Layered catalyst for selectively oxidizing 4-methylguaiacol-to-vanillin, and preparation method thereof

A technology of methyl guaiacol and layered catalyst is applied in the preparation of organic compounds, catalysts for physical/chemical processes, catalysts for organic compounds/hydrides/coordination complexes, etc. The catalyst and the product are difficult to separate and other problems, to achieve the effect of easy separation and purification, strong industrial application value and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

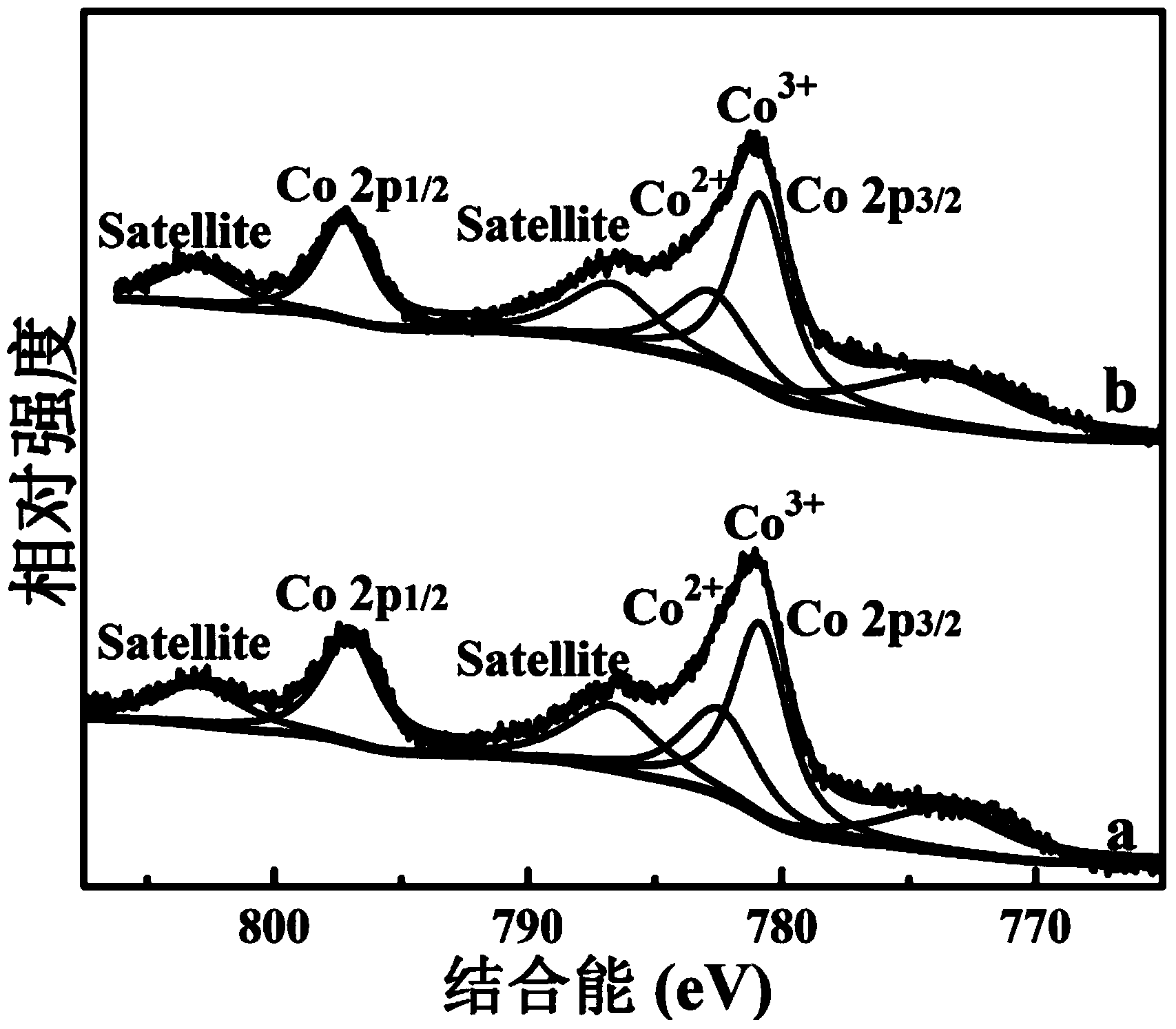

[0033] Cobalt-nickel-aluminum layered hydrotalcite catalysts intercalated with carbonate (Co-Ni-Al-CO 3 2- What the preparation of -LDHs) adopts is dynamic urea method, and its preparation method is: first, accurately weigh reactant Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O,Al(NO 3 ) 3 9H 2 O and (NH 2 ) 2 CO was added to 700mL of deionized water in turn, so that the Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.5mol / L, Ni(NO 3 ) 2 ·6H 2 The concentration of O is 0.5mol / L, Al(NO 3 ) 3 9H 2 The concentration of O is 0.5mol / L, (NH 2 ) 2 The concentration of CO is 0.2 mol / L. Stir to fully dissolve various reactants in deionized water, and heat and stir in an oil bath at 130°C for 48 hours; then, the obtained cobalt-nickel-aluminum layered water Talc Co-Ni-Al-CO 3 2- -LDHs are first filtered and washed with deionized water, and then washed with absolute ethanol, after repeated operations and washings; finally, the cobalt-nickel-aluminum layered hydrotalcite c...

Embodiment 2

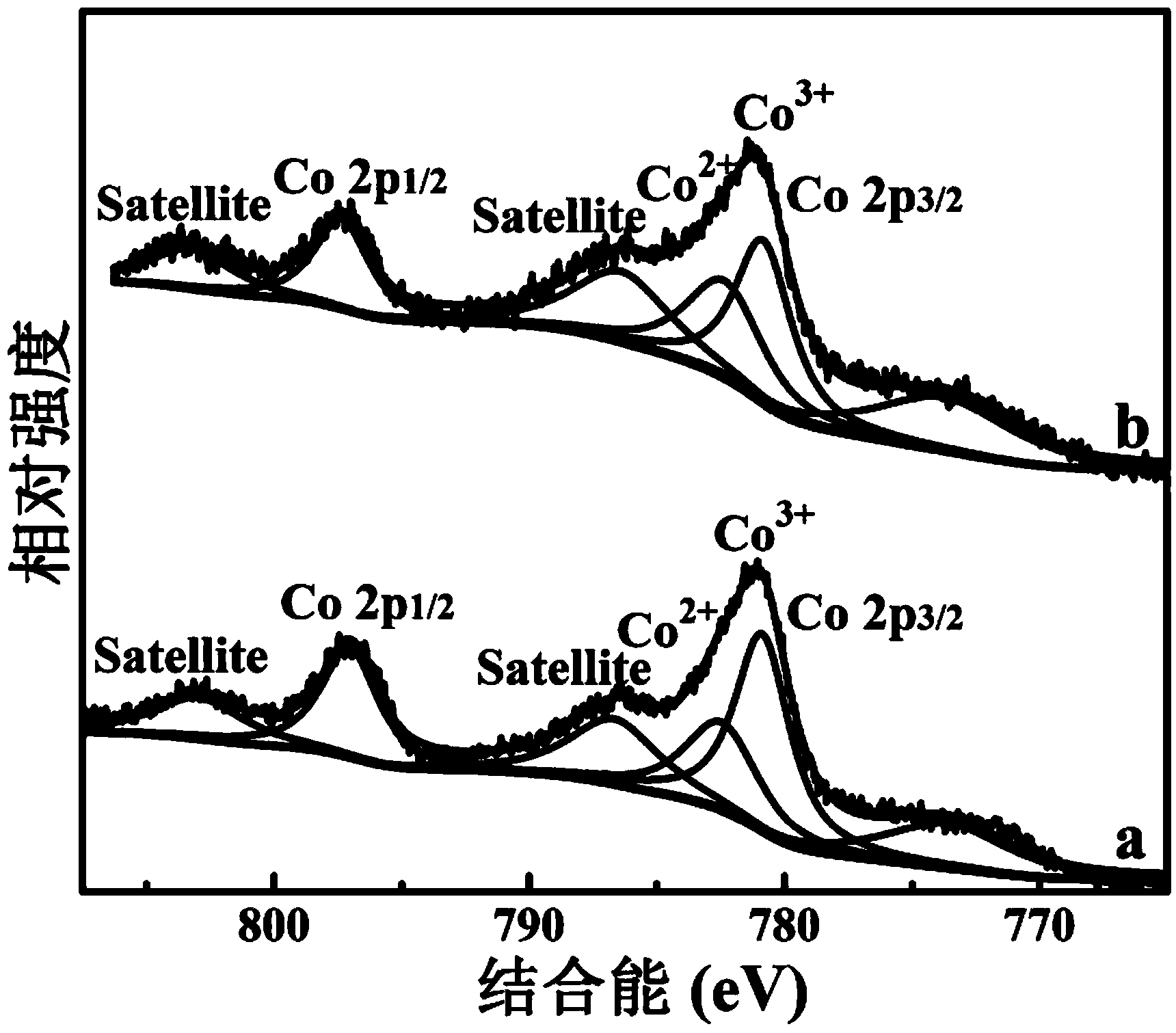

[0036] The preparation method of dodecylsulfonate intercalated cobalt-nickel-iron intercalated hydrotalcite catalysts (Co-Ni-Fe-DS-LDHs): first, the precursor carbonate-intercalated cobalt-nickel-iron layered hydrotalcites were synthesized by dynamic urea method. Talc catalyst (Co-Ni-Fe-CO 3 2- -LDHs), followed by the synthesis of dodecylsulfonate intercalated hydrotalcite catalysts (Co-Ni-Fe-DS-LDHs) using an ion-exchange method.

[0037] (A) Carbonate-intercalated cobalt-nickel-iron layered hydrotalcite catalyst (Co-Ni-Fe-CO 3 2- -LDHs) preparation

[0038] First, accurately weigh the reactants Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, NH 4 F and (NH 2 ) 2 CO was sequentially added to 120mL of deionized water for reaction, so that the Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.08mol / L, Ni(NO 3 ) 2 ·6H 2 The concentration of O is 0.03mol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 0.04mol / L, NH 4 The concentration of F is 0.02...

Embodiment 3

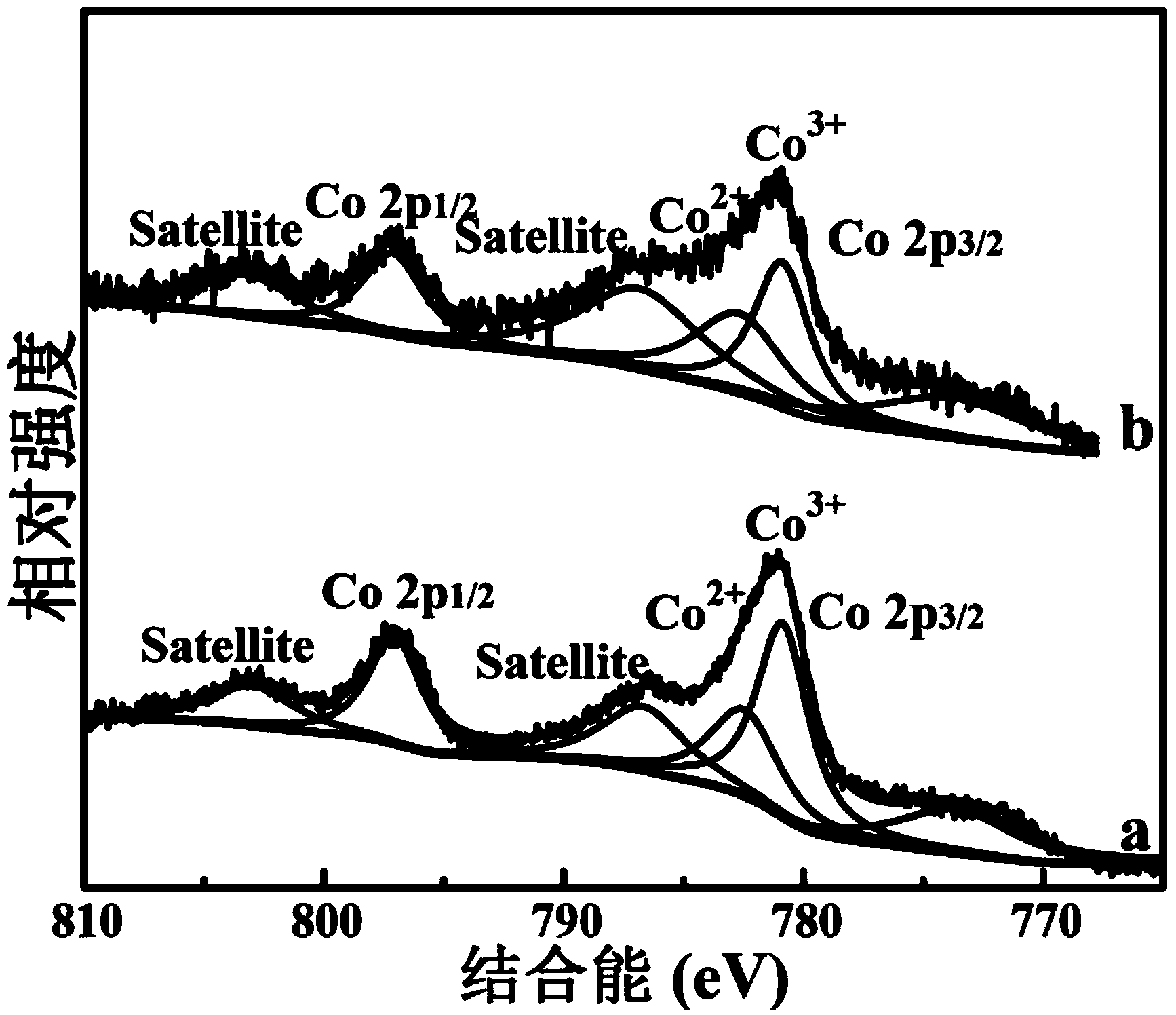

[0043] Preparation method of cobalt-nickel-iron-iron-samarium intercalated hydrotalcite catalyst (Co-Ni-Fe-Sm-DS-LDHs) intercalated with dodecylsulfonate: first, the precursor carbonate-intercalated cobalt-nickel-iron was synthesized by dynamic urea method Samarium layered hydrotalcite catalyst (Co-Ni-Fe-Sm-CO 3 2--LDHs), followed by the synthesis of dodecylsulfonate-intercalated cobalt-nickel-iron-samarium hydrotalcite catalysts (Co-Ni-Fe-Sm-DS-LDHs) using an ion-exchange method.

[0044] (A) Cobalt nickel iron samarium layered hydrotalcite catalyst intercalated with carbonate (Co-Ni-Fe-Sm-CO 3 2- -LDHs) preparation

[0045] First, accurately weigh the reactants Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Sm(NO 3 ) 3 ·6H 2 O, NH 4 F and (NH 2 ) 2 CO was sequentially added to 120mL of deionized water for reaction, so that the Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.08mol / L, Ni(NO 3 ) 2 ·6H 2 The concentration of O is 0.03mol / L, F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com