Concrete pipe vertical production process pipe mold release agent spraying machine

A production process and technology for concrete pipes, which are applied in the field of concrete pipe vertical production process pipe mold release agent spraying machines, can solve the problems of long operation time, danger, and large leakage rate of release agent, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

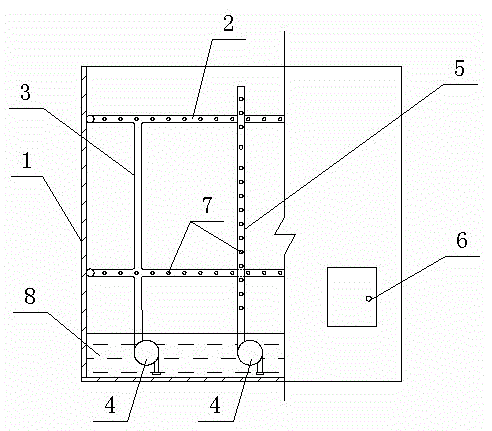

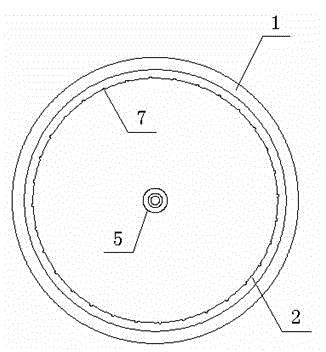

[0018] Embodiment one: if figure 1 and figure 2 As shown, a concrete pipe vertical production process pipe mold release agent spraying machine includes a cylindrical shell 1, the bottom of the shell 1 is integrally formed with the shell 1, and the inside of the shell 1 is close to the inner wall A spraying mechanism A is provided, and the spraying mechanism A includes at least one annular spraying pipe A2 with several spraying holes 7. In this embodiment, there are two annular spraying pipes A2, which are arranged around and close to the inner wall of the housing 1 for a week. The spray holes 7 on it are evenly distributed, which is more conducive to the uniform spraying of the release agent, improves the utilization rate of the release agent, and has a small leakage rate of the release agent. The spray pipeline A2 is connected to the water supply device 4 through the supply pipeline 3 .

[0019] A spraying mechanism B is vertically provided in the center of the housing 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com