Needle Caps for Liquid Injection Ports

A technology of injection port and liquid, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of exquisite structure, low production cost and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

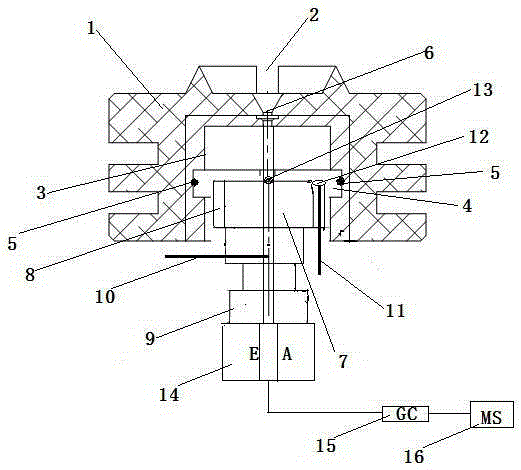

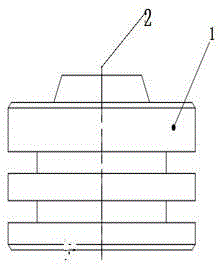

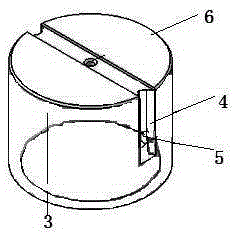

[0015] Below, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0016] Such as Figure 1-5 As shown, a needle-type sampling cap of the liquid injection port is installed on the liquid injection port of the elemental analyzer, and is used as a pre-device for analyzing hydrogen, oxygen, and nitrogen isotopes in liquid samples. It mainly includes an external pressure cap 1. External pressure cap injection port 2, internal pressure cap 3, internal pressure cap purge air groove 4, internal pressure cap purge air hole 5, internal pressure cap injection port 6, cap core 7, cap core upper thread 8, cap core Lower thread 9, cap core carrier gas pipe (port) 10, cap core purge air pipe 11, cap core purge gas port 12, cap core hole 13 and elemental analyzer 14. The external pressure cap 1 has an external pressure cap injection port 2, the upper part of the internal pressure cap 3 has an internal pressure cap injection port 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com