A kind of stamping forming steel plate mold

A technology of stamping forming and steel plate mold, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable positioning, manual material support, and low production efficiency, so as to avoid production safety hazards, improve production efficiency, Effects that are easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

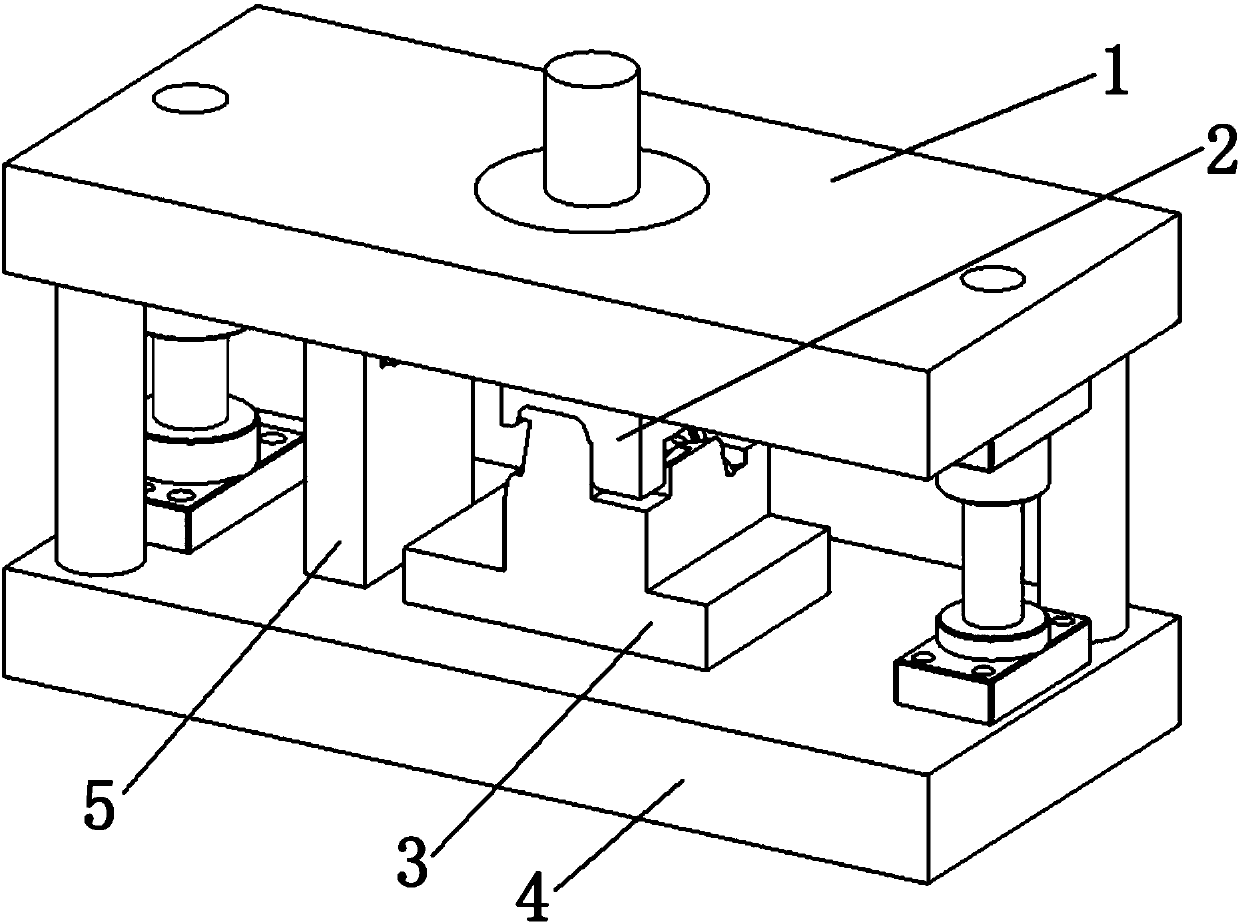

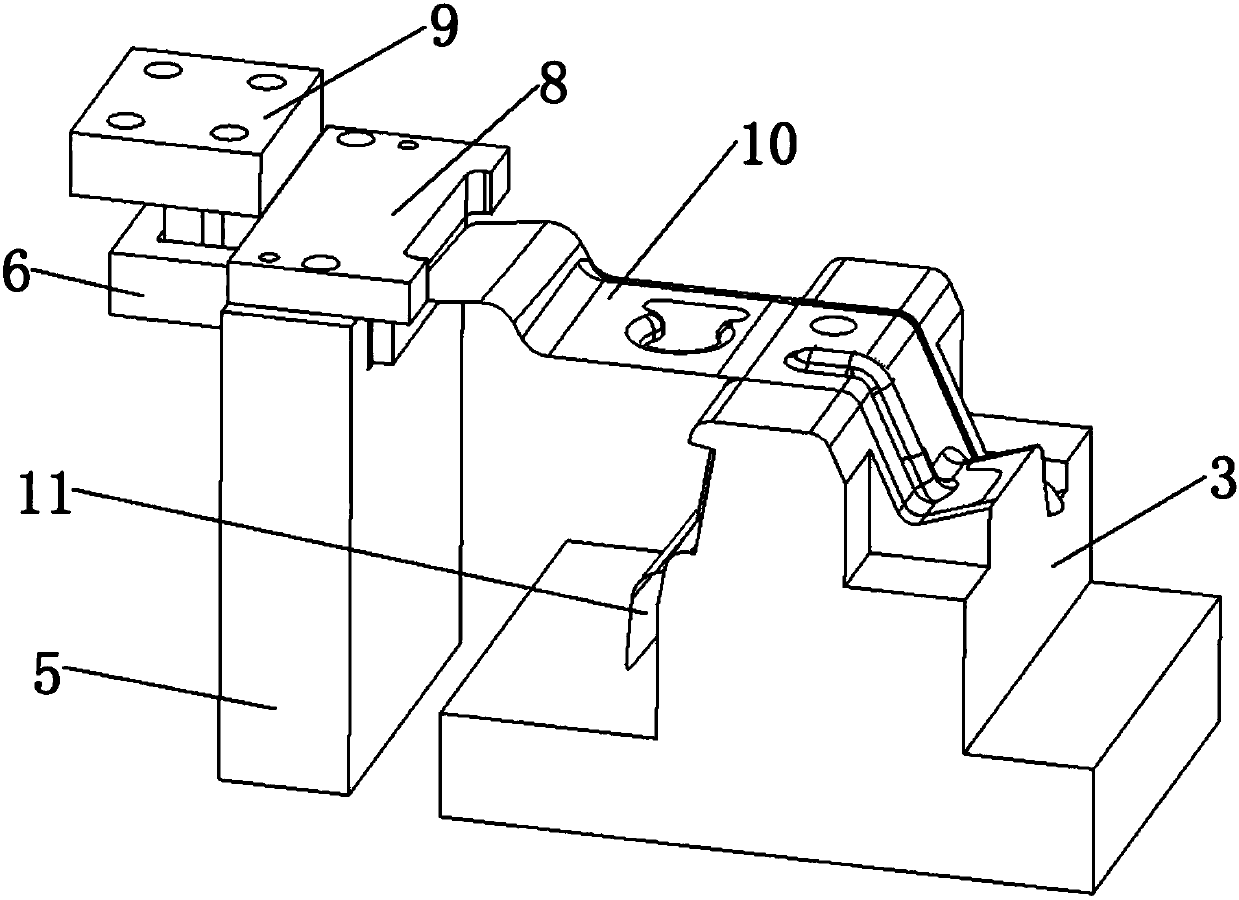

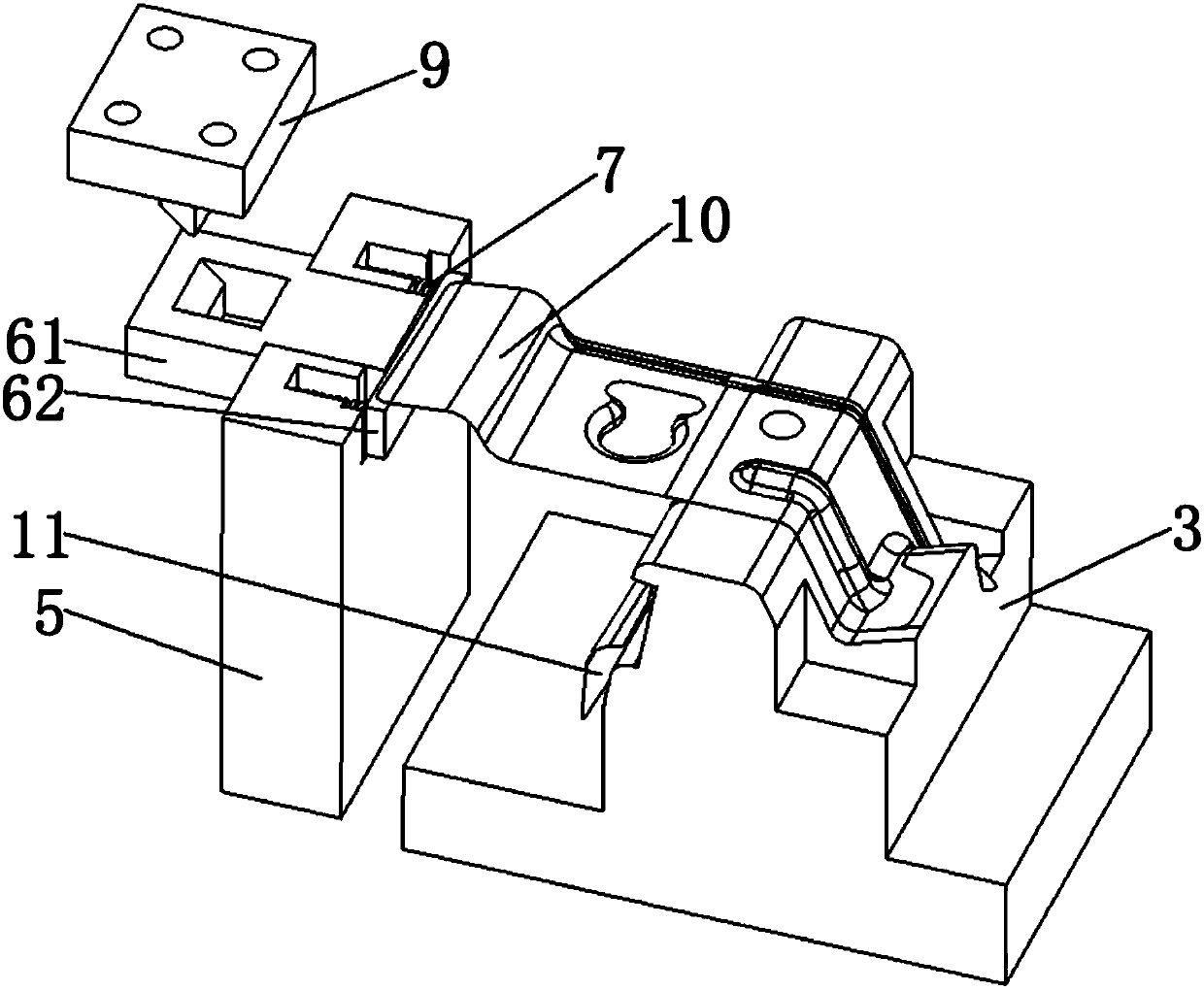

[0027] The invention provides a stamping and forming steel plate mold, such as Figure 1 to Figure 6 As shown, it includes an upper template 1, a die 2, a punch 3, a lower template 4, a base 5, a supporting plate 6, a spring 7 and a driving block 9.

[0028] The die 2 is fixed on the upper template 1; in this application, it also includes a pad 23, which is arranged between the die 2 and the upper template 1, and the pad 23 is used to adjust the height of the die.

[0029] Including unloading bolt 21, pressing spring 22 and pressing core 24; pressing core 24 is movably installed in die 2 for pressing during molding; pressing spring 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com