Paint spraying waste gas treatment device

A waste gas treatment device and oxidation device technology, applied in the combined process field, can solve the problems of high cost of renewable activated carbon adsorbent, heavy dust removal pressure burden, difficult to remove paint mist, etc., to improve VOC removal efficiency, increase residence time, design cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

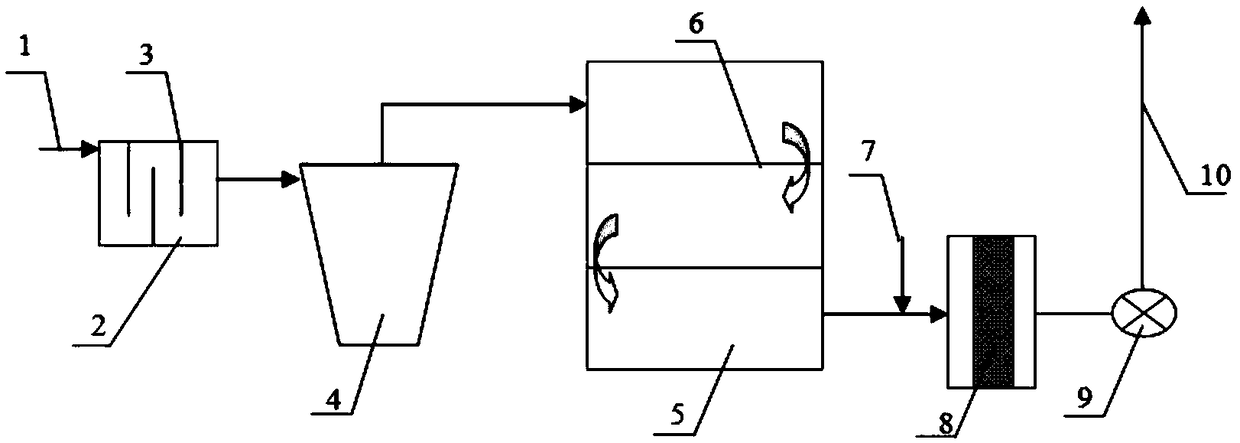

[0015] The spray paint exhaust gas treatment device involved in this embodiment includes an intake pipe 1, a baffle type paint mist removal device 2, a paint mist removal device baffle 3, a pulse bag filter 4, a UV photooxidation device 5, and a UV photooxidation device Baffle plate 6, spray humidification pipe 7, activated carbon liquid film absorption and oxidation device 8, induced draft fan 9 and exhaust tube 10, baffle type paint mist removal device 2 includes a sealed box, and is sequentially fixed on the sealed box along the length direction Several paint mist removal device baffles 3 on the top and bottom surfaces, the paint mist removal device baffles 3 divide the sealed box into several interconnected areas, the air intake pipe 1 is connected to the upper part of the baffled paint mist removal device 2 The air port is connected, and the air outlet at the other end of the baffle type paint mist removal device 2 is connected to the air inlet of the pulse bag filter 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com