Step-by-step quality-improving processing technique and processing system for low-level coal

A processing technology and technology of low-rank coal, which is applied in the field of quality-upgrading treatment technology, can solve the problems of difficult industrial-scale enlarged production, low processing capacity of low-rank coal, high energy consumption, etc., so as to improve the calorific value and stability. , convenient for long-distance transportation, and the effect of reducing the temperature of dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

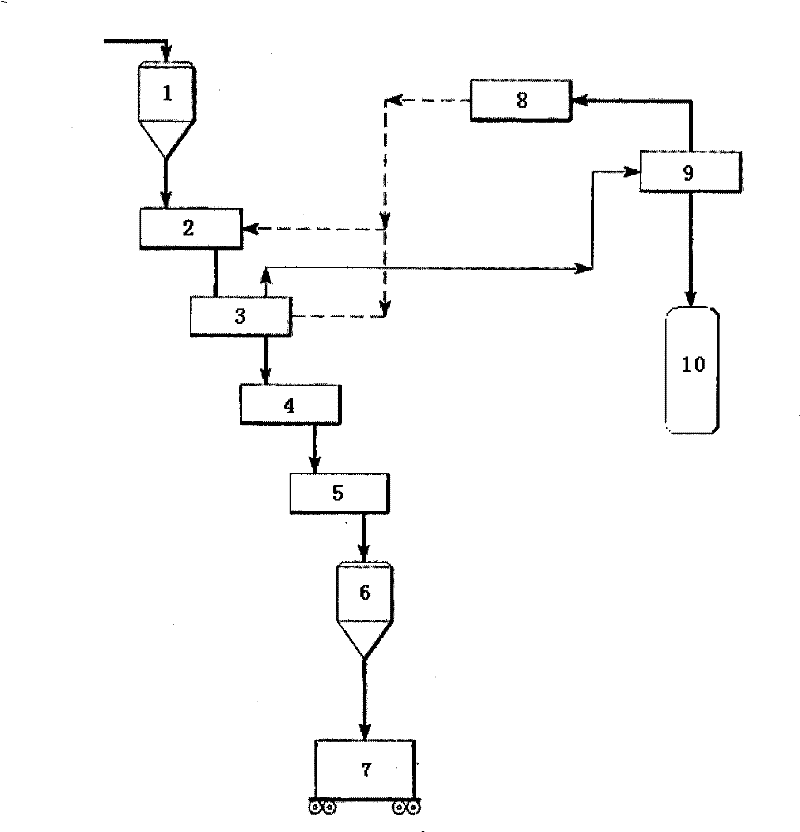

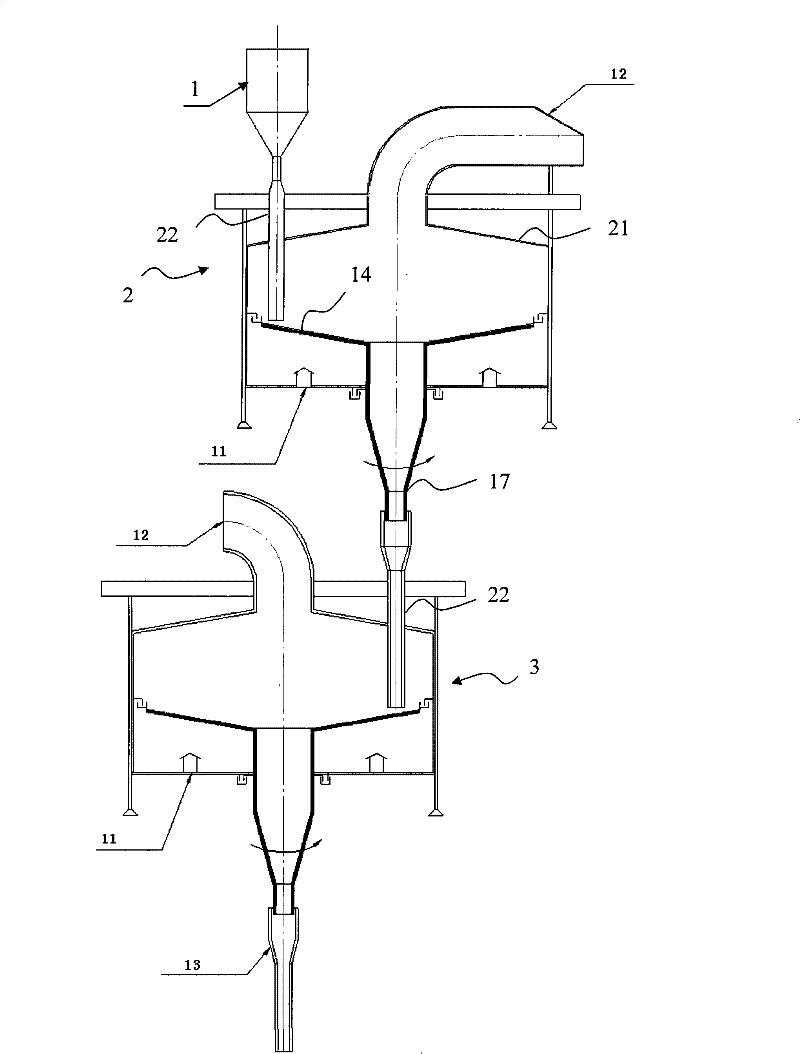

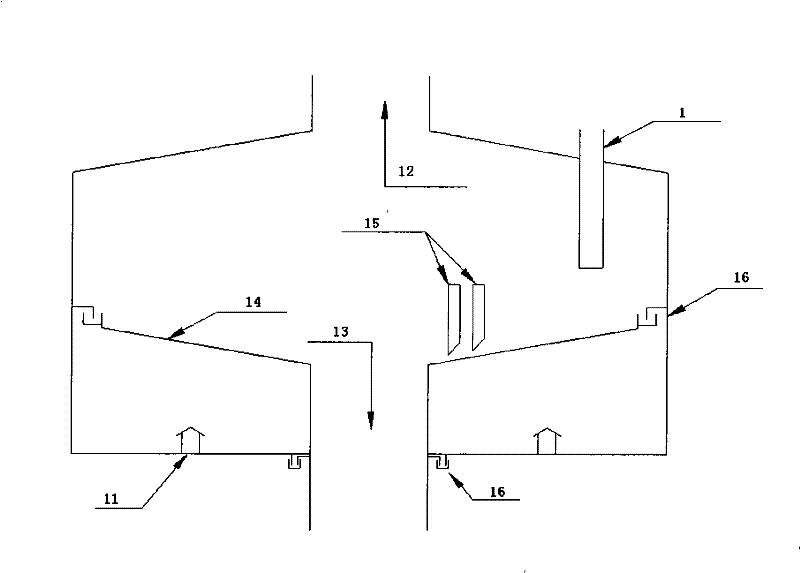

[0050] like figure 1 As shown, the flow process of the whole process of the present invention is: the raw coal through pulverization and sieving process is added in the drying reactor 2 through the coal feeding silo 1, and the raw coal particles are processed in the drying reactor 2 using an oxygen-deficient hot gas. Direct heat transfer drying, the dried coal sample enters the low-temperature carbonization reactor 3, and pyrolysis reaction occurs under the heating of oxygen-deficient hot gas, and the high molecular weight olefins in the gas generated during the pyrolysis reaction process are processed in the pyrolysis gas processing unit 9 is condensed to generate a high value-added liquid product (coal tar) which is collected in the storage tank 10, and the rest of the gas is ignited in the gas burner 8, and after being fully burned, it is used as a heating gas and circulated again in the process, while the pyrolysis reaction The coal material in the container is discharged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com