Five-core composite fireproof flat cable

A fireproof flat and cable technology, applied in the direction of flat/ribbon cables, insulated cables, bendable cables, etc., can solve the problems of easy heating and spontaneous combustion of cables, poor fire resistance of cables, and increased cable length, etc., to achieve good protection. Reduce material waste and reduce the effect of laying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with accompanying drawing:

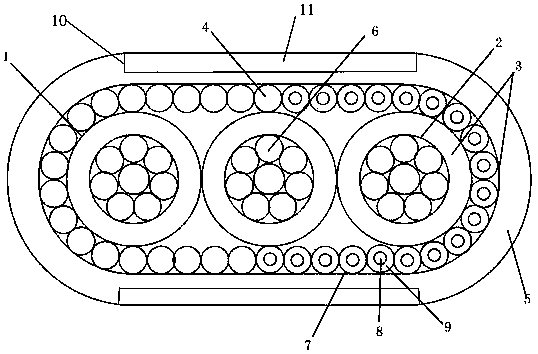

[0015] Such as figure 1 As shown, a five-core composite fireproof flat cable according to the present invention has a flat structure, and the center of the cable is provided with three parallel insulated wire cores 1, and several ground wires are arranged side by side in half a circle outside the insulated wire cores. Core conductor 4 and several neutral wire cores 7 in a half circle, ground wire core conductor 4 and neutral wire core 7 are wrapped with ceramic silicone rubber flame-retardant tape 3, ceramic silicone rubber flame-retardant tape is extruded and wrapped with mineral metal outer sheath The sleeve 5 has a slot 10 in the mineral metal outer sheath, and heat-absorbing cotton 11 is filled in the slot, so that the heat in the cable is dissipated outward; the insulated wire core is wrapped by an aluminum alloy conductor 2 and The outer ceramic silicon rubber flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com