Method for utilizing boiler waste gas in fermentation alcohol production

A technology for fermenting alcohol and boiler waste gas, which is applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve the problems of exhaust gas, reduce production costs, realize recycling, and save water resource fees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for utilizing boiler waste gas in fermented alcohol production, comprising the following steps:

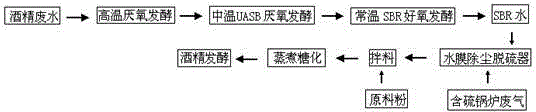

[0036] (1) Alcohol wastewater treatment: The alcohol wastewater produced in the fermentation alcohol production process is treated, and the combined treatment method of high temperature anaerobic fermentation, medium temperature UASB anaerobic fermentation and normal temperature SBR aerobic fermentation is adopted until the COD in the wastewater is ≤100 mg / L, specifically include the following steps:

[0037] (a): Carry out high-temperature contact anaerobic fermentation of the produced alcohol wastewater, the fermentation temperature is 55°C, and the closed fermentation time is 8 days. It is necessary to carry out a cycle of stirring, stirring for 2 hours each time. After the fermentation cycle, the pH value of the water needs to be detected. If the pH is lower than 7.0, the fermentation time should be extended until the pH is greater than 7.0 to ensure that the a...

Embodiment 2

[0049] A method for utilizing boiler waste gas in fermented alcohol production, comprising the following steps:

[0050] (1) Alcohol wastewater treatment: The alcohol wastewater produced in the fermentation alcohol production process is treated, and the combined treatment method of high temperature anaerobic fermentation, medium temperature UASB anaerobic fermentation and normal temperature SBR aerobic fermentation is adopted until the COD in the wastewater is ≤100 mg / L, specifically include the following steps:

[0051] (a): Carry out high-temperature contact anaerobic fermentation on the produced alcohol wastewater, the fermentation temperature is 58°C, and the closed fermentation time is 9 days. It is necessary to carry out a cycle of stirring, stirring for 2 hours each time. After the fermentation cycle, the pH value of the water needs to be detected. If the pH is lower than 7.0, the fermentation time should be extended until the pH is greater than 7.0 to ensure that the a...

Embodiment 3

[0063] A method for utilizing boiler waste gas in fermented alcohol production, comprising the following steps:

[0064] (1) Alcohol wastewater treatment: The alcohol wastewater produced in the fermentation alcohol production process is treated, and the combined treatment method of high temperature anaerobic fermentation, medium temperature UASB anaerobic fermentation and normal temperature SBR aerobic fermentation is adopted until the COD in the wastewater is ≤100 mg / L, specifically include the following steps:

[0065] (a): Carry out high-temperature contact anaerobic fermentation of the produced alcohol wastewater, the fermentation temperature is 60°C, and the closed fermentation time is 10 days. It is necessary to carry out a cycle of stirring, stirring for 2 hours each time. After the fermentation cycle, the pH value of the water needs to be detected. If the pH is lower than 7.0, the fermentation time should be extended until the pH is greater than 7.0 to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com