A treatment method for fracturing flowback fluid

A fracturing flowback fluid and treatment method technology, applied in the fields of filtration treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of high risk and high cost of fracturing flowback fluid treatment process, and achieve high safety, Great application value, the effect of water color clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Sludge domestication process:

[0034] The thickened sludge from the sewage treatment plant in Madong area is selected as the initial seed sludge, and its moisture content is about 70% to 80%. After the concentrated sludge is diluted, coarsely filtered and washed, it is subjected to vexation until the color of the sludge changes from black to yellowish brown to obtain the vexed sludge. Part of the sludge after vexed exposure uses oilfield sewage with an oil content of less than 10 mg / L and poor biodegradability (B / C < 0.2) as wastewater, and the intermittent culture method is used to domesticate the seed sludge. After a few days, stop the aeration, let it stand still, discharge a part of the upper layer of wastewater, and inject fresh sewage. The three processes of stuffy exposure, static settling and water inflow are repeated in this way. The amount of water inflow increases each time compared with the last time, and the time of stuffy exposure is shortened. During th...

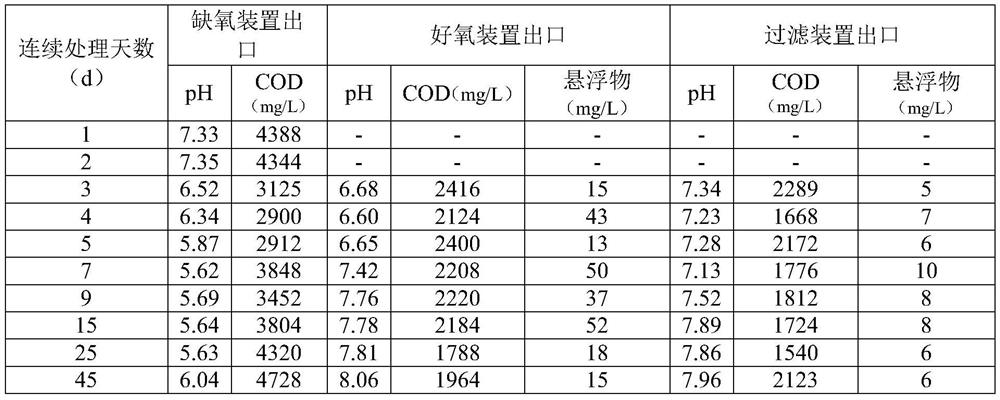

Embodiment 2

[0050] The sludge domestication process is the same as in Example 1.

[0051] The application process is as follows:

[0052] A well in the Madong area of Xinjiang Oilfield obtained fracturing flowback fluid for treatment. The parameters of the flowback fluid are as follows: viscosity 8.03mPa·S, suspended solids value 3376mg / L, salinity 37142mg / L, chloride ion content 22120mg / L, COD 5241mg / L, BOD 714mg / L, pH 5.7, oil content not detected, water type is CaCl 2 .

[0053] The process is as follows:

[0054] The fracturing flowback fluid is pumped into the aeration tank through the lift pump, and the air is blown into the device, the air-water ratio is between 1.5:1 and 2.5:1, and the residence time is 1.5h;

[0055] The flowback liquid after aeration enters the buffer device, and the residence time is 2h;

[0056] The effluent from the upper part of the buffer device enters the anaerobic device, the residence time of the flowback liquid of the anaerobic device is 9h, the t...

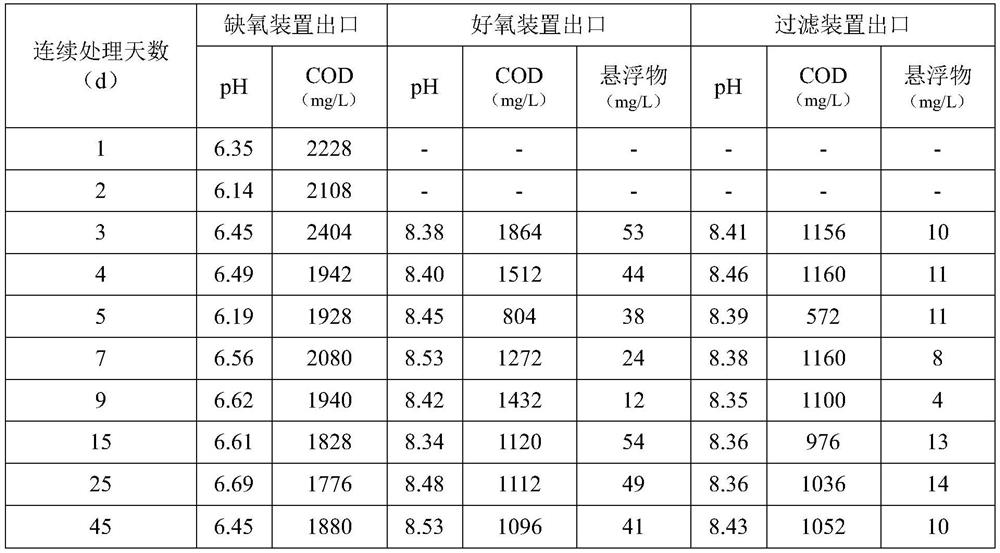

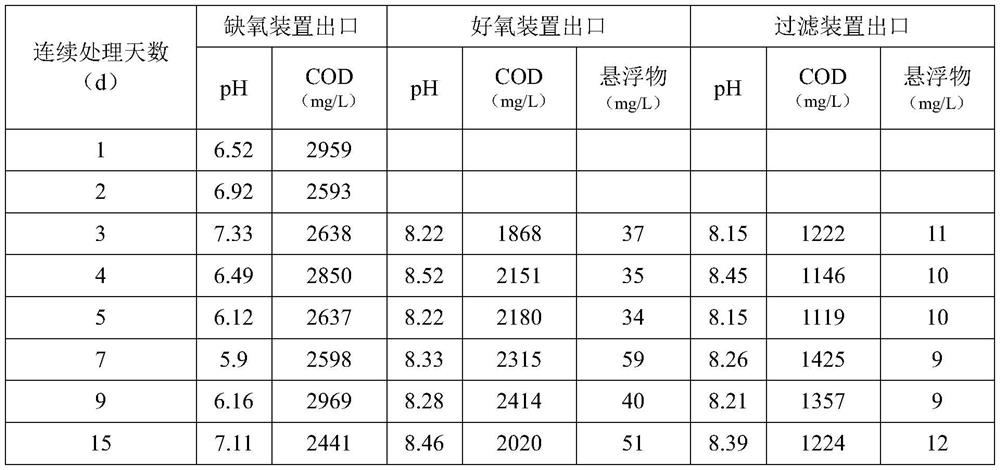

Embodiment 3

[0065] The sludge domestication process is the same as in Example 1.

[0066] The application process is as follows:

[0067] The fracturing flowback fluid was obtained from a well in the Mazhong area of Xinjiang Oilfield for treatment. The parameters of the flowback fluid are as follows: viscosity 8.03mPa·S, suspended solids value 3376mg / L, salinity 37142mg / L, chloride ion content 22120mg / L , COD 5241mg / L, BOD 714mg / L, pH 5.7, oil content not detected, water type is CaCl 2 .

[0068] The process is as follows:

[0069] The fracturing flowback fluid is pumped into the aeration tank through the lift pump, and the air is blown into the device, the air-water ratio is between 1.5:1 and 2.5:1, and the residence time is 0.5h;

[0070] The flowback liquid after aeration enters the buffer device, and the residence time is 2h;

[0071] The effluent from the upper part of the buffer device enters the anaerobic device, the residence time of the flowback liquid of the anaerobic devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com