Sulfur-free propellant and preparation method thereof

A propellant and weight technology, which is applied in the field of propellant, can solve the problems of high impact sensitivity and moisture absorption rate, high impact ignition rate, environmental pollution, etc., and achieve the effects of enhancing safety and stability, simple preparation method, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

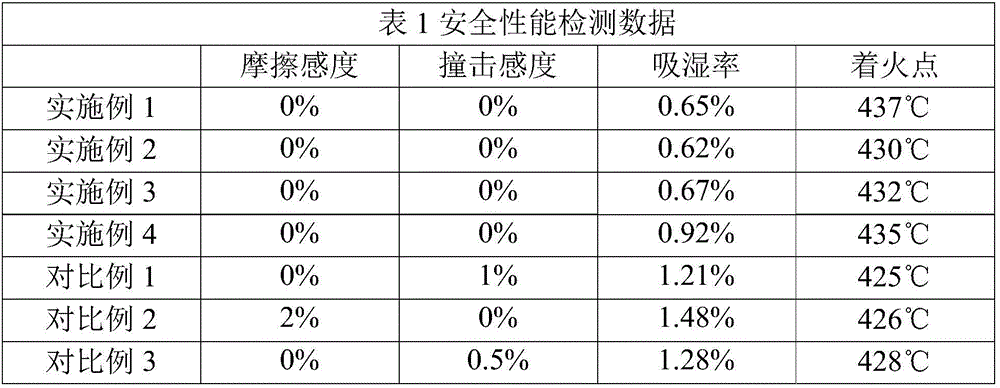

Examples

preparation example Construction

[0018] The present invention also provides a method for preparing sulfur-free propellants, the method comprising: stirring and mixing the filler, the binder, the calcium stearate and the potassium hydrogen phthalate into a powder, and then the powder was mixed with the potassium perchlorate to granulate and air-dried.

[0019] Preferably, the method further includes: sieving and / or pulverizing the granulated particles.

[0020] Preferably, the stirring and mixing is done in a blender.

[0021] Preferably, mixing said powder with said potassium perchlorate is done in a pharmaceutical mixer.

[0022] The above-mentioned stirring and mixing steps are respectively carried out by a blender and a medicine mixer, so that the preparation process is safer. The stirrer and medicine mixer can be conventional stirrers and medicine mixers in the art.

[0023] Specifically, the preparation method of sulfur-free propellant includes:

[0024] a), stirring the filler, the binder, the calci...

Embodiment 1

[0032] 12 parts by weight of hemp straw charcoal, 18 parts by weight of phenolic resin, 9 parts by weight of calcium stearate and 18 parts by weight of potassium hydrogen phthalate were stirred by a mixer to obtain powder.

[0033] Mix the powder and 43 parts by weight of potassium perchlorate through a drug mixer to obtain a mixed drug.

[0034] The mixed drug is granulated by a granulator to obtain sulfur-free propellant granules.

[0035] Sieve the sulfur-free propellant particles through a standard sieve. The standard sieve is divided into upper and lower layers, among which, the upper layer is a standard sieve with a sieve hole of 6mm; the lower layer is a standard sieve with a sieve hole of 4mm. Sulfur-free propellant particles with a particle size larger than 6mm that have not passed the screening are re-screened after crushing, and the sulfur-free propellant particles with a particle size smaller than 4mm are returned to the granulator for re-granulation under a 4mm s...

Embodiment 2

[0038] 13 parts by weight of hemp straw charcoal, 17 parts by weight of phenolic resin, 8 parts by weight of calcium stearate and 24 parts by weight of potassium hydrogen phthalate were stirred by a mixer to obtain powder.

[0039] Mix the powder and 38 parts by weight of potassium perchlorate through a drug mixer to obtain a mixed drug.

[0040] The mixed drug is granulated by a granulator to obtain sulfur-free propellant granules.

[0041] Sieve the sulfur-free propellant particles through a standard sieve. The standard sieve is divided into upper and lower layers, among which, the upper layer is a standard sieve with a sieve hole of 6mm; the lower layer is a standard sieve with a sieve hole of 4mm. The sulfur-free propellant particles with a particle size larger than 6mm that have not passed the screening are re-screened after crushing, and the sulfur-free propellant particles with a particle size smaller than 4mm are returned to the granulator for re-granulation under a 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com