Patents

Literature

113 results about "Alcohol production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

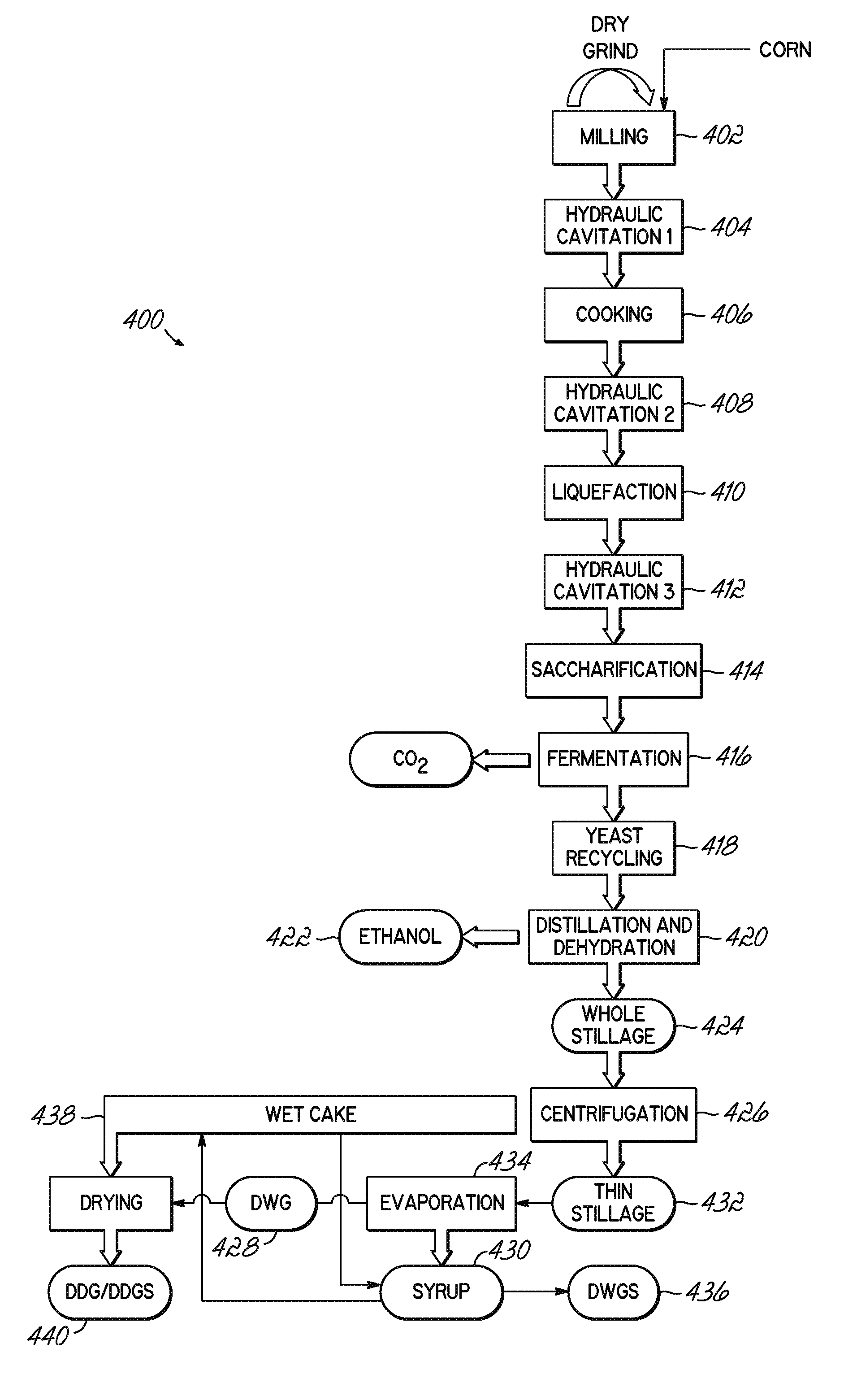

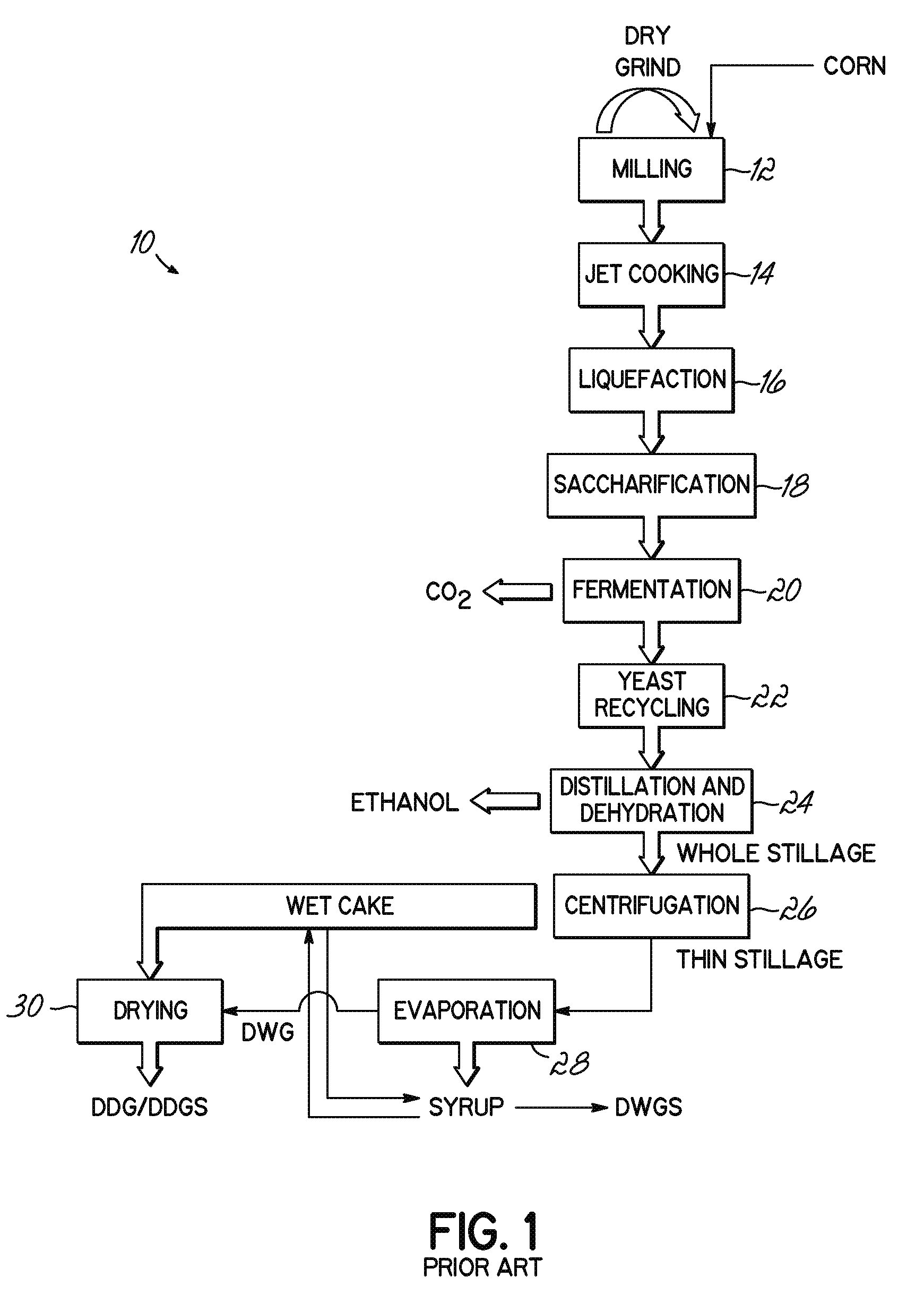

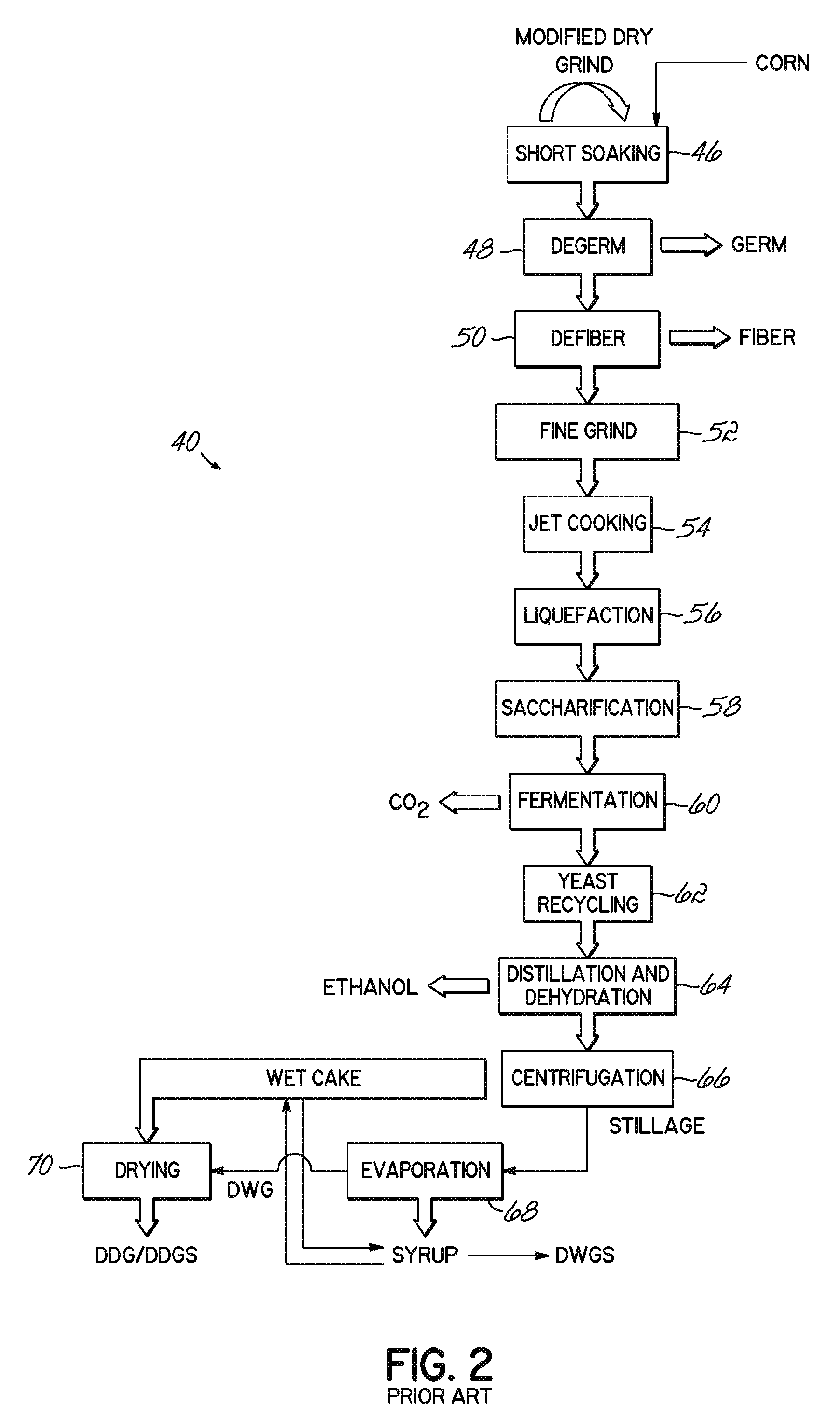

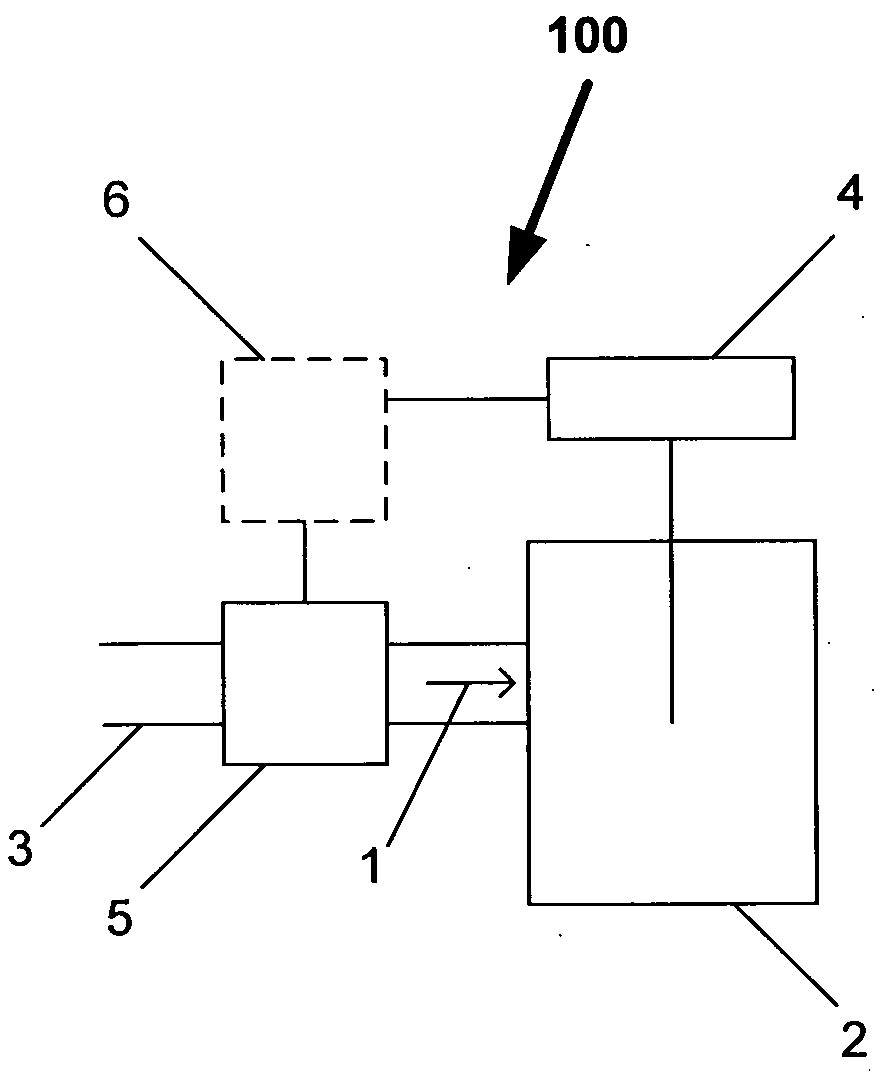

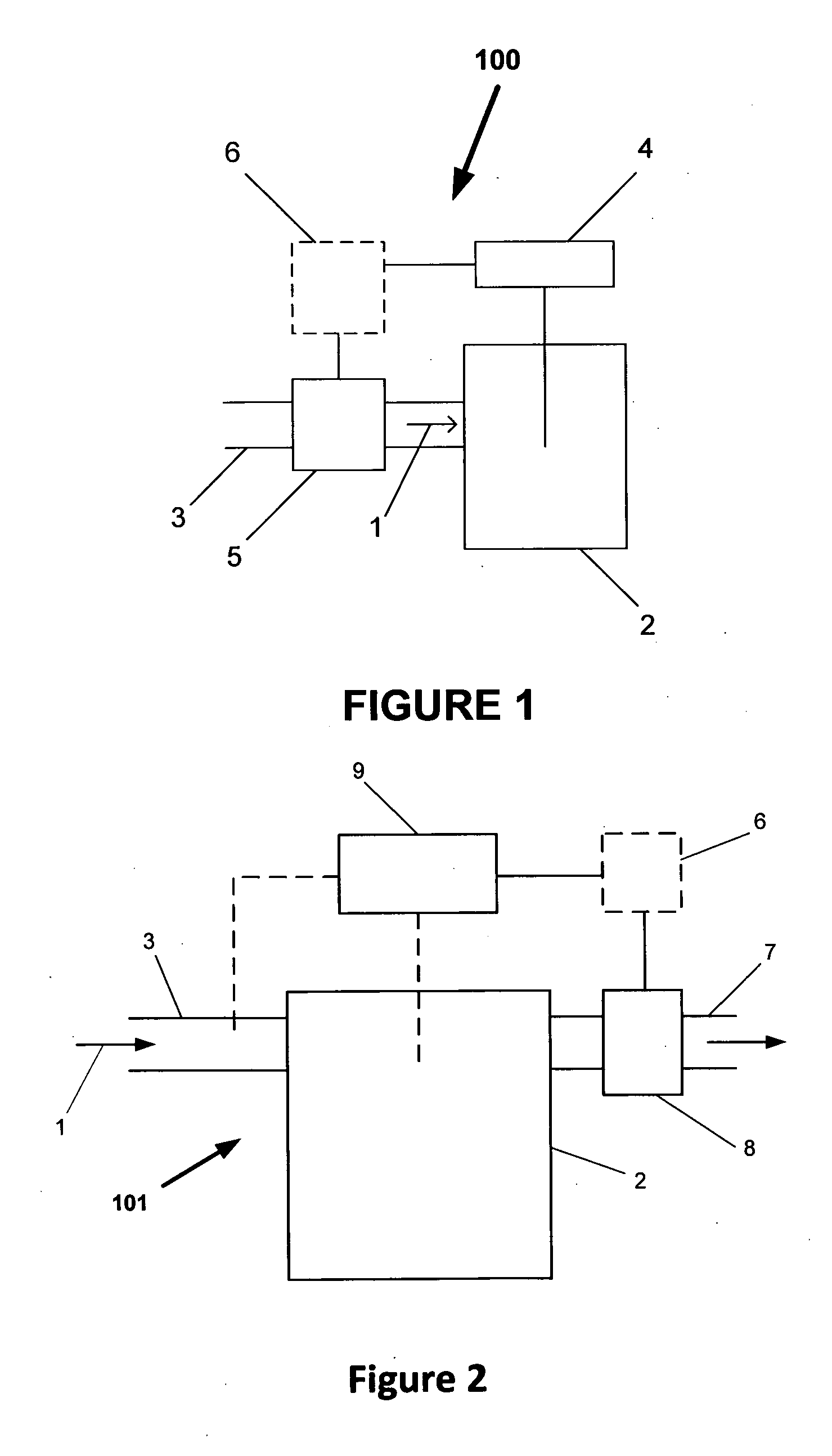

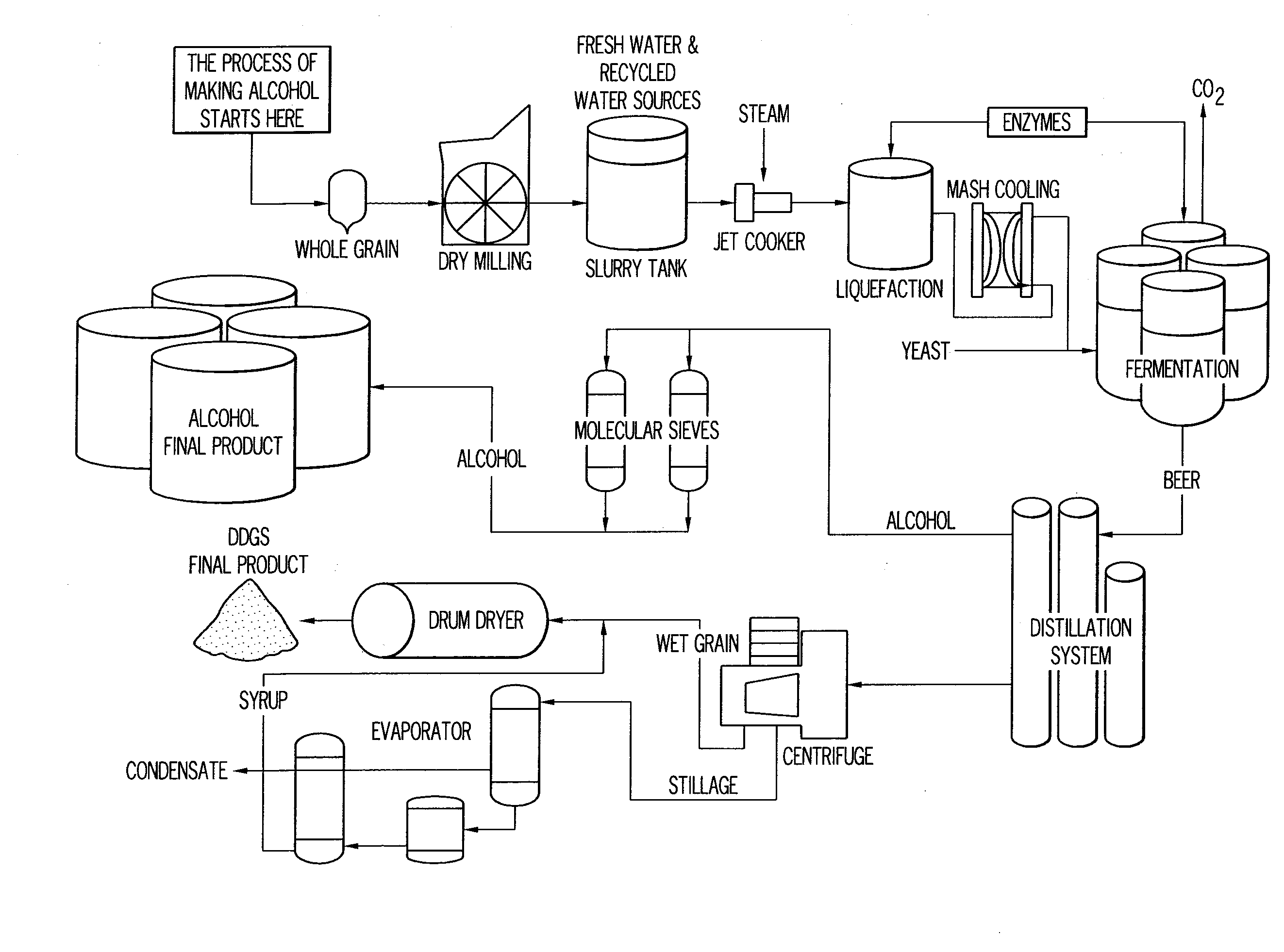

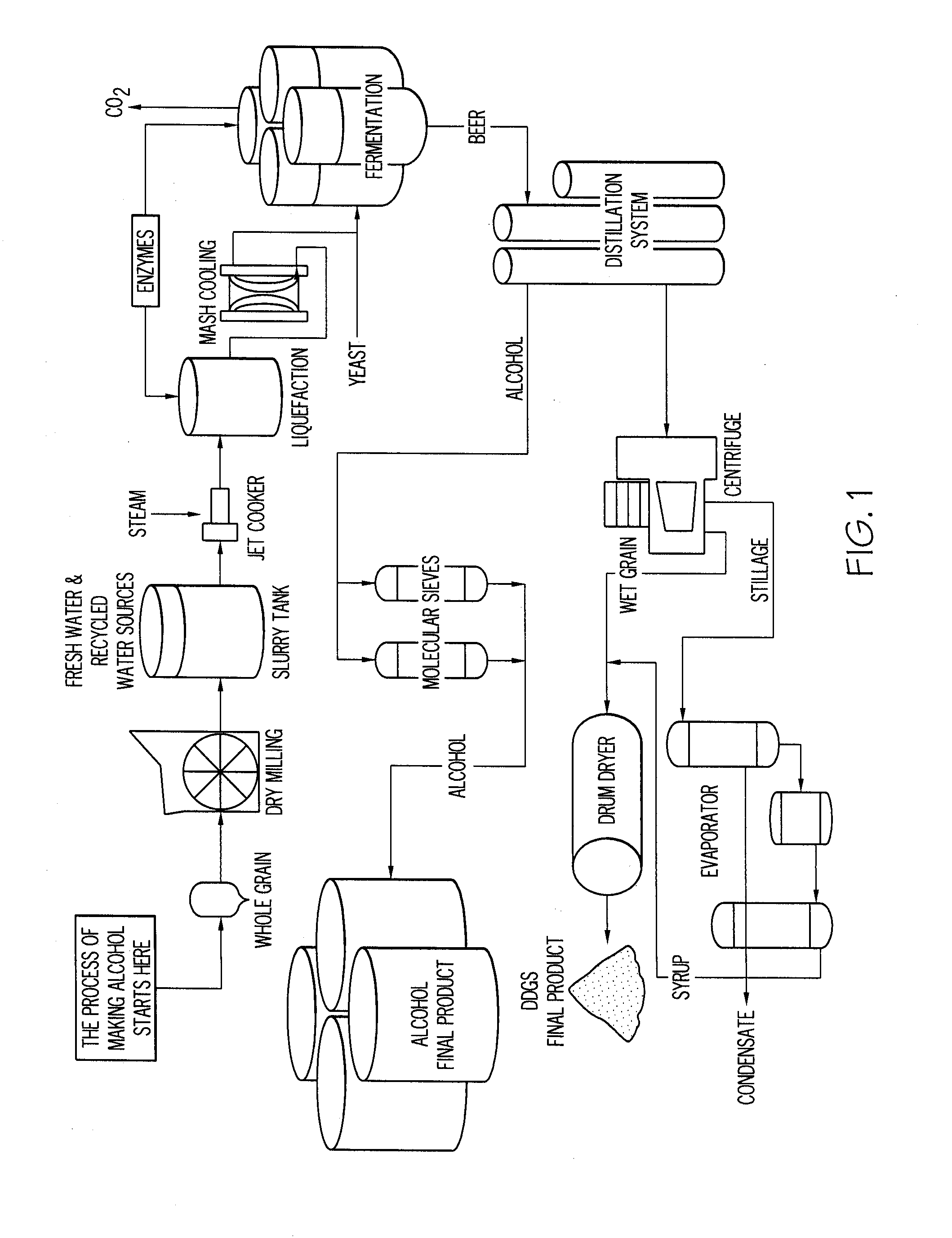

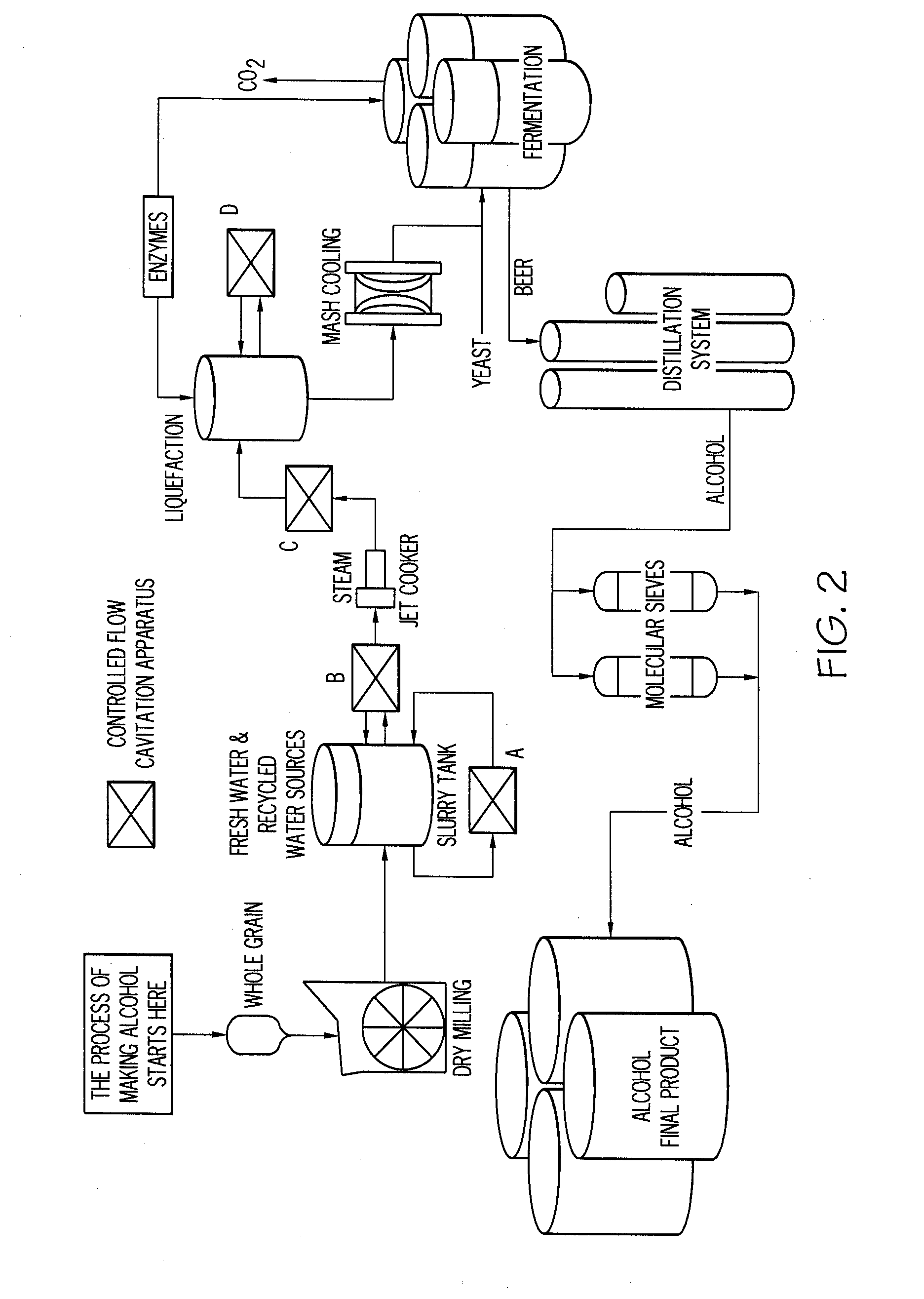

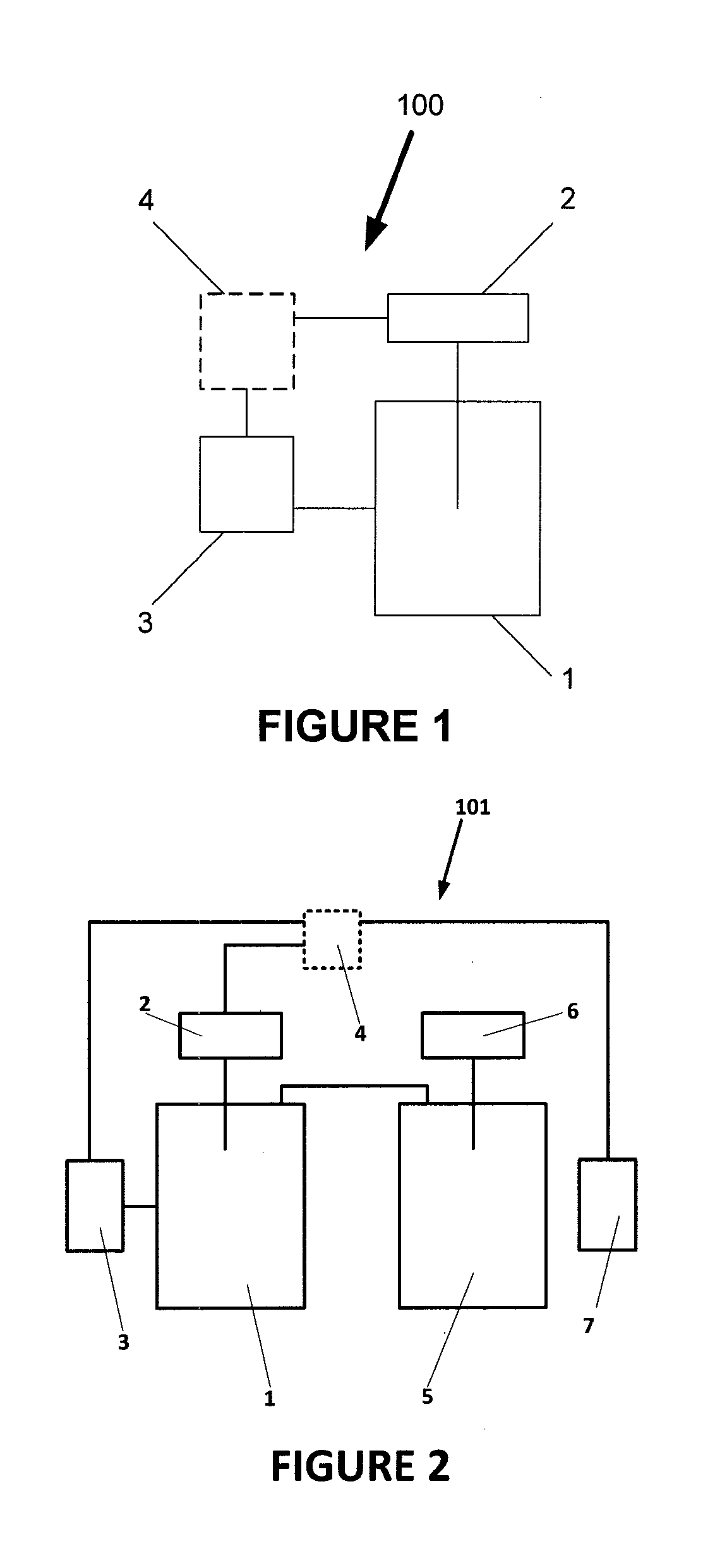

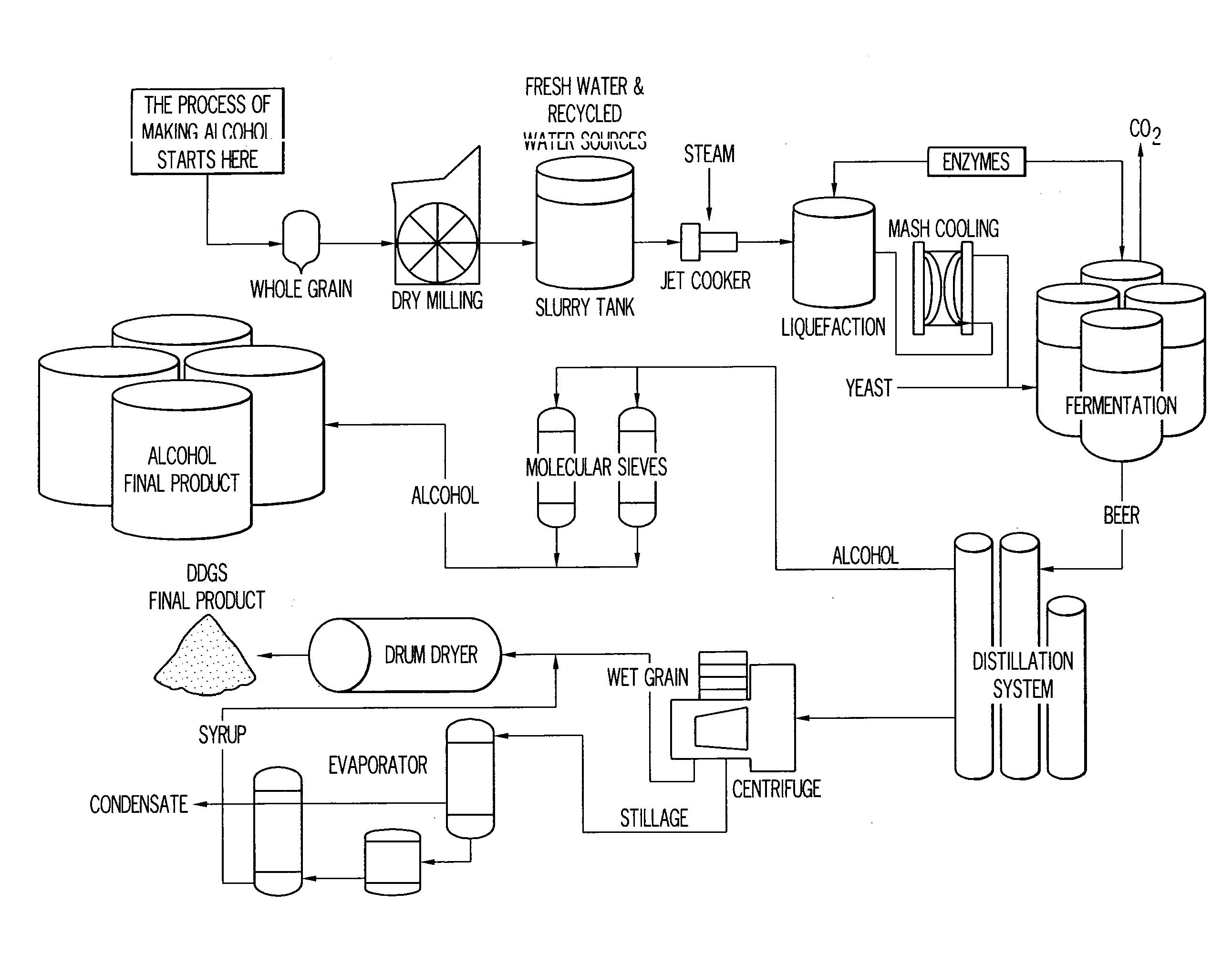

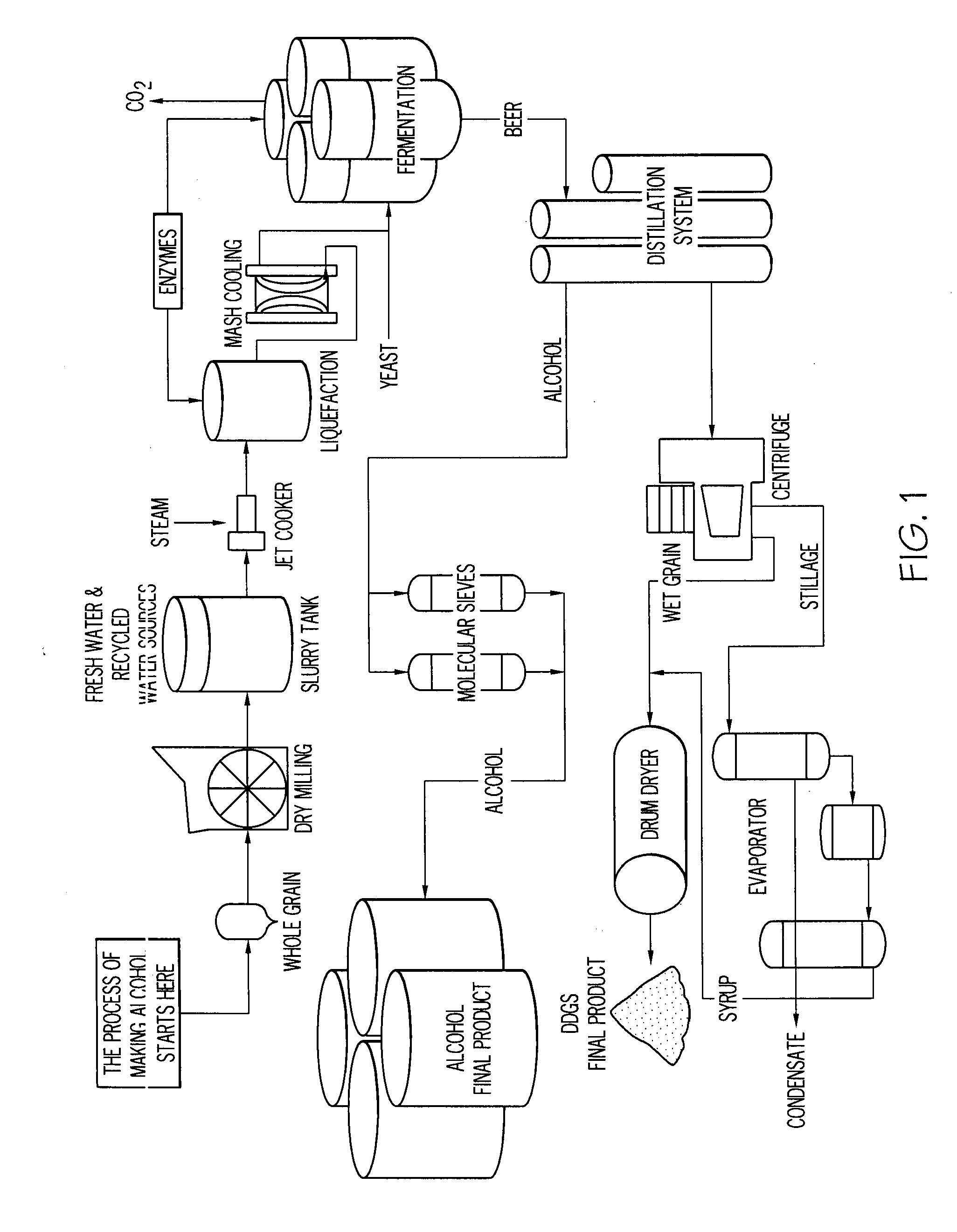

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

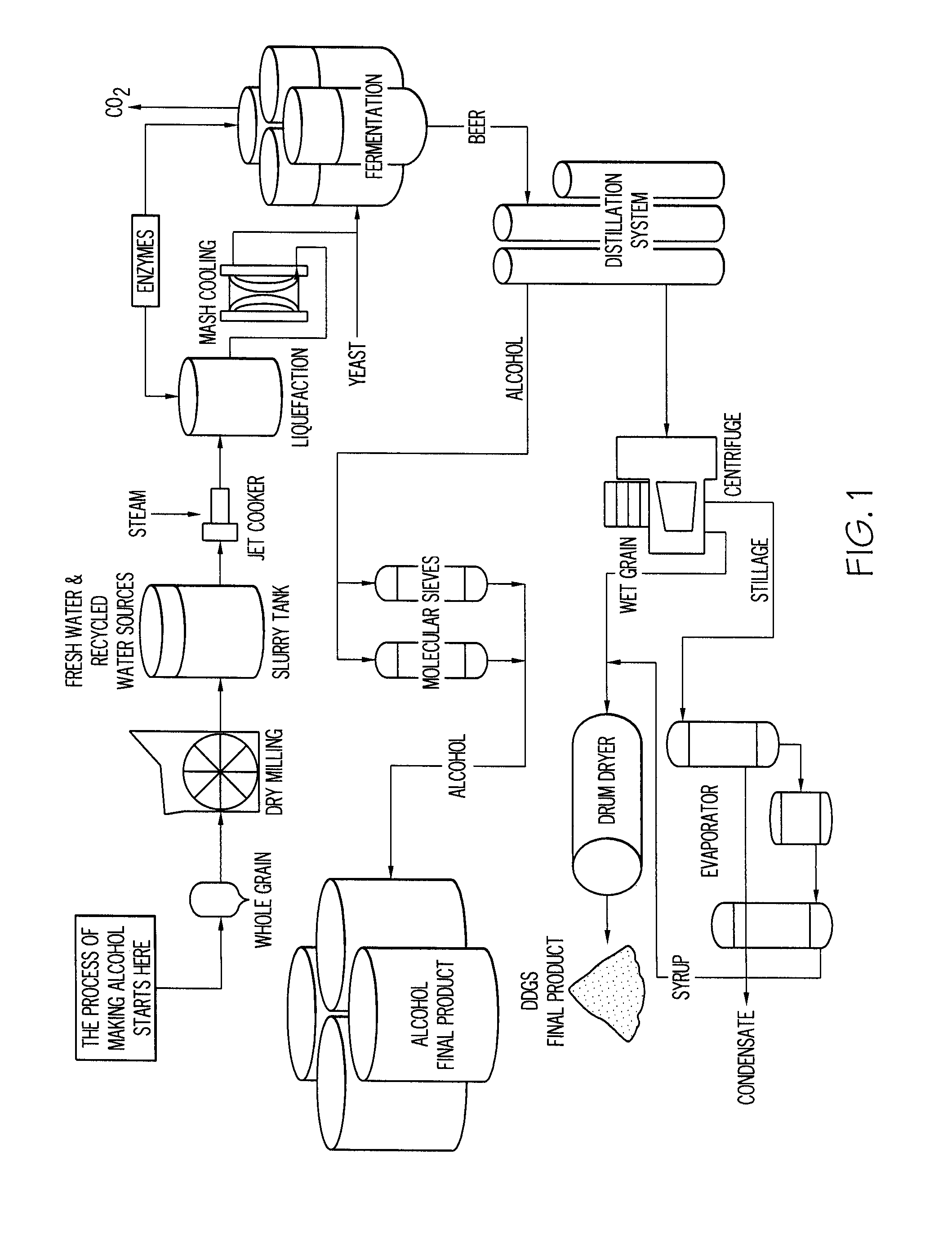

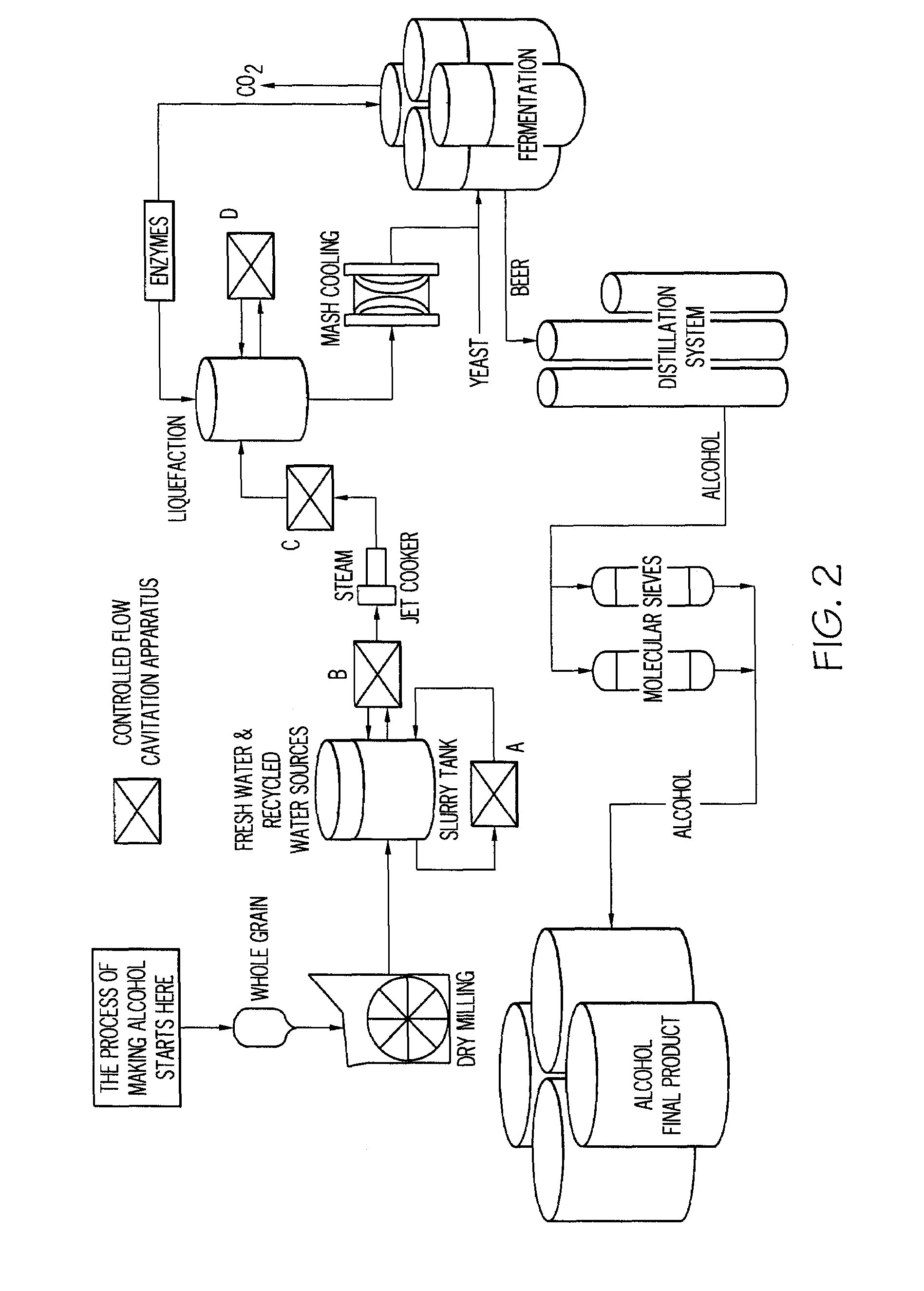

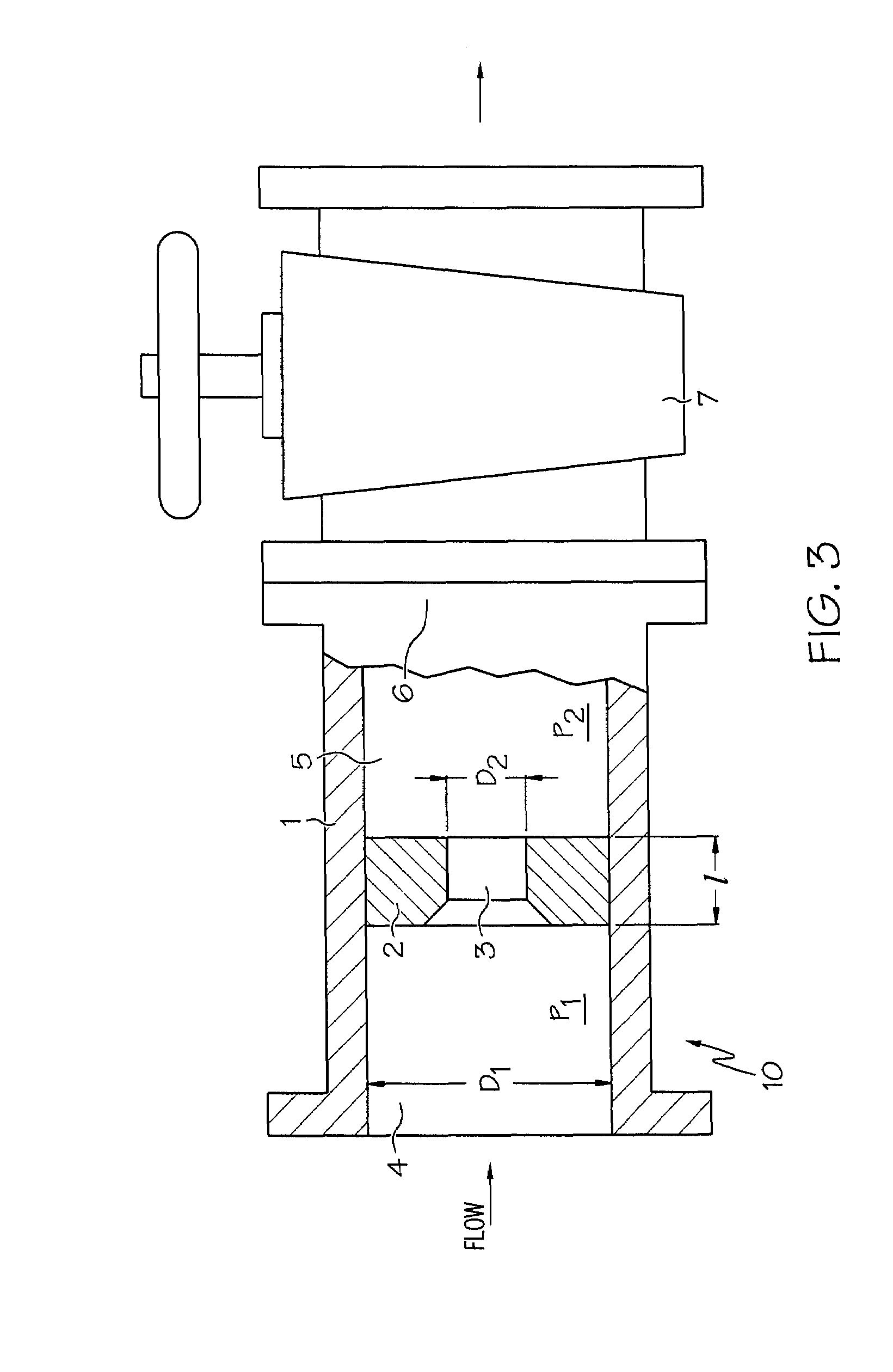

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

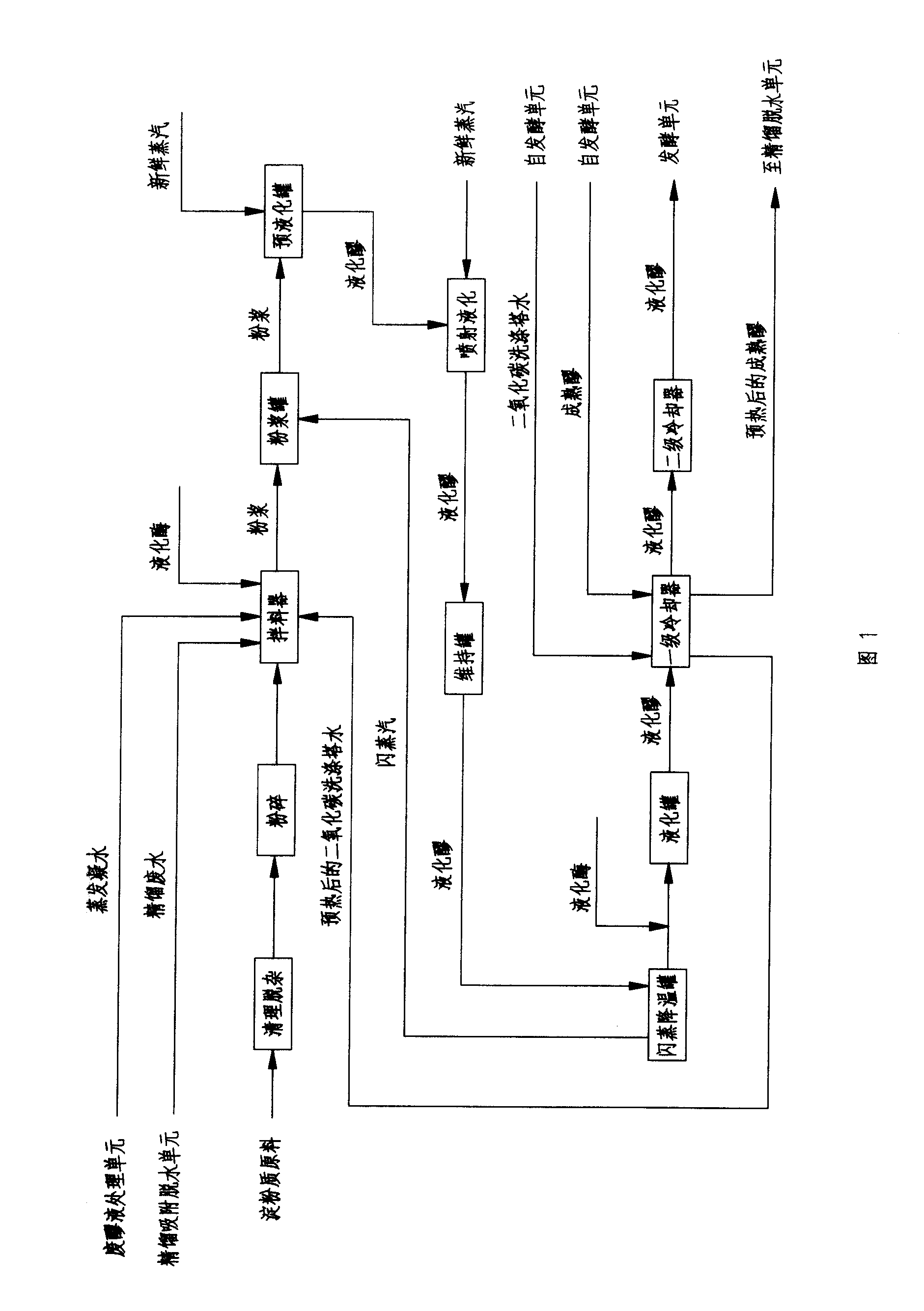

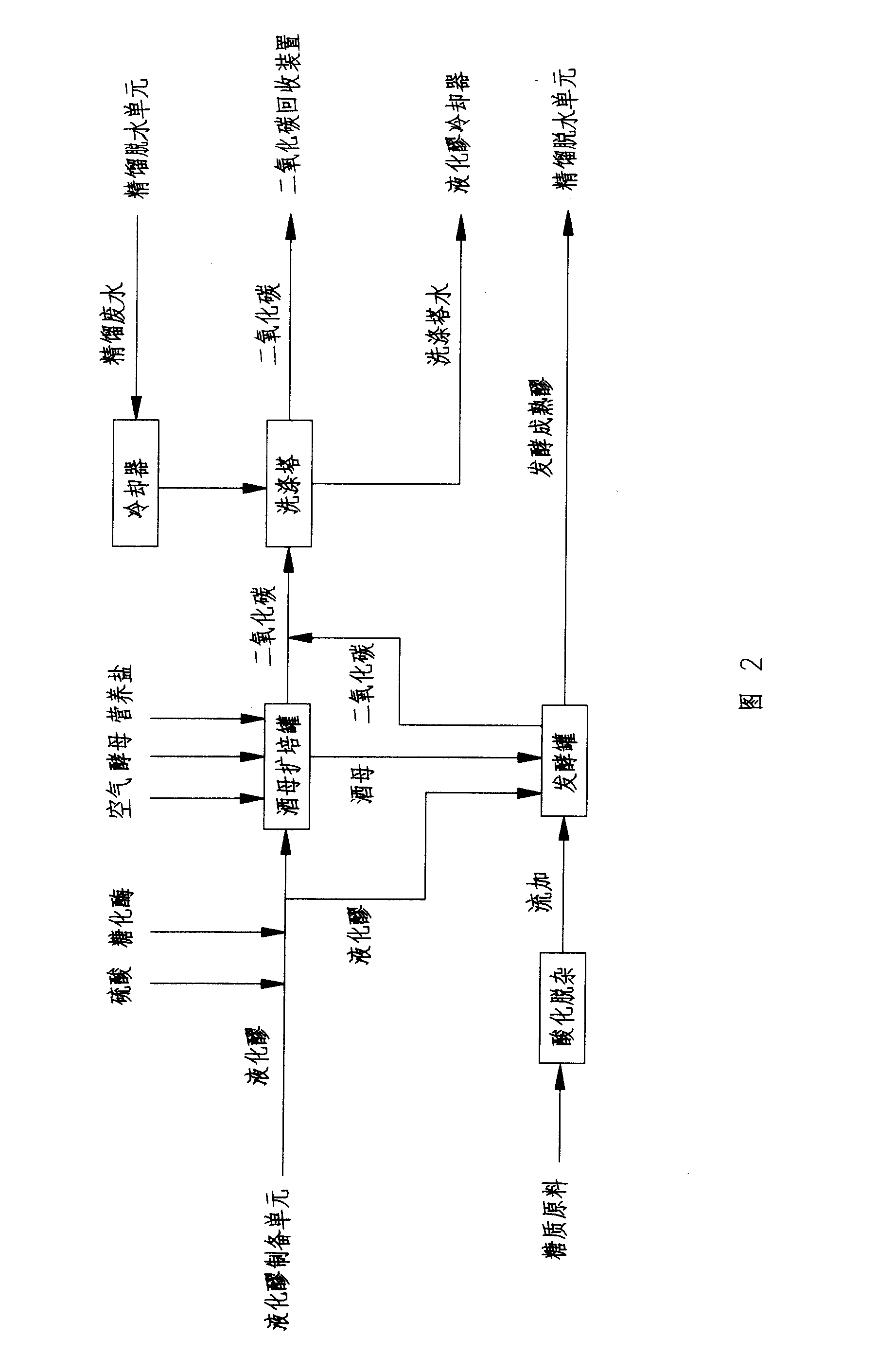

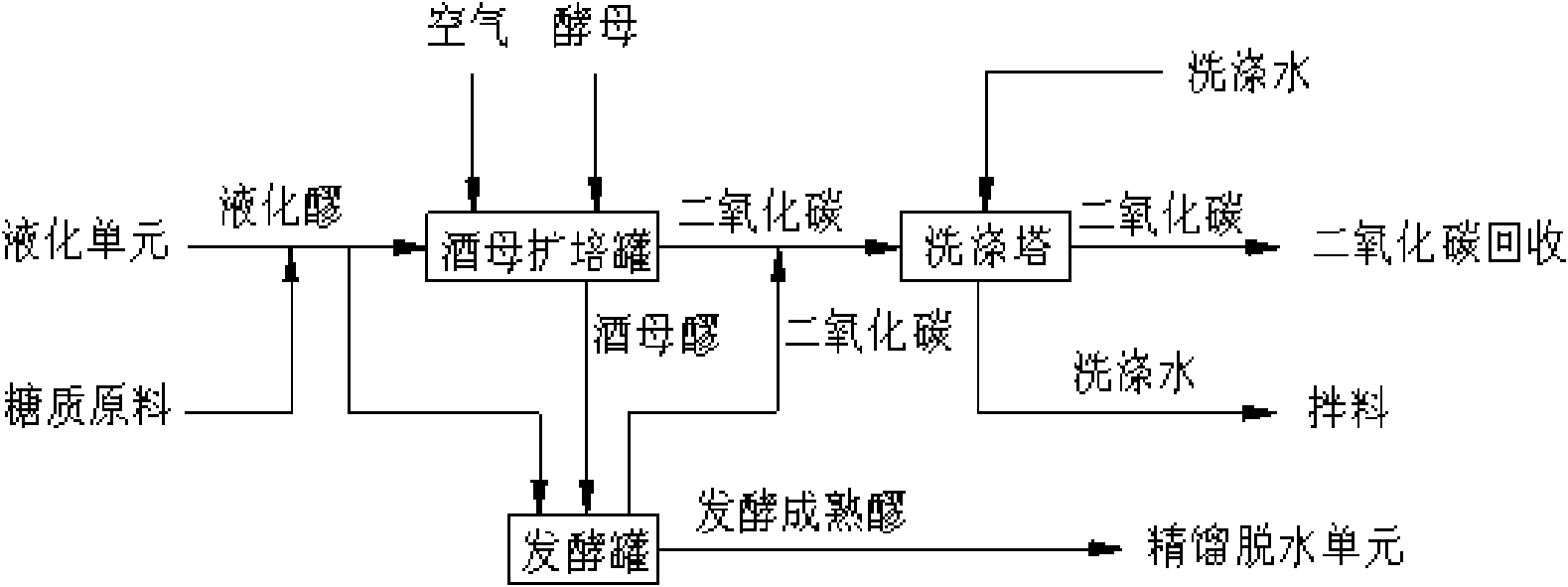

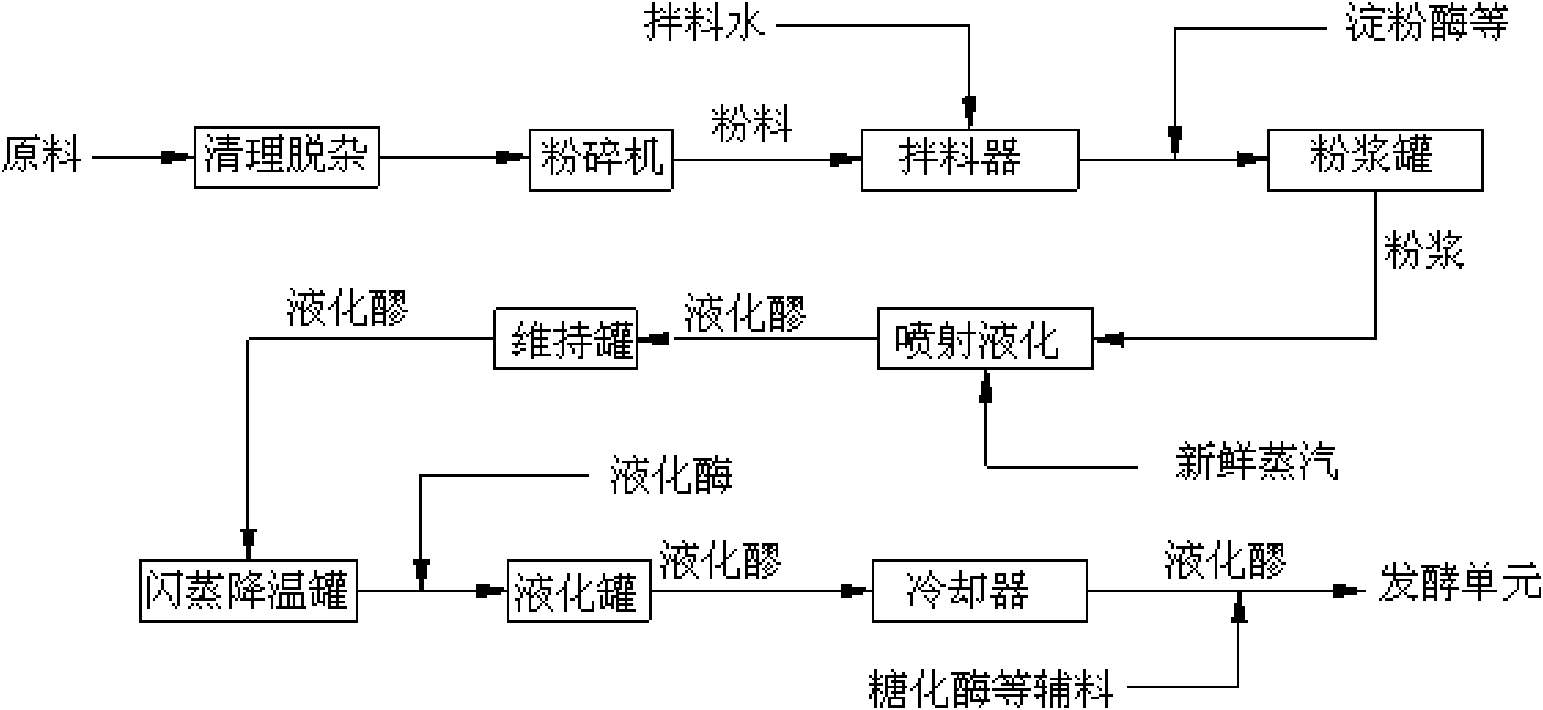

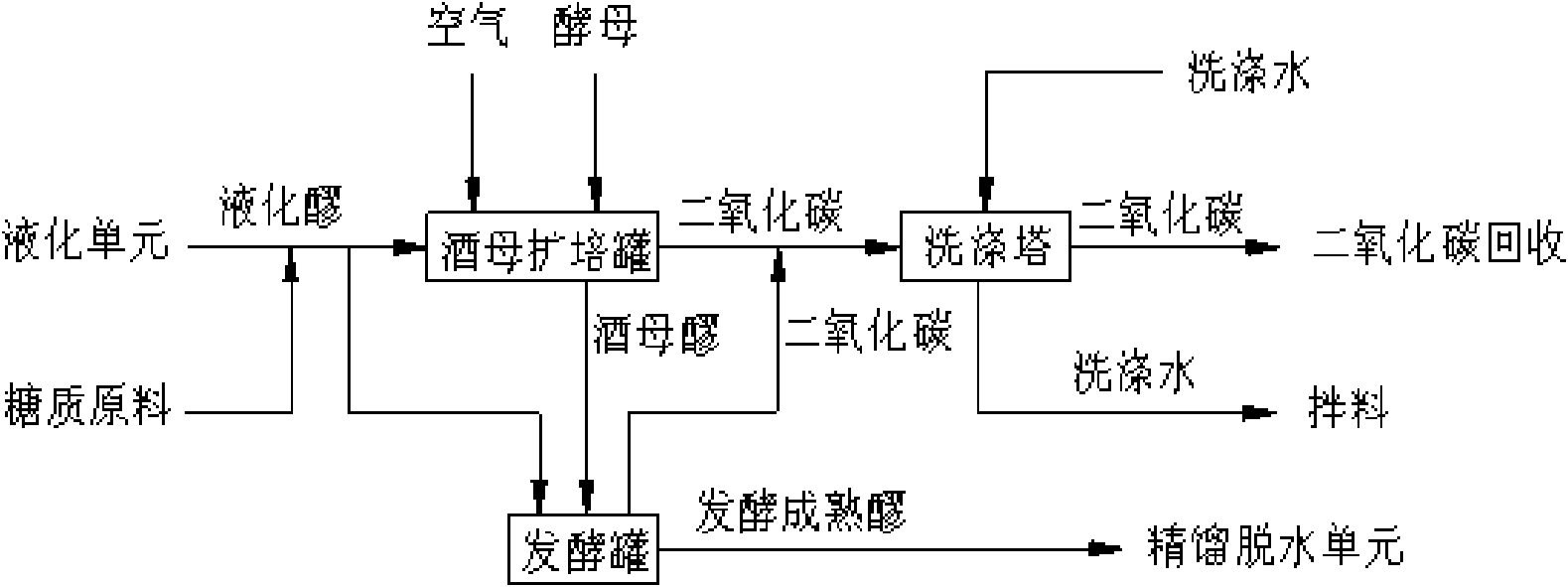

Fuel ethanol production equipment and method

InactiveCN101157890ASolve process problemsSolve problems such as large emissionsBioreactor/fermenter combinationsBiological substance pretreatmentsUltrafiltrationAlcohol production process

The invention relates to a novel equipment and a method of ethanol fuel production. The water resource in a preparation unit of liquefied wort is the washing water in a CO2 washing tower. A recovery tower pot collects waste water and a portion of liquor condensate by vaporing when waste water is dealt with to send to a mixing machine of the preparation unit of liquefied wort. And the consumption of fresh water is zero. The process of rectification and dehydration adopts technology of multieffect thermal coupling rectification. Only when the recovery tower pot uses fresh vapor to heat, the energy consumption of the process of rectification and dehydration is reduced largely. The waste wort solution produced by the alcohol production process which is dealt with by the device for pneumatic drying, multieffect evaporation of clear liquid, being anaerobic and oxygen consumption of the vapored condensate liquor and purifying by using ultrafiltration membrane etc, can be recovered with the valuable product. The reasonable treatment plan realizes zero discharge of technique waste water when in the ethanol fuel production.

Owner:TIANJIN UNIV

Alcohol production process

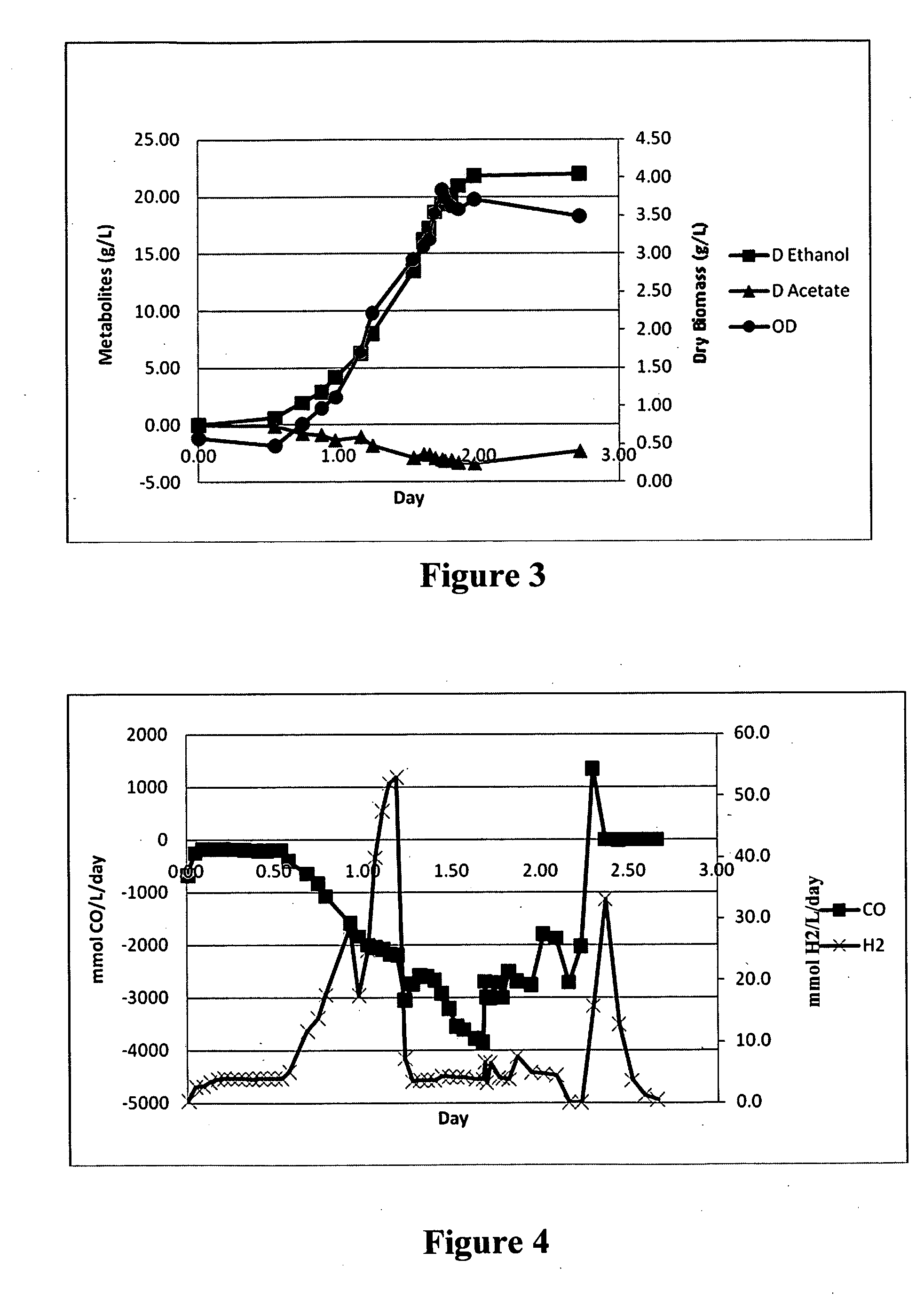

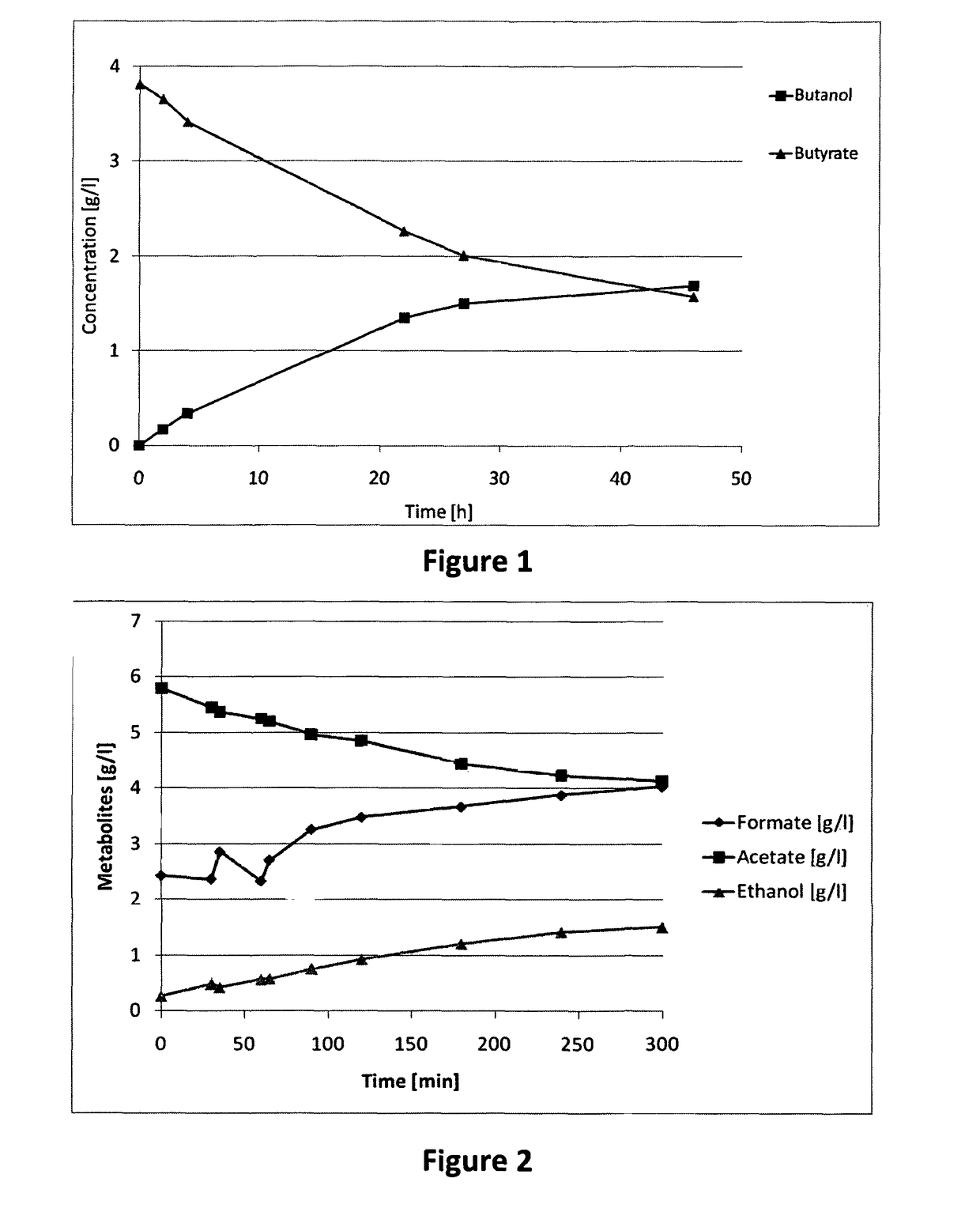

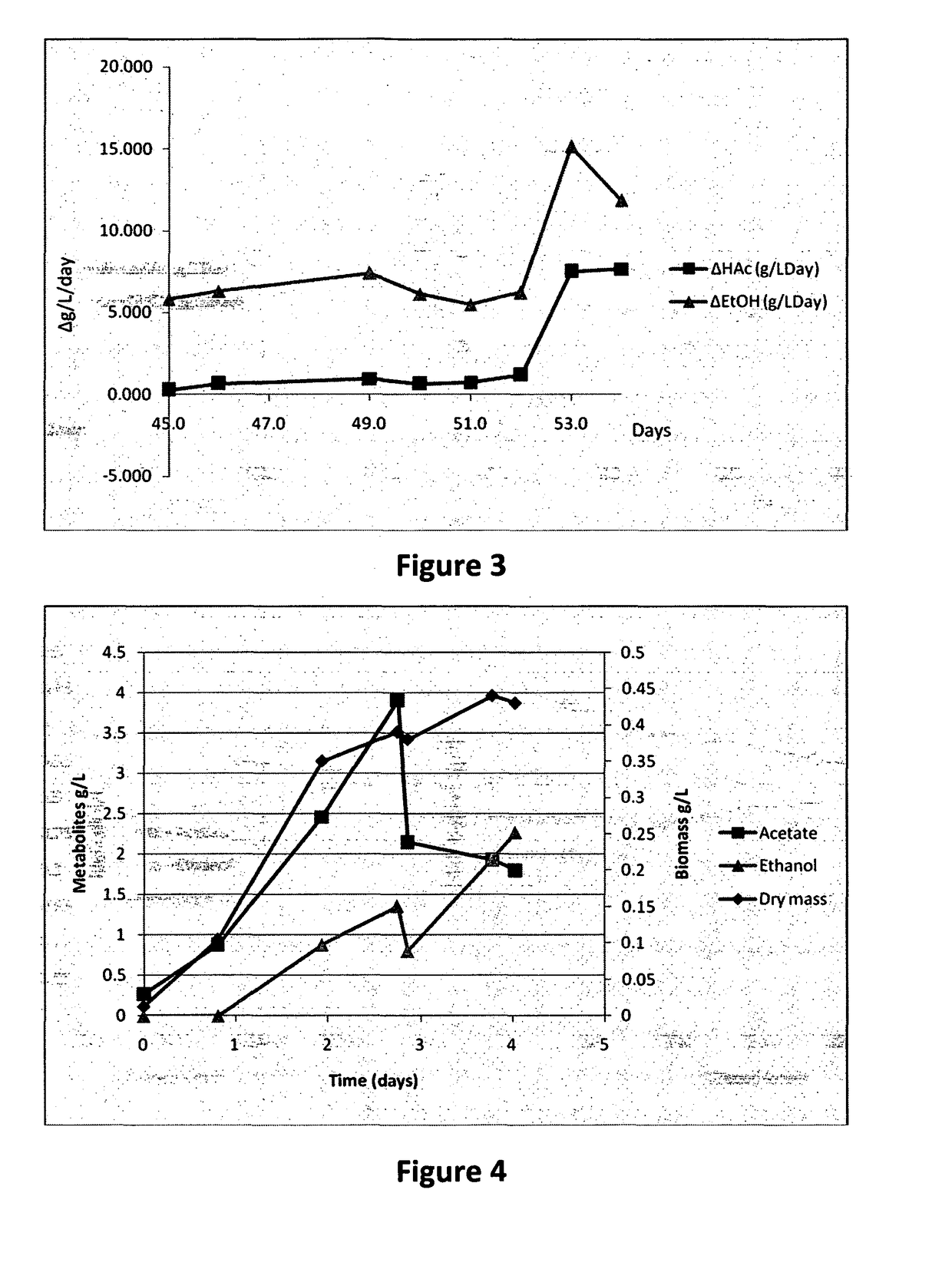

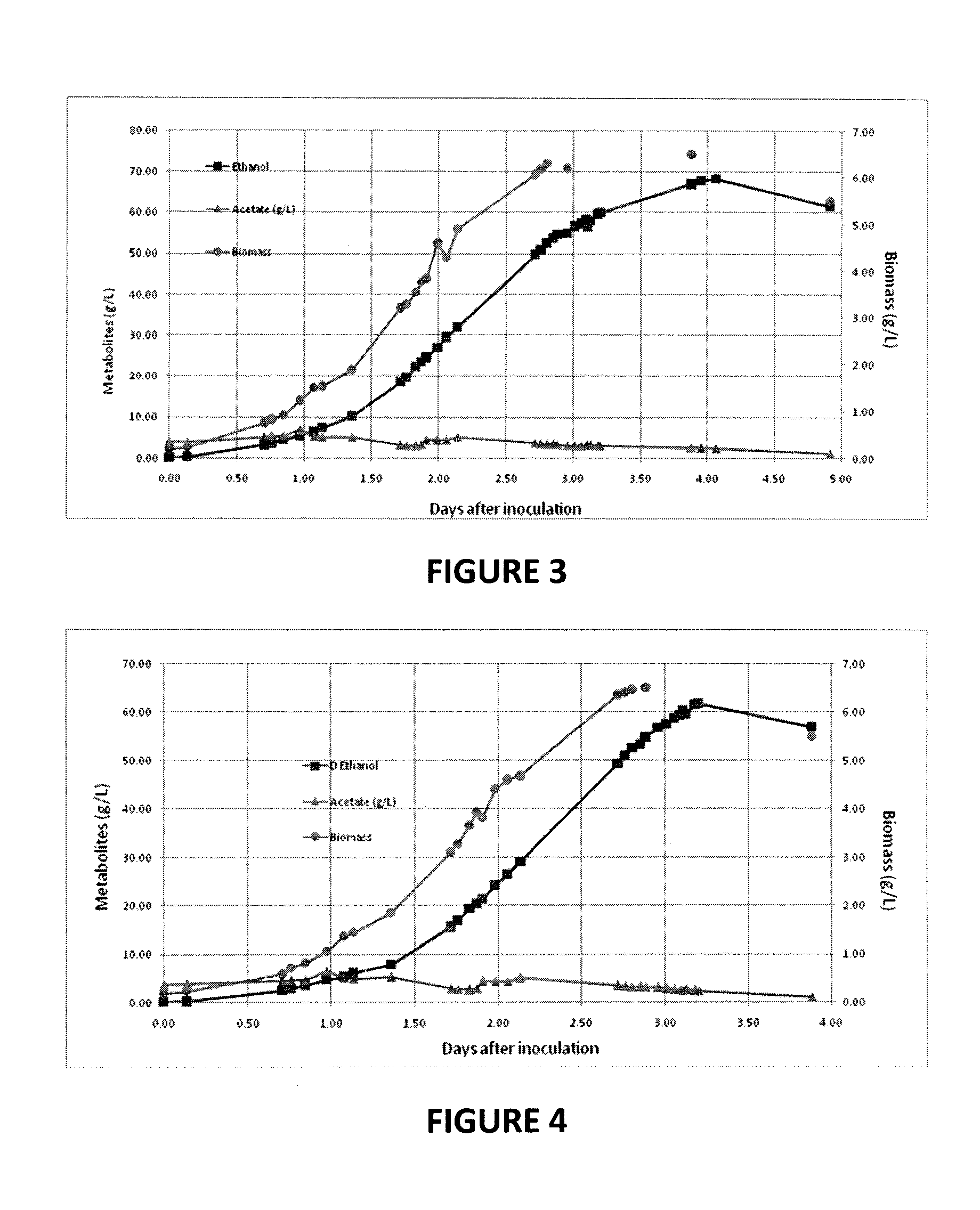

InactiveUS20110212433A1Improve efficiencyImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteChemistry

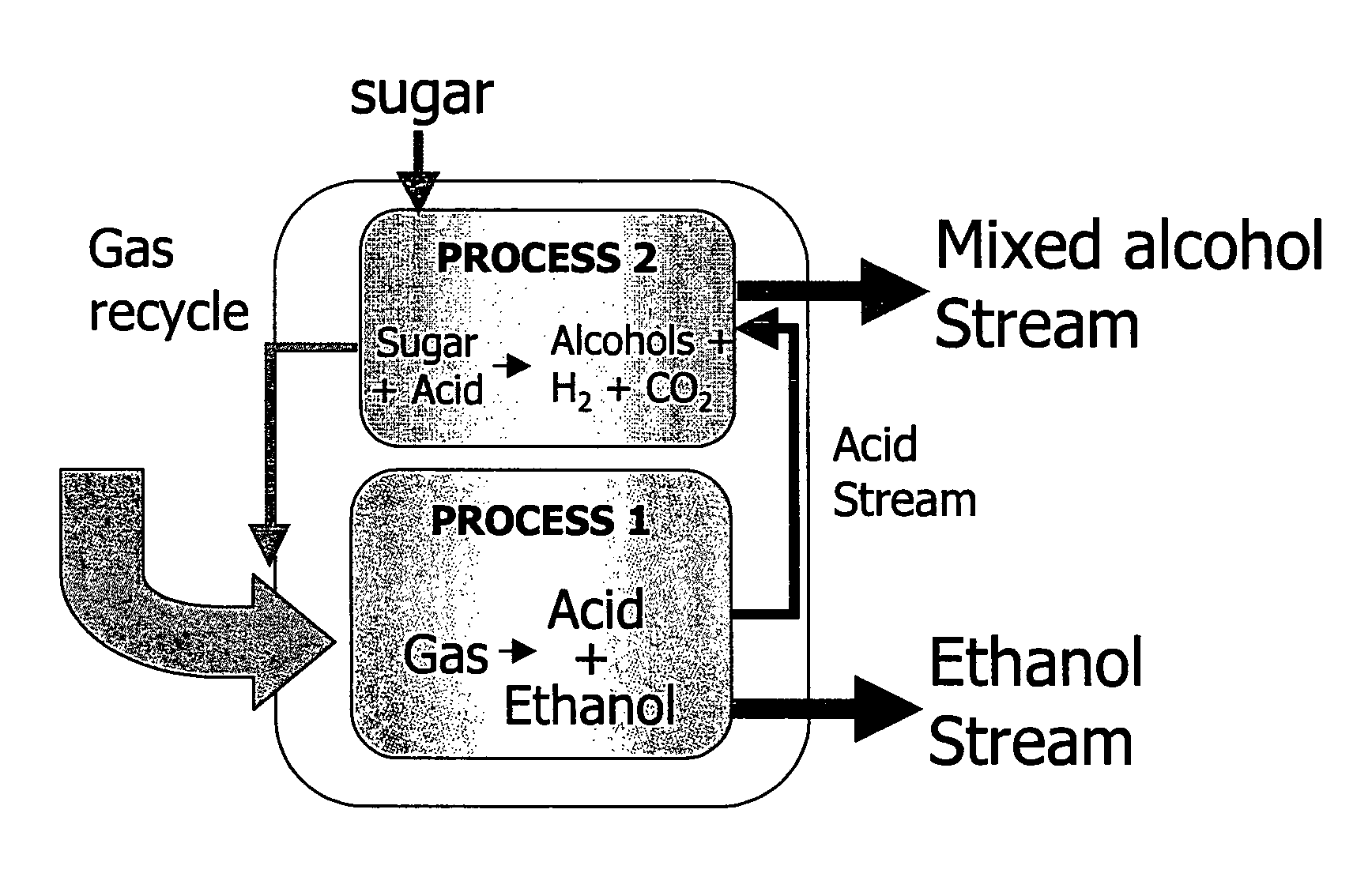

The invention relates to the production of products such as alcohols and acids by microbial fermentation, particularly microbial fermentation of substrates comprising CO. It more particularly relates to methods and systems for improving efficiency of production products by microbial fermentation. In particular embodiments, the invention provides a method of controlling substrate supply, such that production of desired metabolites is optimised.

Owner:LANZATECH NZ INC

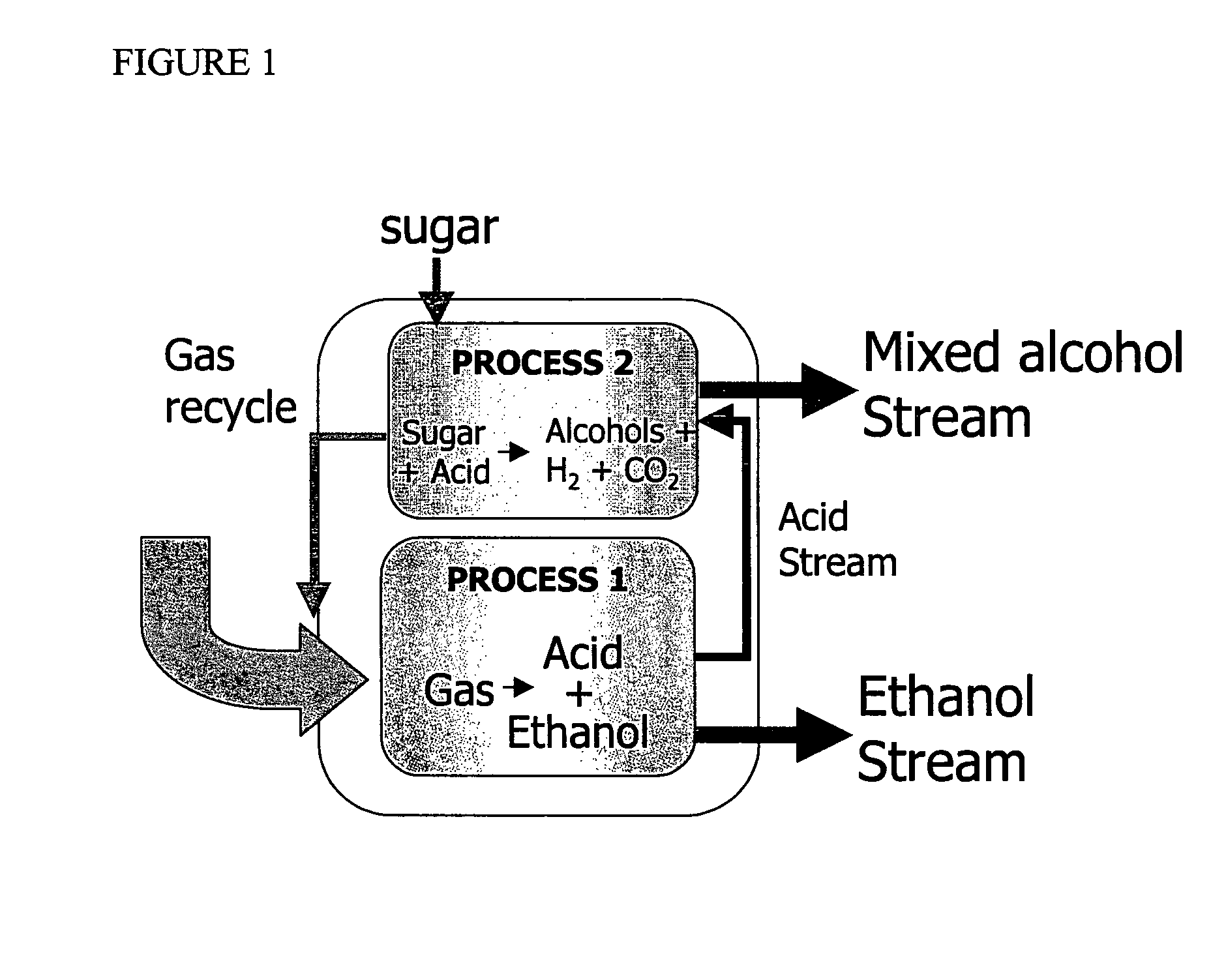

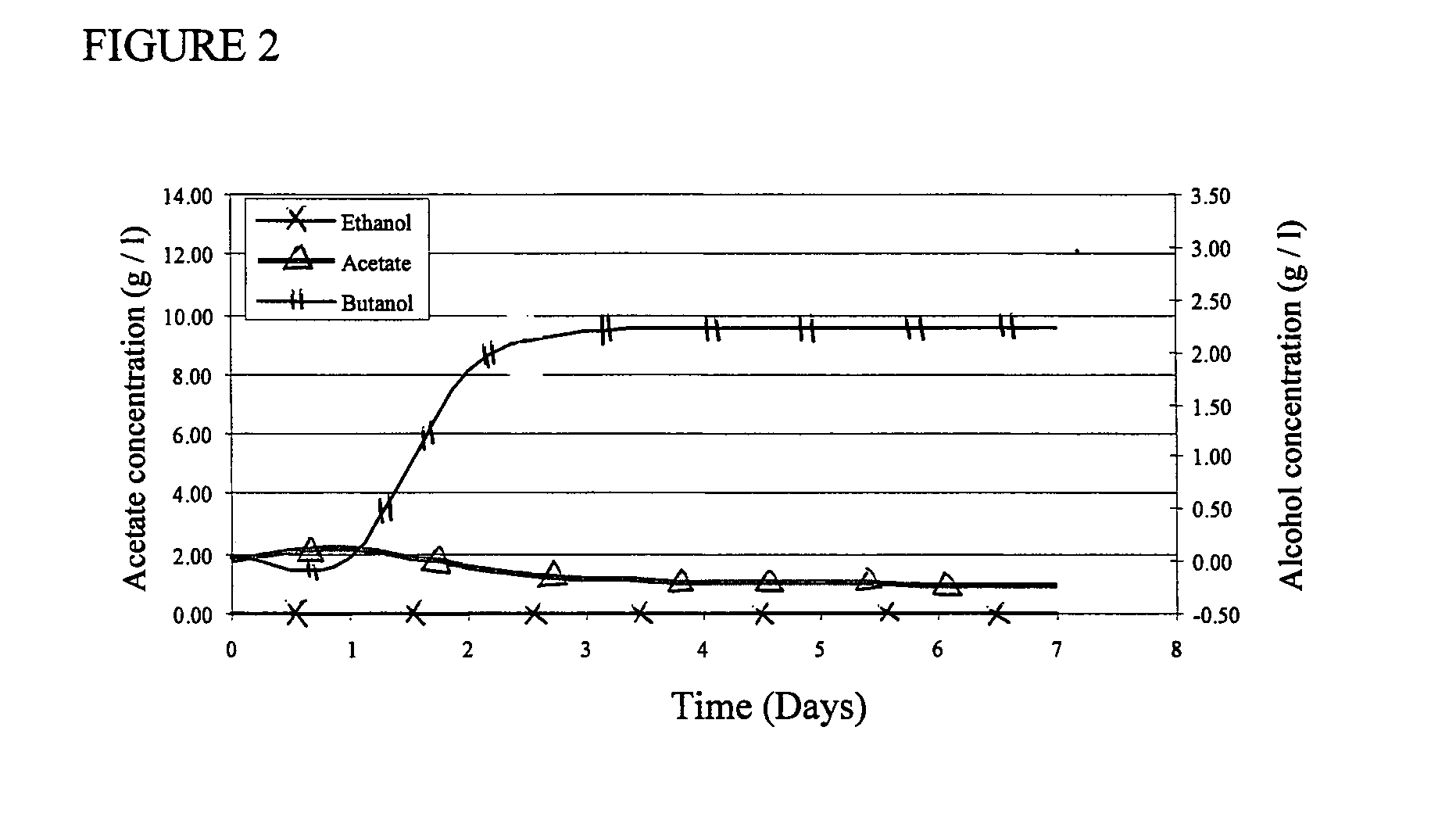

Microbial alcohol production process

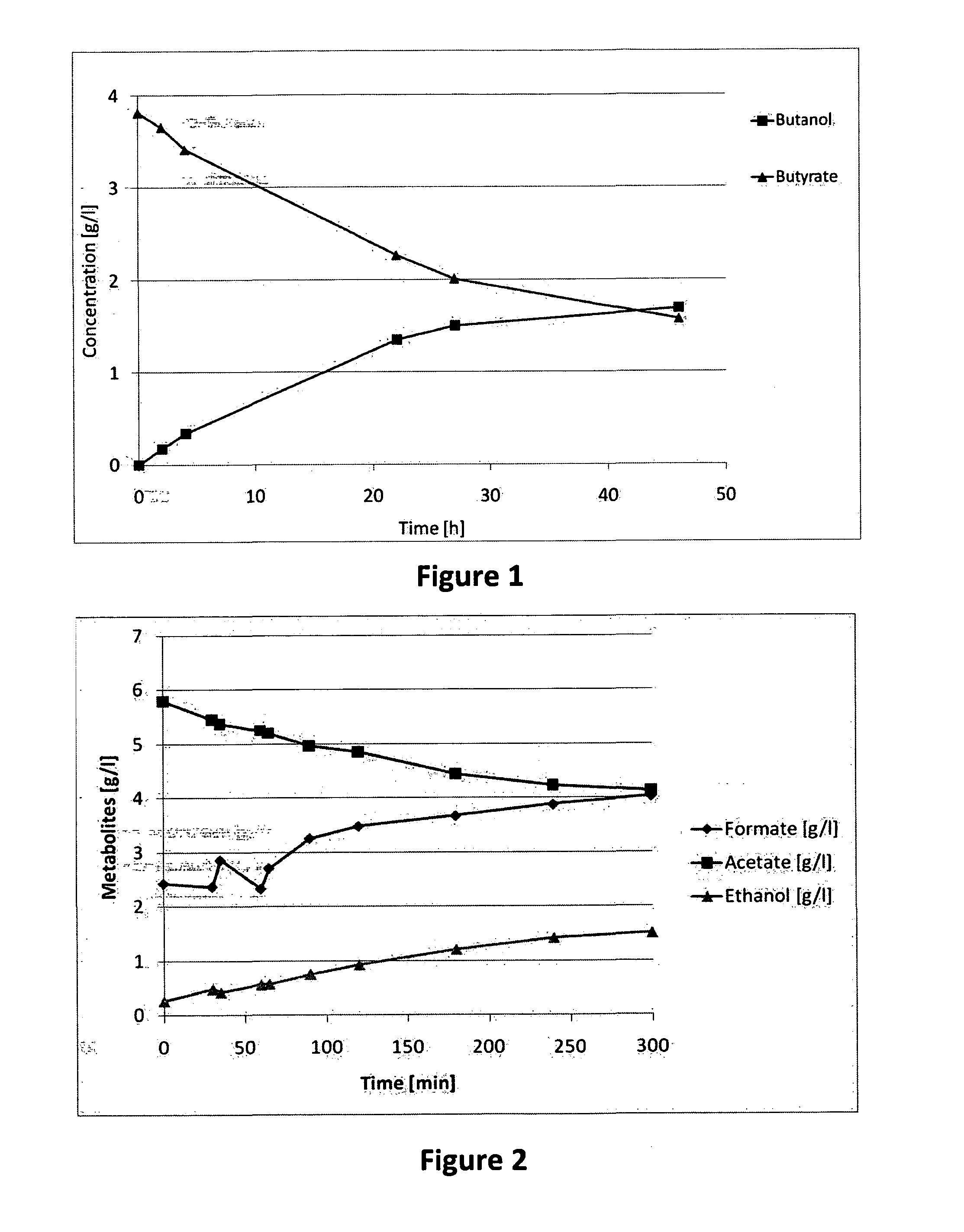

ActiveUS20110059499A1Reduces and prevents productionReduces and prevents microbial growthBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologyAlcohol production process

The invention relates to the production of alcohols by microbial fermentation, particularly to production of alcohols by microbial fermentation of substrates comprising CO. It more particularly relates to processes for the production of alcohols from their corresponding acids in the presence of a substrate comprising CO. In particular embodiments, a fermentation reaction producing acid(s) and optionally alcohol(s) is perturbed such that at least a portion one or more of acid(s) is converted to alcohol.

Owner:LANZATECH NZ INC

Apparatus and method for increasing alcohol yield from grain

InactiveUS7667082B2Increased ethanol productionReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsControl flowLiquid medium

Owner:ARISDYNE STSTEMS INC

Alcohol production process

ActiveUS8293509B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorButanol

Owner:LANZATECH NZ INC

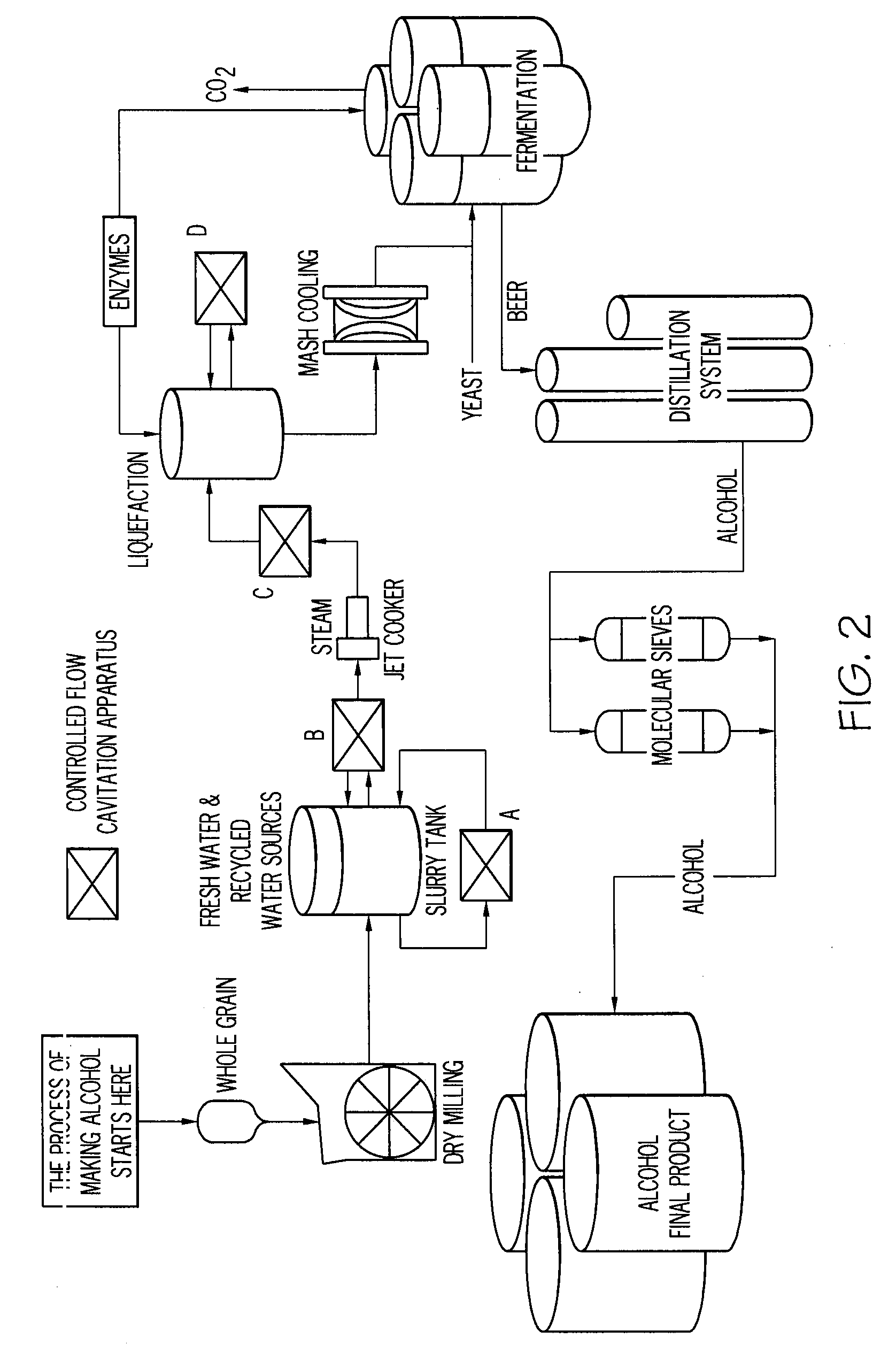

Apparatus and method for increasing alcohol yield from grain

InactiveUS20080281131A1Increased ethanol productionReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsControl flowCavitation

A method comprising applying a controlled flow cavitation apparatus to an alcohol production process in order to increase alcohol yield. A grain-based liquid medium comprising grain and a liquid carrier can be passed through a controlled flow cavitation apparatus at a velocity capable of generating a hydrodynamic cavitation zone where the grain size can be reduced. One or more controlled flow cavitation apparatuses can be applied at various points of an alcohol production process, such as a starch-to-ethanol production process.

Owner:ARISDYNE STSTEMS INC

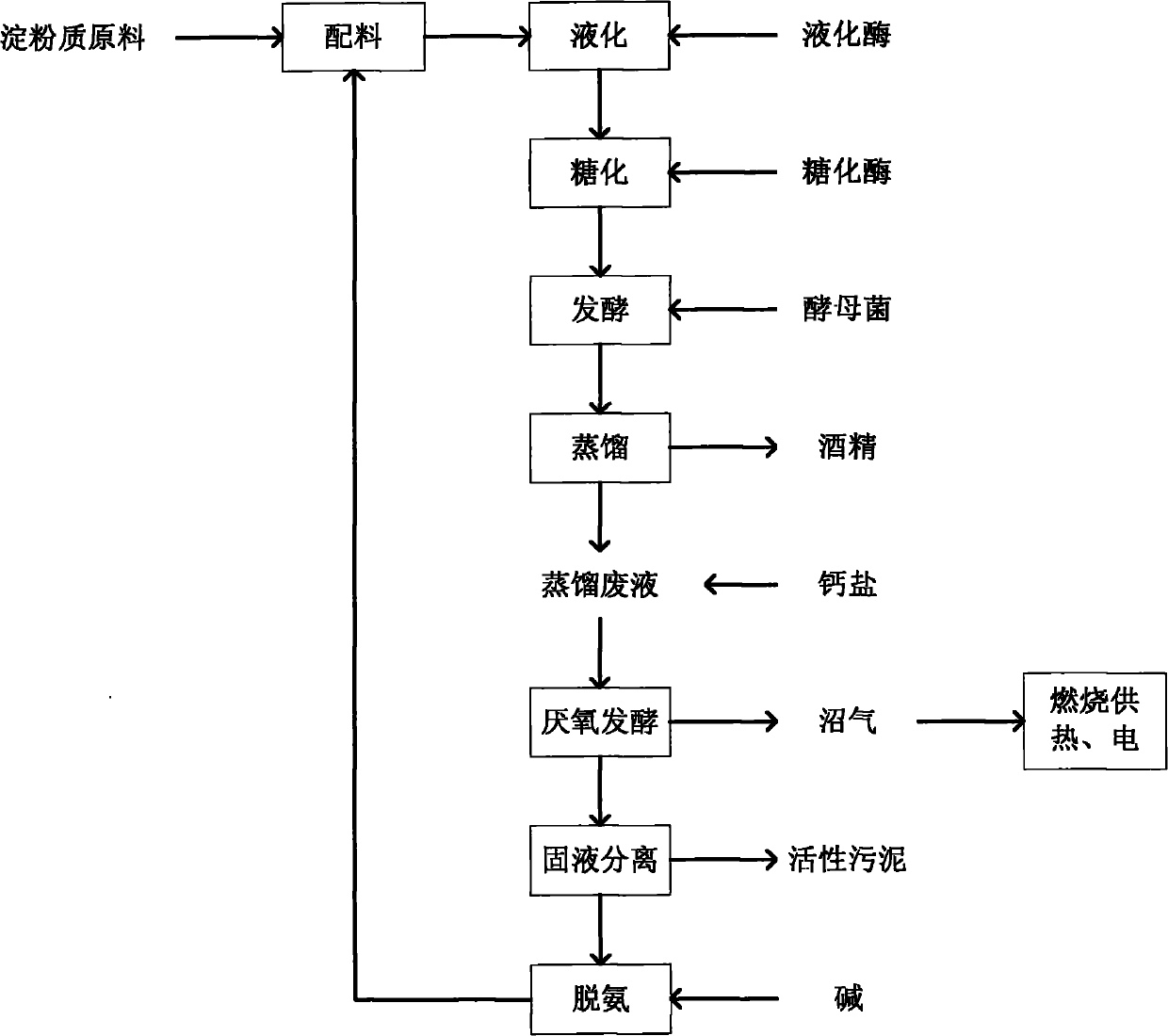

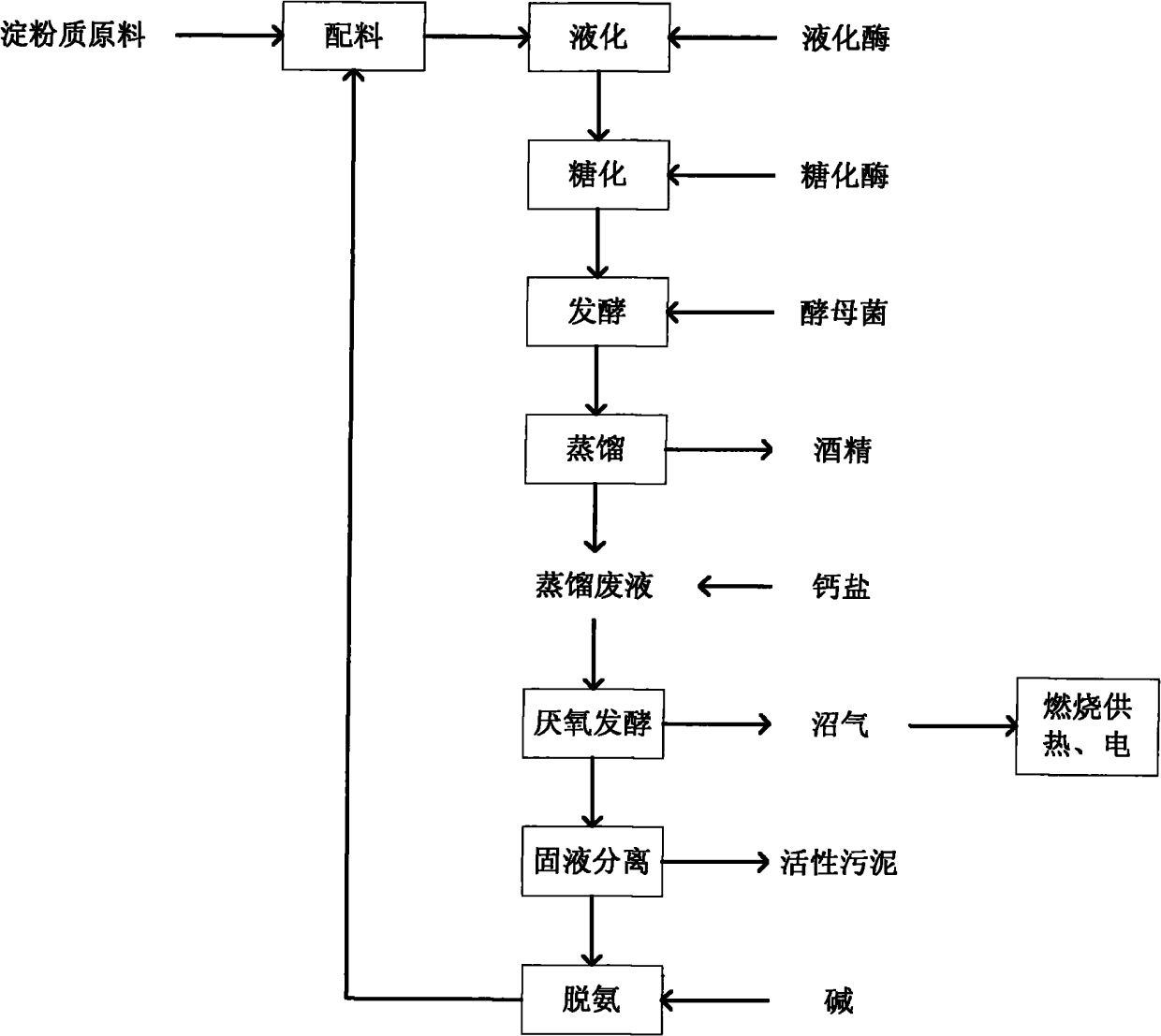

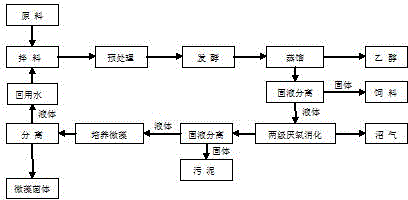

Method for producing alcohol by taking anaerobic effluent as ingredient water

ActiveCN102115764AEliminate potential hazardsImprove stabilityBiofuelsMultistage water/sewage treatmentLiquid wasteSulfate radicals

The invention relates to a method of an alcohol production process in which anaerobic effluent is taken as ingredient water. The method comprises the following steps of: mixing raw materials with deaminized anaerobic effluent in a specified material to water ratio; adjusting pH value and adding liquefied enzyme, heating, digesting and liquefying; cooling, and adding saccharified enzyme for saccharifying; lowering the temperature, inoculating and fermenting; distilling; precipitating sulfate radicals before performing anaerobic treatment on the distilled effluent obtained by distilling; and performing anaerobic treatment on the distilled effluent, and performing deamination treatment to obtain ingredient water for fermenting a next batch of alcohol. By adopting method, the running stability of the process in which the anaerobic effluent is taken as the ingredient water is enhanced, the content of hydrogen sulfide in marsh gas obtained by fermenting anaerobic marsh gas is lowered, and subsequent use of the marsh gas is facilitated.

Owner:JIANGNAN UNIV

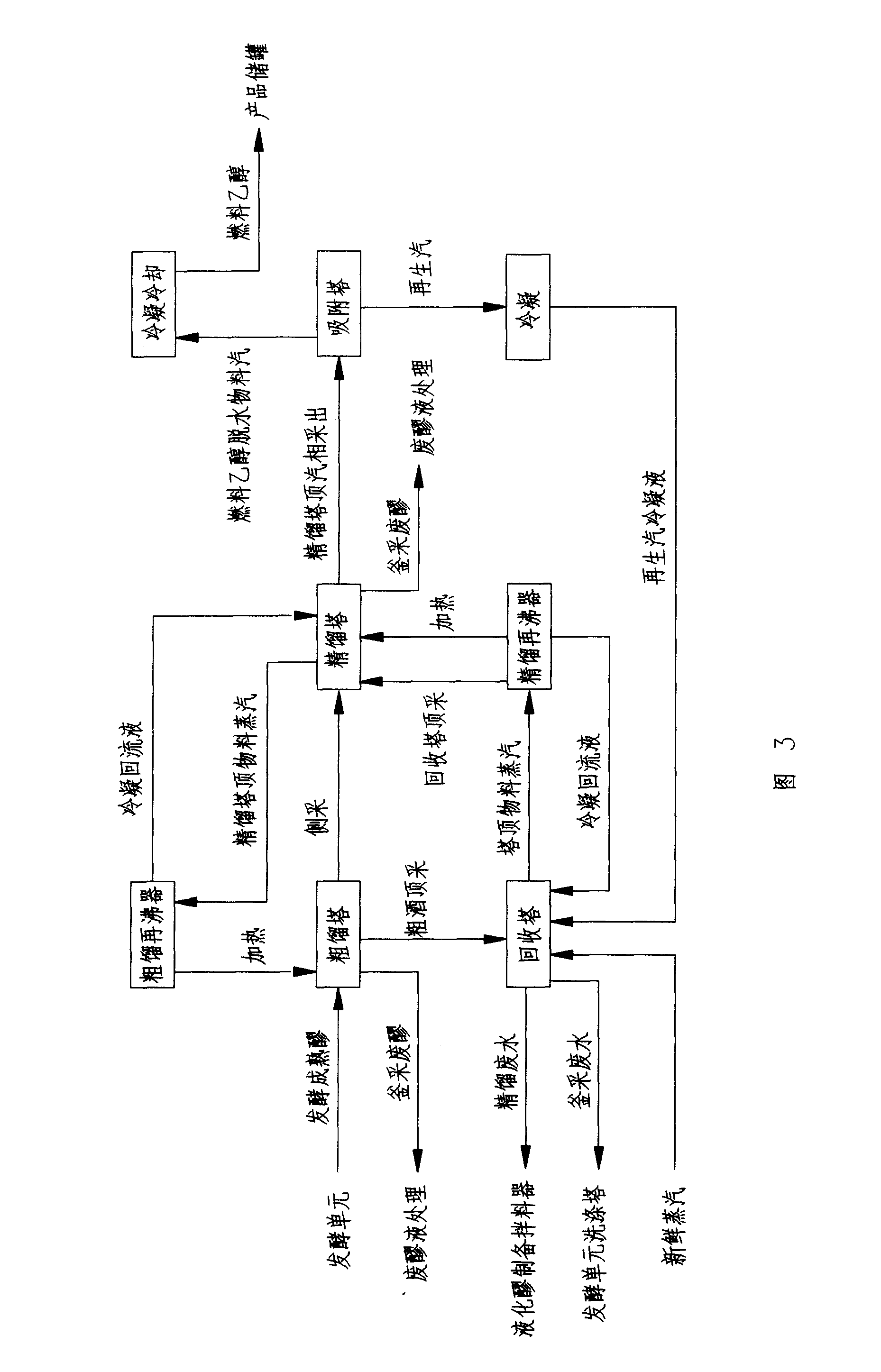

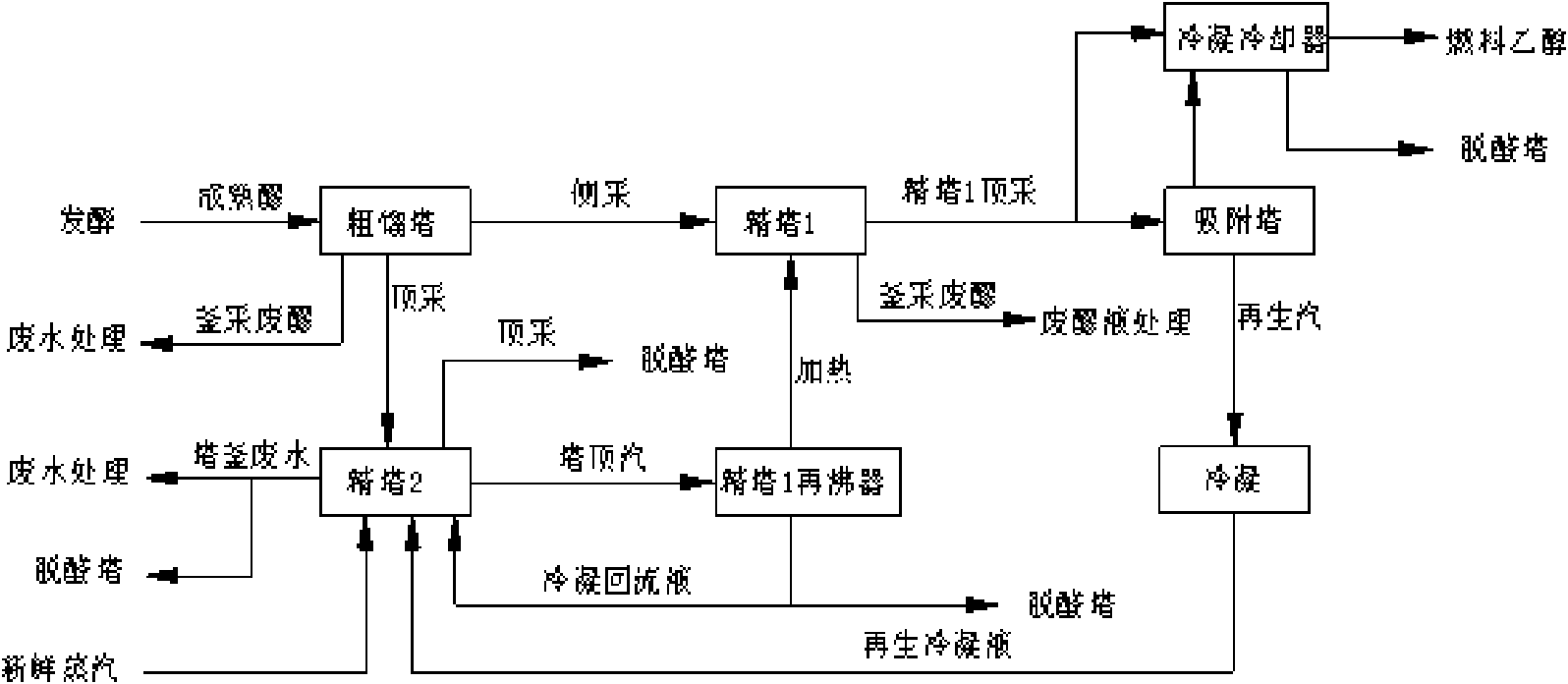

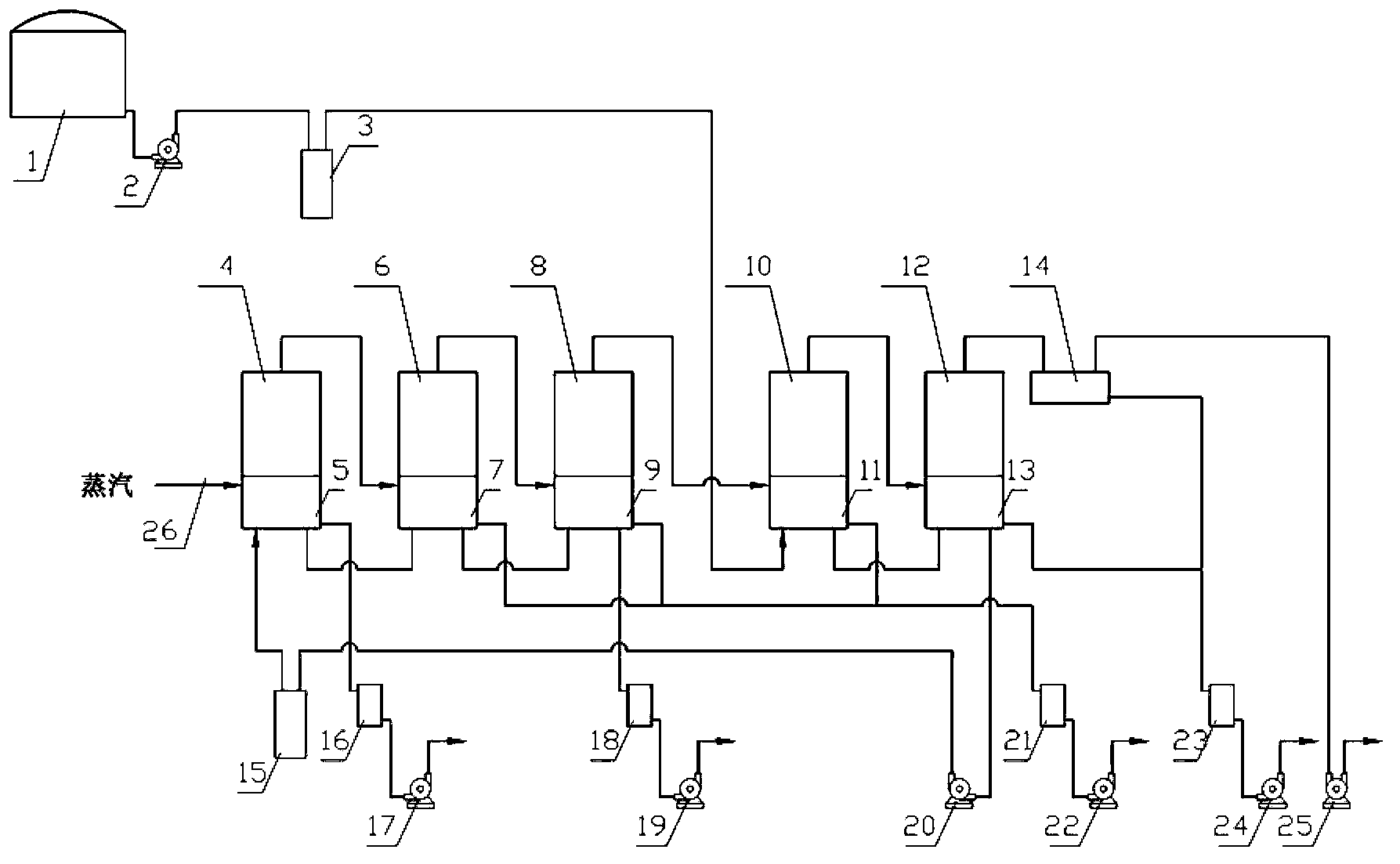

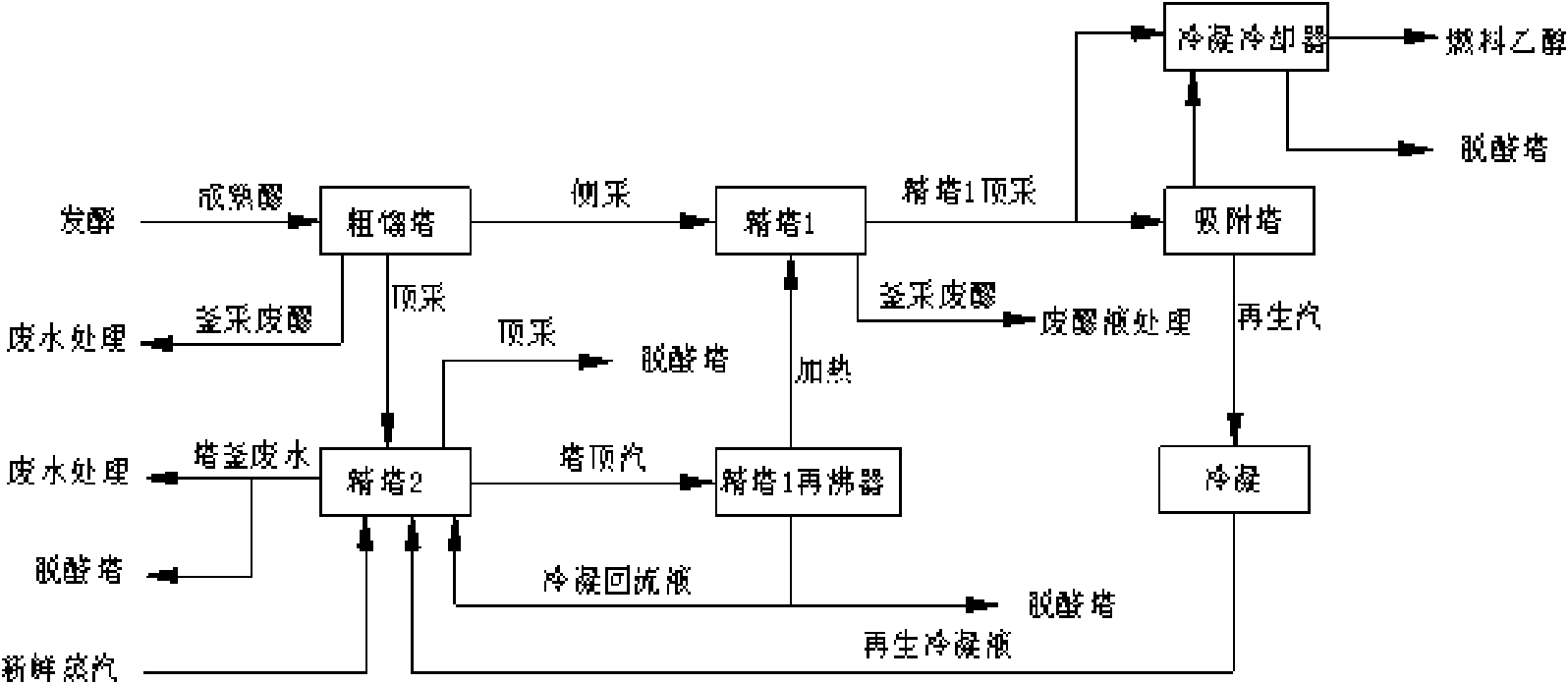

Composite process of fuel alcohol and edible alcohol

ActiveCN101648847AReduce material consumptionReduce energy consumptionOrganic compound preparationBiofuelsMolecular sieveDistillation

The invention relates to a composite process of fuel alcohol and edible alcohol. In the production process of alcohol products, fermented mash mature in a self-fermentation unit enters a rough distillation column, crude alcohol distilled from the top of the rough distillation column is fed into a rectification column (2), liquid alcohol distilled from the side of the rough distillation column column is fed into a feed inlet of a rectification column (1), vapor phase objects distilled from the top of the rectification column (1) are fed into a molecular sieve absorption column, and thus, fuel alcohol is obtained. In the production process of edible alcohol products, objects distilled from the top of the rough distillation column and the top of the rectification column (1) and partial objects distilled from the boiler of the rectification column (2) are all fed into an aldehyde disengagement column, liquid alcohol distilled from the boiler of the aldehyde disengagement column is fed into the rectification column, and then, the liquid alcohol is distilled from the top of the column and fed into a reclaiming column as feed; the liquid alcohol is distilled from the side of the upper part of the rectification column (2) and fed into the feed inlet of a rectification column (3) , and qualified edible alcohol is distilled from the boiler of the rectification column (3). The invention realizes multiple varieties of alcohol products on the same device, effectively decreases consumption in materials and energy in the production process of fuel alcohol and edible alcohol, reduces the investment on device, and improves the market competitiveness of the fuel alcohol and the edible alcohol.

Owner:TIANJIN UNIV

Mixed raw-material fermenting process for producing alcohol

ActiveCN101070549AIncrease total sugar concentrationRealize the fermentation processBiofuelsFermentationWaste processingAlcohol production

This invention has publicized one kind of ethyl alcohol production mix raw material fermentation process, Including raw material processing, mixes the material, the steam boiling to liquefy, the saccharification, the fermentation, the distillation working procedure, in raw material processing working procedure, the starchiness raw material smashing, presses out the sugar cane the juice to filter the sugar cane juice, starchiness raw material powder and sugar cane juice weight allocated proportion for 1:1-1:10. Starch quality raw material is cassava trunk, corn, potato, wheat, barley or the trunk of sweet potato. The beneficial effect of this invention are: increased sugar cane juice in the total sugar concentration, and lower raw material Organization of starch concentration of the solids, improve mobility, enhance mature Organization alcohol concentration, the amount of steam distillation savings, and also reducing units tons of alcohol Pai worse, worse reduce waste handling capacity, but also more easily spoil waste processing, alcohol production process so that environmental protection.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

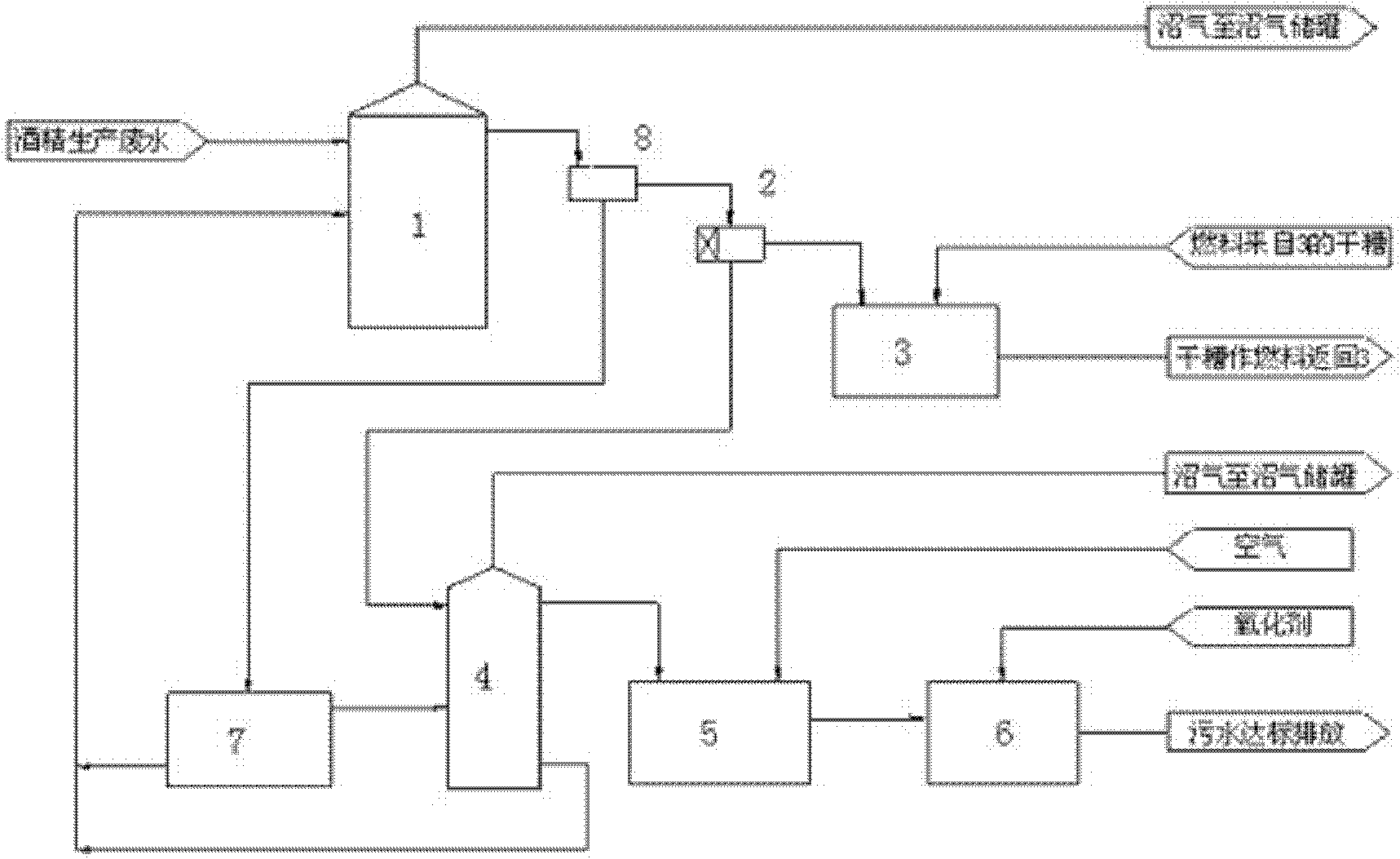

Method for improving activated sludge concentration in alcohol wastewater full-distillage anaerobic digestion process

ActiveCN101805100AHigh yieldReduce COD contentWaste based fuelTreatment with anaerobic digestion processesCelluloseActivated sludge

The invention relates to a method for improving activated sludge concentration in the alcohol wastewater full-distillage anaerobic digestion process. Corn, wheat, paddy rice, sweet potato, sugar-cane, cassava, sweet sorghum and plant straw containing cellulose from the alcohol production process serve as raw materials; and full-distillage waste mash produced in the alcohol production process is subjected to processes of two-stage anaerobic, aerobic, anaerobic activated sludge separation, anaerobic activated sludge concentration and recovery, liquid solid separation, dry-distillage combustion and advanced wastewater treatment. Primary anaerobic effluent containing sludge exhausted from a primary anaerobic jar is fed to an activated sludge recovery device. In the activated sludge recovery device, the primary anaerobic effluent passes through screening equipment to obtain an undersized material of the activated sludge-enriched primary anaerobic water and a sludge-enriched oversized material; and the COD concentration of secondary anaerobic effluent is below 500mg through the aerobic operation in an aerobic jar. The aerobic jar effluent is fed to an advanced wastewater treatment device, the COD concentration of the sewage subjected to the advanced treatment can be less than 100mg / L, and the sewage is discharged after reaching the standard.

Owner:TIANJIN UNIV

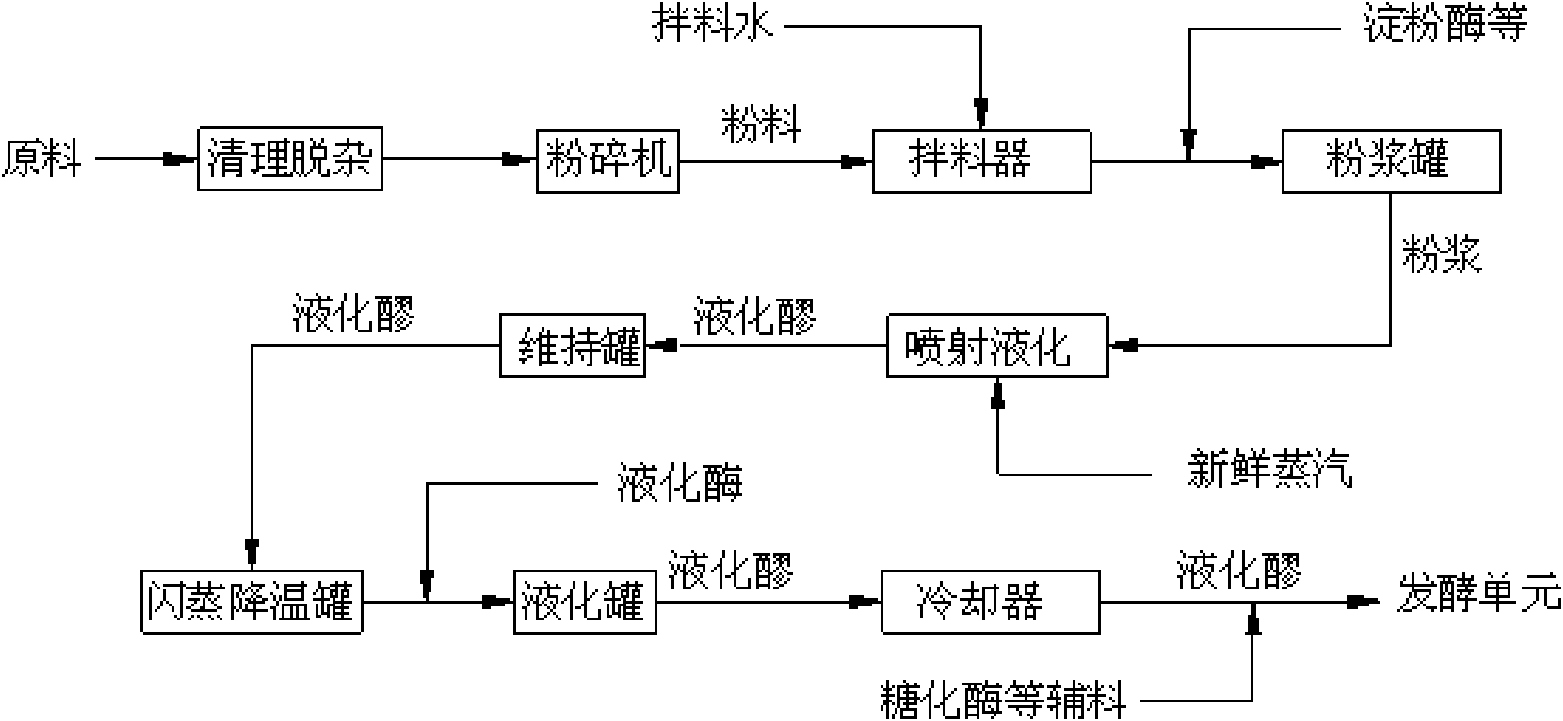

Method for fermentative production of alcohol

The present invention relates to a method for fermentative production of alcohol, and the method is as follows: (1) crushing degermed corn to a particle size of 70-85%, and sieving by a 20 mesh sieve, and mixing with water and a clear solution to obtain powder slurry with dry matter concentration of 30-32 wt. %; (2) adding amylase into the powder slurry for liquefying to obtain liquefied mash; (3) adjusting the pH of the liquefied mash to 4.2-4.8, then inoculating saccharomycetes; and (4 ) adding an acidic protease, a yeast accelerator and glucoamylase into the liquefied mash inoculated with the saccharomycetes for fermentation, wherein the clear solution is a supernatant obtained by centrifugation of waste mash of the bottom of a crude tower in the edible alcohol production process. Ethanol content in a fermentation liquid obtained by the method can be as high as 15% or more by weight.

Owner:COFCO BIOCHEM ENERGY ZHAODONG +2

Method for raising seedlings of rice

InactiveCN107155746ASolve processing problemsEfficient cultivationBiocideSeed and root treatmentAlcohol productionRoot hair

The invention relates to a method for raising seedlings of rice. The method comprises the following steps: step 1: seed soaking and germination; step 2: sowing; step 3: darkening processing; step 4: management of temperature and humidity in a greenhouse; step 5: management before transplanting. The method for raising seedlings of rice has the following beneficial effects: matrixes made by cassava leftovers during alcohol production are fully used so that production cost is greatly reduced; the matrixes are good in water storage performance and water retention performance so that moisture management during the process of raising seedlings is simplified; the method is easy to operate, manage and labor and time-saving; seeding trays are good in consistency with white root hair and robust seedlings; during transplanting, missing and breaking of seedlings are avoided; and the survival rate of seedlings is high.

Owner:TAICANG AGRI TECH EXTENSION CENT

Alcohol waste liquor-based soil improving and planting method

InactiveCN101926242AReduce dosageIncrease contentBio-organic fraction processingOther chemical processesLiquid wasteMicroorganism

The invention relates to a method which can recycle waste liquor discharged in a molasses alcohol production process in a simple, safe and environmentally-friendly way. Alcohol waste liquor is delivered to a field which is to be ploughed and planted or is planted with crops by a tank truck and sprayed onto the ground; and after being fully contacted with the air, the waste liquor is fermented and oxidized rapidly, so that the effects of fighting against drought, conserving water, enriching soil and improving the soil are achieved and 5 to 15 tons of waste liquor is applied to every mu (666.7 mm<2>) of the field. The method has the characteristics of safely treating the alcohol waste liquor in time, eliminating a sewage treatment system with a high investment, improving the microorganism environment of the soil, enhancing soil fertility and realizing cyclic economy, along with simpleness, practicability, a small number of investments, no environmental pollution and full utilization of the alcohol waste liquor.

Owner:王强

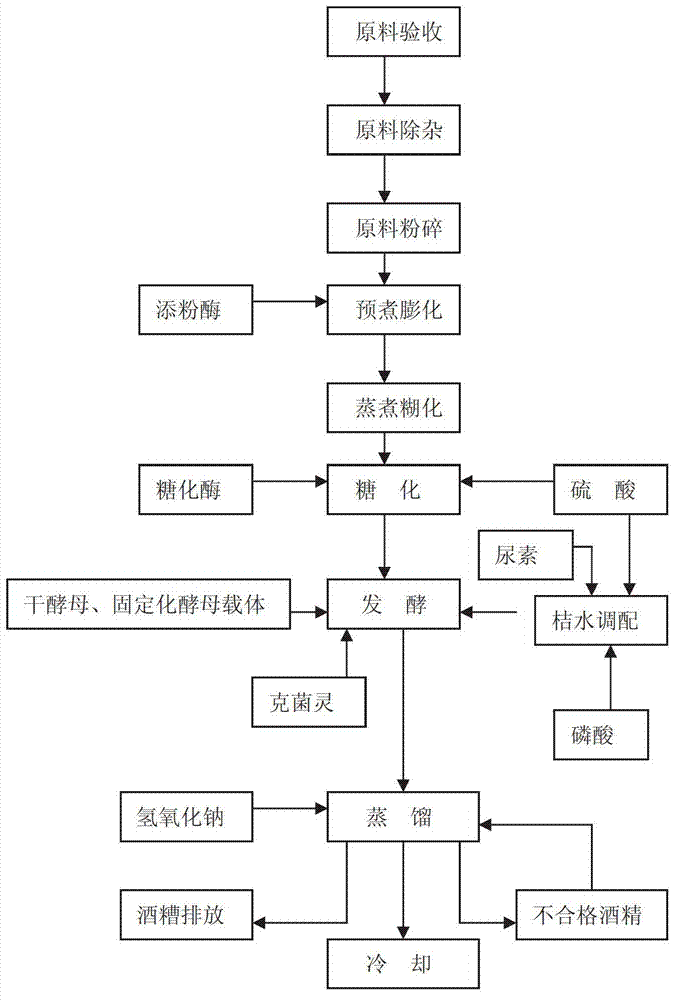

Alcohol production process

InactiveCN102787141AMature technologyEasy to operateBiofuelsMicroorganism based processesDistillationAlcohol production

The invention discloses an alcohol production process, and belongs to the technical field of alcohol production by a fermentation method. The alcohol production process includes the steps of 1) raw material acceptance: selecting potatoes with complete root blocks and uniform sizes as raw materials; 2) raw material purification: removing impurities such as silt, stones and metal in the potatoes by an impurity remover; 3) raw material crushing: crushing the raw materials by a crusher to obtain raw material powder; 4) precooking and puffing: adding amylase according to a fixed feed liquid ratio and precooking the raw materials in a precooking pot; 5) cooking gelatinization: adjusting a PH (potential of hydrogen) value, adding amylase and cooking the raw materials in a cooker; 6) saccharification: saccharifying the raw materials in a saccharifying tank containing blended orange water; 7) fermentation; 8) distillation; and 9) cooling. The alcohol production process is mature, energy-saving, environment-friendly, simple to operate, applicable to industry, food and the like, and has a quite high economic value, and produced alcohol is high in concentration.

Owner:陈玉梅

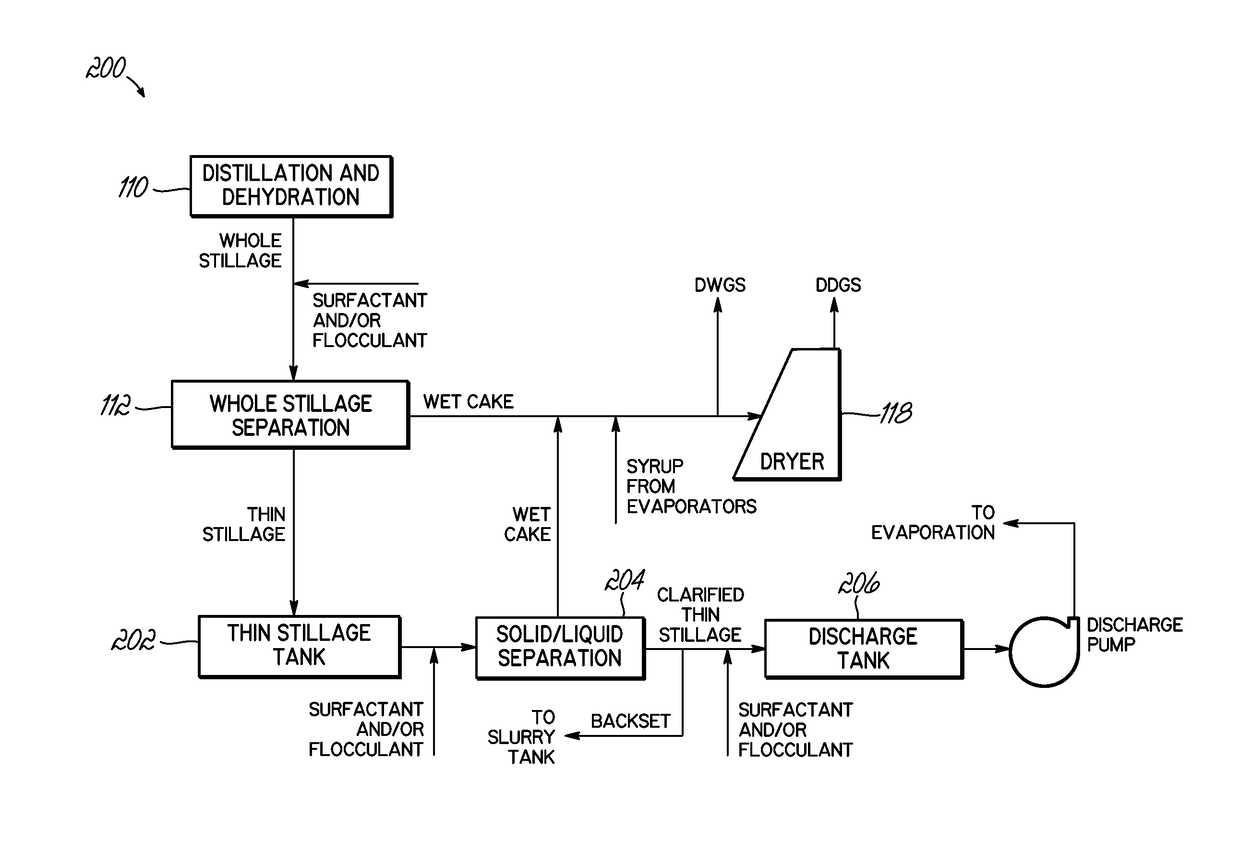

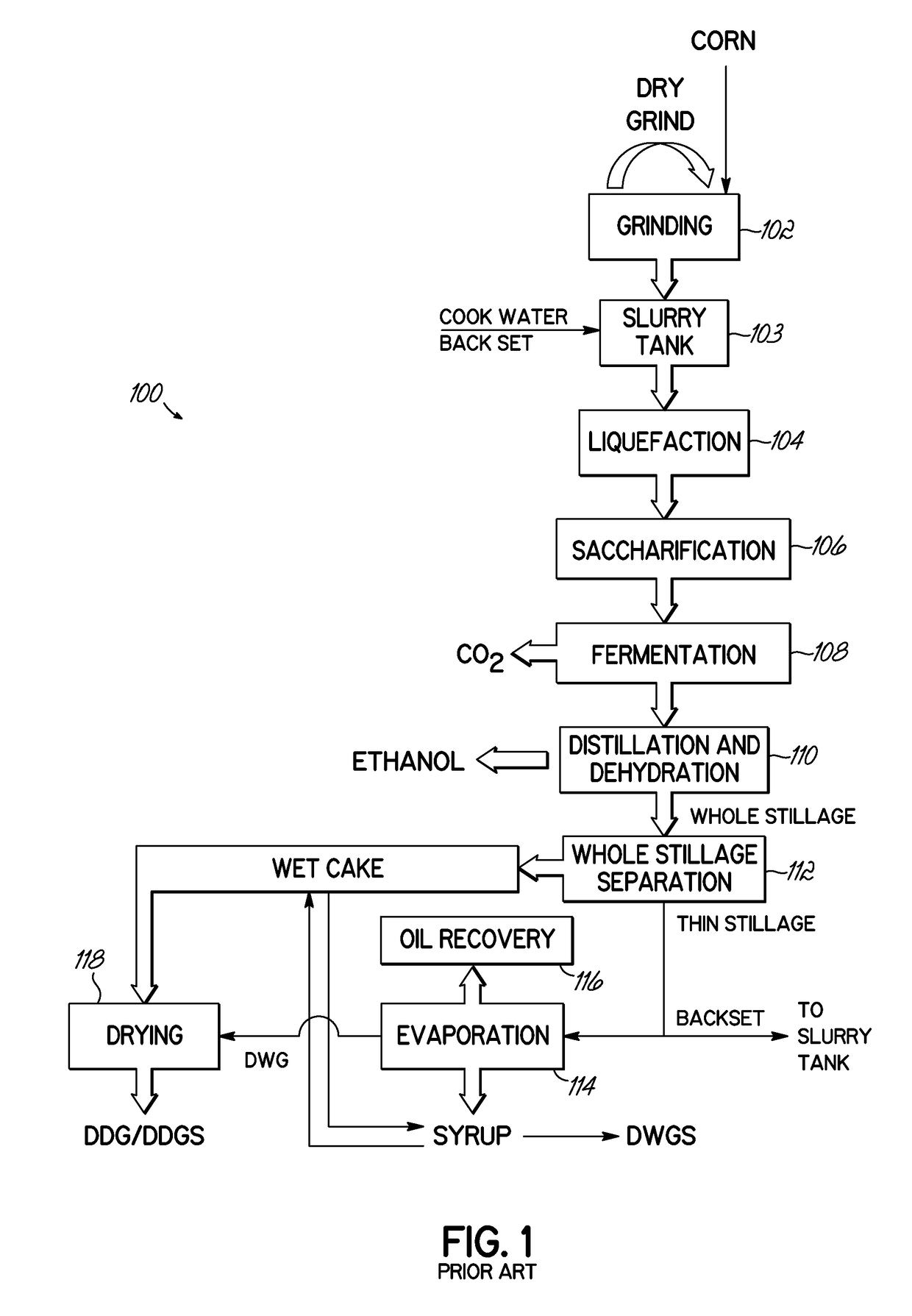

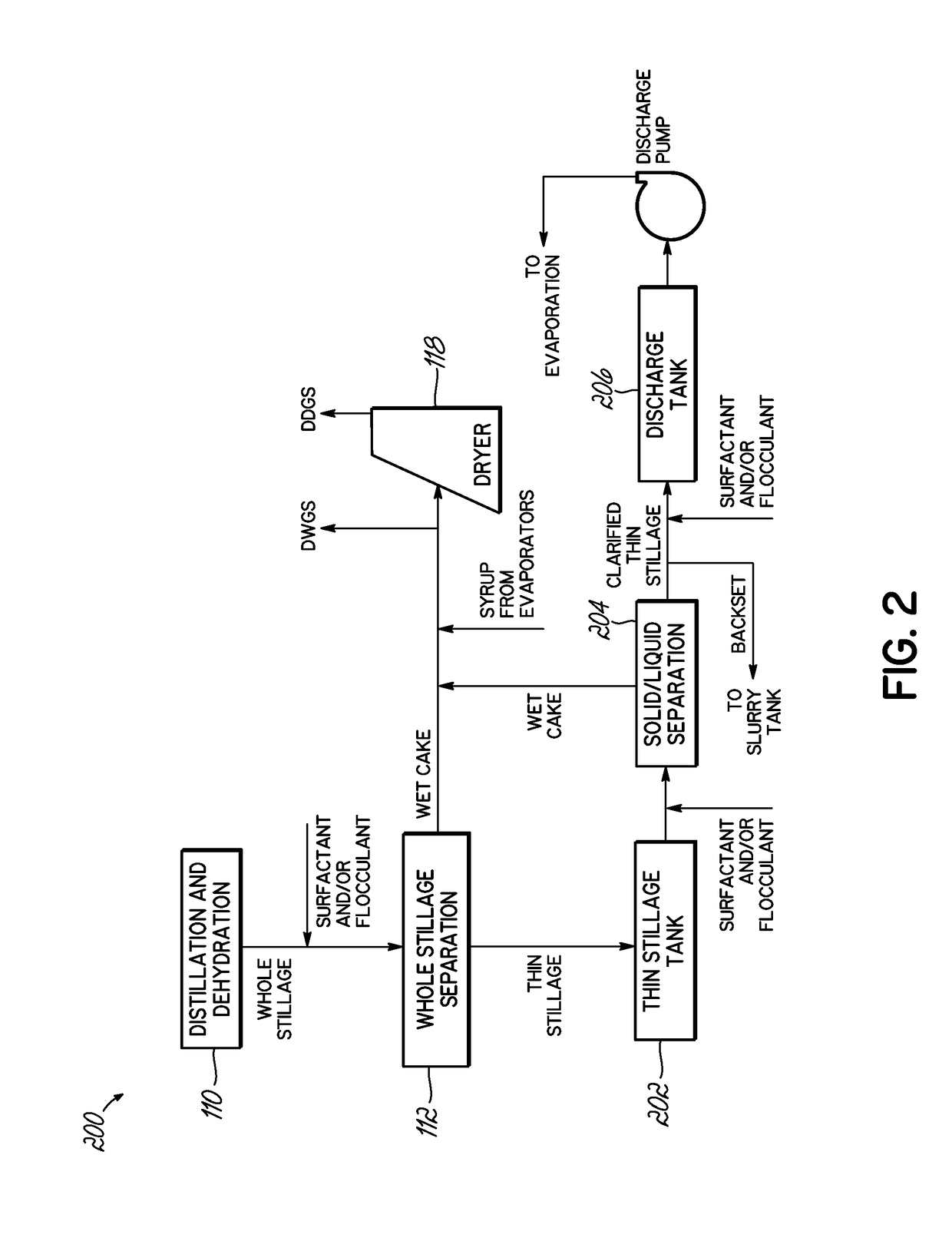

System and process for clarifying thin stillage

ActiveUS20170114293A1Speed up the processBy-product recoveryFermented solutions distillation/rectificationBiofuelGrind

The present invention is directed to improved systems and processes for clarifying a thin stillage stream in a biofuel production process, such as a dry grind alcohol production process, that removes desirable amounts of insoluble solids from at least a portion of the thin stillage stream, thereby realizing any number of process enhancements.

Owner:FLUID QUIP TECH LLC

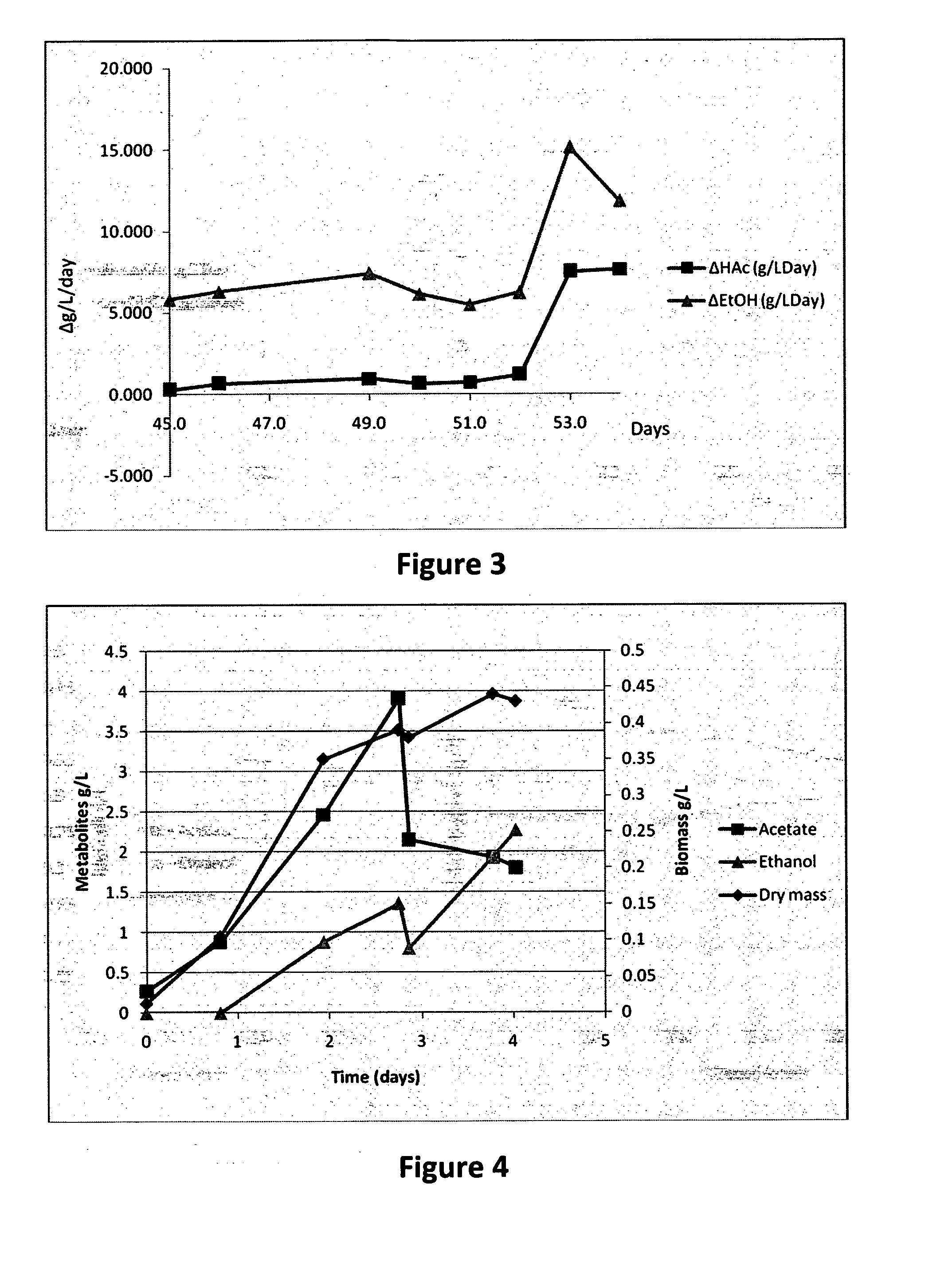

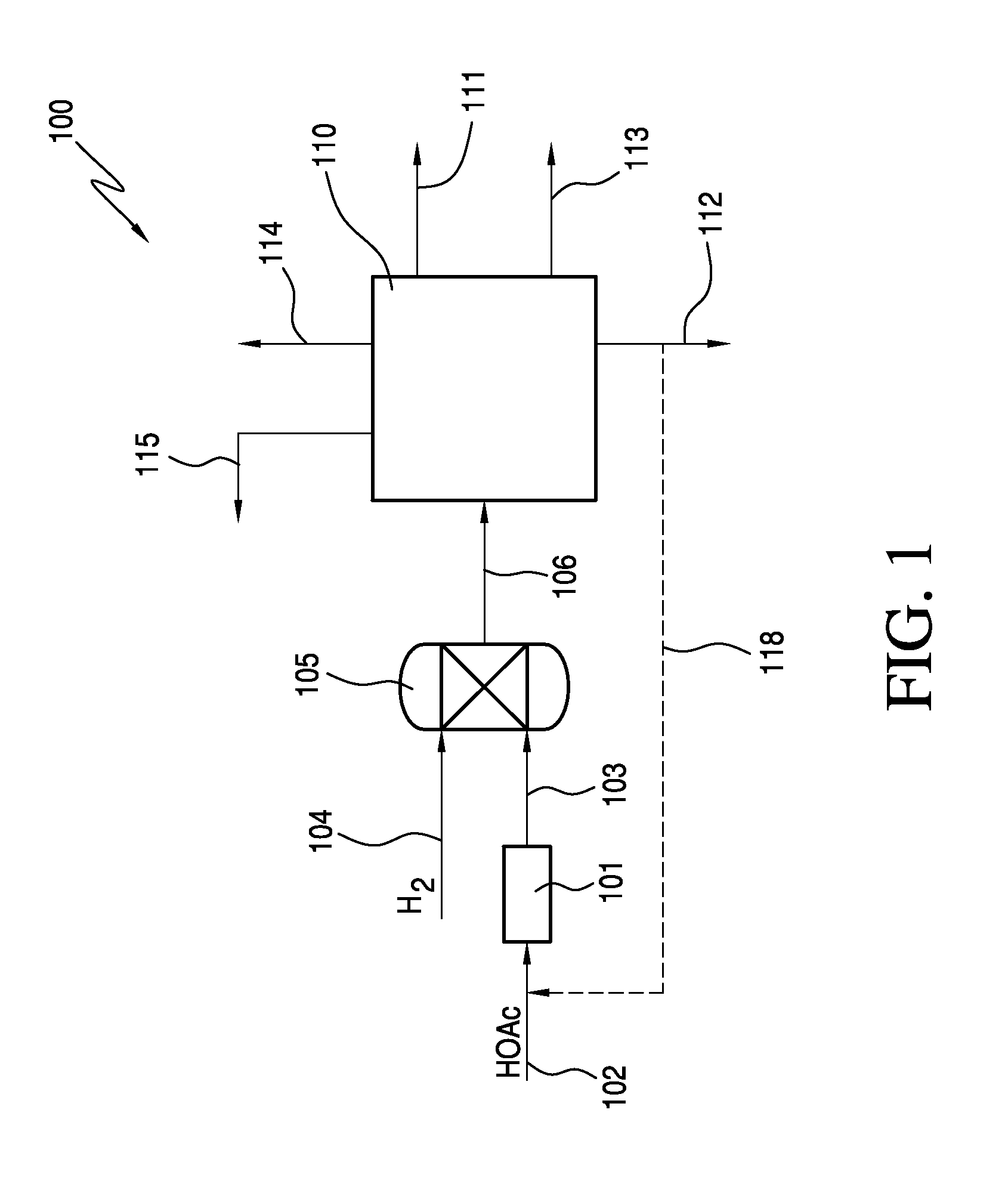

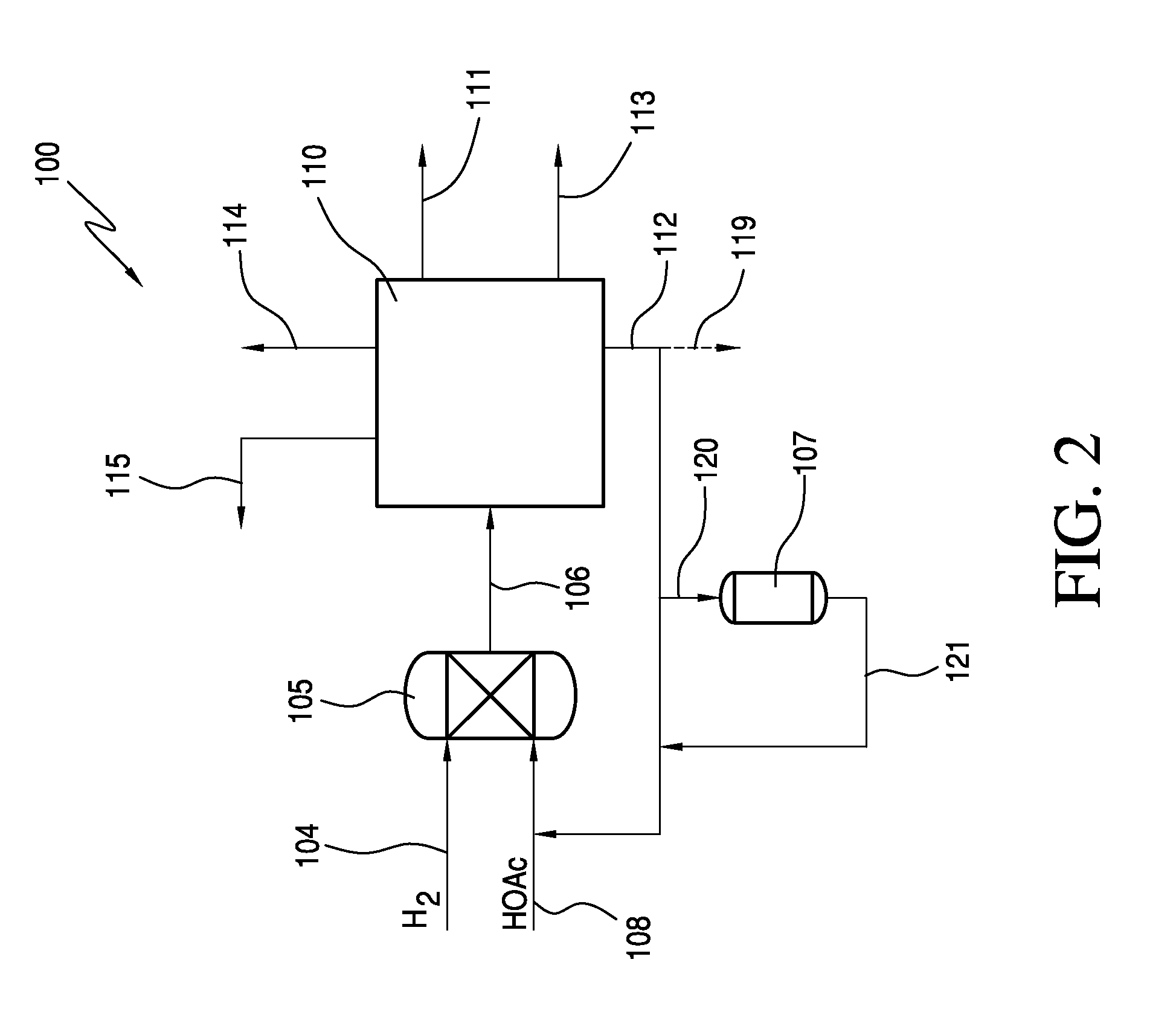

Alcohol Production Process

ActiveUS20090275787A1Improve efficiencyCarbon level is quite lowOrganic compound preparationOxygen compounds preparation by reductionAcetic acidGlycerol

The invention relates to methods for the production of alcohols by microbial fermentation, particularly microbial fermentation of substrates comprising glycerol and / or acetate, to butanol.

Owner:LANZATECH NZ INC

Microbial alcohol production process

ActiveUS8119378B2Reduces and prevents productionReduces and prevents microbial growthBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol production process

Owner:LANZATECH NZ INC

Alcohol Production Process with Impurity Removal

InactiveUS20120010444A1Reduce concentrationOrganic compound preparationOxygen compounds preparation by reductionAcetic acidHalogen

A method of removing impurities, such as halogens, sulfurs, and corrosion metal impurities, in an ethanol production process. Ion exchange resins may be used to remove these impurities from acetic acid feed streams and recycle streams that comprise unreacted acetic acid.

Owner:CELANESE INT CORP

Molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment and process

InactiveCN103394205ADifficult to solveLess fixed investmentMultiple-effect evaporationLiquid wasteAqueous alcohol

The invention discloses molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment and process. The equipment comprises five effect evaporating pots, a separation chamber of the previous effect evaporating pot is communicated with a heating chamber of the next effect evaporating pot, and a mature mash pot is communicated with a heating chamber of the fourth effect evaporating pot; a heating chamber of the first effect evaporating pot is communicated with a condensing water collection pot, heating chambers of the second, third and fourth effect evaporating pots are communicated with a pure water collection pot, and a heating chamber of the fifth effect evaporating pot is communicated with an alcohol collection pot; a heating chamber of the third effect evaporating pot is communicated with a concentrated waste liquid collection pot. The molasses alcohol fermented mature mash multi-effect evaporation concentration integrated equipment has the advantages that a multi-effect differential pressure evaporation concentration system is used for replacing the alcohol separation extraction function of a mash tower, and can be used for concentrating residual waste liquid which can be used as boiler fuel after the residual waste liquid reaches a certain concentration, so that the fixed investment on equipment can be saved, energy consumption can be reduced, the production operation cost can be effectively reduced, and the problem of high difficulty in waste liquid treatment in molasses alcohol production process can be effectively solved.

Owner:NANNING KECHAO ALCOHOL TECH DEV

Method for processing 3,5,6-trichloropyridine-2-sodium alcohol wastewater

ActiveCN103922531AEmission reductionReduce usageMultistage water/sewage treatmentNature of treatment waterMicro nanoElectrolysis

The invention discloses a method for processing 3,5,6-trichloropyridine-2-sodium alcohol wastewater. The method orderly comprises the following steps: adjusting the pH value of wastewater to 2-5 by using an acid tail gas generated in the sodium alcohol production process; feeding the wastewater into a microelectrolysis cell; carrying out micro-nano aeration for 2-4 hours; adding 35% of hydrogen peroxide to electrolysis effluent to oxidize for 2-4 hours; adding activated carbon in the treatment process; adding solid sodium hydroxide to adjust the pH to 7-9; removing activated carbon and sludge, and steaming out water which is 80-85% of mass of the wastewater to obtain an industrial salt; adding mother liquor to the next batch of wastewater; and processing again. A micro-nano bubble technology is creatively combined with an iron-carbon micro electrolysis technology to carry out aeration microelectrolysis, and is combined with a fenton oxidation-flocculating settling-distillation process, so that not only is the sodium alcohol wastewater effectively processed, but also the problem of tail gas emission in the sodium alcohol production process is solved, and meanwhile, the by-product industrial salt is economical and environment-friendly, and safe and reliable.

Owner:JIANGSU JIUJIUJIU TECH

Alcohol production process

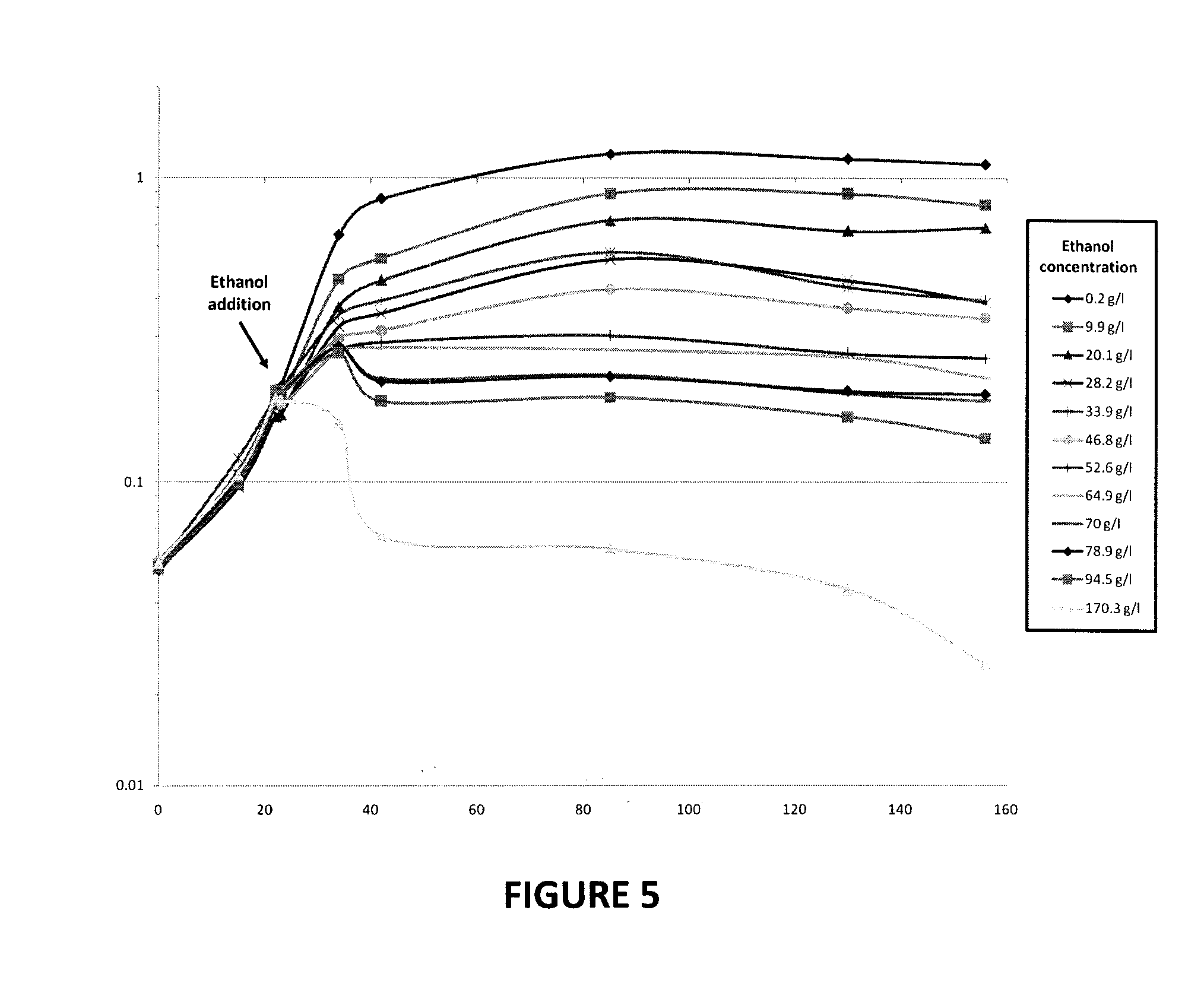

InactiveUS20110250629A1Reduce the impactPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsFermentation brothAlcohol Toxicity

The invention relates to the microbial fermentation of gaseous substrates, particularly to methods of mitigating and / or reducing alcohol toxicity effects on a microbial culture at elevated alcohol concentrations during fermentation. The invention relates particularly to microbial fermentation of substrates comprising CO and the effects of alcohol toxicity are reduced or mitigated by maintaining the temperature below the optimum operating temperature by cooling the fermentation broth.

Owner:LANZATECH NZ INC

Combined production method for fuel alcohol and edible alcohol

ActiveCN101648848ALess investmentBig market demandOrganic compound preparationBiofuelsAbsorption columnDistillation

The invention relates to a combined production method for fuel alcohol and edible alcohol. Fermented mash mature enters a rough distillation column, crude alcohol distilled from the top of the column is fed into a rectification column (2), liquid alcohol distilled from the side of the column is fed into a rectification column (1), vapor phase objects distilled from the top of the rectification column (1) are fed into a molecular sieve absorption column, and objects distilled from the top of the rectification column (1) are made into fuel alcohol under the adsorption effect of dehydrators on amolecular sieve. In the production process of edible alcohol, objects distilled from the top of the rectification column (1) are fed into an aldehyde disengagement column, objects distilled from the top of the rectification column (2) and partial objects distilled from a boiler of the column are also fed into the aldehyde disengagement column, liquid alcohol distilled from a boiler of the aldehyde disengagement column is fed into a product column, and thus, qualified edible alcohol is distilled from the upper side of the product column. The invention realizes multiple varieties of alcohol products on the same device, effectively decreases consumption in materials and energy in the production process of the fuel alcohol and the edible alcohol, reduces the investment on device, and improvesthe market competitiveness of the fuel alcohol and the edible alcohol.

Owner:TIANJIN UNIV

Alcohol distilling production method

ActiveCN106334327AReduce concentrationGood distillationOrganic compound preparationHydroxy compound preparationDistillationAlcohol production

The invention relates to the field of alcohol production processes, in particular to an alcohol distilling production method. The alcohol distilling production method comprises the following steps: maturely-fermented mash enters a preheater, is preheated and enters a degassing section on the top of a crude distilling tower, and in the descending process, a material is heated by steam at the bottom of the crude distilling tower and is separated from ascending alcohol steam; waste mash is discharged by a pump from the bottom of the crude distilling tower, is sent to a sewage treatment plant and is comprehensively treated; the alcohol steam of the crude distilling tower goes up to an aldehyde-removing section of the crude distilling tower and impurities are removed, aldehyde-removed alcohol liquid enters the crude distilling tower and is concentrated, and crude alcohol is preheated by a crude alcohol preheater and enters a scrubbing tower; uncondensed alcohol steam and non-condensable gas are sent into the scrubbing tower and then discharged into air, and scrubbing liquid enters an impurity alcohol tank. By the alcohol distilling production method, the final ethanol concentration reaches 95.8%, the distillation effect is good, the produced alcohol can achieve a super-pure index, and the contents of aldehydes, methanol and other harmful substances in the alcohol are very low, the acetaldehyde concentration is only 2mg / L, and the methanol concentration is also much lower than a standard safety line; therefore, the alcohol distilled by the alcohol distilling production method is excellent in quality.

Owner:ANHUI ANTE FOOD

Alcohol production process

ActiveUS8119844B2Reducing total acetateReducing total glycerolOrganic compound preparationOxygen compounds preparation by reductionAcetic acidGlycerol

The invention relates to methods for the production of alcohols by microbial fermentation, particularly microbial fermentation of substrates comprising glycerol and / or acetate, to butanol.

Owner:LANZATECH NZ INC

Apparatus & method for increasing alcohol yield from grain

InactiveUS20100112125A1Increased ethanol productionReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsControl flowCavitation

A method comprising applying a controlled flow cavitation apparatus to an alcohol production process in order to increase alcohol yield. A grain-based liquid medium comprising grain and a liquid carrier can be passed through a controlled flow cavitation apparatus at a velocity capable of generating a hydrodynamic cavitation zone where the grain size can be reduced. One or more controlled flow cavitation apparatuses can be applied at various points of an alcohol production process, such as a starch-to-ethanol production process.

Owner:ARISDYNE STSTEMS INC

Method for culturing microalgae by using alcohol wastewater and fermentation exhaust

InactiveCN104556566AEfficient degradationMultistage water/sewage treatmentBiological water/sewage treatmentAlcohol productionBottle neck

The invention provides a method for culturing microalgae by using alcohol wastewater and fermentation exhaust, which comprises the steps of anaerobic digestion of alcohol wastewater, microalgae culture, wastewater recovered mixture for alcohol fermentation, and the like. The method specifically comprises the following steps: carrying out anaerobic digestion on the alcohol wastewater; culturing the microalgae by using the liquid obtained by solid-liquid separation to obtain a microalgae thallus product or extracted biological grease, wherein fermentation exhaust is introduced to supplement the carbon source required by microalgae growth in the process; and recovering the microalgae purification liquid to the alcohol production mixture technique. The method for culturing microalgae by using the alcohol anaerobic wastewater and fermentation exhaust can eliminate the inhibiting action of ammonia nitrogen on alcohol fermentation, enhances the feasibility of alcohol fermentation by recovering treated wastewater, implements the zero discharge of the wastewater and fermentation exhaust in the alcohol production process, solves the key technical bottle neck for restricting the clean production of alcohol fermentation, and obtains the high-value microalgae thallus product or biological grease.

Owner:河南天冠生物燃料工程技术有限公司

Amino acid-containing cassava lees organic fertilizer and production method thereof

InactiveCN106146105AReduce pollutionMeet the requirements of NY525-2012Bio-organic fraction processingBioloigcal waste fertilisersTotal amino acidsAscaris

The invention provides an amino acid-containing cassava lees organic fertilizer. The organic fertilizer contains the following raw materials in parts by mass: 800-900 parts of cassava lees, 175-250 parts of plant ash, 50-100 parts of plant protein and 0.2-0.4 part of composite strain. The organic fertilizer provided by the invention is prepared through fermentation by adopting cassava lees as main raw material, the organic content is over 60%, the content of total nutrients is over 8.5%, the content of total amino acids is over 1%, the content of nitrogen phosphorus and potassium is over 2.3, and the water content is about 27%, the organic fertilizer is slightly alkaline, the death rate of ascaris eggs exceeds 99%, and the requirements of NY525-2012 are met; and moreover, the cost is low, the fermentation time is short, the whole fermentation process is controllable, the problem of incomplete fermentation or excessive composting is overcome, the environmental pollution caused by solid wastes is effectively reduced in the alcohol production process, and the production requirements of environmental protection are met.

Owner:江苏联海生物科技有限公司 +1

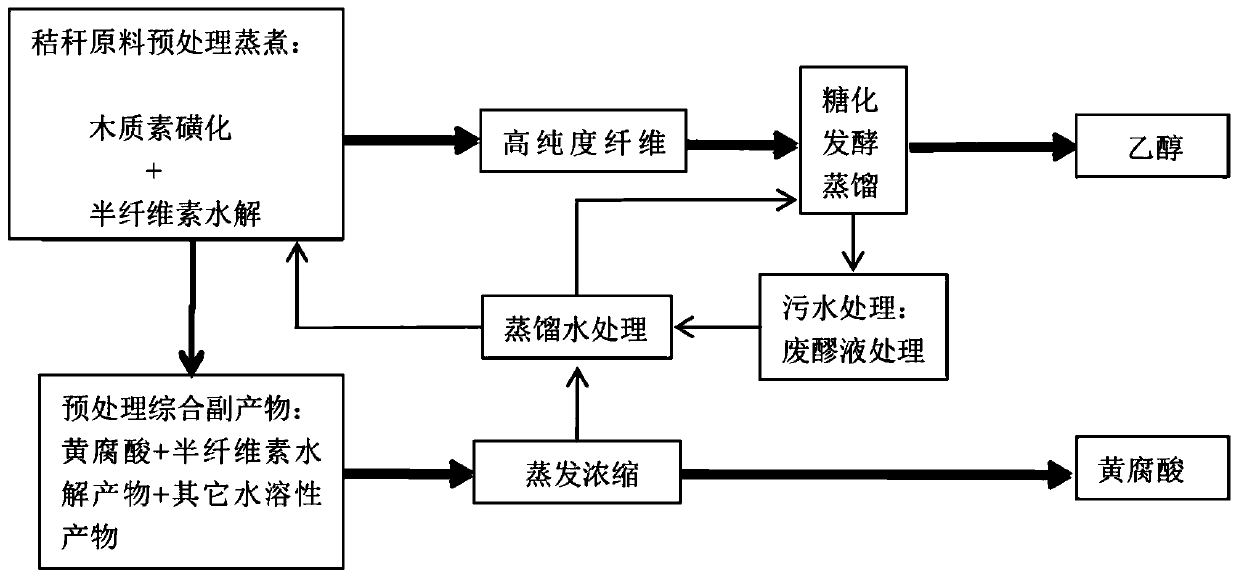

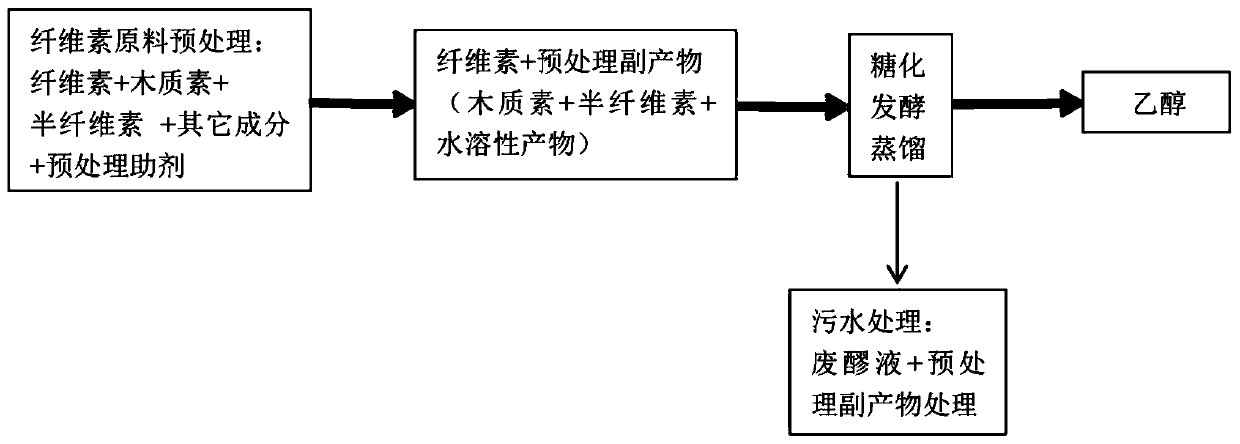

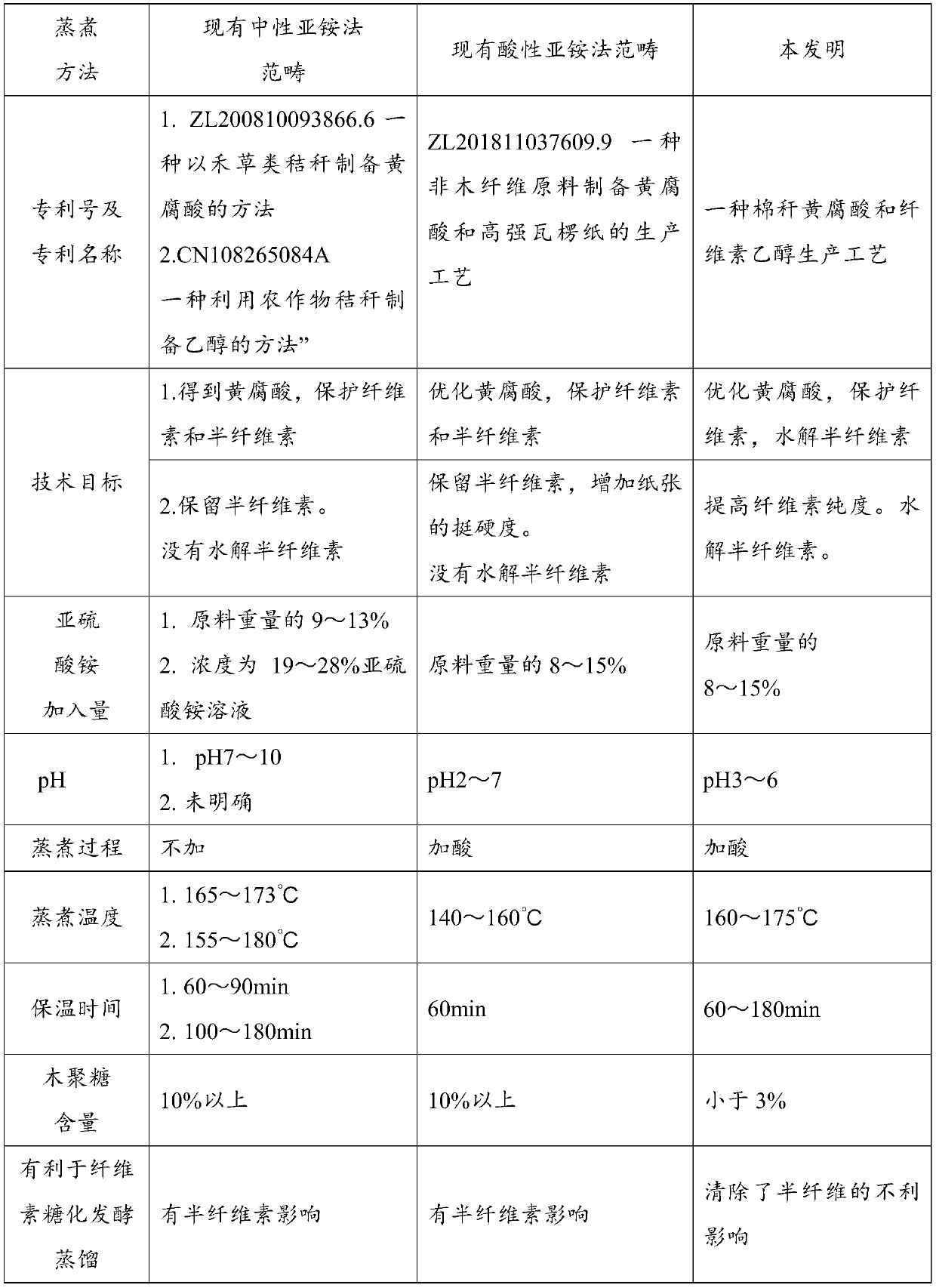

Cotton straw fulvic acid and cellulose ethyl alcohol production process

ActiveCN110846345ALittle side effectsEliminate negative effectsBiofuelsLignin derivativesBlack liquorAlcohol ethyl

The invention relates to a cotton straw fulvic acid and cellulose ethyl alcohol production process. Cotton straws serve as raw materials to produce fulvic acid and cellulose ethyl alcohol, and hemicellulose is hydrolyzed when the fulvic acid is extracted in the same process, fulvic acid extraction and hemicellulose hydrolysis are synchronously implemented in a pretreated manner, comprehensive by-products are pretreated, and high-purity cellulose is separated, so that cellulose pretreated black liquor and diastatic fermentation distillation waste mash sewage are treated and recycled by different systems. According to the process, production costs of cellulose ethyl alcohol are reduced from various links of a whole system, fulvic acid is produced by lignin, harmful materials are turned intowealth, fiber raw material resources are comprehensively utilized, and comprehensive economic benefits of cellulose ethyl alcohol production are improved.

Owner:白博

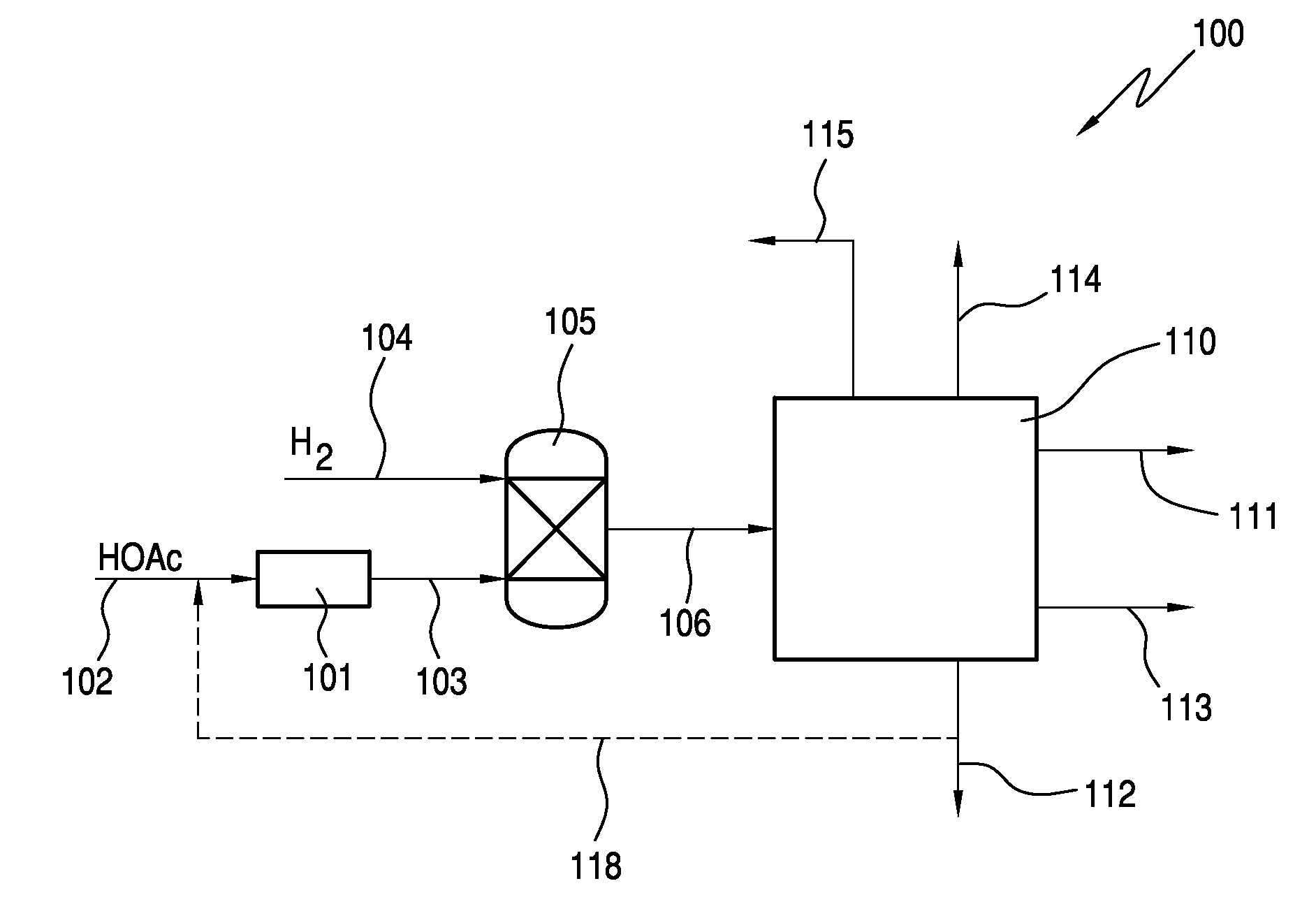

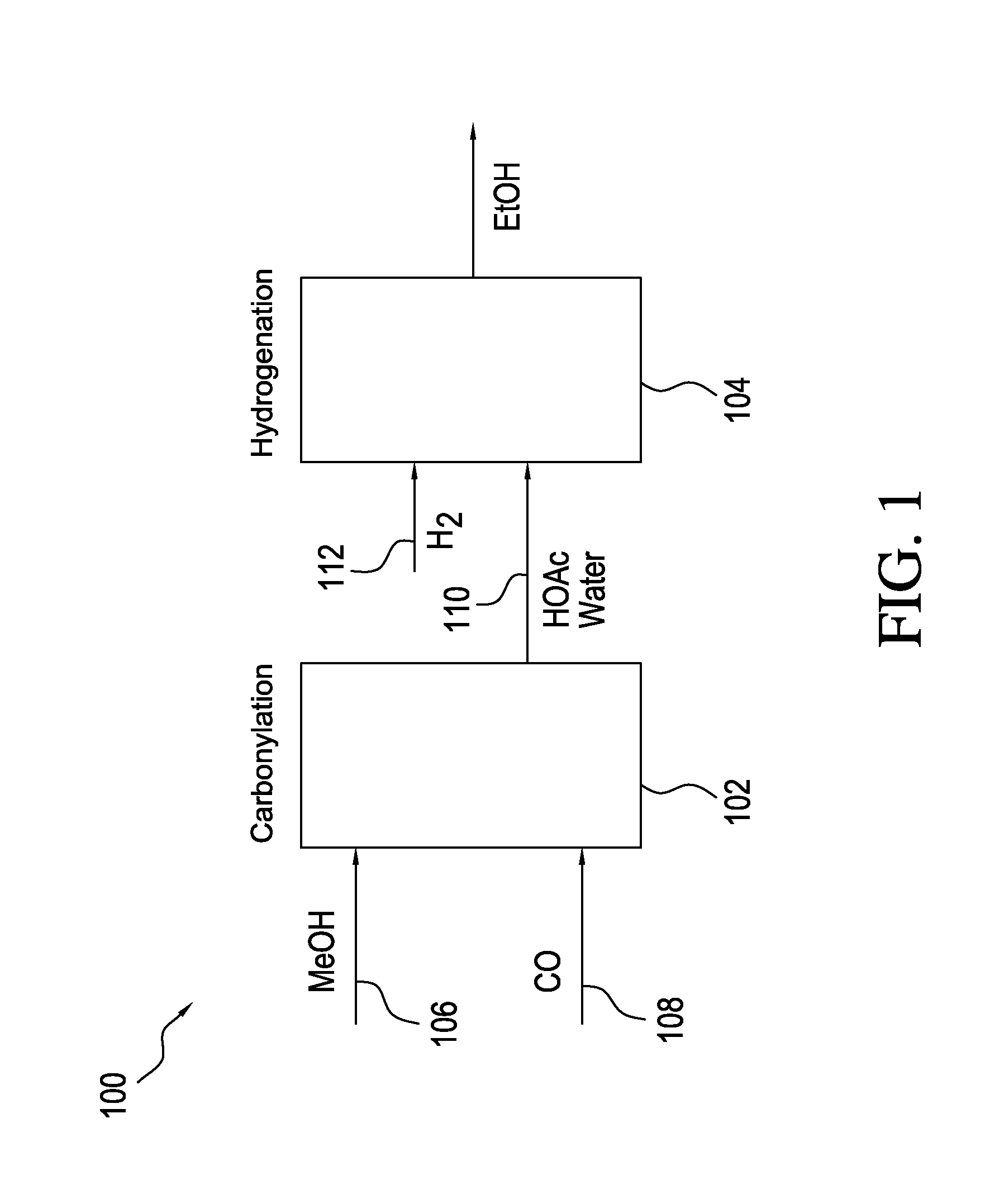

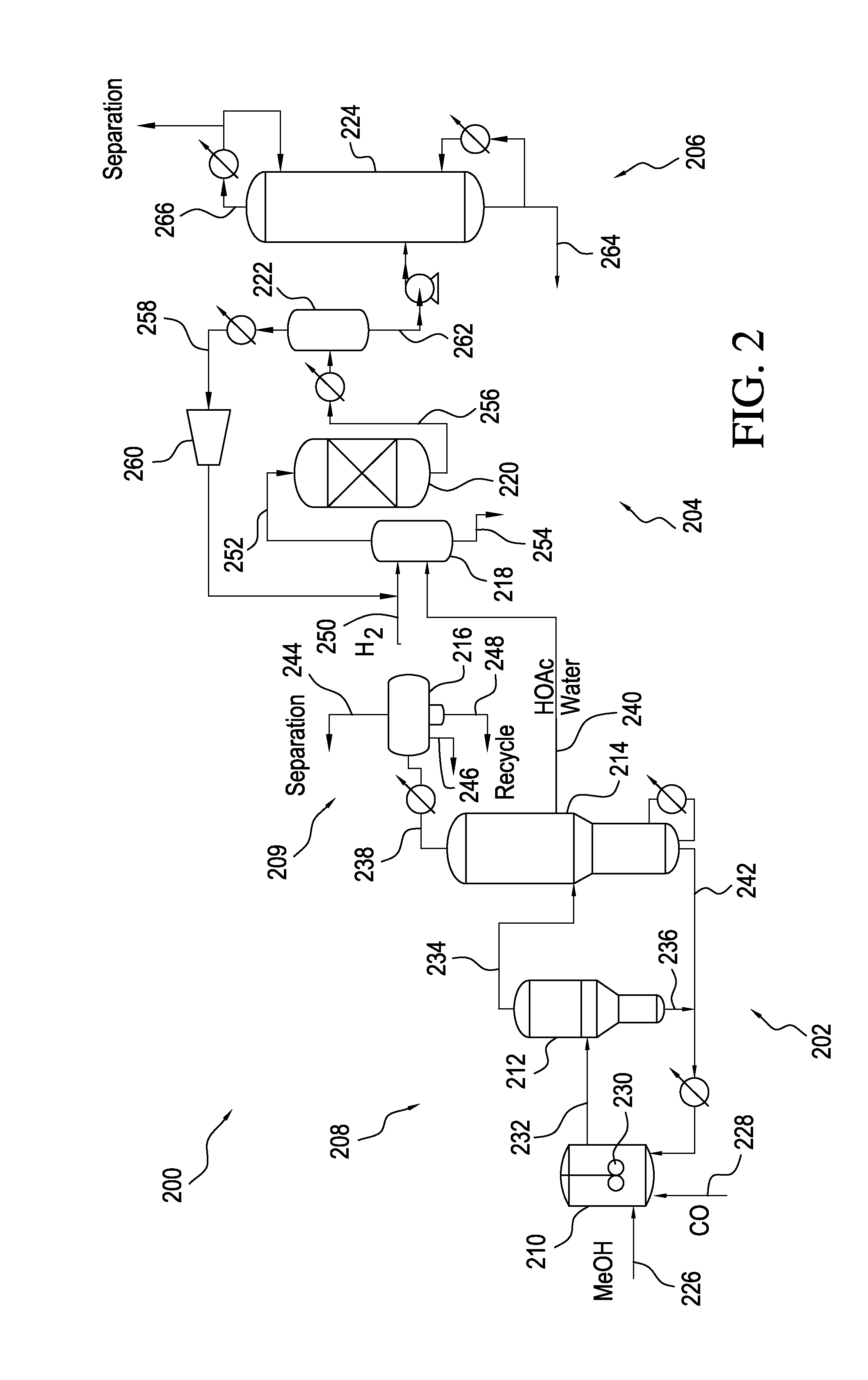

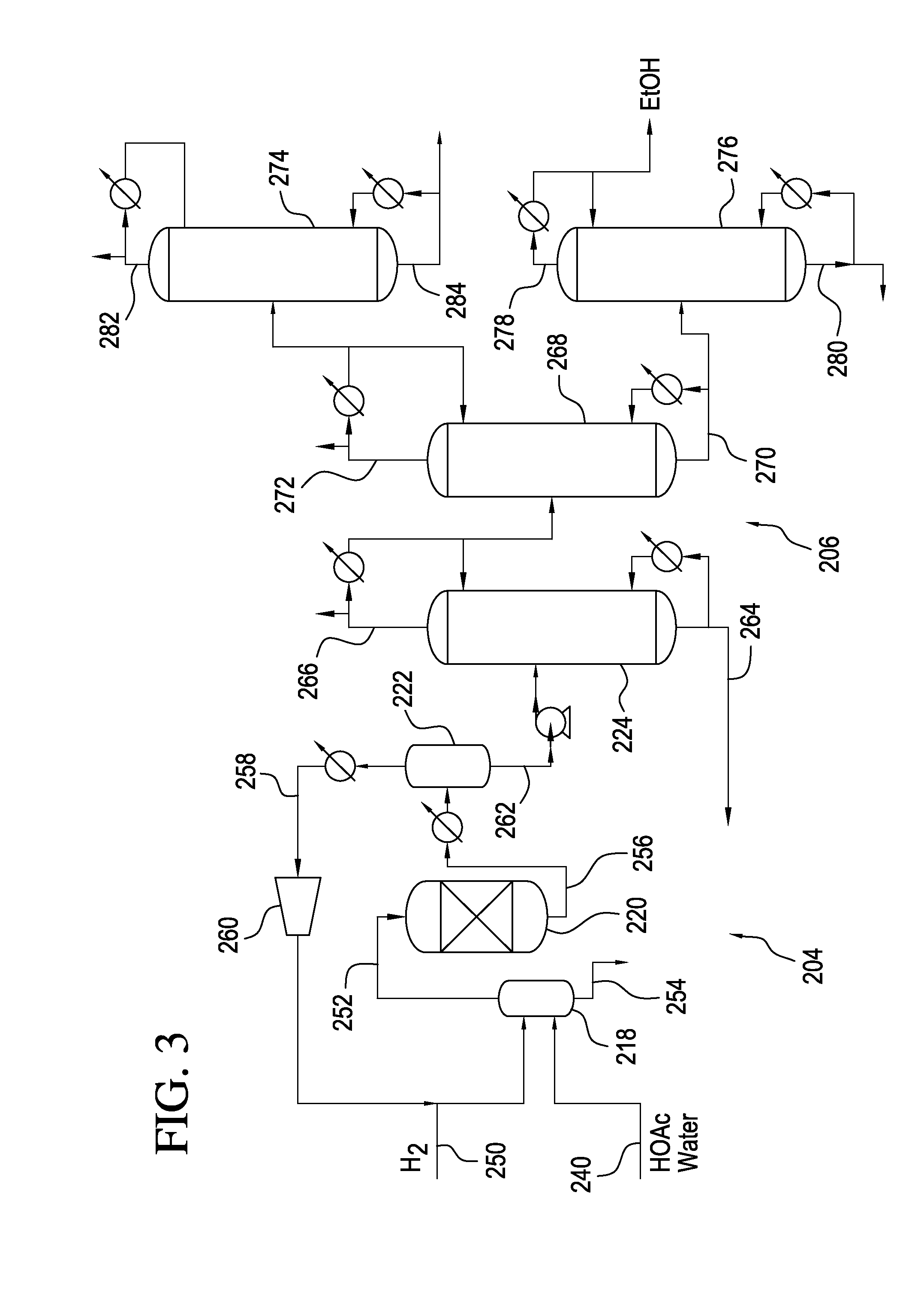

Alcohol production process integrating acetic acid feed stream comprising water from carbonylation process

InactiveUS20120059197A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidDistillation

In one embodiment, the invention is to a process for producing ethanol, comprising the step of providing from a distillation column in a carbonylation process a purified acetic acid stream comprising up to 25 wt. % water. The process further comprises the step of hydrogenating acetic acid of the purified acetic acid stream in the presence of a catalyst and under conditions effective to form a crude ethanol product comprising ethanol and water. Ethanol is recovered from the crude ethanol product.

Owner:CELANESE INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com