A liquid drainage gas collection string and its production method

A gas production pipe and pipe body technology, which is applied in the field of liquid-draining gas production string and its production, can solve the problem that the use speed string cannot meet the requirements of well control, and achieves the improvement of the liquid-carrying capacity of the whole wellbore, the reduction of operating costs, and the reduction of the operating cost. The effect of string work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

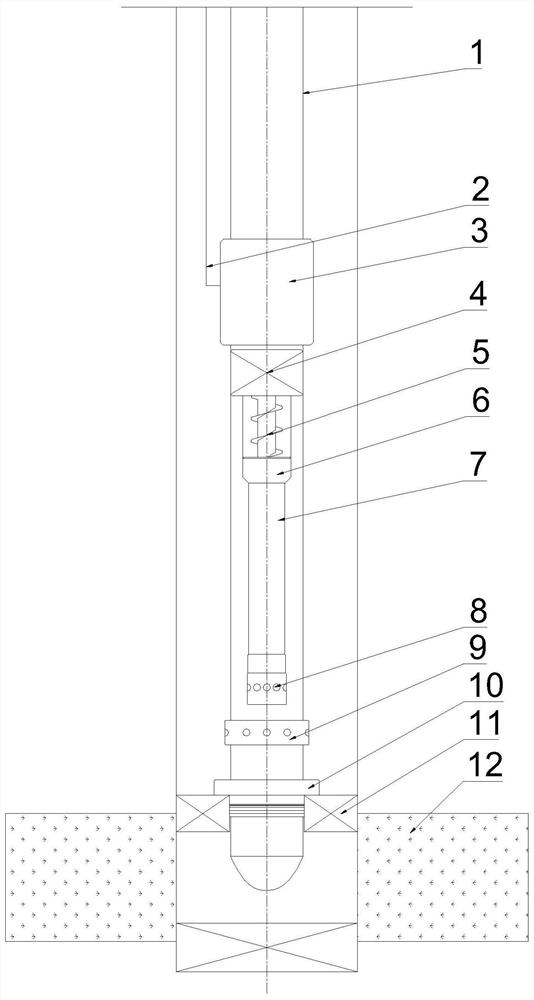

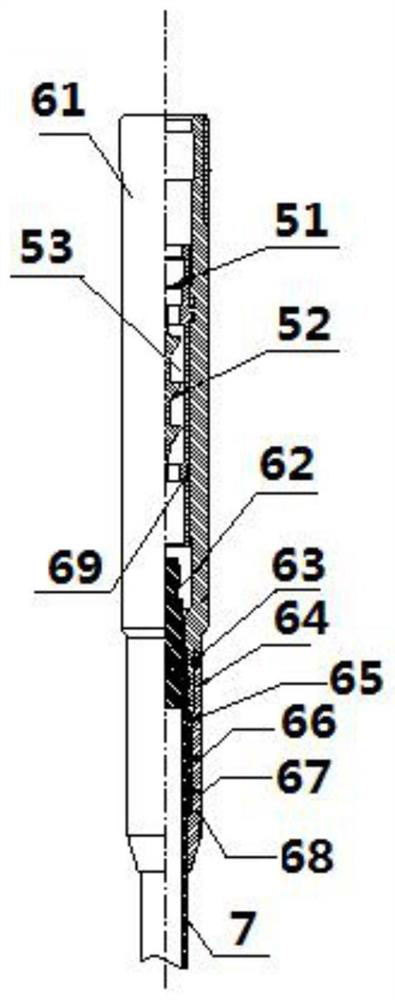

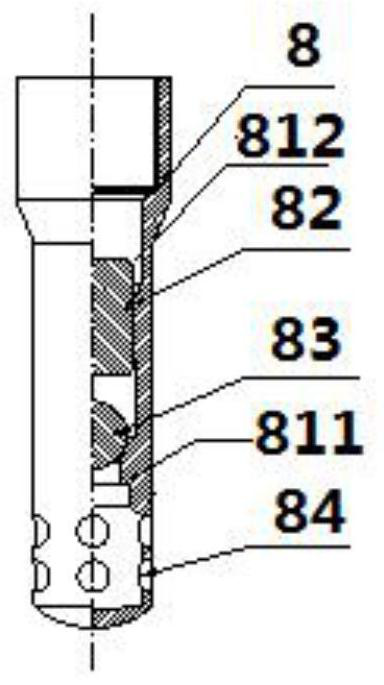

[0028] like figure 1 As shown, the present invention provides a liquid drainage and gas production string, which is composed of a pipe body 1 with a liquid control pipeline 2, and the pipe body 1 is sequentially provided with a lower safety valve 3, a sliding sleeve 9, a positioning seal 10 and a second A packer 11, a second packer 4, a hanger 6, a velocity tube 7 and a blocker 8 are arranged between the safety valve 3 and the sliding sleeve 9; the upper body 61 of the hanger 6 passes through the first The second packer 4 passes through the safety valve 3 and is connected in the pipe body 1, and its lower body 64 is connected with the plug 8 through the velocity pipe 7; the hanger 6 is movably connected with a vortex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com