A kind of brown sugar and processing method thereof

A processing method and technology of brown sugar, applied in the direction of using physical methods to purify, sugar crystallization, sugar products, etc., can solve the problems that affect the taste and nutritional value of the product, cannot accurately control the heating temperature, lack of brown sugar caramel flavor, etc., and achieve operation and maintenance costs Low, increase the domestication time, the effect of mature equipment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

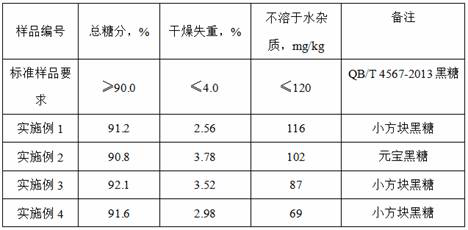

Examples

Embodiment 1

[0029] The method of processing the brown sugar of the present embodiment includes the following steps:

[0030] Step (1), clear juice

[0031] 1 ton of sugar cane is pressed with a five-roller press, and the sucrose juice is permeated by 100 mesh filter. When the filtrate is filtered into the foam, the black floating foam that is constantly floating is cleared;

[0032] Step (2),

[0033] The cleans were filtered with a vacuum cap filter of 300 mesh filtration cloth, and the filtrate was pumped into the evaporation pan at 135 ° C to evaporate to a syrup concentration of 70 ° bx, and then transferred to a sugar pot in 115 ° C to the concentration 90 ° BX, obtaining about 100 L of concentrated syrup, adding 5 L of temperature of 85 ° C, mixing with mixing and mixing until 95 ° bx after mixing mixing.

[0034] Step (3), sand

[0035] Put the syrup prepared by step (2) into the cassette, start sanding immediately, when the syrup flexing, then add water and continuously stir it, conti...

Embodiment 2

[0039] The method of processing the brown sugar of the present embodiment includes the following steps:

[0040] Step (1), clear juice

[0041] 1 ton of sugar cane is pressed with a five-roller press, and the sucrose juice is permeated by 100 mesh filter. When the filtrate is filtered into the foam, the black floating foam that is constantly floating is cleared;

[0042] Step (2),

[0043] The cleans were filtered with a vacuum cap filter of 400 mesh filtration cloth, and the filtrate was pumped into the evaporation pot at 130 ° C to evaporate to a syrup concentration of 75 ° bx, and then transferred to a sugar pot in a concentration of 120 ° C. 92 ° BX, obtaining about 90 l of concentrated syrup, adding 9 l temperature of 80 ° C, mixing with a mixture of 93 ° bx after mixing and mixing.

[0044] Step (3), sand

[0045] Place the sugar slurry of step (2) into the casserole, start sanding, when the syrup foaming, then adding water and continuously stirring, continuing to survive in...

Embodiment 3

[0049] The method of processing the brown sugar of the present embodiment includes the following steps:

[0050] Step (1), the preparation of the sugar glue

[0051] 100 kg of brown sugar powder was placed in the dissolved tank, and a 200kg temperature of about 80 ° C was added, and the stirring motor was stirred to mix the brown sugar to dissolve all dissolved, and the syrup was obtained;

[0052] Step (2),

[0053]The cleansing pulp of step (1) was filtered through a vacuum filter machine of 400 mesh filter cloth, and the filtrate was pumped into the evaporation pan at 127 ° C to evaporate the syrup of 72 ° bx, and then transferred to the sugar pot in 115 ° C The concentration is 91 ° BX to obtain about 70 L concentrated syrup, add 6 L of hot water at 80 ° C, thoroughly stir mixing with mixing to concentrate to 94 ° bx;

[0054] Step (3), sand

[0055] Place the sugar pulp of step (2) into the cassette, start sanding immediately, when the syrup flexing, then add water and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com