Catalyst for catalytic oxidation of gaseous hydrogen tritide, and preparation method and application of catalyst

A catalytic oxidation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of spontaneous combustion, hidden safety hazards, high catalyst costs, etc., to achieve preparation Simple process, long life and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

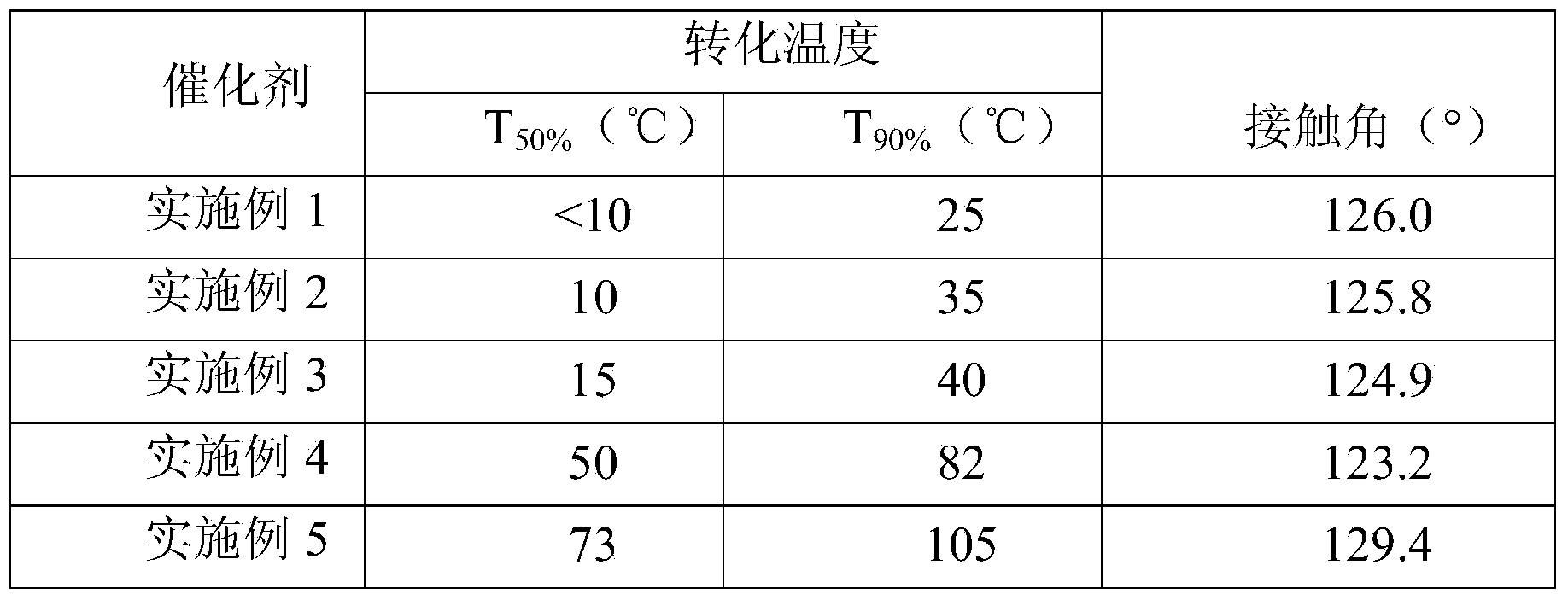

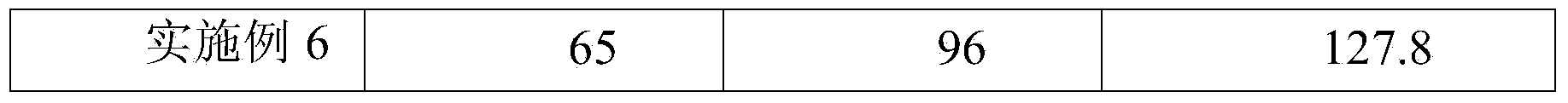

Examples

Embodiment 1

[0027] Dissolve commercially available 10g of aluminum nitrate in 20ml of deionized water, stir for 30min as solution A; mix 7.5g of sodium hydroxide and 50ml of deionized water as solution B; add solution B dropwise to solution A under vigorous stirring, and keep at room temperature Stir for 2 hours, let stand and age for 48 hours, then suction filter, wash, dry, and then move to a muffle furnace for roasting. The specific calcination process is as follows: start heating at 50°C, program temperature rise at a heating rate of 2.5°C / min, and maintain at 500°C for 4 hours to obtain alumina. After removal, the catalyst was ground to ensure that the catalyst was in powder form.

[0028] Weigh 10g of alumina powder prepared by the above method and pour it into 200ml of toluene solution, add 5ml of n-octyltriethoxysilane (OTES), (Sinopharm Reagent, product number XW29437511, CAS: 2943-75-1, molecular formula :C1 4 h 32 o 3 Si, molecular weight: 276.4876, relative density: 0.879g...

Embodiment 2

[0031] Prepare 2%Pt / Al by the same method of embodiment 1 2 o 3 Catalyst, the feeding ratio is the same.

Embodiment 3

[0033] Prepare 3%Pt / Al by the same method of embodiment 1 2 o 3 Catalyst, the feeding ratio is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com