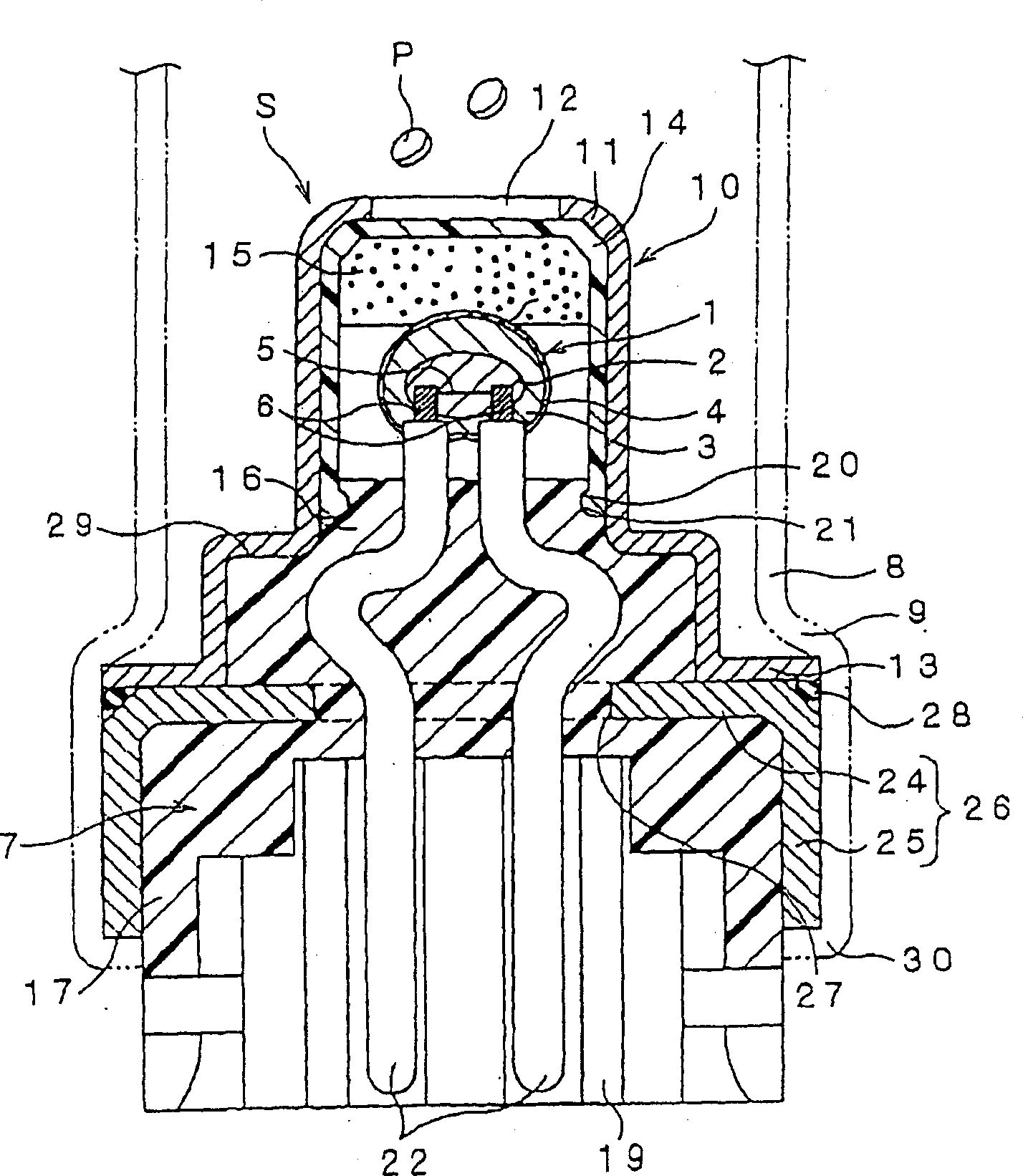

Igniting agent composition and ignitor using same

A technology of igniting agent and composition, which is applied in the direction of inorganic oxyhalogen salt explosive composition, ignition device, belt tightener, etc., and can solve problems such as delayed expansion or development, mis-ignition, and decreased ignition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

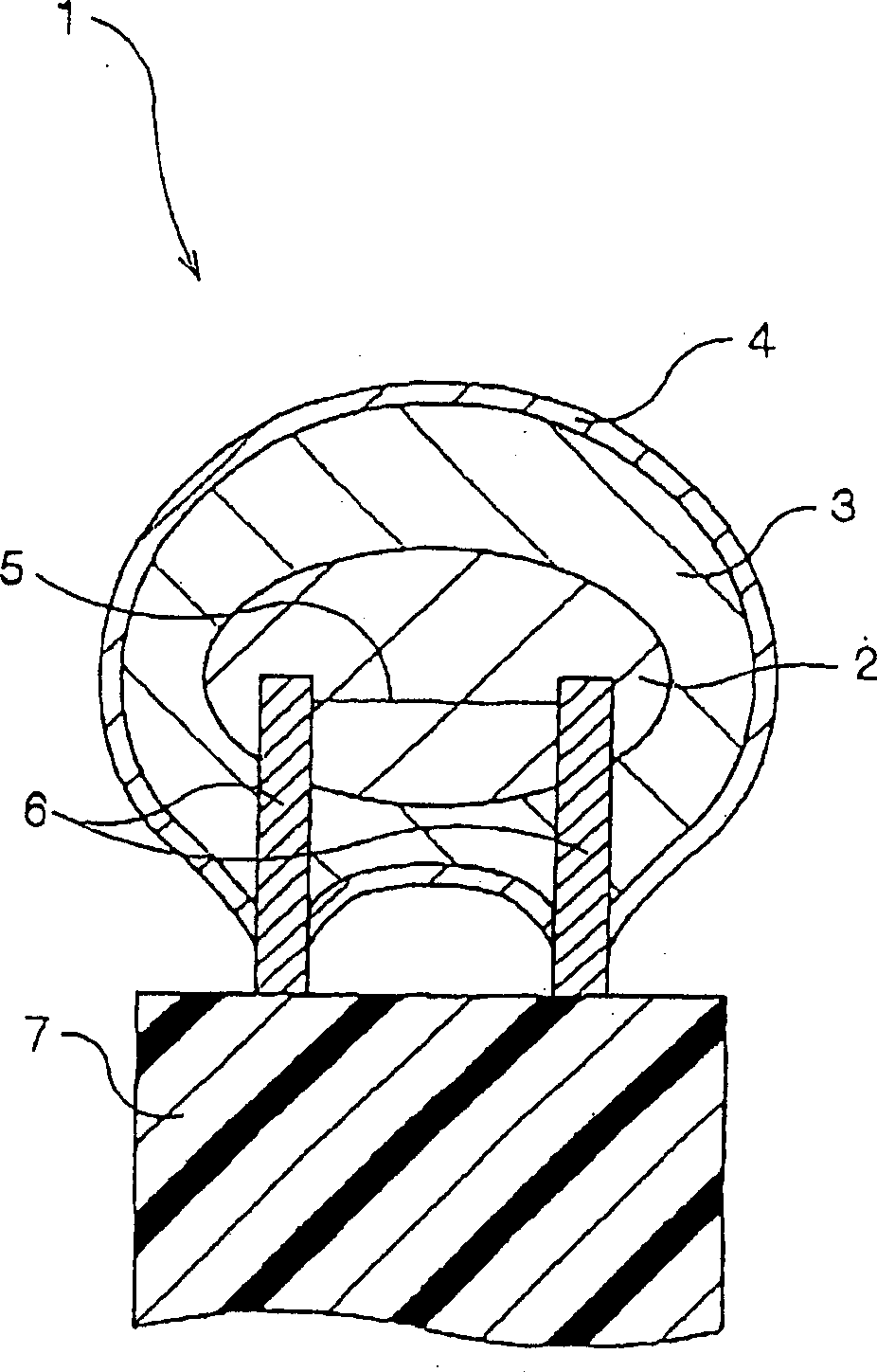

[0062] 40 parts by mass of basic copper nitrate, 60 parts by mass of zirconium and 5 parts by mass of nitrocellulose were dissolved in 100 parts by mass of isoamyl acetate and mixed. This mixture was applied to the surface of an arc-shaped wire, on which it was dried and cured to form a layer of igniter, and this surface was coated with a vinyl acetate-based resin (manufactured by Eastman Chemical Co., Ltd.) to form a coating, so that A fuse tip was made and a plug was fitted into the cup containing the transfer load to form the igniter.

Embodiment 2

[0064] 50 parts by mass of basic copper nitrate, 50 parts by mass of zirconium and 5 parts by mass of nitrocellulose were dissolved in 100 parts by mass of isoamyl acetate and mixed. This mixture was applied to the surface of an arc-shaped wire, on which it was dried and cured to form a layer of igniter, and this surface was coated with a vinyl acetate-based resin (manufactured by Eastman Chemical Co., Ltd.) to form a coating, so that A fuse tip was made and a plug was fitted into the cup containing the transfer load to form the igniter.

Embodiment 3

[0066] 50 parts by mass of basic copper nitrate, 50 parts by mass of zirconium and 5 parts by mass of polyvinyl acetate were dissolved in 100 parts by mass of isoamyl acetate and mixed. This mixture was applied to the surface of an arc-shaped wire on which it dried and cured to form an igniter layer, and the surface was coated with a vinyl acetate-based resin (manufactured by Eastman Chemical Co., Ltd.) to form a coating, thus producing Got the fuse tip and plugged it into the cup containing the transfer load to form the igniter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com