Combined production method for fuel alcohol and edible alcohol

A technology for fuel ethanol and edible alcohol, applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low equipment utilization rate and high investment, and achieve the goal of reducing equipment investment and widening market demand. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Corn is used as raw material to produce fuel ethanol products. The production process mainly includes liquefaction unit, fermentation unit, rectification and dehydration unit, etc. Specific steps are as follows:

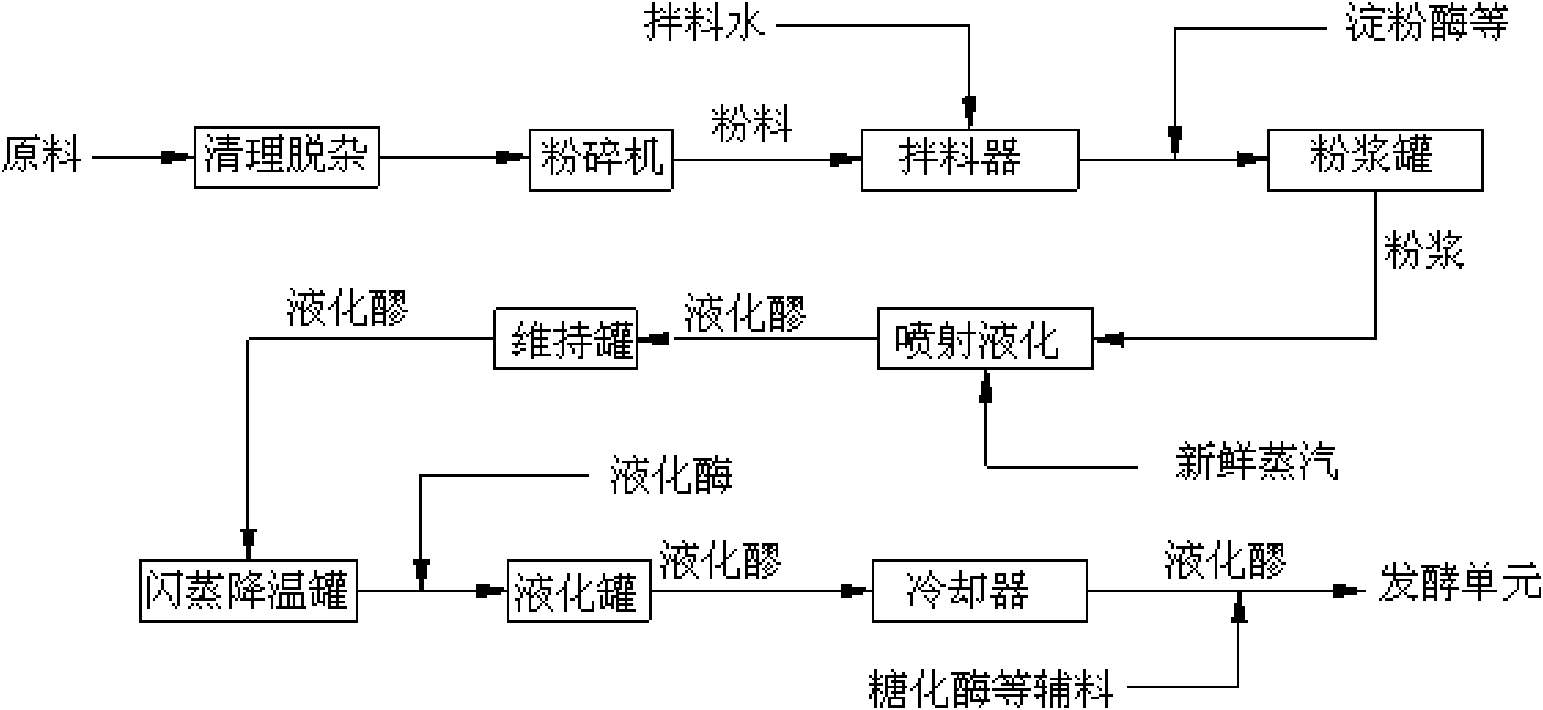

[0037] 1. Liquefaction unit

[0038] For the production process of the liquefaction unit, see figure 1 - Flow chart of liquefaction unit. Firstly, the dry corn raw material is cleaned and removed, and then crushed. The crushed raw materials are added with water in the mixer to make a slurry and sent to the slurry tank, and amylase and other auxiliary materials are added at the same time. In the slurry tank, the slurry is pumped to the jet liquefier with a slurry pump. The jet liquefier controls the heating temperature of the material by controlling the amount of water vapor. The temperature of the material at the outlet of the injector is controlled to 115°C, and then sent to the maintenance tank for 25 minutes. , the material enters the liquefied mash fla...

Embodiment 2

[0047] Cassava is used as raw material to produce edible alcohol products. The production process mainly includes liquefaction unit, fermentation unit, rectification and dehydration unit, etc. Specific steps are as follows:

[0048] 1. Liquefaction unit

[0049] For the production process of the liquefaction unit, see figure 1 - Flow chart of liquefaction unit. Firstly, the dried cassava raw material is cleaned and removed, and then crushed. The crushed raw materials are added with water in the mixer to make a slurry and sent to the slurry tank, and amylase and other auxiliary materials are added at the same time. In the slurry tank, the slurry is pumped to the jet liquefier with a slurry pump. The jet liquefier controls the heating temperature of the material by controlling the amount of water vapor. The temperature of the material at the outlet of the injector is controlled to 110°C, and it is sent to the maintenance tank for 8 minutes. , the material enters the liquefie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com