Method for repairing soil polluted by white phosphorus

A technology for polluted soil and white phosphorus, applied in the field of remediation of white phosphorus polluted soil, can solve problems such as eutrophication of water bodies, and achieve the effects of improving efficiency, reducing application amount, and reducing operational safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

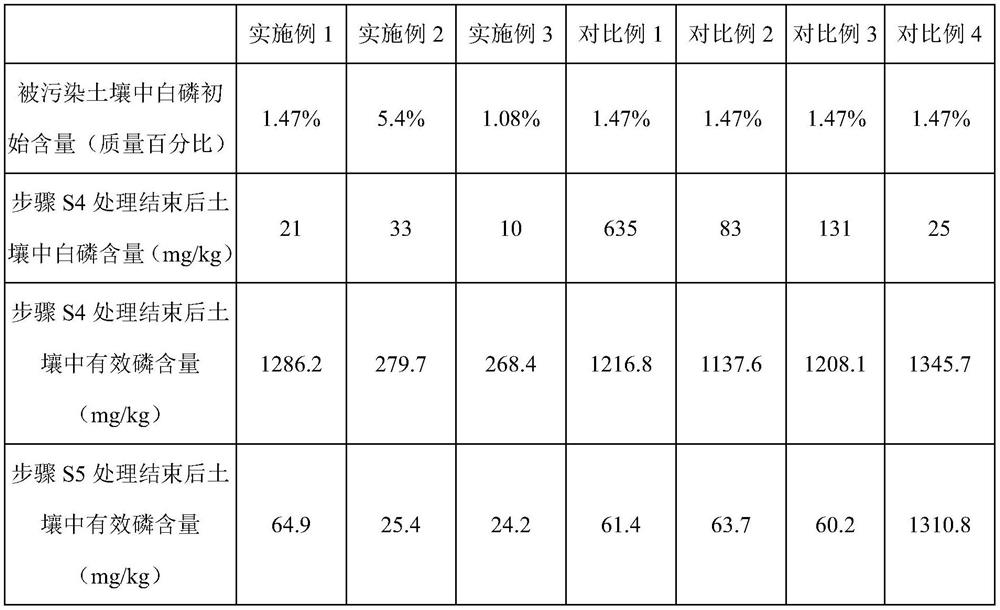

Embodiment 1

[0024] This embodiment provides a method for remediating white phosphorus-contaminated soil, which specifically includes the following steps:

[0025] S1. Take 100kg of soil polluted by white phosphorus, add 600kg of water, and fully stir to obtain mud;

[0026] S2, passing the mud described in step S1 through a 5-mesh sieve to obtain the sieved mud;

[0027] S3, add 120g sodium dodecylbenzenesulfonate to the sieved mud described in step S2, stir 15min, add 10kg sodium persulfate while stirring, continue to add 1kg potassium permanganate under stirring state, stir 5h, Obtain oxidized mud;

[0028] S4, adding 6kg of sodium hydroxide to the oxidized mud described in step S3, stirring and reacting for 5h;

[0029] S5. Add 0.6kg of polyaluminum chloride-chitosan composite flocculant to the mud after the reaction in step S4, stir for 7 hours, add an appropriate amount of water while stirring to keep the soil in a mud state, and stack the treated mud on the hardened ground Soil r...

Embodiment 2

[0031] This embodiment provides a method for remediating white phosphorus-contaminated soil, which specifically includes the following steps:

[0032] S1. Take 100kg of soil polluted by white phosphorus, add 300kg of water, and fully stir to obtain mud;

[0033] S2, passing the mud described in step S1 through a 10-mesh sieve to obtain the sieved mud;

[0034] S3. Add 30g of dodecylbenzenesulfonic acid to the sieved mud described in step S2, stir for 15min, then add 5kg of sodium persulfate, continue to add 0.5kg of 30% hydrogen peroxide under stirring, stir for 4h, and obtain the oxidized mud;

[0035] S4, adding 20kg of calcium hydroxide to the oxidized mud described in step S3, stirring and reacting for 4h;

[0036] S5. Add 0.3kg polyaluminum sulfate-chitosan composite flocculant to the mud after the reaction in step S4, stir for 6 hours, add an appropriate amount of water while stirring to keep the soil in a mud state, and stack the treated mud on the hardened ground So...

Embodiment 3

[0038] This embodiment provides a method for remediating white phosphorus-contaminated soil, which specifically includes the following steps:

[0039] S1, take 100kg of soil polluted by white phosphorus, add 1000kg of water, fully stir to obtain mud;

[0040] S2, passing the mud described in step S1 through an 8-mesh sieve to obtain the sieved mud;

[0041] S3, add 300g fatty alcohol ether sodium sulfate to the sieved mud described in step S2, stir 15min, then add 15kg sodium persulfate, continue to add 2kg calcium peroxide under stirring state, stir 6h, obtain the mud after oxidation;

[0042] S4, adding 3.1 kg of calcium oxide to the oxidized mud described in step S3, stirring and reacting for 6 hours;

[0043] S5. Add 0.1kg of polyaluminum chloride to the mud after the reaction in step S4, stir for 8 hours, add appropriate amount of water while stirring to keep the soil in a mud state, stack the treated mud on the hardened ground and let it stand for 15 days to complete S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com