Propellant for fireworks and crackers

A technology for fireworks and propellants, which is applied to explosives, inorganic oxyhalogen salt explosive compositions, offensive equipment, etc., can solve the problems of strong hygroscopicity, waste, general use effect, etc., achieve simple production process, simple preparation process, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

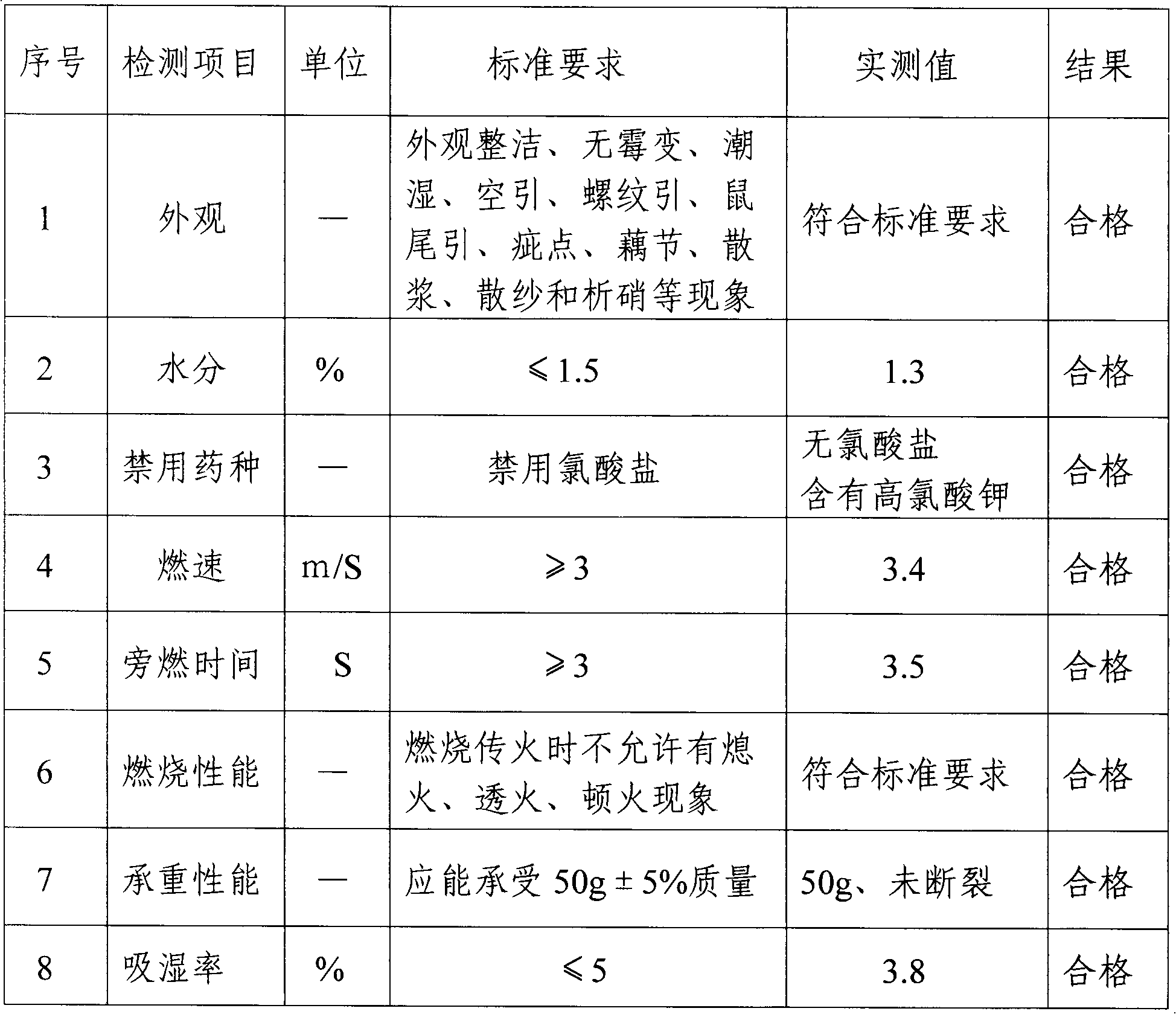

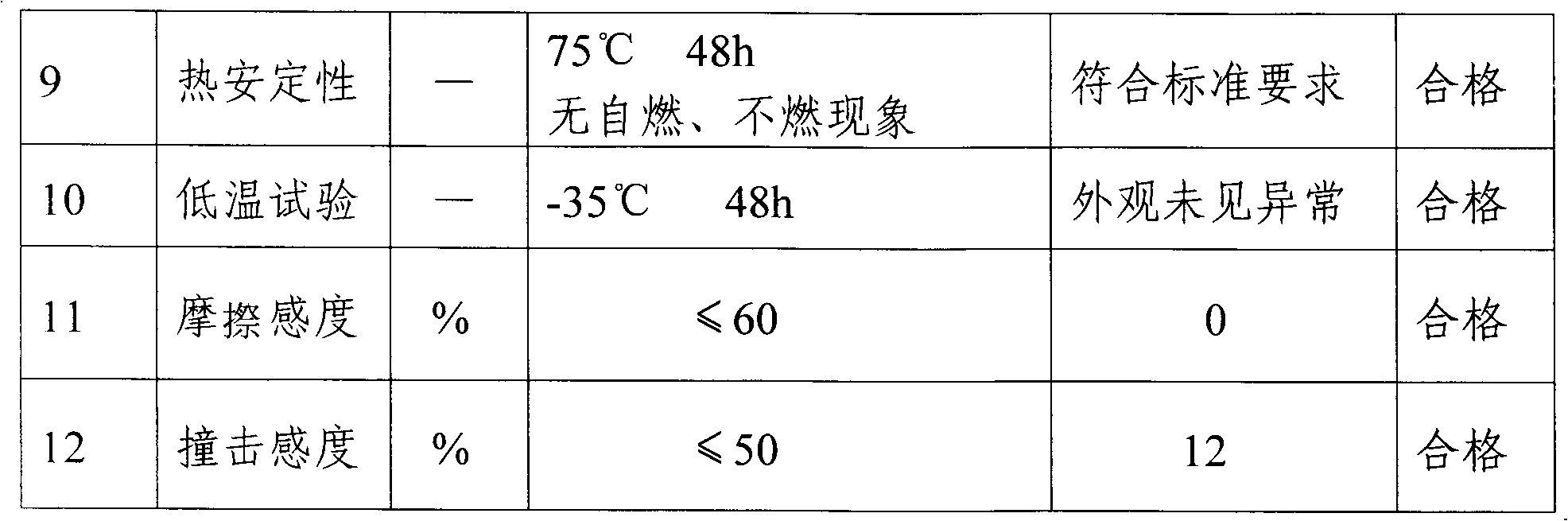

Image

Examples

Embodiment 1

[0035] This embodiment is made of the following raw materials in mass percentage: 41% potassium perchlorate, 17% hemp stalk charcoal, 15% sulfur, 17% additive, 0.3% strong agent powder, 9.7% water, and the additive is magnesium carbonate. The strong agent powder is glutinous rice flour or flour.

[0036] The manufacturing process includes the following steps:

[0037] (1) Potassium perchlorate, hemp stalk charcoal, sulfur and additive magnesium carbonate are uniformly mixed by a drug mixing machine according to the above mass percentage to obtain a mixed drug powder.

[0038] (2) Add strong agent powder and water to the mixed medicinal powder obtained in step (1), stir and press into medicinal cake.

[0039] (3) The medicine cake in the step (2) is granulated, and the particles are dried and then polished and screened to obtain the propellant for fireworks and firecrackers.

Embodiment 2

[0041] This embodiment is made of the following raw materials in mass percentage: 41% potassium perchlorate, 12% hemp charcoal, 15% sulfur, 22% additives, 0.2% strong agent powder, and 9.8% water. The additives and strengthening agent powder in this embodiment are all the same as in Embodiment 1.

[0042] The manufacturing process of the fireworks and firecracker propellants in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0044] This embodiment is made of the following raw materials in mass percentage: 46% potassium perchlorate, 22% hemp charcoal, 10% sulfur, 12% additives, 0.4% strong agent powder, and 9.6% water. The additives and strengthening agent powder in this embodiment are all the same as in Embodiment 1.

[0045] The manufacturing process of the fireworks and firecracker propellants in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com