Method and device for removing soft package battery

A technology for soft-pack batteries and dismantling devices, which is applied in the repair/maintenance of secondary batteries, can solve problems such as increased maintenance costs, achieve the effects of reduced maintenance costs, high safety factor, and improved maintenance quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

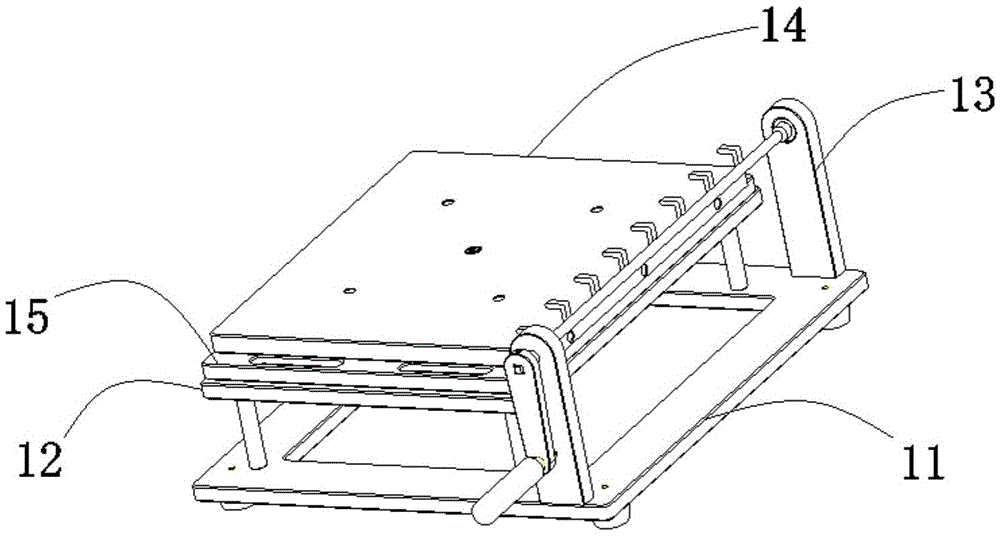

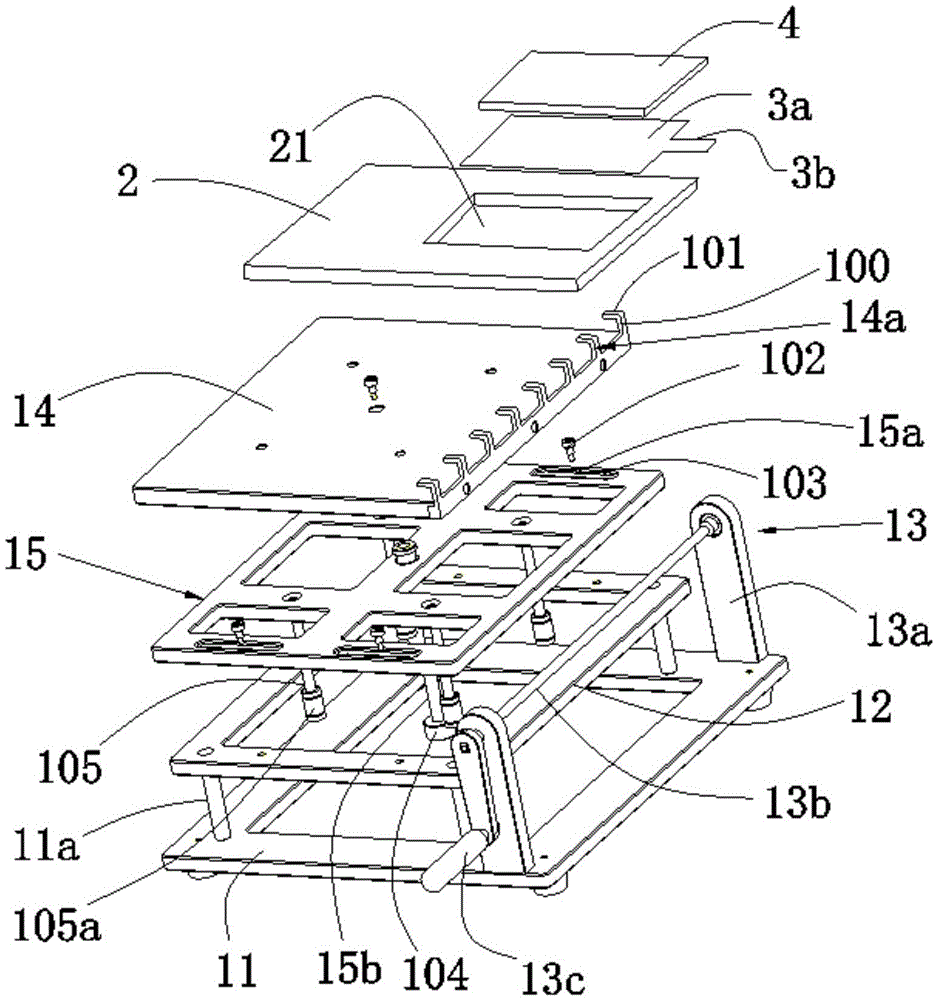

[0032] refer to figure 1 , figure 2 , the present embodiment provides a pouch battery removal device 1, which is used to disassemble the pouch battery 4 attached to the electronic device 2 through the double-sided adhesive tape 3 with a handle. The double-sided adhesive tape 3 with a handle includes a main body 3a and a connected The extension part 3b of the main body part 3a is connected between the soft pack battery 4 and the battery accommodating cavity 21 of the electronic device 2, and is used for adhering the soft pack battery 4 to the battery accommodating cavity 21, its shape can be set according to actual needs, preferably, the shape of the main body 3a is the same as that of the pouch battery 4; the extension 3b is exposed outside the battery accommodating cavity 21, It is convenient to pull out the main body part 3a when the electronic device 2 is maintained.

[0033] Specifically, the pouch battery disassembly device includes a bottom plate 11 , a carrying plate...

Embodiment 2

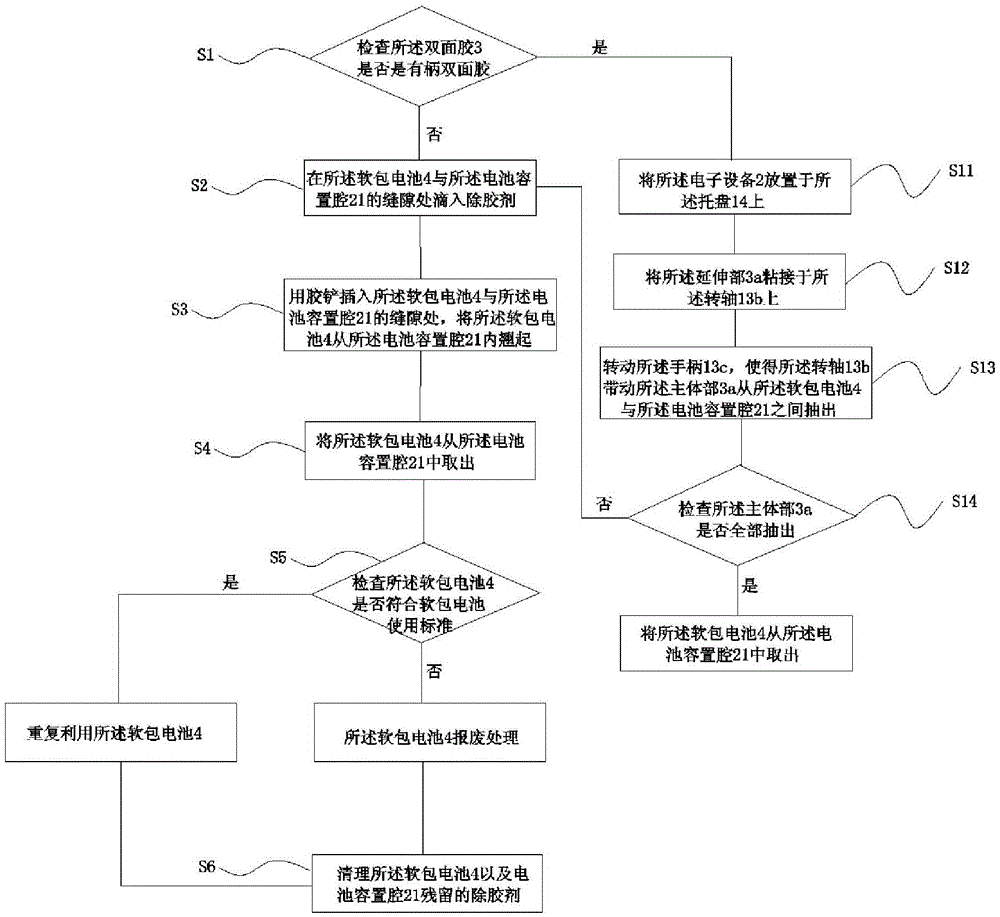

[0040] refer to figure 2 This embodiment provides a method for disassembling a pouch battery. The pouch battery 4 is adhered to the battery accommodating cavity 21 by double-sided adhesive tape 3 . The specific steps of the disassembly method for the pouch battery are as follows.

[0041] Step S1, check whether the double-sided tape 3 is a double-sided tape with a handle; if the double-sided tape 3 is a double-sided tape with a handle, use the soft pack battery removal device 1 in Example 1 to remove the soft pack The battery is disassembled; if the double-sided tape 3 is not double-sided tape with a handle, go to step S2.

[0042] In step S1, if the double-sided tape 3 is double-sided tape with a handle, the specific method for disassembling the soft-pack battery 4 by using the soft-pack battery dismantling device 1 includes:

[0043] S11. Place the electronic device 2 on the tray 14, so that the end of the electronic device 2 corresponding to the extension portion 3b of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com