A zero-emission two-stroke ignition hydrogen-oxygen engine and its control method

A control method and two-stroke technology, applied in the direction of engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of waste heat recovery of high-temperature products, high harmful emissions, low power density, etc., to eliminate harmful emissions, avoid waste, improve The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing:

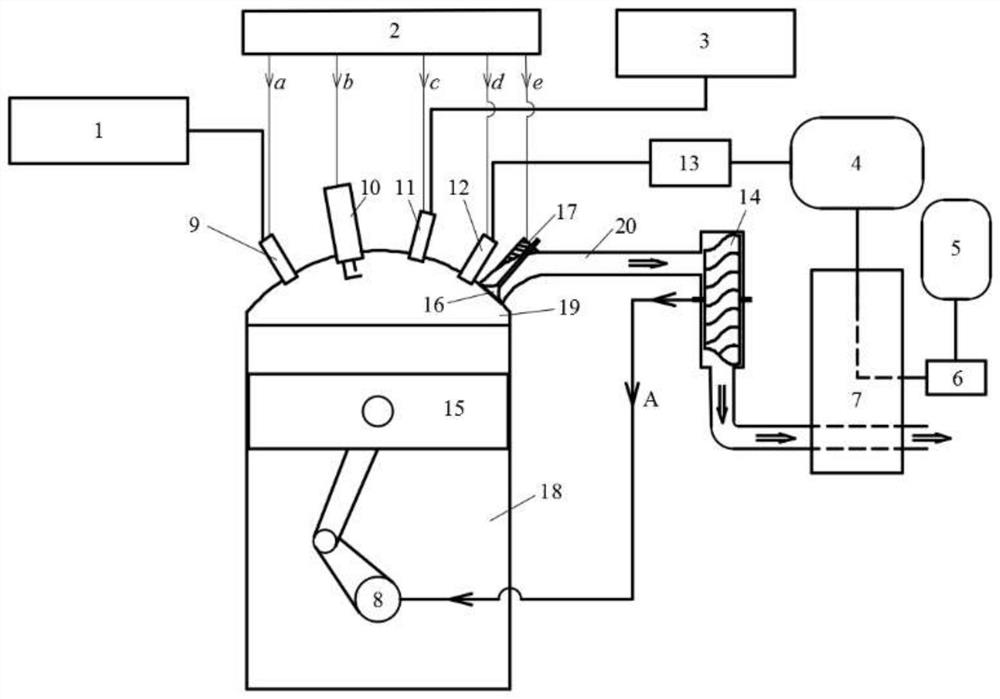

[0044] Such as figure 1 As shown, the zero-emission two-stroke ignition hydrogen-oxygen engine includes a crankshaft 8 installed on an engine block 18, a piston 15 connected to the crankshaft through a crank-and-rod structure, and exhaust gas energy recovery installed on an exhaust pipe 20 in turn. Device 14, heat exchanger 7, hydrogen nozzle 9, spark plug 10, oxygen nozzle 11, water nozzle 12, exhaust valve 16, exhaust valve solenoid valve 17 installed on the engine cylinder head 19, hydrogen tank 1 passes through pipeline and The hydrogen nozzle 9 is connected, the oxygen tank 3 is connected with the oxygen nozzle 11 through the pipeline, and the water spray system in the cylinder includes the water tank 5, which is connected to the low-pressure water pump 6, the high-temperature water storage tank 4, and the high-pressure pump successively on the water tank 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com