Thread end burying spacing electric adjustment mechanism and method for adjusting thread end burying spacing using same

A technology of electric adjustment and transmission mechanism, which is applied in the direction of conductive pattern formation, etc., can solve the problems of increasing the work intensity of operators, reducing the comprehensive utilization rate of equipment, and difficult to guarantee the accuracy, so as to improve the utilization rate of equipment, increase the self-weight of the equipment, shorten the The effect of adjusting the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

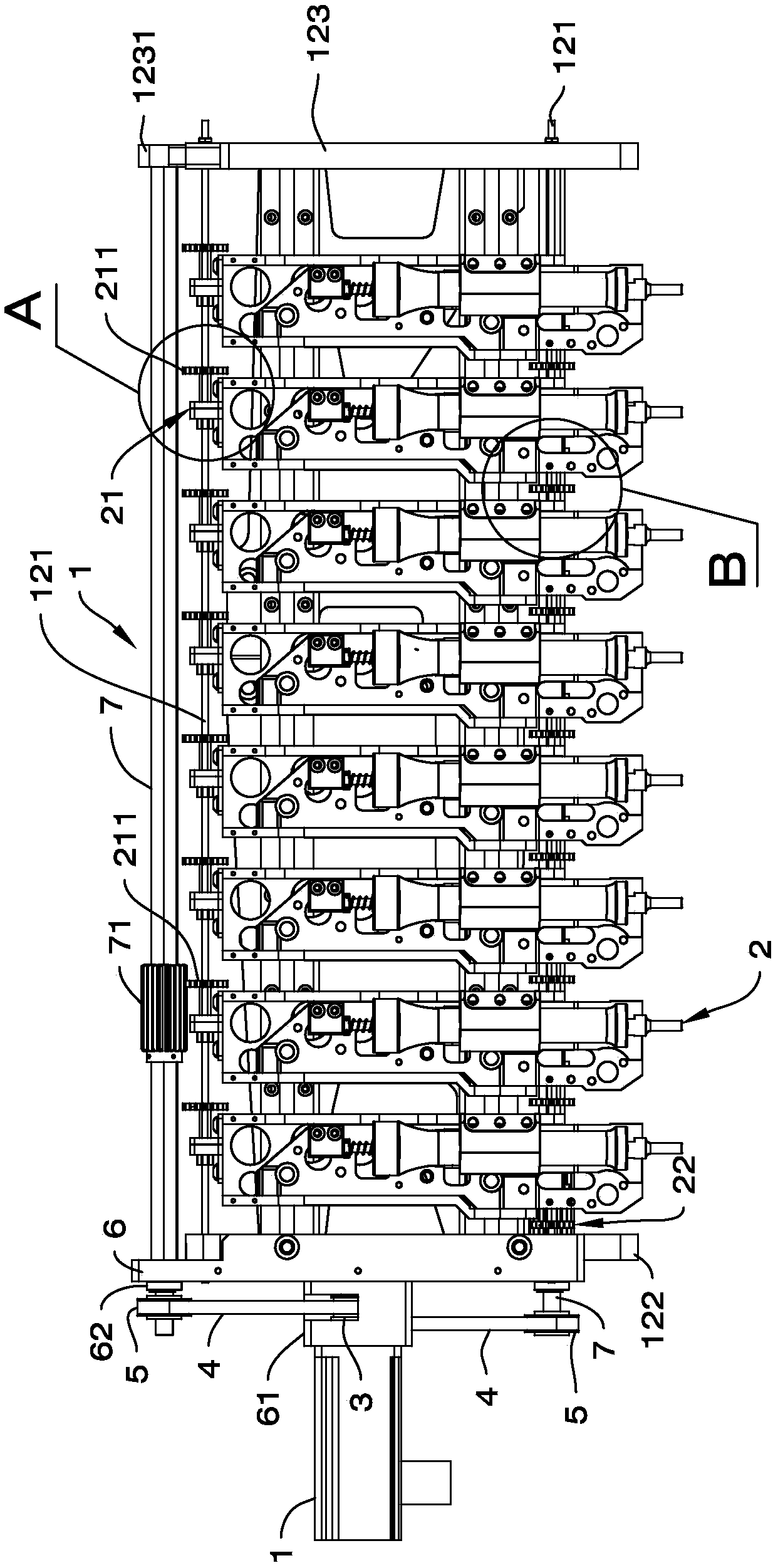

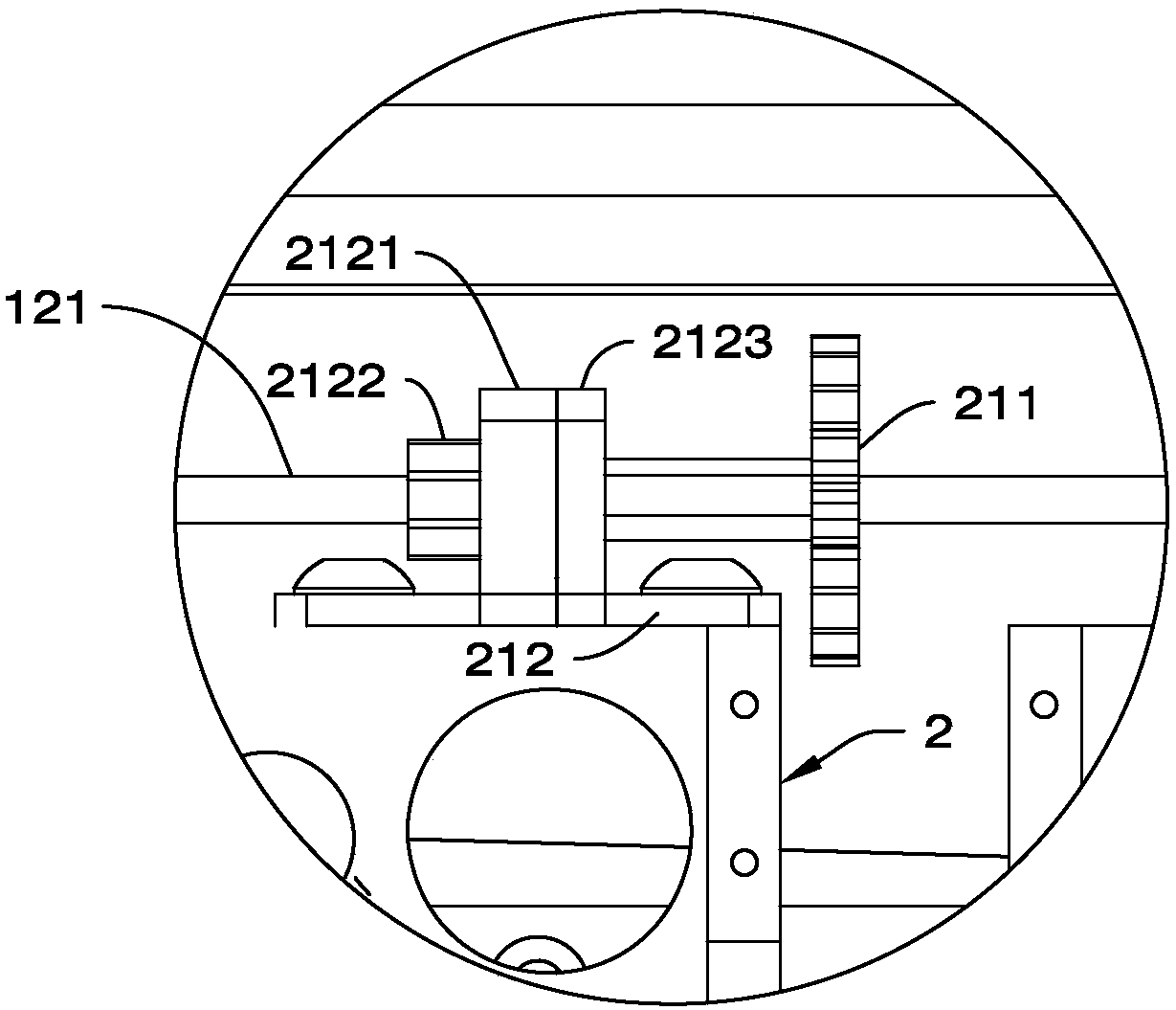

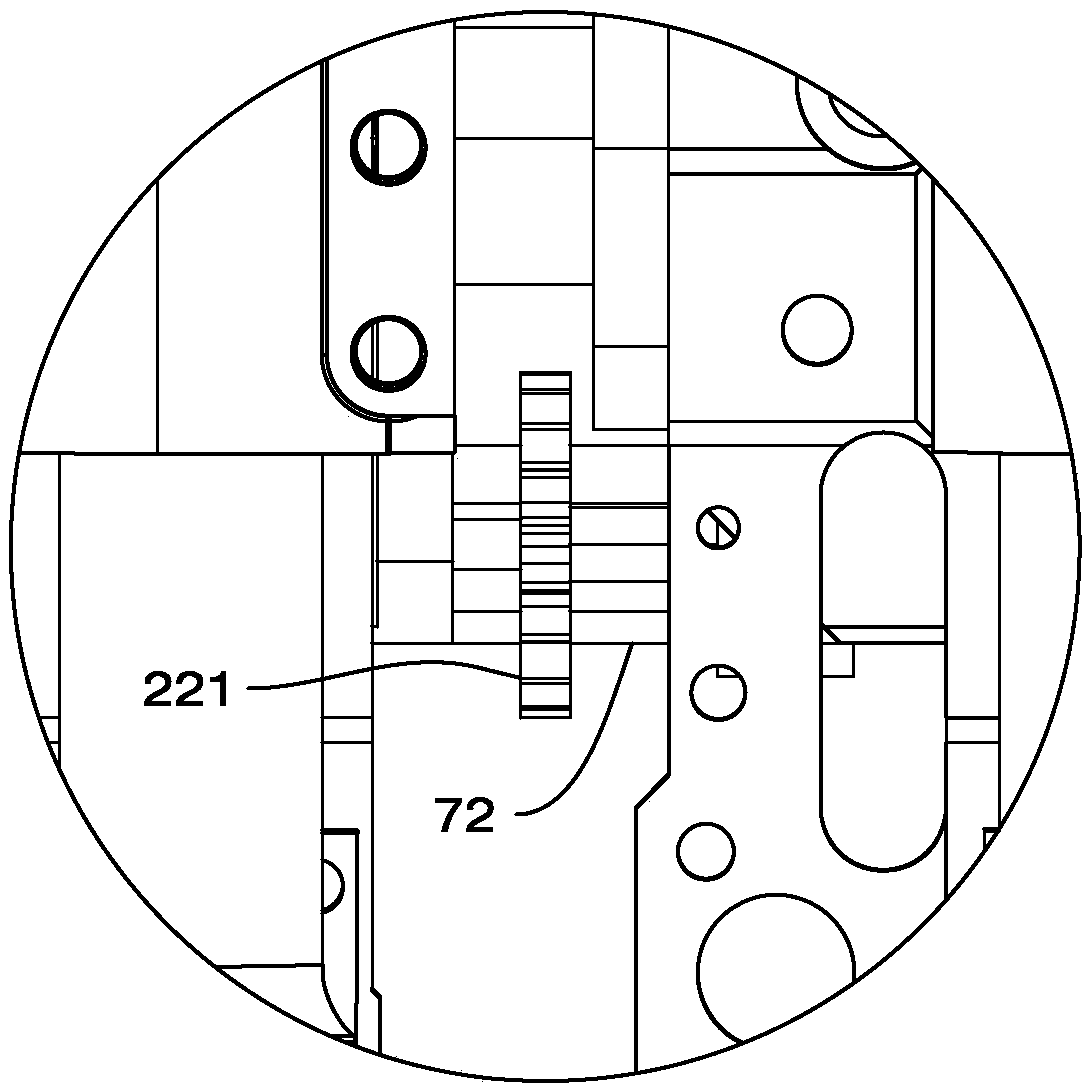

[0042] Such as figure 1 As shown, the thread embedding head spacing electric adjustment mechanism of the present invention includes a thread embedding head adjusting device 1, and two transmission shafts 7 arranged in parallel up and down and with large gears 71, 72 are installed on the thread embedding head adjusting device 1, and the large gears 71, 72 are coaxial The rotation is installed on the transmission shaft 7, and the two transmission shafts 7 are all driven to rotate by the motor-synchronous pulley transmission mechanism. An upper bull gear 71 is installed on the transmission shaft 7 above, and a lower bull gear 72 is installed on the transmission shaft 7 below. preferred, such as Figure 14 to Figure 17 As shown, the cross section of the transmission shaft 7 is a special-shaped quadrilateral. The special-shaped quadrilateral is spliced by a rectangle and two circular arcs with the same length and curvature but opposite bending directions. The two circular arcs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com