Sulfur-free firework propellant

A technology for propellant and sulfur fireworks, applied in the field of pyrotechnics, can solve the problems of difficulty in application, high production cost, unsecured safety performance, etc., and achieve the effects of no abnormal storage performance, reduced production cost, and reduced air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: A sulfur-free fireworks propellant, the parts by weight of each component are 60 parts of potassium perchlorate, 15 parts of charcoal, 17 parts of potassium hydrogen phthalate, and 8 parts of resin.

[0009] Weigh 6kg of potassium perchlorate, 1.5kg of charcoal powder, 1.7kg of potassium phthalate, and 0.8kg of resin, mix the components evenly by hand or mechanically, then mix the medicine evenly with an appropriate amount of alcohol, and then use a 16-mesh sieve Extrude the granules, put them into the bright bead machine to roll out the granules of qualified size (1.0-2.0mm), dry or dry them to get the finished sulfur-free propellant.

Embodiment 2

[0010] Embodiment 2: A sulfur-free fireworks propellant, the parts by weight of each component are 70 parts of potassium perchlorate, 10 parts of charcoal, 12 parts of potassium hydrogen phthalate, and 8 parts of resin.

[0011] Weigh 7kg of potassium perchlorate, 1.0kg of charcoal powder, 1.2kg of potassium phthalate, and 0.8kg of resin, and mix the components evenly by hand or mechanically, then mix the medicine with an appropriate amount of alcohol, and then use a 16-mesh sieve Extrude the granules, put them into the bright bead machine to roll out the granules of qualified size (1.0-2.0mm), dry or dry them to get the finished sulfur-free propellant.

Embodiment 3

[0012] Embodiment 3: A sulfur-free fireworks propellant, the parts by weight of each component are 74 parts of potassium perchlorate, 10 parts of charcoal, 10 parts of potassium hydrogen phthalate, and 6 parts of resin.

[0013] Weigh 7.4kg of potassium perchlorate, 1.0kg of charcoal powder, 1.0kg of potassium phthalate, and 0.6kg of resin, mix the components evenly by hand or mechanically, then mix the drug evenly with an appropriate amount of alcohol, and then use a 16-mesh Extrude the granules through a sieve, put them into a bright bead machine to roll out the qualified sized granules (1.0-2.0mm), and dry them in the sun to get the finished sulfur-free propellant.

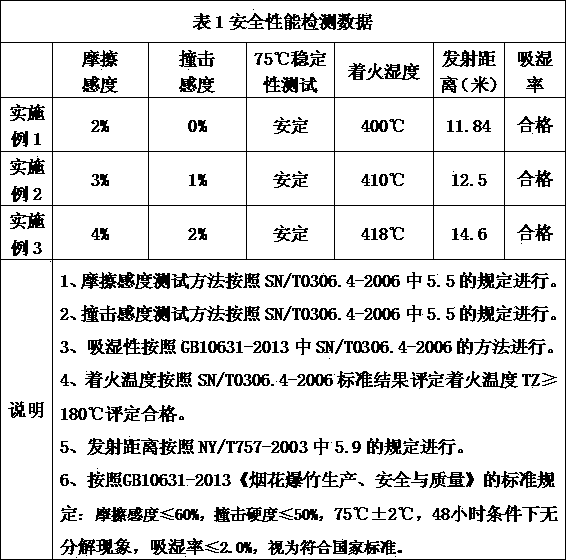

[0014] Get the finished product of sulfur-free propellant in each embodiment and carry out safety performance test, the results are shown in the following table 1:

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com