Sulfur-free propellant powder

A technology of propellant and parts by weight, used in inorganic oxyhalide salt explosive compositions, explosives, offensive equipment and other directions, can solve problems such as large combustion smoke and pollute the environment, achieve low moisture absorption rate, eliminate pollution, and excellent storage stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

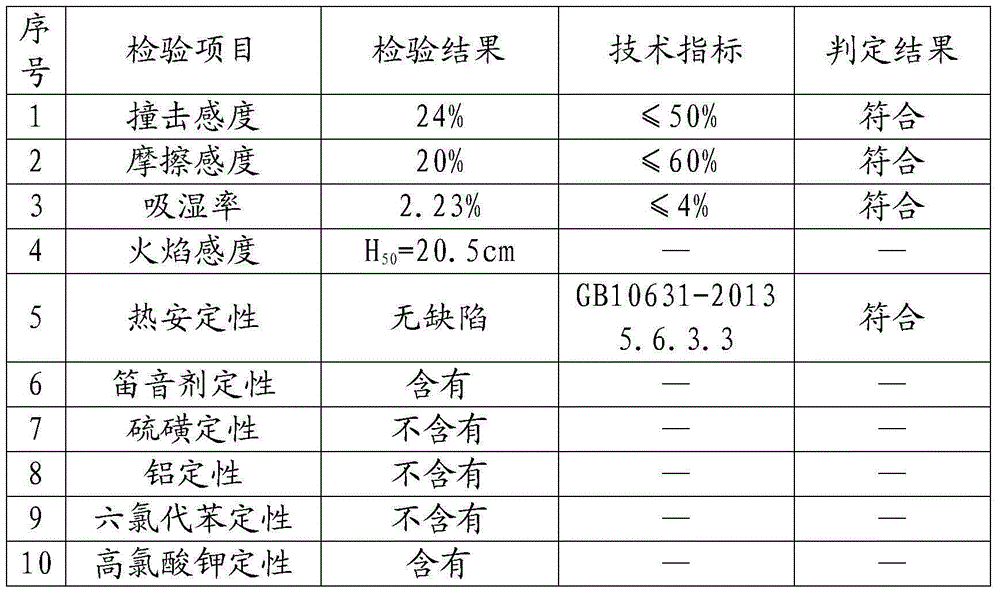

Examples

Embodiment 1

[0008] Embodiment 1: The preparation of described sulfur-free propellant comprises the following steps: take by weight 35 parts of potassium perchlorate, 25 parts of carbon powder, 8 parts of calcium stearate, 5 parts of phenolic resin, 15 parts of hydroxyethyl cellulose Parts, 17 parts of polytetrafluoroethylene. Sieve to mix evenly. If granulation is required, add an appropriate amount of organic solvent, granulate, dry, sieve and pack, and the production is completed.

Embodiment 2

[0009] Embodiment 2: the preparation of described sulfur-free propellant comprises the following steps: take by weight 34 parts of potassium perchlorate, 24 parts of carbon powder, 7 parts of calcium stearate, 4 parts of phenolic resin, 14 parts of hydroxyethyl cellulose Parts, 16 parts of polytetrafluoroethylene. After sieving and mixing evenly, adding an appropriate amount of organic solvent, granulating, drying, sieving and packaging, the production is completed.

Embodiment 3

[0010] Embodiment 3: the preparation of described sulfur-free propellant comprises the following steps: take by weight 36 parts of potassium perchlorate, 26 parts of carbon powder, 9 parts of calcium stearate, 6 parts of phenolic resin, 16 parts of hydroxyethyl cellulose Parts, 18 parts of polytetrafluoroethylene. After sieving and mixing evenly, adding an appropriate amount of organic solvent, granulating, drying, sieving and packaging, the production is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com