Clean fired coal saving agent

A coal-saving agent and coal-burning technology, applied in the directions of fuel additives, fuels, solid fuels, etc., can solve the problems of small investment, and achieve the effect of not increasing production and use costs, simple operation technology, and not increasing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Coal-burning clean and coal-saving agent is divided into liquid and powder products. The liquid product uses chemical raw material sodium nitrite (NaNO 2 ), potassium nitrite (KNO 2 ), potassium nitrate (KNO 3 ), sodium nitrate (NaNO 3 ), sodium sulfonate, and sodium dodecylbenzenesulfonate are dissolved in the mixed liquid of papermaking black liquor, alcohol waste liquid, and coal-fired flue gas water film dedusting and desulfurization alkali regeneration liquid to obtain a liquid agent product. The liquid product prepared by absorbing the hot coal-burning slag is mixed with the raw material of chemical mineral products, mixed evenly, dried and pulverized to obtain the powder product.

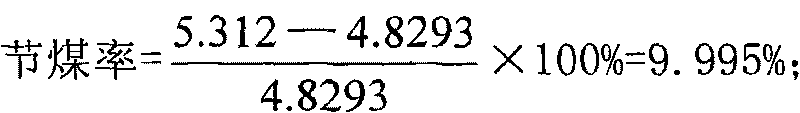

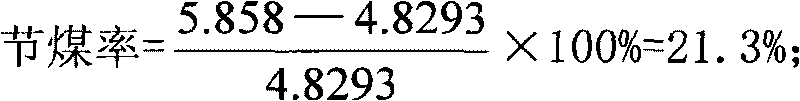

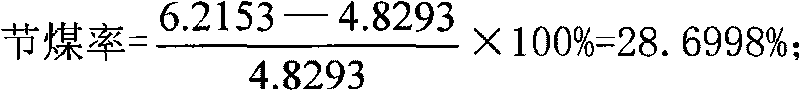

[0033] In the actual production application, the comparative determination of the coal saving rate is based on the same boiler, the same coal type, and the same amount of coal mixed with different proportions of liquid and powder coal-fired clean coal-saving agent products for compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com