Auto-igniting pyrotechnic booster composition

a technology of pyrotechnic booster and composition, which is applied in the direction of inorganic oxygen-halogen salt explosive composition, weapons, etc., can solve the problem of low overall cost, achieve improved inflator performance, facilitate increased heat conduction, and simplify the inflator design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

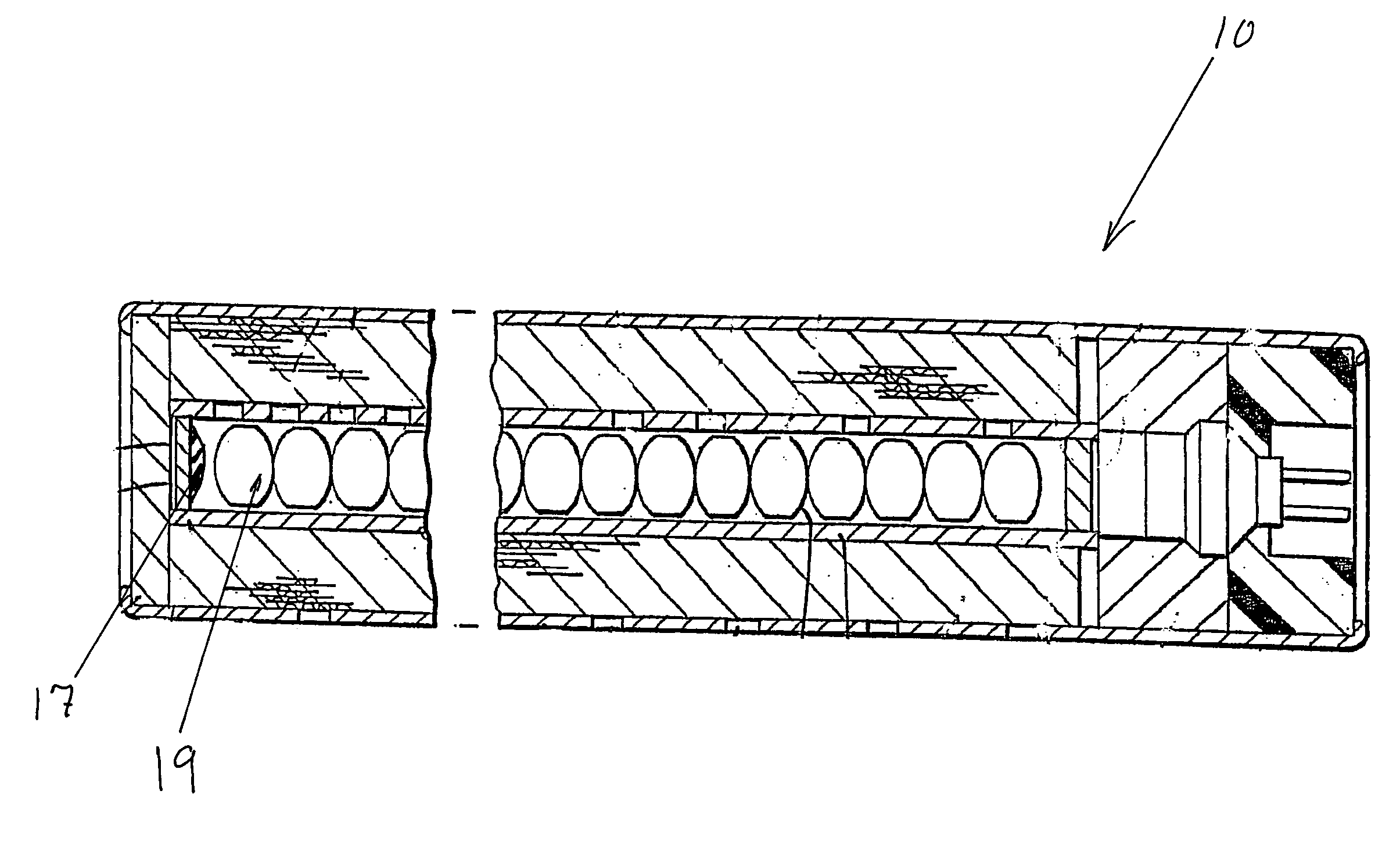

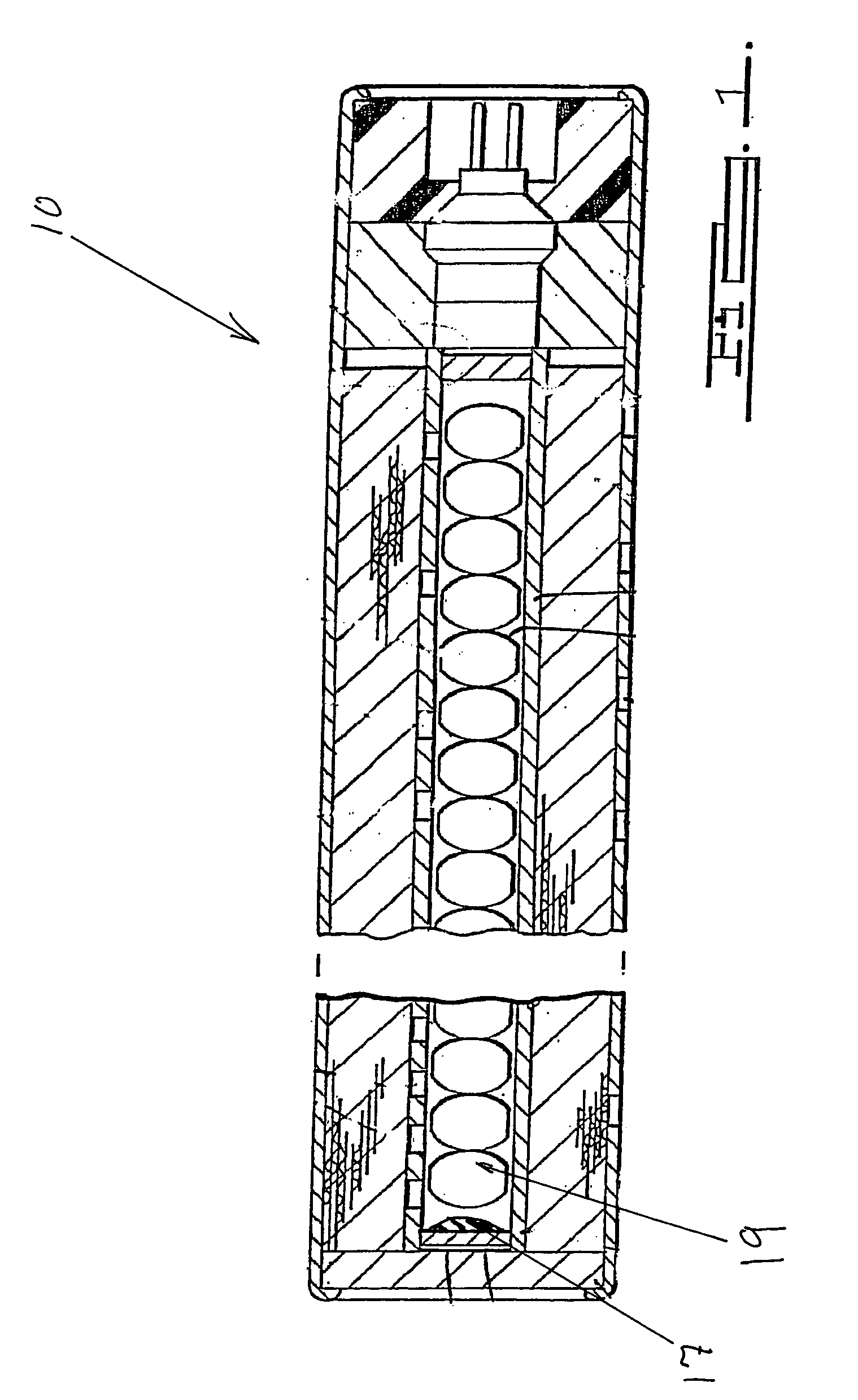

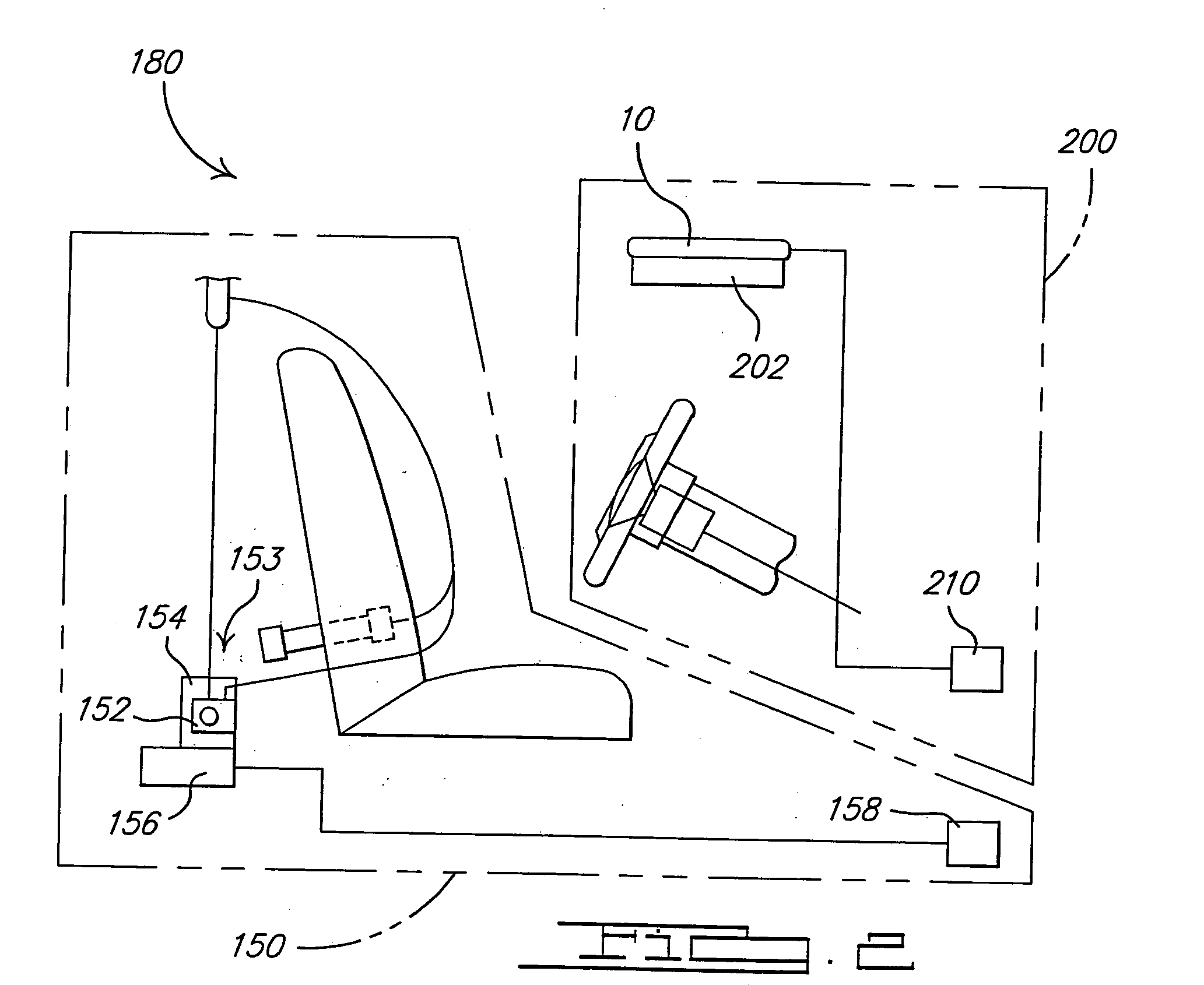

Image

Examples

Embodiment Construction

[0011] An auto-ignition component of the present invention includes a fuel, an oxidizer and an optional fuel / binder that self-ignites at a specific temperature. A fuel is preferably selected from sugars such as d-glucose and organic acids such as tartaric acid at about 15-45 weight percent of the composition. Exemplary organic acids include the various enantiomers of tartaric acid, malic acid, succinic acid, diglycolic acid, malonic acid, trans-glutaconic acid, adipic acid, mucic acid, 2,2-Bis(hydroxymethyl) propionic acid, citric acid, phenylmalonic acid, and quinic acid. Exemplary enantiomers of this group include D-tartaric acid, DL-tartaric acid, Meso-tartaric acid, D-glutamic acid, and D-quinic acid. The organic acid should preferably have a melting point ranging from about 125 to about 250° C. and pass a heat aging test at 107° C. for 400 hours. Typically, the material to be heat aged may be sealed in a glass vial and placed in an oven for 400 hours at 107° C. Or, the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com