Method and system for controlling outlet temperature of coal mill of direct-fired pulverizing system

A technology of outlet temperature and milling system, which is applied in the direction of grain processing, etc., can solve the problems of time-consuming, economical impact, and real-time online adjustment, etc., to achieve the effect of improving operating economy, improving flexibility, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

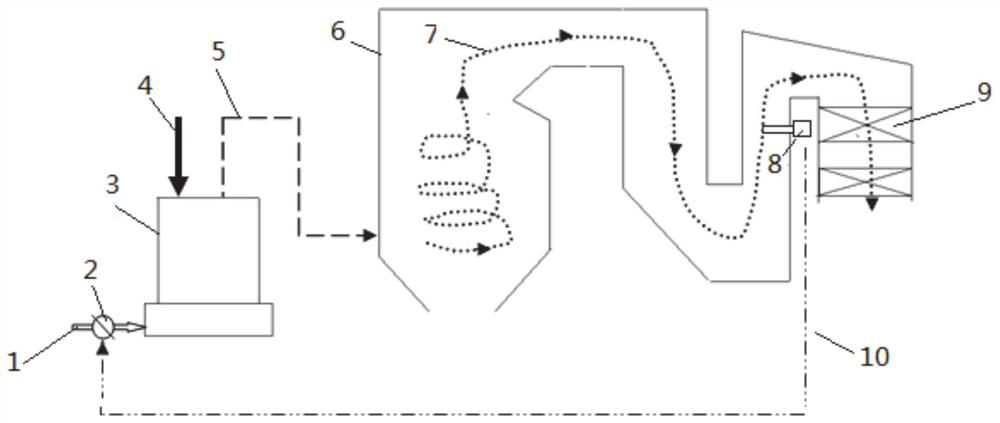

[0028] like figure 1 Distance

[0029] A control method of the exit temperature of the coal-blower system, including:

[0030] Gets the nitrogen oxide content of the inlet of the SCR denitration system;

[0031] The combustible volatile estimation model based on furnace coal-based volatile division and nitrogen oxide content relationship is established, and the combustible volatile estimation is determined by determining the nitrogen oxide amount of the combined volatile estimation model;

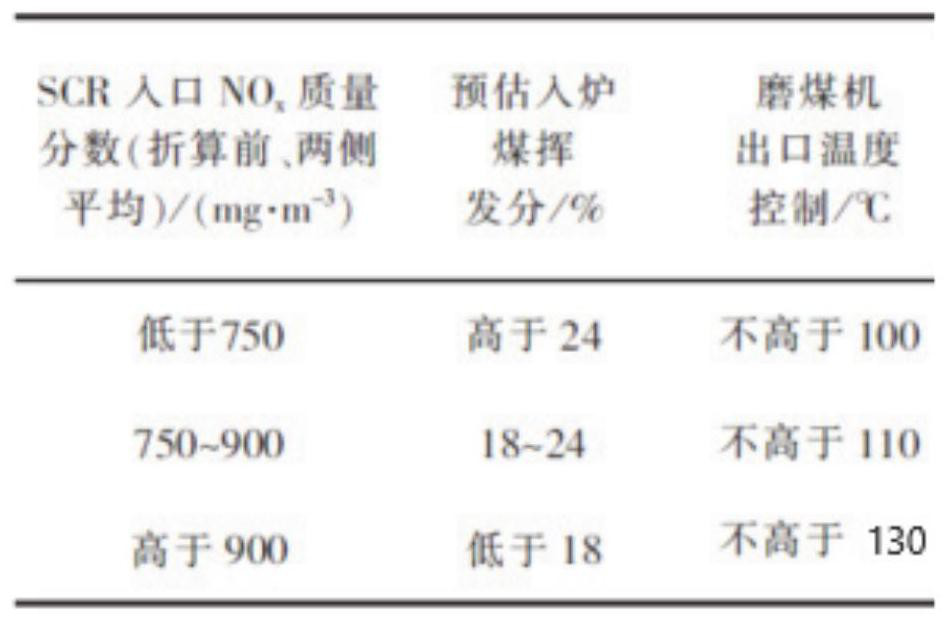

[0032] According to the combustible volatile estimation, the grinding machine outlet temperature control strategy is generated according to the control strategy, the grinding machine outlet temperature is adjusted according to the exit temperature control strategy of the grinding machine.

Embodiment approach

[0033] As a specific embodiment, the nitrogen oxynitride amount step of the inlet of the acquired SCR denitration system includes obtaining a nitrogen oxynitride amount of the SCR denitration system inlet by providing a nitrogen oxide detecting element in an inlet of the SCR denitration system. The nitrogen oxide detecting element can be a nitrogen oxide detector.

specific Embodiment approach

[0034] As another embodiment, the step of establishing an estimated model includes,

[0035] Gets the combustion-free volatile division of the coal sample under the baza load under the boiler load, and detects the amount of nitrogen oxide SCR denitration inlets that matches the time;

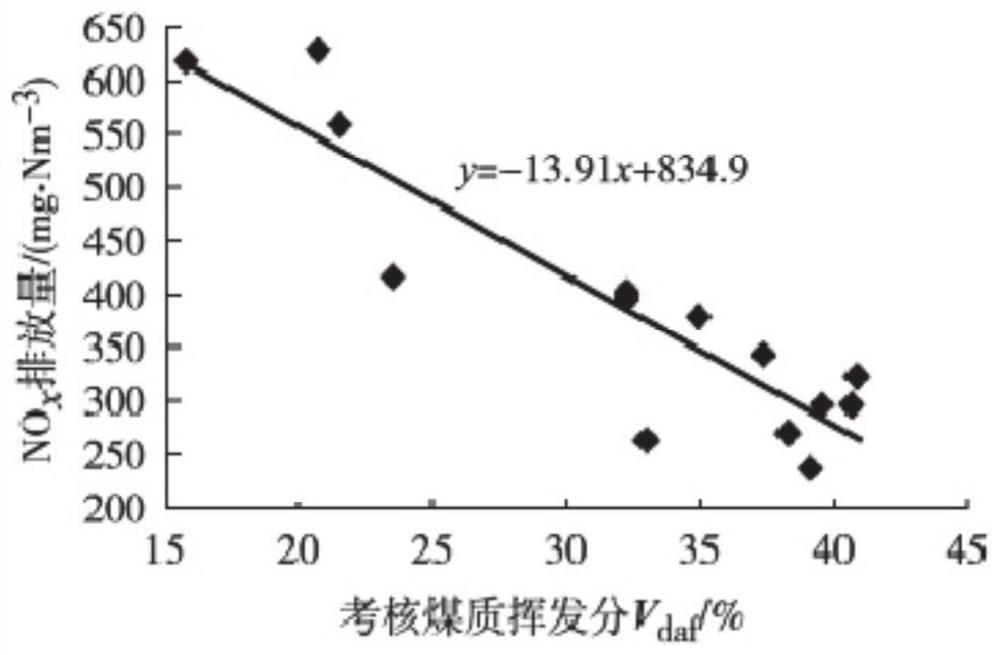

[0036] Adjust the boiler load, repeat the above step to achieve all the detection results under different boiler load, analyze the detection result to obtain the relationship between the inlet nitrogen oxynitride content of the boiler into the inlet. Xi'an Headquarters have indicated that the domestic 39 straight-blown powder system test data indicates that the coal-volatile is negatively correlated between the NOx of the SCR denitration system, that is, the amount of NOx is generated as volatile Decrease. The principle is that the most widely used low NOx combustion technique in the application of the most widely used boiler furnace is air grade combustion. It is targeted to reduce the amount of ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com