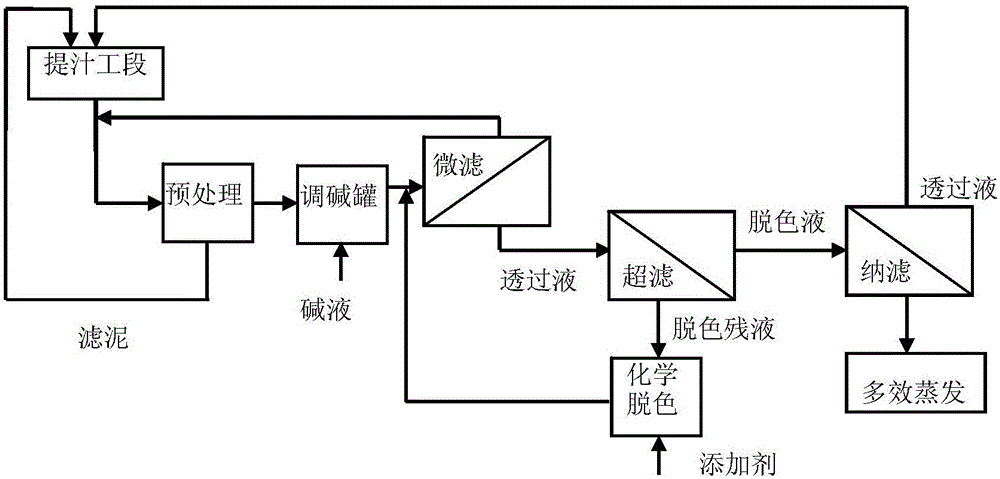

Sugar making process for refining cane mixed juice by use of multi-stage membrane filtration technology

A technology of mixed juice and sugarcane, applied in the field of refined sugar, can solve the problems of low decolorization rate, unresolved impurity removal rate, low removal rate of non-sugar components, etc., achieve high decolorization rate, reduce color and turbidity and non-sugar The content of macromolecular substances and the effect of saving dehydration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) 200kg of sugarcane mixed juice raw materials enter the heat exchange equipment and are heated to about 60°C by low-temperature waste heat steam or hot water;

[0033] 2), adjust the pH to 7 with sodium hydroxide, filter through a 5 micron non-woven filter bag to remove suspended particles, and obtain the filtrate A;

[0034] 3), pressurize the filtrate A to 0.1MPa and then enter the tubular microfiltration membrane module. The organic microfiltration membrane of 0.2 microns is used in the membrane module. Driven by pressure, the remaining suspended particles in the filtrate A, Macromolecular substances, colloids, etc. are intercepted, sucrose is completely penetrated, and filtrate B is obtained;

[0035] 4) Continue to heat the filtrate B at 60°C, pressurize it to 1.0MPa and enter the roll-type ultrafiltration membrane module. The organic ultrafiltration membrane with a molecular weight cut-off of 3000Da is selected in the membrane module. Driven by pressure, the fil...

Embodiment 2

[0040] 1) 200kg of sugarcane mixed juice raw materials enter the heat exchange equipment and are heated to 65°C by low-temperature waste heat steam or hot water;

[0041] 2), adjust the pH to 8 with calcium hydroxide, remove the suspended particles through a centrifuge at 4000 rpm, and obtain the filtrate A;

[0042] 3), pressurize the filtrate A to 0.05MPa and enter the hollow fiber microfiltration membrane module. The organic hollow fiber microfiltration membrane of 0.1 micron is selected in the membrane module. Driven by pressure, the remaining Suspended particles, macromolecular substances, colloids, etc. are intercepted, sucrose is completely penetrated, and filtrate B is obtained;

[0043] 4), continue to heat the filtrate B to about 65°C, pressurize it to 1.0 MPa, and enter the roll-type ultrafiltration membrane module. The organic ultrafiltration membrane with a molecular weight cut-off of 2000Da is used in the membrane module. Driven by pressure, the filtration The r...

Embodiment 3

[0048] 1) 200kg of sugarcane mixed juice raw materials enter the heat exchange equipment and are heated to 70°C by low-temperature waste heat steam or hot water;

[0049] 2), add alkali to adjust the pH value to 7.5, remove suspended particles through a centrifuge at 4000 rpm, and obtain filtrate A;

[0050] 3), the filtrate A is pressurized to 0.05MPa and enters the hollow fiber microfiltration membrane module, and the organic hollow fiber microfiltration membrane of 0.1 micron is used in the membrane module. Driven by pressure, the remaining suspended particles in the filtrate A Particles, macromolecular substances, colloids, etc. are intercepted, sucrose is completely penetrated, and filtrate B is obtained;

[0051] 4), continue to heat the filtrate B to about 70°C, pressurize it to 1.0MPa, and enter the roll-type ultrafiltration membrane module. The organic ultrafiltration membrane with a molecular weight cut-off of 1000Da is selected in the membrane module. Driven by pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com