Ultra-high-speed maglev train positioning and speed measuring system based on Manchester encoding

A magnetic levitation train, ultra-high-speed technology, applied in the direction of code conversion, electrical components, individual digital conversion, etc., can solve the problems that the ultra-high-speed magnetic levitation train cannot be guaranteed, can only reach 3cm, and affects performance, so as to facilitate redundant design and maintenance , avoid the influence of strong magnetism, and ensure the effect of single row

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

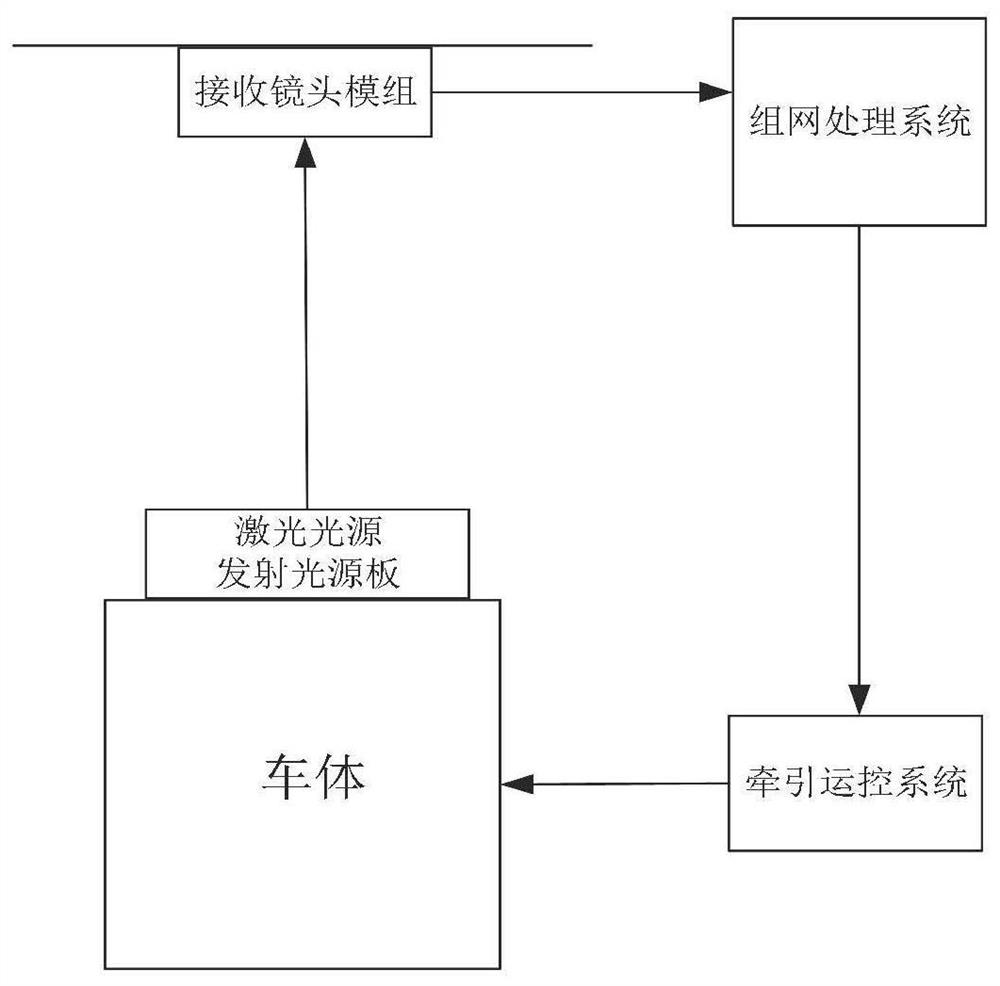

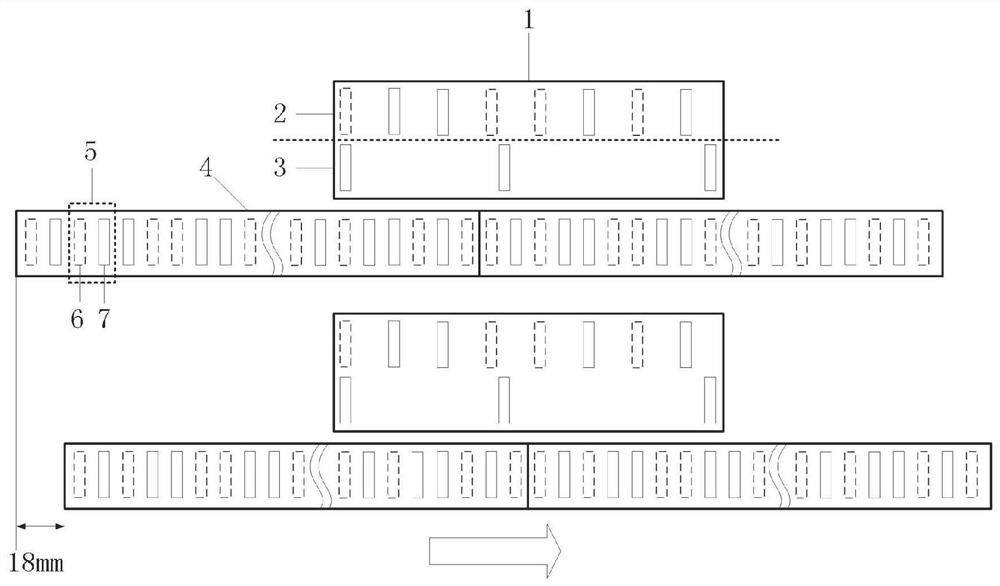

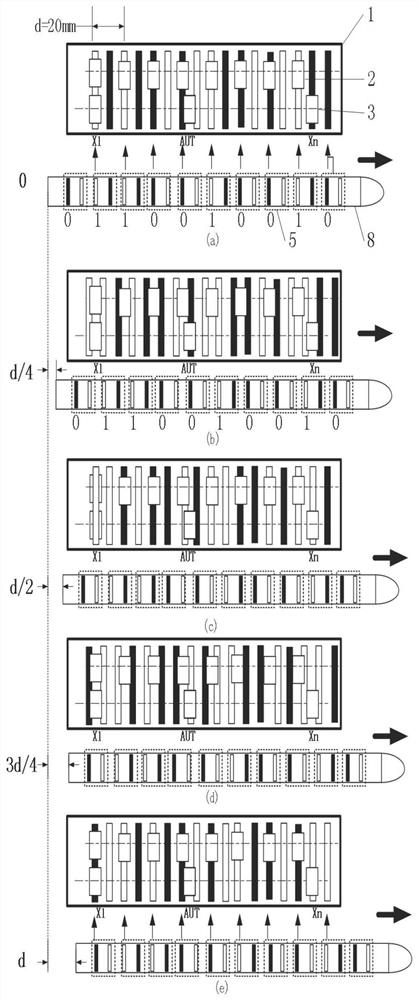

[0029] A positioning and velocity measurement system for ultra-high-speed maglev trains based on Manchester coding, such as figure 1 As shown, it includes a vehicle body 8, a laser light source, a beam splitter, a transmitting light source board, a receiving lens module 1, a networking processing system, and a traction control system. The laser light source, beam splitter and emitting light source board are installed on the top of the front car body 8 of the ultra-high-speed maglev train, and the receiving lens modules 1 are installed on the inner pipe wall of the pipeline at equal intervals with a distance of 4.5 meters. An optical transmitting lens and an optical receiving lens are installed on the transmitting light source board and the receiving lens module respectively. The 1550nm continuous optical signal output by the laser light source passes through the beam splitter to form a "one"-shaped light at the end of the emitting light source board. As the body of the ultra-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com