Production method of large-size chalcogenide glass

A chalcogenide glass, large-size technology, applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problem of difficult to ensure glass optical uniformity and infrared transmittance, difficult to achieve large-size chalcogenide glass preparation, Issues such as high safety protection measures are required to achieve the effects of eliminating pollution effects, preventing secondary pollution, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

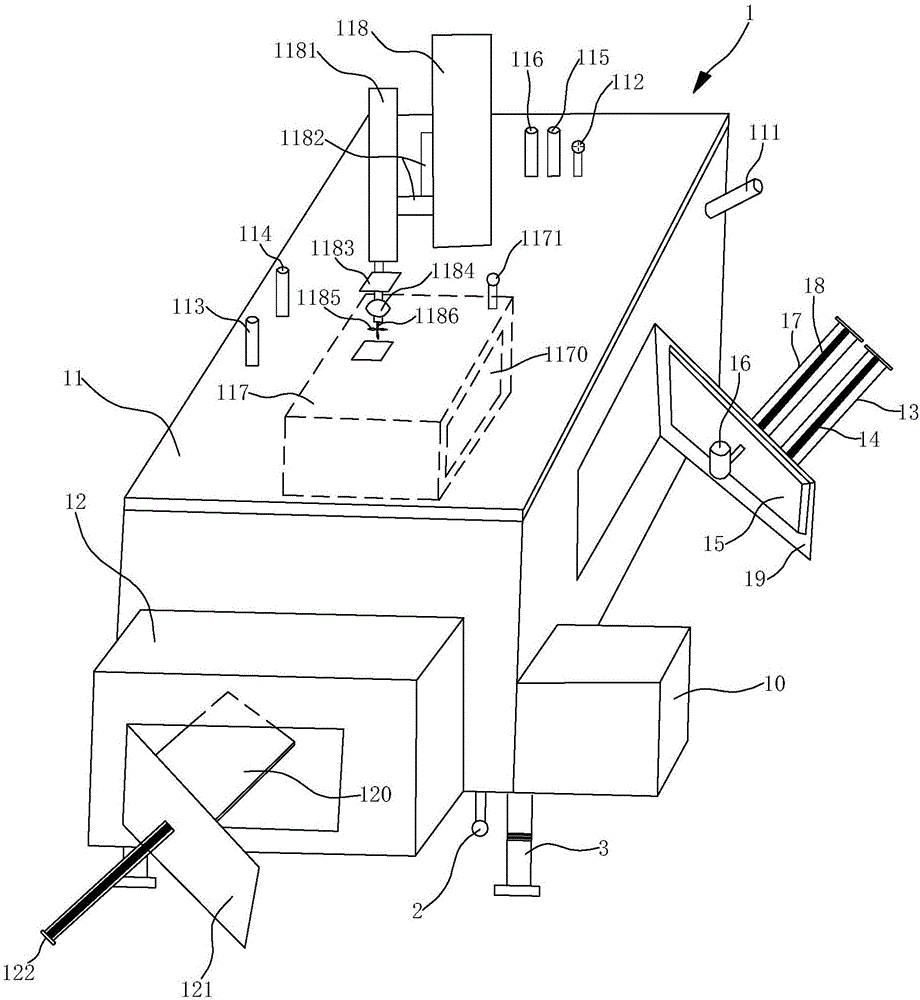

[0035] Such as figure 1 As shown, the chalcogenide glass preparation device for preparing large-sized chalcogenide glass in this embodiment includes a furnace body 1 and a central console 10 located outside the furnace body 1 for controlling the operation of various components. The furnace body includes a vacuum chamber 11 and An annealing furnace 12 with a side furnace door. There is a cooling chamber between the inner wall of the vacuum chamber and the outer wall of the vacuum chamber. Cooling water is poured into the cooling chamber. The water inlet valve of the cooling chamber and the drain valve of the cooling chamber are located On the outer wall, the water inlet valve of the cooling chamber is connected to the water outlet of the cooling water refrigeration device outside the furnace body, and the drain valve of the cooling chamber is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com