Preparation method for copper-ion ferrous sulfide cleaning agent, and cleaning method

A technology of ferrous sulfide and cleaning agent, which is applied in the field of preparation of copper ion ferrous sulfide cleaning agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, contents and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the examples.

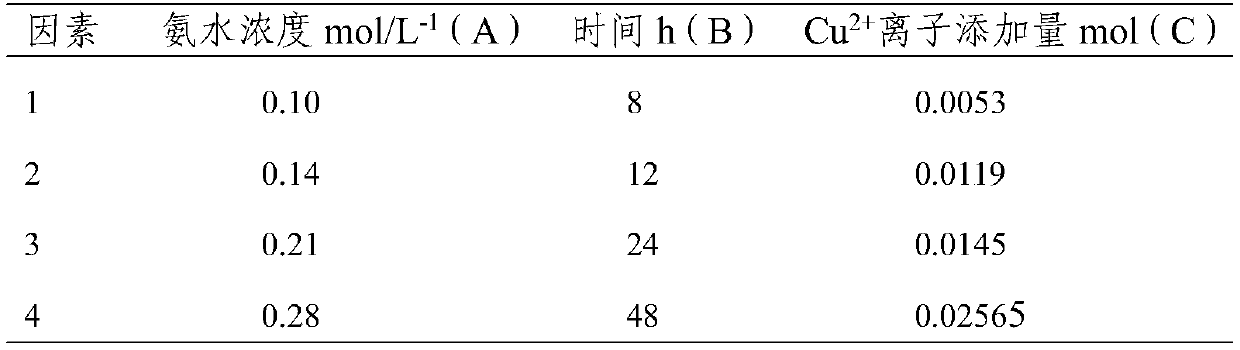

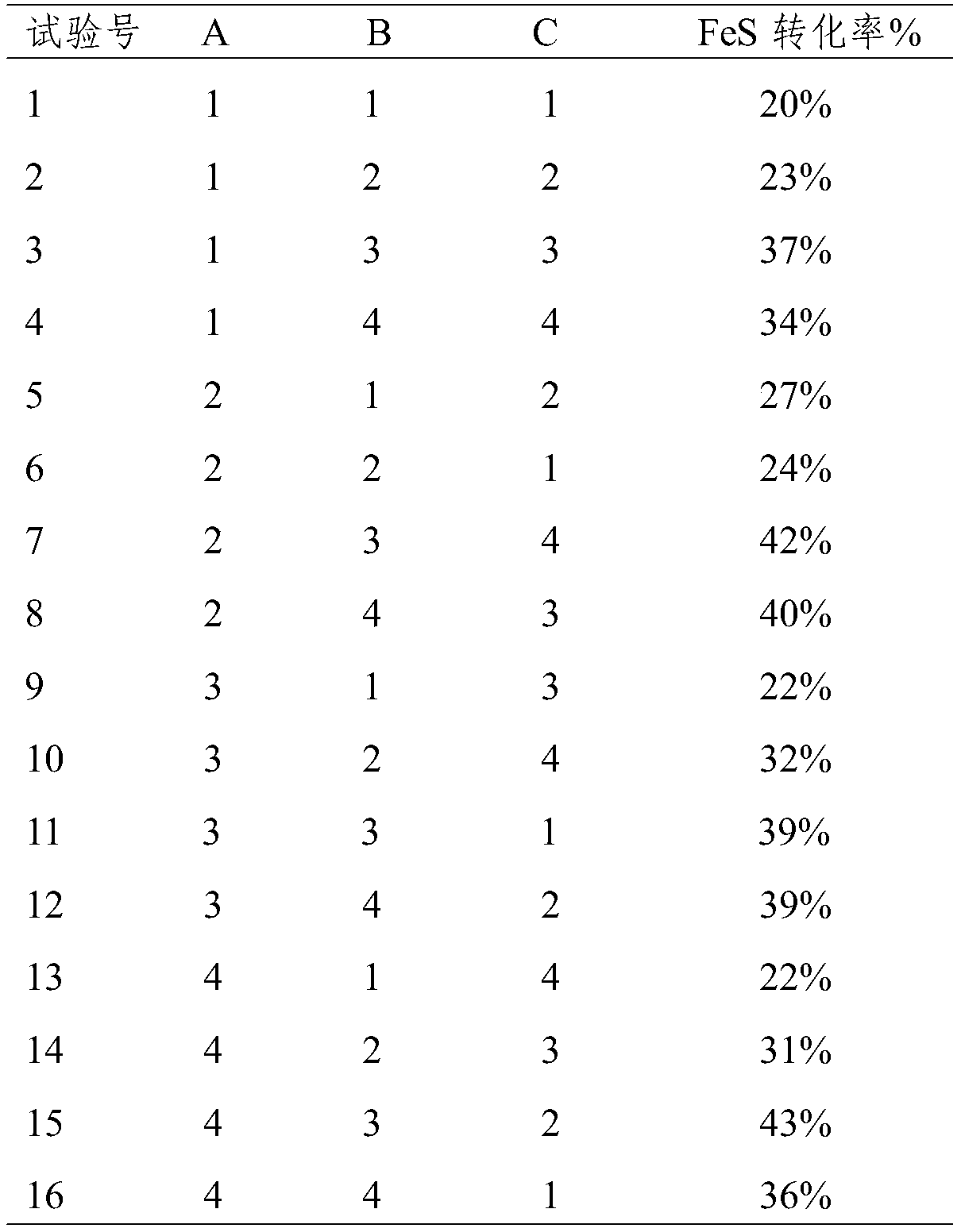

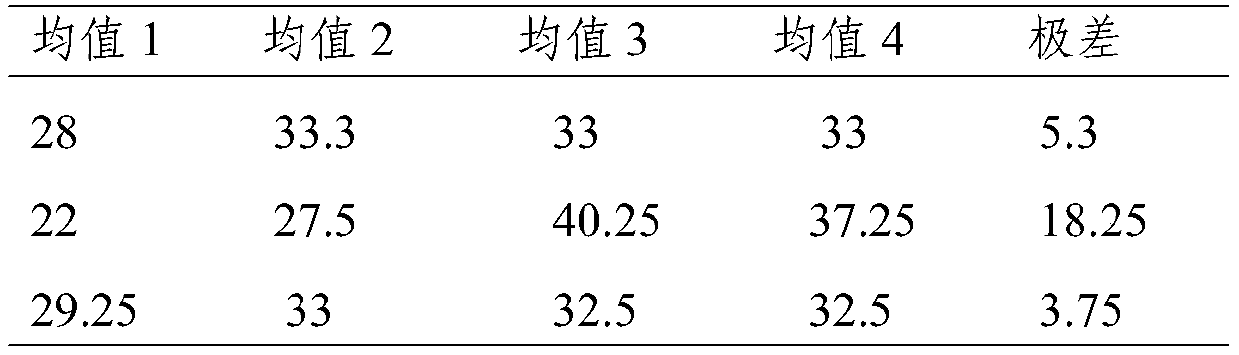

[0015] The present embodiment proposes a preparation method of copper ion ferrous sulfide cleaning agent, the preparation method comprises weighing CuSO 4 ·5H 2 O; CuSO 4 ·5H 2 O was dissolved in deionized water and NH was added 3 ·H 2 O, to obtain ferrous sulfide cleaning agent. Soluble Cu is added to the cleaning agent 2+ , making it dissociate from ferrous sulfide (FeS) S 2- Generate CuS precipitates, Fe 2+ Fe(OH) is formed after hydrolysis 3 precipitation. In order to reduce the corrosion of the cleaning agent to the equipment, Cu in the solution 2+ The concentration cannot be too high, Cu 2+ The ion concentration is 0.01~0.02mol / L, add ammonia water NH to the cleaning agent 3 ·H 2 O, NH 3 ·H 2 O concentration is 0.1~0.2mol / L, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com