guanylurea dinitramide, 5.59%-26.79% of heat-resistant epoxy resin, 1.77%-10.38% of bisphenol A epoxy resin, 6.04%-13.7% of an epoxy resin reactive diluent, 0.5% of an accelerant, 0.03% of an antifoaming agent and 4.80%-9.87% of diamino diphenyl sulfone, wherein the sum of the raw materials in percentage by weight is 100%. The raw materials for the propellant are premixed, then are mixed, and finally are cast into a mold tobe molded, so as to prepare the finished product. The heat-resistant solid propellant is excellent in hydrolysis resistance. The heat-resistant solid propellant is soaked in clean water and 3.5% saline water for 24-48 hours; the weight loss is smaller than 3%; the volume change is smaller than 2%; the heat resistance is relatively good; the heat-resistant level reaches the condition that the solid propellant does not spontaneously combust or explode when being at 200 DEG C for 48 hours; and the heat-resistant solid propellant can be used in a high-temperature washy environment.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com