Heap storage method for preventing spontaneous combustion of coal gangue hill

A coal gangue and gangue technology, which is applied in the storage field of preventing spontaneous combustion of coal gangue, can solve the problems of spontaneous combustion and multiple burning of the mountain body, so as to prevent coal gangue from polluting the environment, increase soil moisture, and prevent coal gangue from spontaneous combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The storage method for preventing coal gangue from spontaneous combustion comprises the following steps:

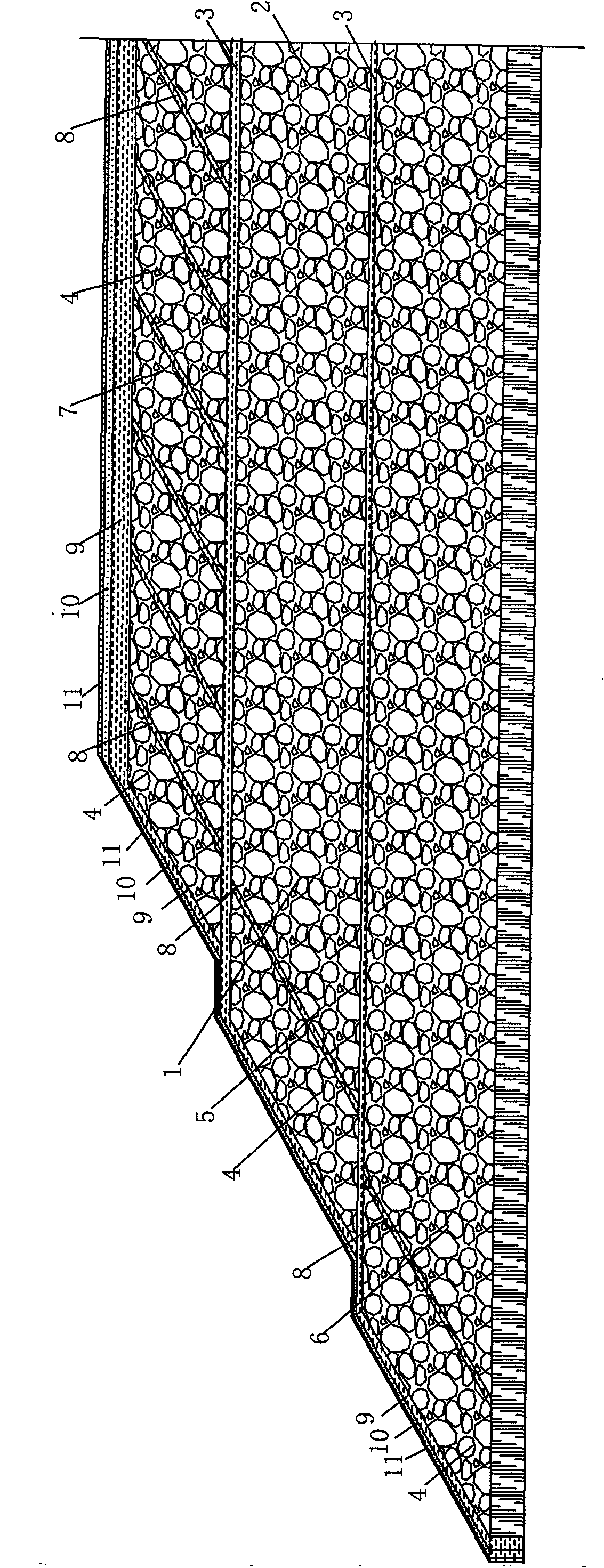

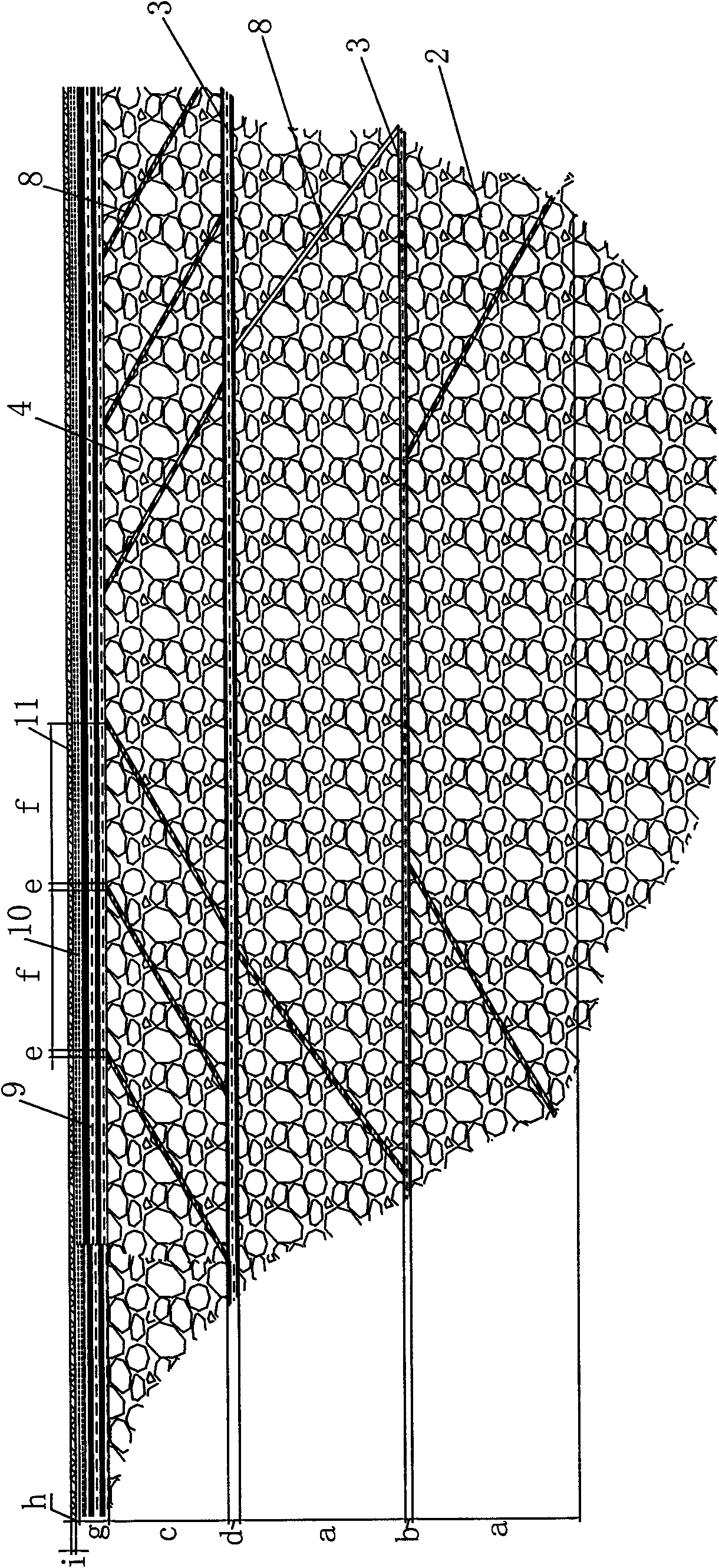

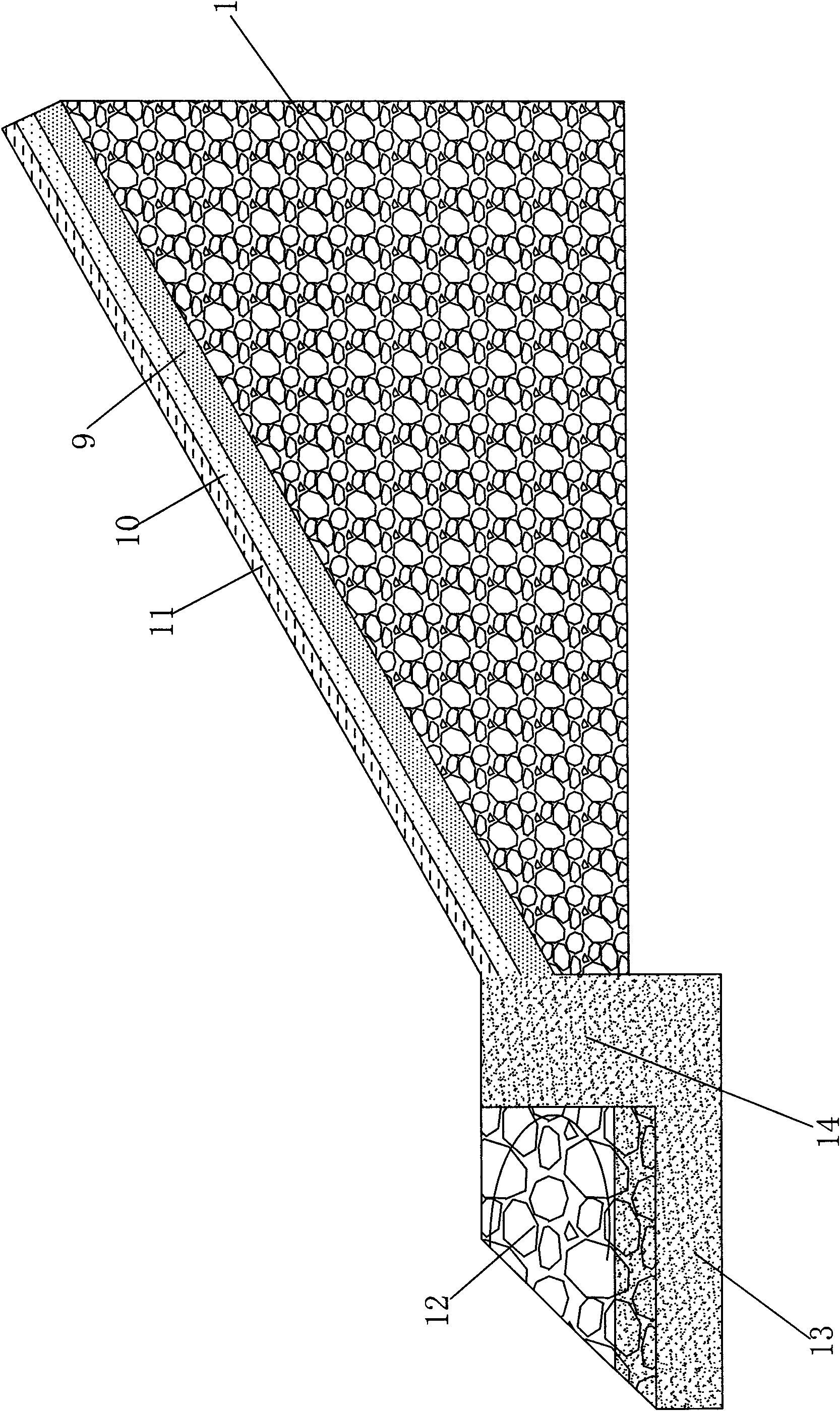

[0016] (1) if figure 1 As shown, each layer of the coal gangue hill body 1 is subjected to horizontal stratified soil covering and rolling treatment, that is, every time a layer of gangue layer 2 is discharged, a layer of loess layer 3 is covered and compacted, and then the discharge is continued on the basis of the compacted loess layer. One layer of gangue layer, and so on until the top layer; as figure 2 As shown, the thickness a of the gangue layer 2 located in the middle part 5 and the lower part 6 of the gangue hill body is 6-8m, and the thickness b of the compacted loess layer 3 between adjacent gangue layers is 0.2-0.3m; The thickness c of the gangue layer 2 is 4-5m, and the thickness d of the compacted loess layer 3 between adjacent gangue layers is 0.5-0.6m;

[0017] (2) A single soil compartment 4 is arranged along the longitudinal direction on the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com