Storage tank breathing waste-gas desulfurization deodorizing technique

A waste gas and storage tank technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of not meeting the emission standards of odor pollutants, the surrounding environment and the impact on human health, so as to avoid secondary pollution and pollution transfer, equipment investment and travel costs are low, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

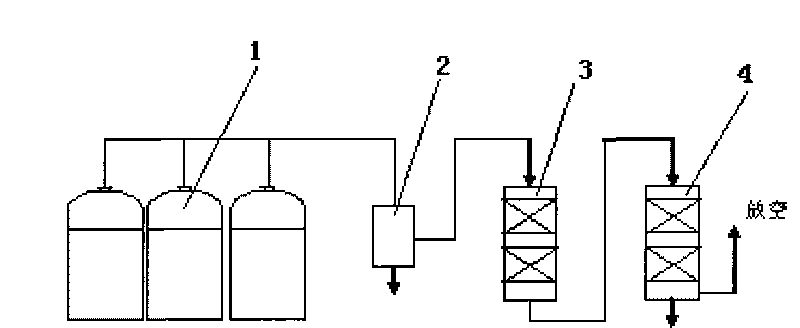

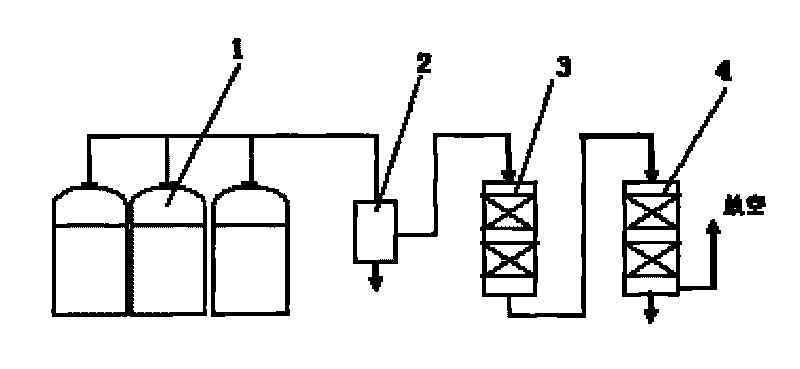

Image

Examples

Embodiment 1

[0025] In a petrochemical company in Nanjing, Jiangsu, the respiratory exhaust gas of its refinery sewage tank contains H 2 S 1400ppm, RSH 396ppm, O 2 12ppm, the operating temperature is 13°C, the pressure is normal pressure, and the instantaneous gas space velocity is 530 hours -1 , gas H after fine desulfurization 2 S<0.1ppm, RSH<1ppm, no obvious odor, in line with the national "Odor Pollutant Discharge Standard" (GB14554-93).

Embodiment 2

[0027] In a petrochemical company in Zhejiang, the respiratory exhaust gas of its refinery sewage tank contains H 2 S 1230ppm, RSH 480ppm, O 2 20ppm, the operating temperature is 23°C, the pressure is normal pressure, and the instantaneous gas space velocity is 640 hours -1 , gas H after fine desulfurization 2 S<0.1ppm, RSH<1ppm, no obvious odor, in line with the national "Odor Pollutant Discharge Standard" (GB14554-93).

Embodiment 3

[0029] H in the breathing exhaust gas of a storage tank 2 S 830ppm, RSH 620ppm, O 2 0.1ppm, the operating temperature is -3°C, the pressure is normal pressure, and the instantaneous gas space velocity is 490 hours -1 , After fine desulfurization, the gas H2S<0.1ppm, RSH<1ppm, no obvious odor, in line with the national "Odor Pollutant Emission Standard" (GB14554-93).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com