Non-lethal payloads and methods of producing same

a non-lethal and formulation technology, applied in the field of formulations, can solve the problems of ineffective non-lethal payload including only powdered metal as the illuminant is not efficient, and the risk of permanent injury is calculated,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

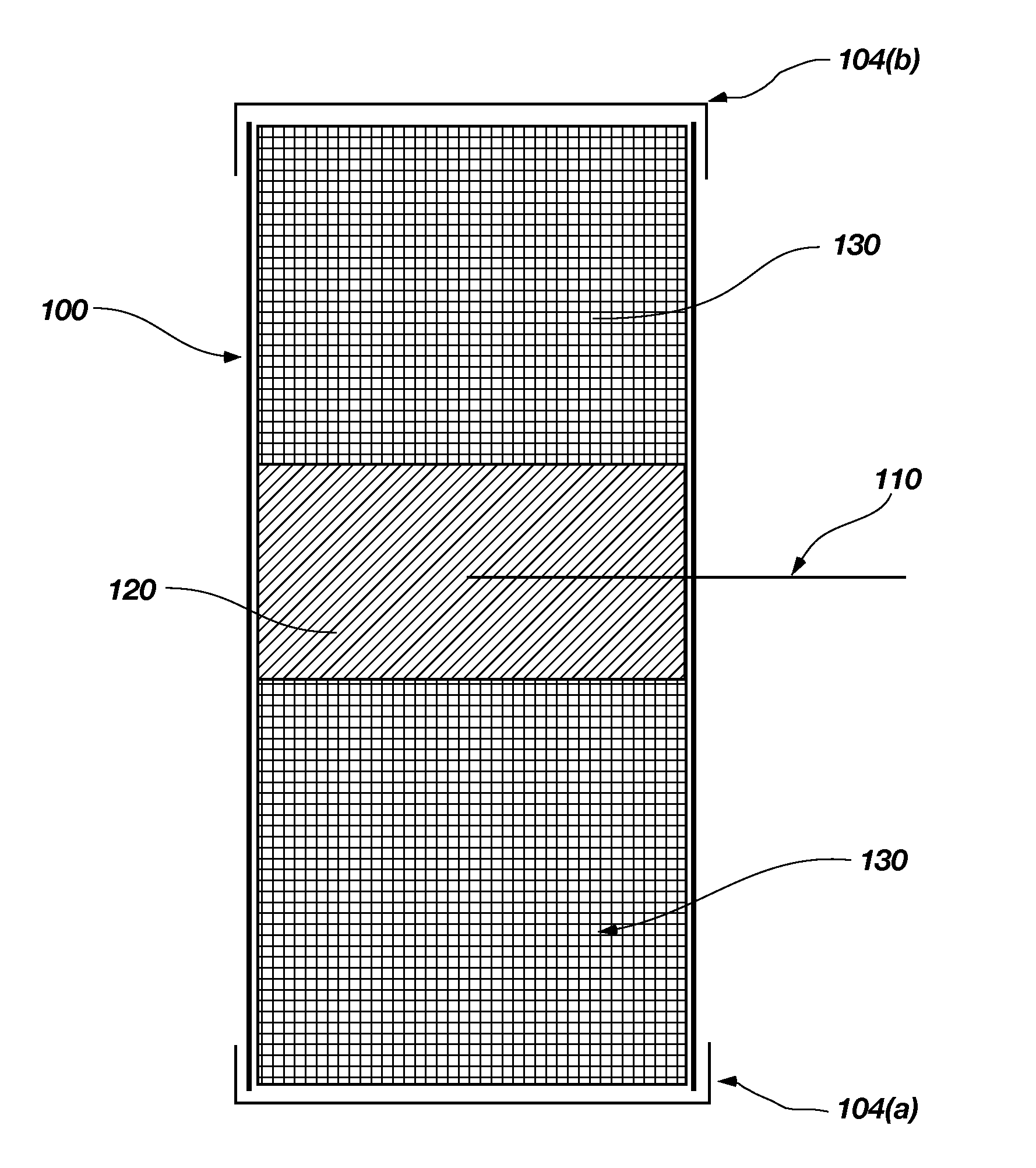

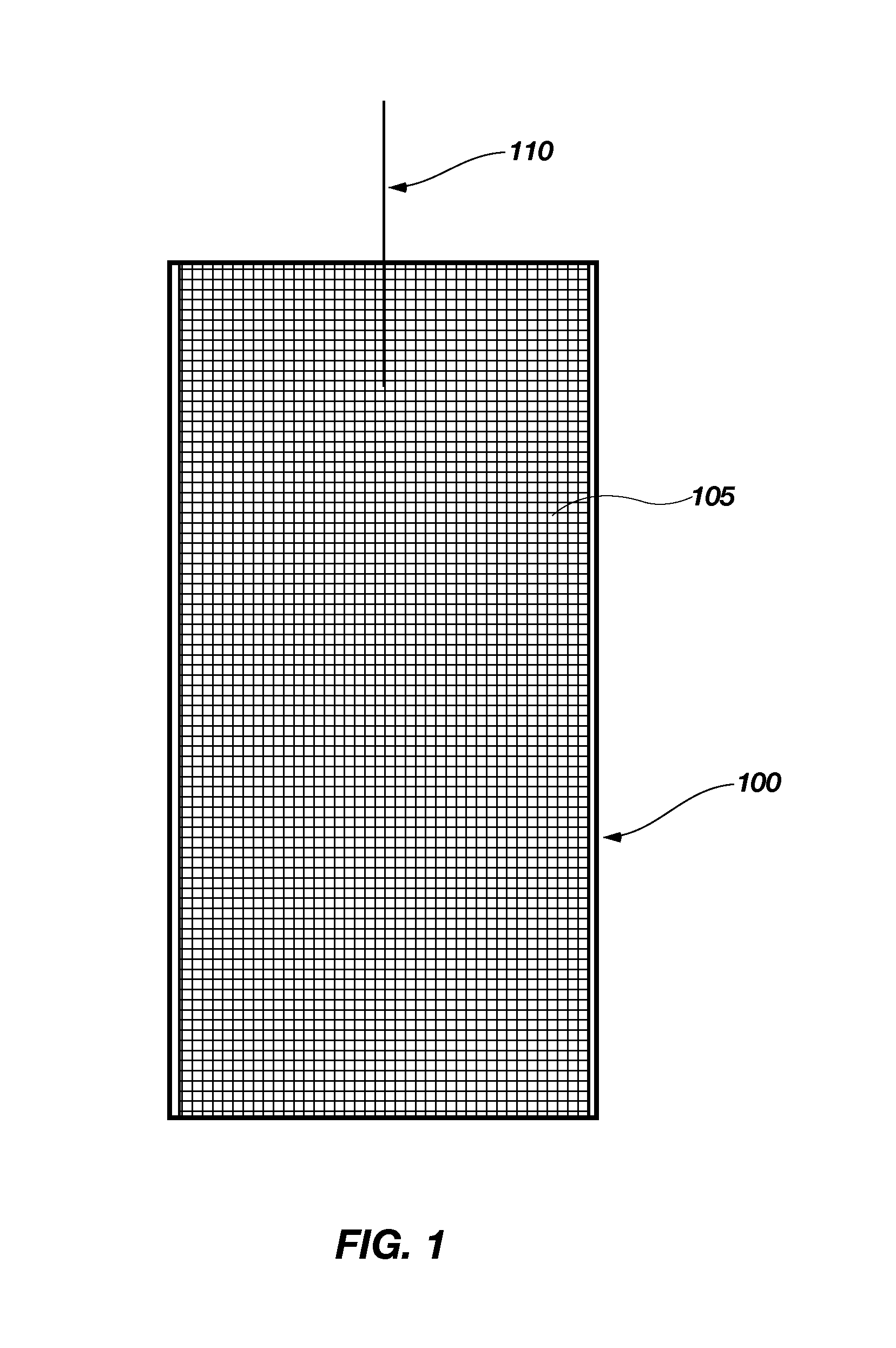

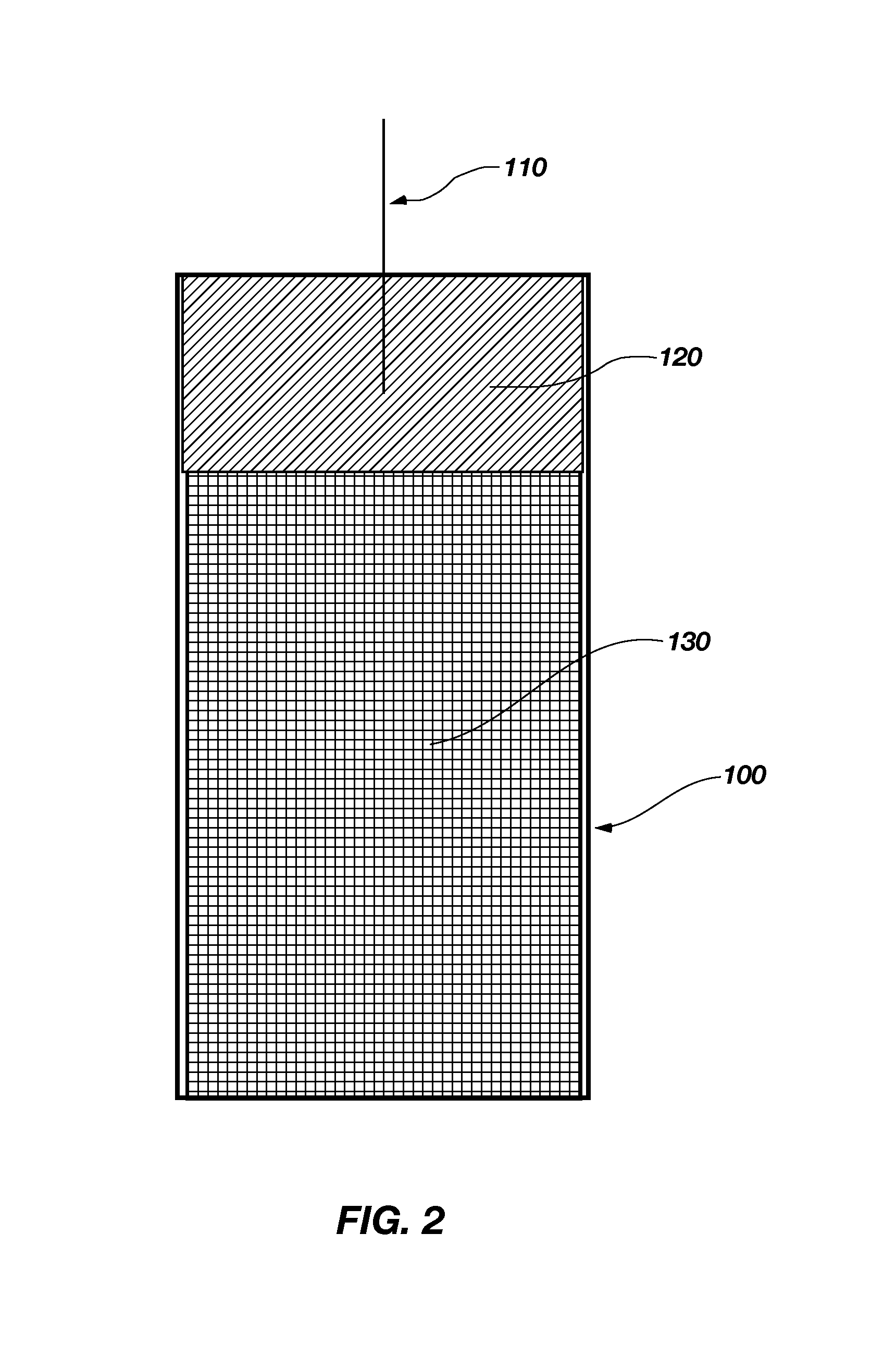

Image

Examples

example 1

Cylindrical Test Vehicle Performance

[0046]Formulations A-C were tested in a cylindrical test vehicle in which the igniter was placed in a central flash tube fabricated with sixteen outlet holds. The outer diameter of the flash tube was sealed with a wrapping of aluminum tape to block the holes in the flash tube and prevent leakage of the igniter into an annulus of the flash tube. The illuminant was loaded into the annulus between the flash tube and an outer body of the test vehicle. An electric match was inserted into the flash tube through the top of the test vehicle to activate the test vehicle. Cameras and test gauges were set up surrounding the test vehicle according to measure the flash intensity and the magnitude of the pressure impulse upon activation of the test vehicle. The cameras and test gauges used to measure the flash intensity and pressure impulse were set up according to conventional techniques.

[0047]The flash intensity and pressure impulse of Formulations A-C were d...

example 2

Shotshell Test Vehicle Performance

[0049]The pressure and light output for non-lethal payload formulations was tested in 12-gauge shotshells as the test vehicle. The formulations included Formulation B as described above. For comparison, a formulation including a granular mix (70:30) of Mg / Sr(NO3)2 (available from Alliant Techsystems Inc. as UIX 191) and B / KNO3 (available from Alliant Techsystems Inc. as UIX 156) as the igniter, and 59.3 wt % magnesium, 32.7 wt % B / KNO3 (available from Alliant Techsystems Inc. as UIX 156), and 8 wt % Mg / Sr(NO3)2 (available from Alliant Techsystems Inc. as UIX 191) was prepared and is designated below as Formulation D. An additional formulation lacking boron in the illuminant was also produced and is designated below as Formulation E. Formulation E included 13.4 wt % KNO3, 76.6 wt % magnesium, and 10 wt % Sr(NO3)2 as the illuminant, and 21 wt % KNO3, 38 wt % magnesium, 33 wt % Sr(NO3)2, and 8 wt % B as the igniter. Formulation E differed from Formulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com