Camphor producing method and isoborneol dissolving equipment thereof

A production method and isoborneol technology, applied in the field of isoborneol dissolving equipment, can solve problems such as increased difficulty in xylene recovery, increased consumption of isoborneol, and impact on camphor quality, so as to shorten working time, improve utilization rate, Effect of reducing dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A kind of camphor production method described in the present invention, in order to improve the feeding safety of isoborneol in the dehydrogenation process, a dissolving process is carried out before the dehydrogenation process. The isoborneol crystals produced in the hydrolysis process are put into the isoborneol dissolving equipment in the dissolving process, then the isoborneol crystals are fully dissolved with a solvent to obtain the isoborneol solution, and finally the isoborneol solution is extracted from the isoborneol solution with an inert gas The borneol dissolving equipment is discharged and put into the dehydrogenation process for production to obtain camphor products. Wherein said solvent can be xylene.

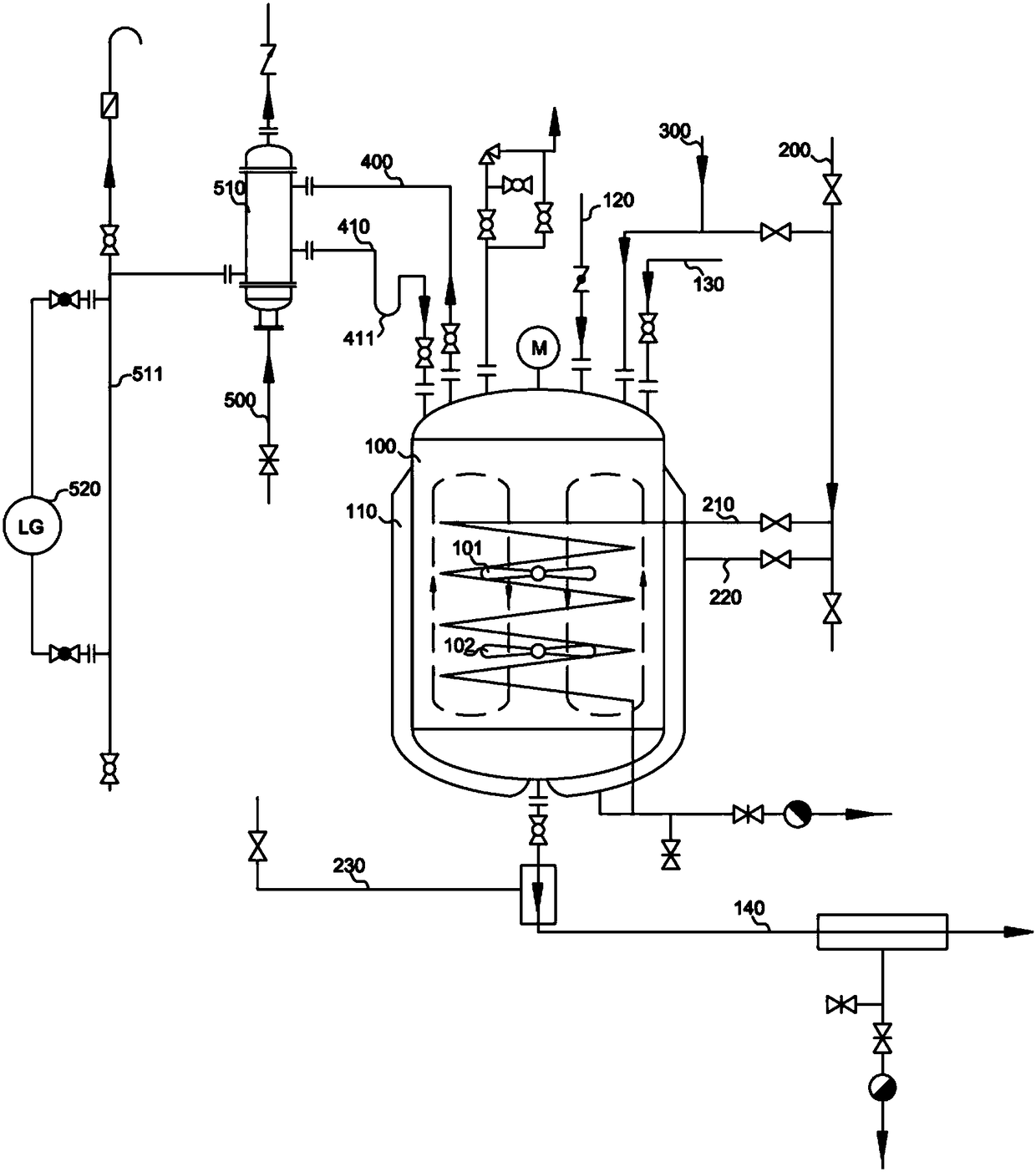

[0019] Such as figure 1 As shown, a kind of isoborneol dissolving equipment according to the present invention includes a kettle body 100 for dissolving isoborneol crystals, and the upper end of the kettle body 100 is provided with an isoborneol feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com